Documente Academic

Documente Profesional

Documente Cultură

Best Practice For Implementing ERP

Încărcat de

Ade OctoraDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Best Practice For Implementing ERP

Încărcat de

Ade OctoraDrepturi de autor:

Formate disponibile

TRANSPLANTING THE BEST PRACTICE FOR IMPLEMENTATION OF AN ERP SYSTEM: A STRUCTURED INDUCTIVE STUDY OF AN INTERNATIONAL COMPANY

SHl-MING HUANG National Chung Cheng University Chia-Yi, Taiwan YU CHUNG HUNG Tatung University Taipei, Taiwan

ABSTRACT Enterprise Resource Planning (ERP) systems have the potential to integrate seamlessly organizational processes using common shared information and data flows. The implementation of ERP systems involves sophisticated business processes integration and conflicts between different departments of the organization. Furthermore, it also costs organizations a huge amount of money and manpower. Therefore, even major ERP vendors cannot guarantee the success of implementation. Consequently, how to implement ERP systems successfully in an effective and efficient manner is an imperative issue in the field of enterprise information systems. Major ERP package vendors have recently used the concept of Best Practice (BP), which is related to transfer the past successful experience to the new ERP projects, to make the implementation effective and efficient. In this paper, we investigate the influences of the BP through a structured inductive study of an international conglomerate by examining their successful implementation of ERP projects. It is not surprising that the results of this study indicate that transplanting BP from the parent company to subsidiaries indeed plays a key role on the implementation of ERP systems. The results also reveal that successful transplanting of BP has positive impacts on the success in ERP implication, through reducing the cultural discrepancies, boosting project efficiency, and empowering coordination of systems integration. Keywords: Enterprise Resource Planning (ERP), Best Practice (BP), Knowledge Management (KM), Critical Success Factor (CSF). INTRODUCTION Changing market demands, shortened product life cycles and growing global competition have increased pressures on enterprises. It is definitely more difficult and complicated to manage a company under intense pressures of competitive market pricing. Managers therefore must rely on real-time information in order to make vital decisions correctly and promptly. To achieve business targets and maintain long-term competitive advantage, real-time and precise operation flows must be integrated within the organization, and information technology and limited company resources must be fully utilized

Summer 2004

HOUN GEE CHEN National Tsing Hua University Hsin-Chu, Taiwan CHENG YUAN KU National Chung Cheng University Chia-Yi, Taiwan

as well. In this light, many enterprises have devoted themselves to implementing enterprise resource planning (ERP) systems. ERP systems, which provide system flexibility, quick response and resources integration, were introduced in the early 1990s to cope with the changing market requirements. The ERP system not only provides real-time information to the enterprise, but also improves business operations flow by means of advanced information technology. In addition, ERP systems improve the efficiency of management decisions and plans and increase the flexibility with adjustments of functionality to react to changes in business needs (Zheng, Yen, and Tarn, 2000). Furthermore, an ERP system is built up with core business operations by integrating aspects such as business strategy, sales and distribution operation, manufacturing process, finance and accounting methodology, as well as human resource function. It is a business trend to change the traditional role of a computer system froiii a transaction processing system to an enterprisewide management system. Owing to the complicated integration of organizational and technical levels, the implementation of ERP systems has been difficult to achieve in practice. According to the comprehensive survey conducted by Robbin-Gioia (2002), 51% of American companies said that their ERP system implementation was unsuccessful. More surprisingly, 46% of the responding companies did not clearly know how to use the ERP system to improve the way they conduct business. In addition, PMP research (2001) finished an ERP-related survey on the impact of manufacturing system, and the results pointed out that 70% of the sample companies believed that the average implementation time of ERP system ranges from six months to two years. As regard to the investment effort of ERP system in U.S. Top 5000 manufacturing firms, more than 68% of companies would employ the Big Bang methodology to change their system and business processes at one time, and ERP system implementation costs companies at the average of approximately one million dollars, as indicated by the survey results of Mabert et al. (2000). Although challenged by extremely high costs, long duration, and high failure rate, enterprises today still keep struggling to implement ERP systems. In 1998, more than 27% of companies in Europe, especially large and international ones had already implemented ERP systems (Everdingen et al., 2000). However, the major ERP vendors such as SAP and Baan 101

Journal of Computer Information Systems

were suffering from the maturity-of-market problem, and the price of their stock declined at the end of the 1990s, In addition, there were even articles predicting that ERP will be dead (Dempsey, 1999; Stein, 1999), Nevertheless, the ERP vendors are now trying to fight for the next generation of ERP systems and extend their market to companies in developing countries, small and medium-sized enterprises, and different kinds of industries (Kumer et al,, 2000). Themistocleous et al. (2001) found that the major technical problems facing organizations undertaking ERP implementation were "Integration with Existing Systems," "Customization," and "Integration with Other Applications." Moreover, the results also showed that the major ERP project management problems are "Project Cost Overruns," "Project Delays," "Conflicts with Business Strategy," and "Employees Resistance to Change." To both overcome the existing ERP implementation problems and extend market share, the major ERP vendors such as SAP and Baan are now providing implementing reference models or process templates that embody the idea of best practice (BP). The essential intention of applying BP is to speed up the implementation of ERP systems and increase the success rate of adoptive customers. More recently, the BP-related information is the most important knowledge asset of main ERP vendors in the next generation arena. Instinctively, BP should have a positive impact on the implementation of ERP systems, especially since BP attracts significant attention from international companies. Because each parent company has successfully implemented the SAP/R3 system, it naturally transplants the BP to subsidiaries' SAP/R3 implementing project. However, few related researches clearly pointed out the role of BP and its influence. In this paper, we extended the previous work (Huang et al., 2001) and aim to identify the BP, investigate the role of BP in the ERP project through a case study of a cross-national P company, and give future directions to both academics and practitioners in the field of ERP systems. It is hoped that our findings will shed light on BP issues in the implementation and adoption of ERP systems, LITERATURE REVIEW Currently, most popular ERP systems adopt the modular concept in design euid implementation. Under this concept, system developers have separated the ERP system into several modules according to the managerial functional area and provide different solutions to specific industry. SAP/R3 is a typical

