Documente Academic

Documente Profesional

Documente Cultură

Polypipe Gdy20 Pe2406/Pe2708 Gas Pipe: Other Dimensional Standards or Custom Requirements Available

Încărcat de

Adam KnottDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Polypipe Gdy20 Pe2406/Pe2708 Gas Pipe: Other Dimensional Standards or Custom Requirements Available

Încărcat de

Adam KnottDrepturi de autor:

Formate disponibile

PolyPipe GDY20 PE2406/PE2708 Gas Pipe

formerly PolyPipe 3810

Yellow Medium Density Polyethylene (MDPE) for natural gas distribution.

Other dimensional standards or custom requirements available.

TYPICAL PHYSICAL PROPERTIES

*NOMINAL VALUES

ASTM

TEST METHOD

SI UNITS

ENGLISH UNITS

Density, Natural

D1505

0.940 gm/cc

--

Density, Yellow

D1505

0.943 gm/cc

--

Melt Index (190C/2.16 kg)

D1238

0.20 gm/10 min.

--

Flow Rate (190C/21.6 kg)

D1238

20 gm/10 min.

--

Tensile Strength @Ultimate

D638

31.0 MPa

4,500 psi

Tensile Strength @ Yield

D638

19.3 MPa

2,800 psi

Ultimate Elongation

D638

>800%

>800%

Flexural Modulus

D790

690 MPa

100,000 psi

D1693

>10,000 hrs.

>10,000 hrs.

>10,000 hrs.

>10,000 hrs.

F1473

>1000 hrs.

>1000 hrs.

Brittleness Temperature

D746

<-117C

<-180F

Hardness, Shore D

D2240

64

64

Vicat Softening Temperature

D1525

120C

248F

Izod Impact Strength (Notched)

D256

0.53 KJ/m

10 ft lbf/in

PROPERTY

2% Secant

Environmental Stress Crack Resistance (ESCR)

F0, Condition B

F0, Condition C

PENT

Volume Resistivity

D991

15

--

-4

-4

>10 ohm-cm

Thermal Expansion Coefficient

D696

2x10 cm/cm/C

1.0x10 in/in/F

CELL CLASSIFICATION:

D3350

234373E

Grade PE27

MATERIAL CLASSIFICATION:

D1248

Type II

Class B

Category 5

PPI HYDROSTATIC DESIGN BASIS:

D2837

(As listed in PPI TR-4)

8.6 MPa @ 23C

1,250 psi @ 73.4F

6.9 MPa @ 60C

1,000 psi @ 140F

*Nominal values are intended to be guides only, and not as specification limit.

PolyPipe, Inc.

2406 N. I-35 | P.O. Box 390 | Gainesville, TX 76241

Phone 940.665.1721 | 800.433.5632 | Facsimile 940.668.8612

Sales Facsimile 940.668.2704 | www.polypipeinc.com

B-1000

05/06

PolyPipe GDY20 PE2406/PE2708

Gas Pipe Data and Pressure Ratings CTS & IPS

Nominal Pipe

Size

CTS

1

1

DR

Design

Pressure

Rating* for

Natural Gas,

psig @ 73F

100

69

77

Dimensions

Average OD,

inches

Min. Wall

Thickness,

inches

Standard Coil

Length, ft

Weight,

lbs/ft

0.625

1.125

1.125

0.0901,2

0.090

0.0992

1,000

500

500

0.065

0.126

0.139

IPS

9.3

96

0.840

0.090

500

0.092

111,2

80

1.050

0.095

500

0.123

1

111,2

80

1.315

0.120

500

0.193

1

101

88

1.660

0.166

500

0.335

1

112

80

1.660

0.151

500

0.308

1

111,2

80

1.900

0.173

500

0.404

2

111,2

80

2.375

0.216

250

0.631

2

111,2

80

2.375

0.216

500

0.631

2

111,2

80

2.375

0.216

1,500

0.631

3

11

80

3.500

0.318

500

1.370

3

11.51

76

3.500

0.304

500

1.317

3

112

80

3.500

0.318

40 Joints

1.370

3

11.51

76

3.500

0.304

40 Joints

1.317

4

112

80

4.500

0.409

40 Joints

2.265

4

11.51

76

4.500

0.391

40 Joints

2.176

4

13.51

64

4.500

0.333

40 Joints

1.882

6

11

80

6.625

0.602

40 Joints

4.909

6

11.51

76

6.625

0.576

40 Joints

4.717

6

13.51

64

6.625

0.491

40 Joints

4.079

8

11

80

8.625

0.784

40 Joints

8.320

8

11.51

76

8.625

0.750

40 Joints

7.995

8

13.51

64

8.625

0.639

40 Joints

6.913

10

11

80

10.750

0.977

40 Joints

12.924

10

11.5

76

10.750

0.935

40 Joints

12.419

10

13.5

64

10.750

0.796

40 Joints

10.739

12

11

80

12.750

1.159

40 Joints

18.180

12

11.5

76

12.750

1.109

40 Joints

17.471

12

13.5

64

12.750

0.944

40 Joints

15.106

Ratings are in accordance with DOT CFR 49, Part 192, 192.121 and 192.123.

Effective July 14, 2004, the maximum design pressure was amended to 125 psig (reference 192.123a) when

designed in accordance with 192.121 for nominal pipe sizes up through 12IPS (192.123e.3).

All products are manufactured in accordance with ASTM D2513.

Notes:

API 15LE monogram available.

1Products tested and certified by IAPMO.

2Products tested and certified by CSA.

Some sizes are special order. Call for availability on sizes or DRs not shown.

The above weights are calculated per PPI TR-7, using a density of 0.943.

PolyPipe, Inc.

ISO 9001:2000

2406 N. I-35 | P.O. Box 390 | Gainesville, TX 76241

Phone 940.665.1721 | 800.433.5632 | Facsimile 940.668.8612

Sales Facsimile 940.668.2704 | www.polypipeinc.com

PolyPipe is an active member of the Plastics Pipe

Institute, AWWA, AGA and ASTM.

B-1000

05/06

S-ar putea să vă placă și

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 paginiElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkÎncă nu există evaluări

- B-1003 HDPE GDB50 PE4710 Natural Gas Distribution PipeDocument2 paginiB-1003 HDPE GDB50 PE4710 Natural Gas Distribution PipeZulfikar NoerÎncă nu există evaluări

- HDPE 4710 FM Pipe SpecificationDocument2 paginiHDPE 4710 FM Pipe SpecificationJulio CongonaÎncă nu există evaluări

- HDPE Brochure (Lamson)Document6 paginiHDPE Brochure (Lamson)arkadjyothiprakashÎncă nu există evaluări

- Polypipe Potable Water (PW) Pipe: Other Dimensional Standards or Custom Requirements AvailableDocument4 paginiPolypipe Potable Water (PW) Pipe: Other Dimensional Standards or Custom Requirements AvailableAdam KnottÎncă nu există evaluări

- Perfiles y AngulosDocument2 paginiPerfiles y AngulosAlejandro Isaac López RamírezÎncă nu există evaluări

- A1200 Red Thread II PipingDocument0 paginiA1200 Red Thread II PipingjimmycabreraÎncă nu există evaluări

- Tuberias Hdpe PDFDocument5 paginiTuberias Hdpe PDFA. C. V.Încă nu există evaluări

- Tateyama CatalogDocument8 paginiTateyama CatalogDenis William Librahim Rahardjo GÎncă nu există evaluări

- CATALOG-TATEYAMA Low PDFDocument8 paginiCATALOG-TATEYAMA Low PDFtri hantoroÎncă nu există evaluări

- The PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustryDocument2 paginiThe PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustrysreeÎncă nu există evaluări

- Polyethylene Gas Pipe 2007Document10 paginiPolyethylene Gas Pipe 2007asgharkhanÎncă nu există evaluări

- Property of FRP Chart 1 PDFDocument1 paginăProperty of FRP Chart 1 PDFKurt FinkÎncă nu există evaluări

- Roll PinsDocument8 paginiRoll Pinshemanth337Încă nu există evaluări

- 1038 TDD GD 100t Continuous Duty Pump Brochure Data SheetDocument2 pagini1038 TDD GD 100t Continuous Duty Pump Brochure Data SheetYeins Edson OrdoñezÎncă nu există evaluări

- PROGEF Standard PolypropyleneDocument74 paginiPROGEF Standard PolypropyleneoctavioÎncă nu există evaluări

- QUO-I20-421 RevDocument13 paginiQUO-I20-421 RevbettafÎncă nu există evaluări

- Geothermal Exchange Pipe and Fittings: Quality and Service That SoarsDocument4 paginiGeothermal Exchange Pipe and Fittings: Quality and Service That SoarsIbrahim DanishÎncă nu există evaluări

- Enate50std518-Natural Standard Biozinalium PipesDocument2 paginiEnate50std518-Natural Standard Biozinalium PipesAngelo AgostiniÎncă nu există evaluări