example of modular design, A different approach toward ERP systems design involves the operation process. Under this design concept, the ERP system focuses on integrating the business internal operation information to streamlining the information flow among all functional departments. Through this streamlining feature, the impact of asymmetric information between internal functional departments may be alleviated to the best possible extent and to facilitate, customer-oriented production. Due to the difficulties in implementing the ERP systems, the concept of the BP becomes fairly commonplace, especially for the major ERP vendors. The giant ERP vendors, such as SAP, incorporated the previous best implementing practices on the implementation of their ERP package modules to speed up implementation time and increase the success rate of new customers. However, the failure rate of ERP implementation remains high and the concept of BP has been applied not only to the practical business process flow or successful cases, but also to management perspectives such as implementation experience knowledge, project management knowledge, and risk management knowledge. There still lacks appropriate attention on the role and influences of BP on the implementation of ERP systems. According to Bogan et al. (1994) and Zairi (1996), BP may be defined as strategies, activities, or approaches of performing work processes to achieve high performance, O'Leary et al. (2000) referred to BP as "the best way to perform some activity" in knowledge management systems. Dutta et al. (1999) defined the BP as "using systematic processes and management practices such as Capability Maturity Model and Bootstrap for the management of software engineering and to improve their development processes" in software engineering perspective, Curran et al. (2000) defined the BP as "contributing to the customers to examine many proven processes without the cost of benchmarking themselves against another organization" in SAP R/S project. Table 1 shows the related research on ERP implementation. As can be seen, these studies focus mainly on ERP implementation and how to increase the success rate of implementing ERP systems. The importance of considering ERP success at multiple points in time was determined by Kim and Peterson (2000) and Ahitur et al. (2002), Their research results show that a company's success or failure is not a reflection of a single action but rather a result of protracted process. Therefore, it is important to understand how the past ERP implementation experience impacts new ERP implementation projects.

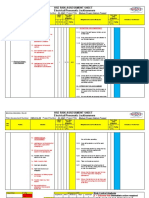

TABLE 1 Related Research on ERP Implementation Tareet Area ERP implementation concept Related Research Davenport, 1998; Cliffe, 1999; Krumbholz et al., 2000; Adam et al., 2000; Sho et al., 2000; Mark et al., 2000; Chiara, 2001; Huang and Kim, 2002; Robert, 2002; Kim and Peterson, 2000 Holland et al,, 1999; Anne et al., 2000; Scheer et al., 2000; Markus et al., 2000; Christopher et al., 2001; Huang et al., 2000; Motwani et al,, 2002; Rajagopal, 2002; Ahitur et al., 2002 Zoonky et al., 2000; Kuludeep et al,, 2000; Scotty and Kaindl, 2000

ERP implementation model or methodology

Knowledge Management on ERP implementation

RESEARCH METHOD This study uses a structured inductive method for deriving BP from parent company to be transplanted to subsidiaries. In Summer 2004

this research, the definition of BP is the knowledge of critical success factors of ERP implementation. This definition is adopted from Zairi (1996) and Curran (2000). To ensure that the ERP system can be successfully implemented in subsidiaries, it 102

Journal of Computer Information Systems

is important to know whether the parent company's consulting team has suceessfuUy transferred their knowledge to the subsidiaries. However, the critical success factors may differ not only according to the management view of the company but also with respeet to localization, culture, etc. (Franz, 1993). To understand the key success factors, this study starts with an interview of the ERP implementing members of the parent company. The aim is to gather their past experience knowledge as the BP for the study. To verily whether the BP has been successfiilly transplanted to the subsidiary, a questionnaire is sent to the ERP key users of the subsidiary. The purpose of the questionnaire is to make this study more credible by a systematic and structural investigation and analysis, including not only top management but also all related major users. The measurement indicated that a higher score implies a higher degree of BP influencing the ERP implementation success factor, while a lower score implies a lower degree of BP influencing ERP implementation success factor, INTRODUCTION OF CASE COMPANY The case company. Company P, is one of the largest in Europe and a top-rated electronics company worldwide. Its employees are active in more than 60 countries in the areas of lighting, consumer electronics, domestic appliances, components, semiconductors, and medical systems. As an international company. Company P had implemented ERP systems in Europe and America. The sponsored implementing team successfully set up the BP strategy to help different branches to install their SAP ERP packages into their working processes. Project RISE was established to implement in phases this new way of working within the consumer product divisions in the Asia Pacific Region, RISE stands for RELIABLE, INFORMATIVE, SPEEDY and EFFICIENT, which describes the expected end result of this project. Using their previous experience and the powerful ERP solution developed by software vendor SAP, the Project RISE team is now building the tools that will help company P embrace a new way of working and implement new business processes. The core project team members of RISE are the professional staff from each related department and assigned responsible people as project managers to complete the job at the specified time intervals. During ERP implementation, each member should report only to the project manager instead of to his or her original direct supervisor. However, the project member will return to his or her position in the department when the project is finished. There were also senior contracted consultants, from neither the ERP system provider side nor a consulting company, who joined the project team to assist with the ERP implementation. Furthermore, a steering committee, organized by high-level management in each subsidiary in different countries, held monthly meetings for the following functions: 1. Instruct project direction 2. Provide management support on budget and software modification 3. Make decisions on company policies or strategies 4. Resolve bottleneck problems 5. Dispatch user representatives to assist the core project team members in implementing ERP. To insure success in implementation of ERP system in Taiwan, the Taiwan RISE team leader of the case company is formed to study whether the same CSF of parent company has been applied to the Taiwan branch.

PHASE I: GATHERING BP The first phase of this study is to conduct an interview with the RISE project members. The objectives of this phase are to understand the status of the project and to gather the RISE team members' ideas about the CSFs from the BP of ERP implementation in the parent company. From the successful experience in Europe and America, this team identifies the CSFs of ERP implementation including: (1) facilitating the effective business process reengineering, (2) providing sufficient/ appropriate training, (3) building good communication and coordination among different business units, (4) integrating legacy systems with EPR, (5) having good project team/ management, and (6) receiving full support from the management team. The CSF would be confirmed by literature review. The CSFs in each aspect are confirmed by the related studies listed in Table 2. PHASE II: BP TRANSPLANTING The structure of this questionnaire was designed according to the characteristics of company P and also the literature published which uses the Likert Scale as a measurement method. After the first run interview with the team members, most of the members agreed that the CSFs should involve the ERP life cycle structure. After consulting with the project leader, the model of Markus and Tanis (9) is adopted in this study. The model is developed from the ERP life cycle and composed primarily of four aspects of primitive factors: "Preparation and implementation processes," "Characteristics of the ERP System," "Vendor Characteristics for the ERP System," and "Evaluation of ERP System Implementation." All the factors related to the CSFs of ERP implementation life cycle are summarized. The Lawshe's approach (16) is employed to justify the content validity of each factor by a steering committee of eight members. From the outcomes of the Lawshe's screening procedure, 39 questions were designed (Table 3) and were divided into four structural frames, as follow. 1. 2. 3. 4. Preparation and implementation processes: 14 questions Characteristics of the ERP system: 9 questions Vendor characteristics for the ERP system: 5 questions Evaluation of ERP system implementation: 11 questions The participants were asked to state their feeling of the procedure for the entire ERP implementation life cycle. In this survey, 35 persons responded to the questionnaire: Finance (16 persons). Warehouse (5 persons). Logistics and Distribution (6 persons), and Information Technology (8 persons). Those who participated in the whole process of ERP implementation in Company P filled in the questionnaire. In this research, the content validity was established first after the draft of the questionnaire was finished under the direction of the general manager of Corporate IT Division of Company P, Taiwan, In addition, four senior managers in the IT department were invited to participate in a pilot test by completing the questionnaire, and the contents of the questionnaire were modified accordingly. The formal investigation started immediately after the questionnaire was finalized to get sufficient precision for the validity test. This research obtained a high level of support from Company P, and all questionnaires were retrieved. Sample data were first measured with a certain level of reliability and validity. Then, using descriptive statistics, the average and standard deviation of the 35 respondents were measured, using average ranking. Finally, we employed principle component

Summer 2004

Journal of Computer Information Systems

103

analysis to explain the variance-covariance structure of a set of variables through a few linear combinations of these variables.

Its general objectives are data reduction and interpretation (Johnson et al,, 1997),

TABLE 2 References Related to Critical Success Factors of ERP Implementation Critical success factors of ERP implementation Communication Education and training Enterprise Level of e-business Clear definition of demand Efficient management Accurate information Support from senior management Support by software suppliers

\ ^

Item

Scholar

\^

Rogers and Barrar (12) Vasilash(l8) Falkowski et al. (6) Bancroft et al. (2) Ptak and Schragenheim (11) Trepper (17) Bingi et al, (3) Buckhout et al, (4) Stefanou(15) Sumner(16) Holland et al. (7) Laughlin (8) Rosario (13) Scheer and Habermann (14) Wee (19) Markus and Tanis (20) Matthys and Shorter (37) Ahituv, Neumann, and Zviran (39)

* * * * *

* * * * * * * * * *

* * * * * * *

* * * * *

* * *

* * * * *

* * * *

* * * * *

* *

* * * * * * *

* * *

* * * * *

* * * * * *

ANALYSIS OF RESULTS In this study, we employed split-half reliability to examine the equivalence for the questionnaire. Thus, we divided the questionnaire into two separate parts and asked the same group to complete them and then calculated the measured reliability by Pearson r, using the scores of the two separate questionnaires. The coefficient r of the split-half reliability for this questionnaire is 0,93, which shows good internal equivalence. To measure stability, the methodology of test-retest reliability was used. The methodology of test-retest reliability is to apply repeatedly the same test to the same sample group at different times to get the related coefficient for each test score; which is called the stability coefficient. There were eight persons selected to redo the questionnaire one month after the initial testing to examine the test-retest reliability. The results indicate a Pearson r coefficient greater than 0.85 among the 35 samples, showing high stability for the questionnaire. The data listed in Tables 4 to 7 indicate the calculated average acceptance value, standard deviation and sorting sequence using questionnaire results which are under the four categories, i.e. preparation and implementation processes. Summer 2004

characteristics of the ERP system, vendor characteristics for the ERP system, and evaluation of ERP system implementation. As seen in Table 4, under the category of preparation and implementation process, the BP for successful ERP implementation included management's declaration and determination (4,23), project team set-up (4.17), adequate training provided (4,06), and the data transformation between old and new systems (4.03), Moreover, because implementation of the ERP system may have great impact on the enterprise, and a high risk of failure, the management determination and public declarations helped to lower the conflict of ERP implementation with organization, and also made staff compliant with company strategy on ERP implementation. Delivering the message of management determination to implement ERP system to employees indicated that the management level would be completely involved in any problems during ERP implementation process. As for other factors, specifying the obligations of project team members to assist in implementing ERP, conducting system training to eliminate concerns of the staff, and converting data between old system and ERP system to assure the same operation quality during the ERP implementation stages were also critical to the 104