- HdpeeDocument38 paginiHdpeeSamet BelliÎncă nu există evaluări

- Garware Polyester Limited-Electrical Films EM6, Thickness, Unit, Yield, DensityDocument2 paginiGarware Polyester Limited-Electrical Films EM6, Thickness, Unit, Yield, Densitybenghoe77100% (2)

- Ss01014 SmithDocument6 paginiSs01014 SmithAchmad TabaÎncă nu există evaluări

- PC WireDocument7 paginiPC Wirejupe01Încă nu există evaluări

- Amal Cast Arrester CatalogueDocument8 paginiAmal Cast Arrester CatalogueTifano KhristiyantoÎncă nu există evaluări

- Pipe CatalogueDocument6 paginiPipe CatalogueirfanÎncă nu există evaluări

- y 130영문 (Astm)Document1 paginăy 130영문 (Astm)qshakimÎncă nu există evaluări

- Butterfly ValveDocument1 paginăButterfly ValveDnyaneshwar0% (1)

- Seamless Mechanical Steel Tubing Specification & SizesDocument6 paginiSeamless Mechanical Steel Tubing Specification & Sizespasanac77Încă nu există evaluări

- Hopelen PP Homopolymer General Information: DescriptionDocument2 paginiHopelen PP Homopolymer General Information: DescriptionKormanyos JoppeÎncă nu există evaluări

- 11 - TW Thermo-KineticsDocument14 pagini11 - TW Thermo-Kineticsthomas_v501925Încă nu există evaluări

- Typical Uses: Product Description: Solids: Tubes: Rectangles: Standard Lengths: Shape/FormDocument2 paginiTypical Uses: Product Description: Solids: Tubes: Rectangles: Standard Lengths: Shape/FormraresÎncă nu există evaluări

- Spirol Pins Bissel Pins Tension Pins SLTP - UsDocument8 paginiSpirol Pins Bissel Pins Tension Pins SLTP - Usstuartj01Încă nu există evaluări

- Sanitary TurbinaDocument4 paginiSanitary TurbinaCindy MateusÎncă nu există evaluări

- SafariDocument20 paginiSafarizahiruddinÎncă nu există evaluări

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 paginiSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengÎncă nu există evaluări

- 7721 Tee Mecanica Rosc Marca Americana Shurjoint TycoDocument3 pagini7721 Tee Mecanica Rosc Marca Americana Shurjoint TycoDavid EnríquezÎncă nu există evaluări

- Bagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesDocument15 paginiBagian C - Spesifikasi Pengadaan Pipa Dan AcessoriesSoleh SulaemanÎncă nu există evaluări

- PeDocument55 paginiPeمنير أحمدÎncă nu există evaluări

- Poly Pipe DetailsDocument2 paginiPoly Pipe DetailsDamara PriantoÎncă nu există evaluări

- Min1244a12 - Tag 130-Pu-029Document7 paginiMin1244a12 - Tag 130-Pu-029Monty MathewsÎncă nu există evaluări

- Nylon MC901Document2 paginiNylon MC901V ShankarÎncă nu există evaluări

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDocument2 paginiStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771Încă nu există evaluări

- GDS134Document4 paginiGDS134Saurabh VermaÎncă nu există evaluări

- Especificacion DELTA PDFDocument14 paginiEspecificacion DELTA PDFecovarrubias1Încă nu există evaluări

- BlaceMaster CPVC Pipe PDFDocument2 paginiBlaceMaster CPVC Pipe PDFPaola LopezÎncă nu există evaluări

- Kooltherm PipeDocument8 paginiKooltherm Pipenaseema1Încă nu există evaluări

- Amipox at Asl PDFDocument8 paginiAmipox at Asl PDFZeshanÎncă nu există evaluări

- 2 - 20 Spec - of Line PipesDocument1 pagină2 - 20 Spec - of Line PipesCharu ChhabraÎncă nu există evaluări

- PVC Pipe BrochureDocument12 paginiPVC Pipe BrochureJohanAndrésVillarrealÎncă nu există evaluări

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Document2 paginiTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiÎncă nu există evaluări

- Oilfield Hoses Fittings AccembliesDocument29 paginiOilfield Hoses Fittings Accembliesthapa786mÎncă nu există evaluări

- Parafusos PT SemblexDocument10 paginiParafusos PT SemblexSBonderÎncă nu există evaluări

- Delta Delta Meter InfoDocument8 paginiDelta Delta Meter InfokawkatrÎncă nu există evaluări

- TD Pmo 6000 en 080108Document16 paginiTD Pmo 6000 en 080108Ricardo DávilaÎncă nu există evaluări

- Southern Marine Engineering Desk Reference: Second Edition Volume IDe la EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IÎncă nu există evaluări

- Gas Sweetening and Processing Field ManualDe la EverandGas Sweetening and Processing Field ManualEvaluare: 4 din 5 stele4/5 (7)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDe la EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceEvaluare: 5 din 5 stele5/5 (1)

- UntitledDocument4 paginiUntitledAdam KnottÎncă nu există evaluări

- Polyethylene Water & Sewer: Submittal and Data SheetDocument8 paginiPolyethylene Water & Sewer: Submittal and Data SheetAdam KnottÎncă nu există evaluări

- Driscoplex 6500 Series Pe2708 (Pe2406) Standard Size and Dimension SheetDocument1 paginăDriscoplex 6500 Series Pe2708 (Pe2406) Standard Size and Dimension SheetAdam KnottÎncă nu există evaluări

- Cenfuse: Hdpe 3408 - Astm D3035Document1 paginăCenfuse: Hdpe 3408 - Astm D3035Adam KnottÎncă nu există evaluări

- Molded Pe Service Saddles: Available Outlet Size Range: Available Base Size RangeDocument1 paginăMolded Pe Service Saddles: Available Outlet Size Range: Available Base Size RangeAdam KnottÎncă nu există evaluări

- Electrofusion Flex RestraintDocument1 paginăElectrofusion Flex RestraintAdam KnottÎncă nu există evaluări

- Transition Fittings: Gas Distribution ProductsDocument20 paginiTransition Fittings: Gas Distribution ProductsAdam KnottÎncă nu există evaluări

- Pressure Rated Electrofusion Branch Saddles: Available Base Sizes: Available Outlet SizesDocument1 paginăPressure Rated Electrofusion Branch Saddles: Available Base Sizes: Available Outlet SizesAdam KnottÎncă nu există evaluări

- Reducers: Butt Fusion FittingsDocument1 paginăReducers: Butt Fusion FittingsAdam KnottÎncă nu există evaluări

- Molded Pe Self-Tapping Tee: Available Outlet Size Range: Available Outlet Types: Available Base Size RangeDocument2 paginiMolded Pe Self-Tapping Tee: Available Outlet Size Range: Available Outlet Types: Available Base Size RangeAdam KnottÎncă nu există evaluări

- 150# & 3000# INSULATING Unions: Ground Joint & O-RingDocument1 pagină150# & 3000# INSULATING Unions: Ground Joint & O-RingAdam KnottÎncă nu există evaluări

- This File Contains Submittals For Both Mueller and Nordstrom ValvesDocument51 paginiThis File Contains Submittals For Both Mueller and Nordstrom ValvesAdam KnottÎncă nu există evaluări

- Weld-End Transition FittingDocument1 paginăWeld-End Transition FittingAdam KnottÎncă nu există evaluări

- Conflex RisersDocument3 paginiConflex RisersAdam KnottÎncă nu există evaluări

- Electrofusion High Volume Tapping Tees Available Outlet Sizes: Available Base Sizes: "Document1 paginăElectrofusion High Volume Tapping Tees Available Outlet Sizes: Available Base Sizes: "Adam KnottÎncă nu există evaluări

- Transition Meter RisersDocument1 paginăTransition Meter RisersAdam KnottÎncă nu există evaluări

- Compression Meter RisersDocument1 paginăCompression Meter RisersAdam KnottÎncă nu există evaluări

- Compression Male Adapter With Built-In StiffenerDocument1 paginăCompression Male Adapter With Built-In StiffenerAdam KnottÎncă nu există evaluări

- Molded Electrofusion Couplings: Available Size RangeDocument1 paginăMolded Electrofusion Couplings: Available Size RangeAdam KnottÎncă nu există evaluări

- Molded Pe Branch Saddle: Available Outlet Size Range: Available Base Size RangeDocument1 paginăMolded Pe Branch Saddle: Available Outlet Size Range: Available Base Size RangeAdam KnottÎncă nu există evaluări

- Con-Stab Id Seal Fittings: Gas Distribution Products ®Document7 paginiCon-Stab Id Seal Fittings: Gas Distribution Products ®Adam KnottÎncă nu există evaluări

- Compression Couplings With Built-In Stiffener (External Epoxy Coating)Document1 paginăCompression Couplings With Built-In Stiffener (External Epoxy Coating)Adam KnottÎncă nu există evaluări

- State Magazine, May 2001Document38 paginiState Magazine, May 2001State MagazineÎncă nu există evaluări