Journal of Computer Information Systems

successful implementation of ERP system. As seen in Table 5, under the category of the characteristics of ERP system. The BP for ERP implementation are system integration, system module, and system function for an international company; the acceptance value of which had a score of over 4. This can be explained by the fact that Company P is multi-national, with a diverse portfolio of enterprises, and that is the reason why Company P pays more attention to system

flexibility and system integration. Comparing ERP system with traditional MIS system in the past, ERP system may provide the functions of cross-company, cross-region, and multi-currency to simplify and speed up the business operation processes for a multi-national company. Therefore, ERP system was preferred by the interviewee. It is also significant that among the nine questions, the question on the requirement of localization for ERP system had the lowest score (3.11).

TABLE 3 Items of Each Aspect Dimension Factor Announce the determination to implement ERP system by executive management level. Reduce employee resistance and suspicion of the new systems through communication during the preparation stage. Set up cross function project team. Empower project team by executive management level in your company. Follow exactly planned implementation schedule by Project Team. Define clearly defining implementation scope, procedures and task targets. Preparation and implementation processes Communicate with each department during implementation stage. Provide proper training program for project teams and end users during implementation stage. Llnderstand fully ERP scope and support fi-om your department head; the deep involvement in ERP project by your department head. Provide appropriate resources and budget to support fully ERP implementation in your department. Make public all information and documentation for the process in your department. Possess the knowledge on information system and the ability to apply information system in your department. Accommodate and accept the changing process flow and information system. Convert properly data fi-om legacy system to ERP system before putting ERP system into operation. The build-up cost and implementation schedule for ERP system. The localization for ERP system. The integration and data conversion between legacy system and ERP system. The integration of information system and databsise for ERP system among departments in your company. The flexibility for future function expansion of each module under ERP system. The integration functions of inter-company, international and multi-currency under ERP system. The immediate management information provided to executive level through ERP system. The friendly interface, operation procedure and report provided by ERP system. The flexibility of modification for ERP system to fulfill enterprise demand. ERP vendors can provide strong technical service support after ERP system implementation. ERP vendors can assist to conduct end-user training program and transfer technical skill. ERP vendors can help customer with system implementation, system testing and execution, maintenance and future upgrading. ERP vendors may provide Best Practice or Benchmark in the market. ERP vendors can provide detailed system specification and related documentation. Reduce operation cost. Reduce inventory scale and improve inventory turnover rate. Distribute properly company resources. Improve information flow among different departments. Make business flow and operation more efficient. Improve company automation. Improve customer satisfaction and service quality. Enhance efTiciency of global business Increase data accessibility in time. Smooth purchase process. Increase data accuracy and credibility. Literature

3, 4, 7, 16, 19, 20 6, 16, 19 3.4. 13.19.20 4, 12, 19, 20, 37 7, 12, 19,37 4, 16, 19,20,37, 39 13,19,37 3, 16, 37, 39 3,4, 16, 19,20 7. 12, 15, 19 7, 17,20 3,7, 13.20 7, 13, 16,20 7, 13, 39 7, 13, 20 37,39 7, 12, 16 7, 16. 20 13, 16,39 7, 16. 39 3, 7. 13. 14 3. 7. 14 4, 13 7, 13, 14,20.39 13,14,37 2, 7, 13, 20 8, 16 13,14 13, 16 12, 18 6, 13,20 6. 16,20.39 11,16,20,39 6, 18,39 13,16 15,17 6, 16 13,14. 19 11, 18,20

Characteristics of the ERP system

Vendor Characteristics for the ERP system

Evaluation of ERP system implementation

Summer 2004

Journal of Computer Information Systems

105

Table 6 explains the influence of vendor characteristics on the success of ERP implementation. Compared with the high perception of interviewees on the previous two categories, i.e. preparation and implementation process and the characteristics of ERP system, lower interest and requirements were expressed on vendor characteristics for ERP system. However, this can be explained by the way Company P implemented its ERP system, using the project team which was composed of both its own senior professional system staff and also contracted specialty system consultants. The project did not lead by the ERP vendor or a consulting company. The analysis restilts on evaluation of ERP system implementation are listed in Table 7. The most noteworthy phenomenon was that there was very low perception by the interviewees on the items, "reduce operation cost," "reduce inventory scale and improve inventory turnover rate," "distribute

properly company resources" and "improve customer satisfaction and service quality," all of which management executive respected (the average acceptance value lower than score 3,5), Oti the contrary, those operation-related items were highly affirmed by the interviewees, such as increasing data accuracy and credibility (3,97), increasing data accessibility in time (3,94), This is due to the questionnaire was given to 35 people from four different departments, i,e. Finance, Logistics, Distribution, and Information Technology. Their original business operation process was practically changed after ERP system was implemented. Furthermore, only management executives may strongly perceive the points of business strategy and business management, as found in Company P by interviews with management level officials. Complete and successfiil ERP system implementation will certainly make the business operation more appropriate for achieving the strategic goals.