- Lotte Advanced Materials Co., LTD.: ISO 9001:2015, KS Q ISO 9001:2015Document2 paginiLotte Advanced Materials Co., LTD.: ISO 9001:2015, KS Q ISO 9001:2015Tayyab KhanÎncă nu există evaluări

- Differentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2Document186 paginiDifferentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2integrationbyparths671Încă nu există evaluări

- Cell Signaling - The ComponentsDocument7 paginiCell Signaling - The Componentsk10 Lớp Dinh DưỡngÎncă nu există evaluări

- FeCl3 Msds - VISCOSITYDocument9 paginiFeCl3 Msds - VISCOSITYramkesh rathaurÎncă nu există evaluări

- XIInfo Pract H Y 416Document4 paginiXIInfo Pract H Y 416Neelima VijayanÎncă nu există evaluări

- Restricted Earth Fault RelayDocument5 paginiRestricted Earth Fault Relaysuleman24750% (2)

- GMN RodamientosDocument51 paginiGMN RodamientosJayÎncă nu există evaluări

- Fractal Approach in RoboticsDocument20 paginiFractal Approach in RoboticsSmileyÎncă nu există evaluări

- Site AnalysisDocument4 paginiSite AnalysisS O NALÎncă nu există evaluări

- Clavija L5-30P Ref 2611Document3 paginiClavija L5-30P Ref 2611CristianDuarteSandovalÎncă nu există evaluări

- Zencrack Installation and ExecutionDocument48 paginiZencrack Installation and ExecutionJu waÎncă nu există evaluări

- Data Mining With Apriori AlgorithmDocument12 paginiData Mining With Apriori AlgorithmMAYANK JAINÎncă nu există evaluări

- Medicine Colloquium Exam - 2015 ADocument41 paginiMedicine Colloquium Exam - 2015 ArachaÎncă nu există evaluări

- Linberg V MakatiDocument2 paginiLinberg V MakatiChimney sweepÎncă nu există evaluări

- Review Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFDocument3 paginiReview Women With Moustaches and Men Without Beards - Gender and Sexual Anxieties of Iranian Modernity PDFBilal SalaamÎncă nu există evaluări

- Ekoplastik PPR Catalogue of ProductsDocument36 paginiEkoplastik PPR Catalogue of ProductsFlorin Maria ChirilaÎncă nu există evaluări

- Accessing Biodiversity and Sharing The BenefitsDocument332 paginiAccessing Biodiversity and Sharing The BenefitsNelson MartínezÎncă nu există evaluări

- Factors Influencing The Selection Of: MaterialsDocument22 paginiFactors Influencing The Selection Of: MaterialsMaulik KotadiyaÎncă nu există evaluări

- Axis Bank - Group 4Document34 paginiAxis Bank - Group 4Deep Ghose DastidarÎncă nu există evaluări

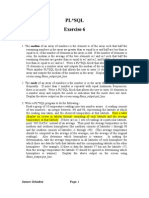

- PL SQL Exercise6Document2 paginiPL SQL Exercise6Nishant AndhaleÎncă nu există evaluări

- Assembling Your Antenna SystemDocument27 paginiAssembling Your Antenna SystemKam MusÎncă nu există evaluări

- B. Tech. - CSE - R13-Syllabus JntuaDocument132 paginiB. Tech. - CSE - R13-Syllabus JntuaVasim AkramÎncă nu există evaluări

- Public Economics - All Lecture Note PDFDocument884 paginiPublic Economics - All Lecture Note PDFAllister HodgeÎncă nu există evaluări

- GSM Rtu Controller Rtu5011 v2 PDFDocument27 paginiGSM Rtu Controller Rtu5011 v2 PDFAbdul GhaniÎncă nu există evaluări

- Phyto Pharmacy: Current Concepts and GMP NormsDocument22 paginiPhyto Pharmacy: Current Concepts and GMP NormsSunitha Katta100% (1)

- Aggregate Turf PavementDocument6 paginiAggregate Turf PavementDevrim GürselÎncă nu există evaluări

- 12 - Community OutreachDocument3 pagini12 - Community OutreachAdam ThimmigÎncă nu există evaluări

- Analisis Perencanaan Rekrutmen Aparatur Sipil Negara Kabupaten Mamuju UtaraDocument11 paginiAnalisis Perencanaan Rekrutmen Aparatur Sipil Negara Kabupaten Mamuju UtarafitriÎncă nu există evaluări

- Technik: RefraDocument54 paginiTechnik: Reframustaf100% (1)