TABLE 4 Analysis Results on the Preparation and Implementation Process

1 -1, 1-2. 1 -3, 1-4. 1-5. 1-6. 1-7. 1-8. 1 -9. 1-10. l-l 1, I-I2. 1-13. 1-14.

Item (1) Announce the determination to implement ERP system by executive management level. Reduce employee resistance and suspicion of the new coming system by communication during the preparation stage. Set up cross function project team. Empower project team by executive management level in your company. Follow exactly planned implementation schedule by Project Team. Define clearly implementation scope, procedures suid task targets. Communicate with each department by project team member during implementation stage. Provide proper training program for project teams and end users during implementation stage. Understand fully ERP scope and support from your department head; the deep involvement in ERP projects by your department head Provide appropriate resources and budget to fully support ERP implementation in your department. Make transparent all information and documentation for the process in your department. Possess the knowledge on information system and the ability to apply information system in your department. Accommodate and accept the changing process flow and information system. Convert proper data from legacy system to ERP system before the ERP system is put into operation.

Averaae 4,23 3.37 4.17 3.91 3.89 3.83 3.86 4.06 3.89 3.80 3.86 3.60 3.71 4.03

Standard Deviation 1.00 0.84 0,79 0.78 0.93 0.82 0.81 0.73 0.90 0.81 0.77 0.77 0.71 0.79

Sorting Seauence 1 13 2 5 6 10 8 3 6 11 8 13 11 4

The principal component analysis (PCA) was employed as the extraction technique and Varimax as the method of rotation (Kim and Peterson, 2000) to extract critical factors. According to Kaiser's (1960) standards, this study selected variance explanation eigenvalue greater than 1.0. The results indicate that the BP to successful implementation of the ERP system, as divided into the eight major parts listed in Table 8, had cumulative variance explaining up to 80,5%, In order to make component structure much simpler and easier to name the factors and explanations, this study uses Varimax with Kaiser normalization for the rotation method. According to the suggestion of Zaitman and Burger (1985), this study selected variable factor loading with absolute value greater than 0.3, where the factor is composed of two or more variable loadings absolutely greater than 0,35. Table 9 shows the rotated factor matrix, this study selected variable loading with absolute value greater than 0.45 for the factor explanation standard.

Summer 2004

Although the results of PCA show that there are eight factors with eigenvalue greater than 1,0, when looking at Table 9 in greater detail, we can find that the seventh factor is composed of a single variable only. According to the suggestion of Zaitman and Burger (1985), the explanation ability of the seventh factor is not sufficient, so we deleted this factor, selecting the remaining seven factors to be named. Factors are named from the highest value in each factor group shown in Table 9. Finally, Table 10 shows the results of factor naming. CONCLUSION This study examines the influences of BP transplantation on implementing an ERP system in sub-companies, using questionnaires and conducting interviews with Company P, which has already successfully implemented ERP system in Taiwan. The seven critical success factors for the case study

106

Journal of Computer Information Systems

company in ERP system implementation are: (1) the degree and the efficiency of business process reengineering, (2) ERP system supplier option and service, (3) clear ERP strategy, training program, communication skills and coordination capability, (4) integration and communication between legacy system and ERP, (5) project team and project management; (6) participation and support from the management level, and (7) accurate and prompt data acquisition. From the BP of previous ERP implementation, we know that the RISE team has mentioned six critical success

factors that lead to similar conclusions as the above test results. This proves to have high consistency with the migration of BP. As to the factor of supplier option and service, it has not been mentioned in BP. The possible reasons may he that Company P has already decided to introduce SAP's Ry3. Therefore, it seems not necessary to emphasize this factor. However, Company P's subsidiaries in the world consider this factor important for successful ERP implementation.

TABLE 5 Analysis Results on the Characteristics of ERP System Standard Deviation 0.81 1.02 0.97 0.80 0.64 0.61 0.64 0.75 1.06 Sorting Seauence 7 9 6 2 2 1 4 5 8

2-1. 2-2. 2-3. 2-4. 2-5. 2-6. 2-7. 2-8. 2-9.

Item (2) The build-up cost and implementation schedule for ERP system. The localization for ERP system. The integration and data conversion between legacy system and ERP system. The integration of information system and database for ERP system among departments in your compeiny. The flexibility for future function expansion of each module under EPR system. The integration flinctions of inter-company, international and multi-currency under ERP system The immediate management information provided to executive level through ERP system. The friendly interface, operation procedure and report provided by ERP system. The flexibility of modification for ERP system to fiilfill enterprise demand.

Averaee 3.60 3.11 3.63 4.00 4.00 4.03 3.86 3.80 3.43

TABLE 6 Analysis Results on the Vendor Characteristics for ERP System Standard Deviation 0.97 0.98 0.90 0.91 0.88 Sorting ^ Seauence 3 2 1 3 3

3-1. 3-2. 3-3. 3-4. 3-5.

Item (3) ERP vendors can provide strong technical service support after ERP system implementation. ERP vendors can assist to conduct end user training program and transfer technical skill. ERP vendors can help customer with system implementation, system testing and execution, maintenance and future upgrading. ERP vendors may provide Best Practice or Benchmark in the market. ERP vendors can provide detail system specification and related documentation.

Average 3.43 3.51 3.66 3.43 3.43

TABLE 7 Analysis Results on Evaluation of ERP System Implementation Standard Deviation 0.94 0.87 0.81 0.67 0.65 0.86 0.97 0.94 0.91 0.81 0.88 Sorting Seauence 11 9 7 4 6 4 8 3 2 10 1

Item (4) 4-1. 4-2. 4-3. 4-4. 4-5. 4-6. 4-7. 4-8. 4-9. 4-10. 4-11. Reduce operation cost. Reduce inventory scale and improve inventory turnover rate. Distribute properly company resources. Improve information flow among different departments. Make business flow and operation more efficient. Improve company automation. Improve customer satisfaction and service quality. Enhance efficiency of global business. Increase data accessibility in time. Smooth purchase process. Increase data accuracy and credibility.

Averaee 3.23 3.34 3.46 3.80 3.74 3.80 3.40 3.86 3.94 3.29 3.97

Summer 2004

Journal of Computer Information Systems

107

TABLE 8

The Eigenvalue and the Proportion to the Explanation of Variability for Each Principa Component

Factors 1 2 i^ieenvalue 19.092 3.096 2.283 1.796 1.582 1.263 1.240 1,044 Variance explanation | %) 48.954 7.928 5.854 4.606 4.057 3.238 3.180 2.676 Cumulative variance explanation (%> 48.954 56.892 62.747 67.353 71.410 74.647 77.828 80.504

3

4 5 6 7

TABLE 9 Rotated Factor Matrix

actors

1 Item \ 2 4 5 6 7 8 3 .837 .242 V405 .149 .225 V406 .780 .127 .112 .185 .310 -.109 V407 .757 .246 .244 .166 .100 .107 .252 .744 .191 .323 V403 .397 .717 .173 .427 .269 V410 .178 .664 .144 V408 .219 .479 .612 .311 .117 .153 .172 V402 .178 .159 .487 V404 .578 .313 .521 .126 .404 V112 -.178 .115 .238 .359 .574 V411 .542 .515 ,279 .334 .157 .166 .294 V302 .769 .129 .257 .151 .190 .139 V209 .757 .248 .193 -.184 .127 V208 .262 .739 .199 .287 -.160 V301 .126 .738 .247 2 .265 -.120 .428 V305 .312 .708 .255 .117 .245 .162 .326 .119 V303 .401 .702 .203 .177 .215 .150 .120 V304 .457 .667 .349 .231 .135 .260 V409 .486 .523 .112 .260 .130 .355 V203 .283 .500 .431 .121 .396 .206 .123 V107 .242 .257 .770 .247 .159 .243 .268 V205 .395 -.124 .749 .193 .146 .396 .264 V202 .376 .601 .147 .237 .264 V106 .379 .558 .270 .433 .109 -.253 V108 .348 .360 .512 .145 .510 .156 .654 VI13 .358 .166 .116 .103 .289 .194 .226 .514 .638 .110 V206 .142 .216 .200 V114 .627 .345 .253 .275 .193 V102 .221 .579 .349 .343 .201 .197 VI03 .344 .826 .288 .452 .238 .147 VlOl -.205 .557 .229 V104 .111 .541 .263 -.292 .305 .405 .223 V105 .296 .341 .425 .482 .360 .312 V201 .388 .132 .447 .163 .281 .458 .781 VllO .196 .123 .194 .160 .155 .285 .670 V109 .211 .309 .186 .349 V204 .138 .431 .341 .255 .291 .487 .299 V401 .588 .118 .138 .219 .597 .167 .633 V207 .581 .289 .554 .361 .421 Vlll .148 .206 .329 Note: Shaded box indicates factor loading value smaller than 0.45, continue gray grid indicates the same factor group, black box indicates factor loading absolute value smaller than 0.1, and is not listed.

Summer 2004

Journal of Computer Information Systems

108

TABLE 10 CSFs of ERP Implementation Variance Explanation Factor 1 2 3 Factor Name The degree and the efficiency of business process reengineering ERP system supplier option and service Clear ERP strategy, training program, communication siciils and coordination capabiiity Integration and communication between iegacy system and ERP Project team and project management Participation and support from the management level Accurate and prompt data acquisition Eieenvalue 19.092 3.096 2.283 1.796 1.582 1.263 1.044 48.954 7.938 5.854 4.606 4.057 3.238 2.676 Cumulative Variance Explanation (%) 48.954 56.892 62.747 67.353 71.410 74.647 77.323

4 5 6 7

Despite different defmition and perceptions of the success of this ERP system implementation, the case company is regarded as a relatively successful case in Taiwan in terms of ERP system implementation. However, it is difficult to provide a concrete definition for "success." Therefore, it is suggested to set up the quantified measurements such as a fmancial index or output index for future study of ERP implementation. Generally, the methodology frequently used for case studies is to conduct thorough discussion and perform data analysis, not the use of questionnaires. However, much manpower would be required for this due to the size of the case company. We therefore used a questionnaire survey, which is why we suggest collecting more related information on the enterprises, which would be of great help for the completion of the study. Since this study investigates the ERP implementation of Company P, inferences from the study results should be limited to enterprises similar to Company P. It is suggested that future studies should focus on the implementation methodology for other industries (such as service industry, middle scale enterprises, local enterprises, etc.) and a comparative analysis among various industries should be performed. IMPLICATIONS FOR MANAGEMENT

ACKNOWLEDGMENT The work presented in this paper was supported by the MOE Program for Promoting Academic Excellence of Universities under grant no. 91-F-FA08-1-4. We deeply appreciate their financial support and encouragement. We would like to thank Clement Yang, General Manager, Corporate Information Technology Division, Royal Philips Electronics Taiwan, for his support in making the study possible. We also would like to thank Yuan-Te Chu and Tsui-Chen Chao for their assistance in data collection and analysis. REFERENCES Adam, F. and P. O'Doherty. "Lessons from Enterprise Resource Planning Implementations in Ireland - Toward Smaller and Shorter ERP Projects," Journal of Information Technology 15:4, 2000, pp. 305-316. 2. Anne, P. and G. Shanks. "A Model of ERP Project Implementation," Journal of Information Technology, 15:4,2000, pp. 289-303. 3. Bogan, C , and M. English. Benchmarking for Best Practices: Winning Through Innovative Adaptation. New York: McGraw-Hill, 1994. 4. Chiara, F. "Predicting the Implementation Effort of ERP Projects: Empirical Evidence on SAP/R3," Journal of Information Technology, 16:1, 2001, pp. 33-48. 5. Cliffe, S. "ERP Implementation," Harvard Business Review, 77:1, 1999, pp. 16-17. 6. Curran, T., A. Ladd, and G. Keller. SAP R/3 Business Blueprint: Understanding the Business Process Reference Model. Prentice Hall, 1999. 7. Davenport, T. "Putting the Enterprise into Enterprise System," Harvard Business Review, 76:4, 1998, pp. 121131. 8. Dempsey, M. "ERP: Staying Out of Trouble," Financial Times, 1999. 9. Dutta, S., M. Lee, and L. Van Wassenhove. "Software Engineering in Europe: A Study of Best Practices," IEEE Software, 16:3, 1999, pp. 82-90. 10. Everdingen, Y.V. and J. Van Hillegersberg. "ERP Adoption by European Midsize Companies," Communications of the ACM, 43:4, 2000, pp. 27-31. 11. Huang, K.K. and Y.G. Kim. "The Critical Success Factors for ERP Implementation: An Organizational Fit 109 1.

The ERP implementation from the parent company and subsidiaries, verified by the practical and theoretical studies gained similar CSF. Thus, we can conclude that the industry and academia share consistent views of CSF in introducing ERP. This can be a model helping other companies that possess the verified CSF to launch ERP successfully. For an international company, the headquarters' successful experience can provide a guideline to assist the local office to implement new policy effectively and efficiently. Therefore, the headquarters' BP sharing is quite valuable. Past winning experience does not guarantee future success. The RISE team leader in the case company searched academic confirmation in addition to taking headquarters BP to avoid culture impact or resistance due to different practice. This is the right attitude for managers adopting BP. The BP implementation in this study is under the same group company though there are ethnic differences but may share the same company culture. If BP realization is under different company or industry, the obstruction can be very big. More in-depth studies are definitely required. Summer 2004

Journal of Computer Information Systems

12.

13. 14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

Perspective," Information & Management, 40:1, 2002, pp. 25-40. Huang, S.M., S.Y. Irene, and Y.C. Hung. "Planning Enterprise Resources by Use of a Reengineering Approach to Build a Global Logistics Management System," Industrial Management & Data Systems, 101:9, 2001, pp. 483-491. Johnson, R.A. and D.W. Wichem. Applied Multivariate Statistical Analysis. Prentice Hall, 1998. Krumbholz, M., J. Galliers, N. Coulianos, and N.A.M. Maiden. "Implementing Enterprise Resource Planning Packages in Different Corporate and National Cultures," Journal of Information Technology, 15:4, 2000, pp. 267269. Kuludeep, K. and J. Van Hillegersberg. "ERP Experiences and Evolution," Communications of the ACM, 43:4, 2000, pp. 23-26. Kumar, K. and J. Van Hillegersberg. "Enterprise Resource Planning: Introduction," Communications of the ACM, 43:4, 2000, pp. 22-26. Holland, C. and B. Light. "A Critical Success Factors Model for ERP Implementation," IEEE Software, 16:3, 1999, pp. 30-36. Mabert, S. and Venkataramanan. "Enterprise Resource Planning Survey of U.S. Manufacturing Firms," Production and Inventory Management Journal, 41:2, 2000, pp. 52-58. Mark, K. and D. Van Han. "Enterprise Resource Planning: ERP System Migrations," Communications of the ACM, 43:4,2000, pp. 53-56. Markus, M.L. and C. Tanis. "The Enterprise System Experience - From Adoption to Success." In Zmud, R.W. (Ed.). Framing the Domains of IT Management: Projecting the Future Through the Past. Pinnaflex Educational Resources, Inc., 2000, pp. 173-207. Motwani, J., D. Mirchandani, M. Madan, and A. Gunasekaran. "Successfiil Implementation of ERP Projects: Evidence from Two Case Studies," International Journal of Production and Economics, 75:1, 2002, pp. 83-96. O'Leary, D.E. and P. Selfridge. "Knowledge Management for Best Practice," Communications of the ACM, 43:11, 2000, pp. 281-292. PMP Research. "ERP Continues to Have a Major Impact on Manufacturing Systems," http://www.pmpresearch. com/, 2001. Rajagopal, P. "An Innovation-Ditfusion View of Implementation of Enterprise Resource Planning (ERP) Systems and Development of a Research Model," Information & Management, 40:2, 2002, pp. 87-114. Roa, S.S. "Enterprise Resource Planning: Business Needs

26.

27. 28.

29.

30.

31. 32.

33.

34. 35.

36.

37.

38.

39.

40.

and Technologies," Industrial Management & Data Systems, 100:2, 2000, pp. 81-88. Robbins-Gioia LLC. "ERP Survey Results Point to Need for Higher Implementation Success," http://www. robbinsgioia.com/, 2002. Robert, D. "Cultural Complications of ERP," Communications of the ACM, 45:7, 2002, pp. 109-111. Scheer, A.W. and H. Frank. "Enterprise Resource Planning: Making ERP a Success," Communications of the ACM, 43:4, 2000, pp. 57-61. Scott, J.E. and L. Kaindl. "Enhancing Functionality in an Enterprise Software Package," Information & Management, 37:3, 2000, pp. 111-122. Sho, C , S.S. Kien, and J. Tay-Yap. "Cultural Fits and Misfits: Is ERP a Universal Solution?" Communications of the ACM, 43:4, 2000, pp. 47-51. Stein, T. "ERP's Fight for Life," http://www. informationweek.com/, 1999. Themistocleous, M., Z. Irani, R.M. O'Keefe and R. Paul. "ERP Problems and Application Integration Issues: An Empirical Survey," Proceedings of the 34th Annual Hawaii International Conference on System Sciences, 2001, pp. 3775-3784. Christopher, P.H. and L. Ben. "A Stage Maturity Model for Enterprise Resource Planning Systems Use," ACM SIGMIS Database, 32:2, 2001, pp. 34-45. Zairi, M. Benchmarking for Best Practice. Oxford: Butterworth-Heinemann, 1996. Zheng, S., D.C. Yen, and J.M. Tarn. "The New Spectrum of the Cross-Enterprise Solution: The Integration of Supply Chain Management and Enterprise Resources Planning Systems," Journal of Computer Information Systems, Fall 2000, pp. 84-93. Zoonky, L. and L. Jinyoul. "An ERP Implementation Case Study from a Knowledge Transfer Perspective," Journal of Information Technology, 15:4, 2000, pp. 281-288. Matthys, N. and J.D. Shorter. "Electronic Resource Planning Solutions for Business Process," Journal of Computer Information Systems, Fall 2000, pp. 45-48. Kim, C.S. and P.K. Peterson. "Developers' Perceptions of Information System Success Factors," Journal of Computer Information Systems, Winter 2000-2001, pp. 29-35. Ahitur, N., S. Neumann, and M. Zviran. "A System Development Methodology for ERP Systems," Journal of Computer Information Systems, Spring 2002, pp. 56-67. Lehner, F. "Success Factor Analysis as an Instrument for Information Management," Journal of Computer Information Systems, Spring 1993, pp. 58-66.

Summer 2004

Journal of Computer Information Systems

110

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Craving Mind From Cigarettes To Smartphones To Love - Why We Get Hooked and How We Can Break Bad Habits PDFDocument257 paginiThe Craving Mind From Cigarettes To Smartphones To Love - Why We Get Hooked and How We Can Break Bad Habits PDFJacques Savariau92% (13)

- Muscle Building MythsDocument5 paginiMuscle Building MythsKarolÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Body ImageDocument7 paginiBody ImageCristie MtzÎncă nu există evaluări

- Essential Nutrition The BookDocument115 paginiEssential Nutrition The BookTron2009Încă nu există evaluări

- English File: Grammar, Vocabulary, and PronunciationDocument4 paginiEnglish File: Grammar, Vocabulary, and PronunciationFirstName100% (2)

- M. J. T. Lewis - Surveying Instruments of Greece and Rome (2001)Document410 paginiM. J. T. Lewis - Surveying Instruments of Greece and Rome (2001)Jefferson EscobidoÎncă nu există evaluări

- CBLM FBS NC-II (Develop and Update Food and Beverage Service)Document24 paginiCBLM FBS NC-II (Develop and Update Food and Beverage Service)Angel PanganibanÎncă nu există evaluări

- Chapter 9 &10 - Gene ExpressionDocument4 paginiChapter 9 &10 - Gene ExpressionMahmOod GhÎncă nu există evaluări

- LAID BACK - Sunshine ReggaeDocument16 paginiLAID BACK - Sunshine ReggaePablo ValdezÎncă nu există evaluări

- 9 Electrical Jack HammerDocument3 pagini9 Electrical Jack HammersizweÎncă nu există evaluări

- Catalogue of Khalsa Darbar Records Vol.1 - Compiled by Sita Ram KohliDocument180 paginiCatalogue of Khalsa Darbar Records Vol.1 - Compiled by Sita Ram KohliSikhDigitalLibrary100% (1)

- Pratham Bhardwaj: Education SkillsDocument1 paginăPratham Bhardwaj: Education SkillsashuÎncă nu există evaluări

- Learning Activity 5.2 Concept ReviewDocument4 paginiLearning Activity 5.2 Concept ReviewJames CantorneÎncă nu există evaluări

- Multigrade Lesson Plan MathDocument7 paginiMultigrade Lesson Plan MathArmie Yanga HernandezÎncă nu există evaluări

- Corporate Plan 2018 2021Document94 paginiCorporate Plan 2018 2021Nkugwa Mark WilliamÎncă nu există evaluări

- Ad&d - Poison Costs & Poison CraftDocument4 paginiAd&d - Poison Costs & Poison Craftweb moriccaÎncă nu există evaluări

- Computer Awareness: Special Edition E-BookDocument54 paginiComputer Awareness: Special Edition E-BookTanujit SahaÎncă nu există evaluări

- Dampak HidrokarbonDocument10 paginiDampak HidrokarbonfikririansyahÎncă nu există evaluări

- Task 1: Choose The Present Simple, The Present Continuous, The PresentDocument5 paginiTask 1: Choose The Present Simple, The Present Continuous, The PresentAlexandra KupriyenkoÎncă nu există evaluări

- INA28x High-Accuracy, Wide Common-Mode Range, Bidirectional Current Shunt Monitors, Zero-Drift SeriesDocument37 paginiINA28x High-Accuracy, Wide Common-Mode Range, Bidirectional Current Shunt Monitors, Zero-Drift SeriesrahulÎncă nu există evaluări

- MPLS Fundamentals - Forwardi..Document4 paginiMPLS Fundamentals - Forwardi..Rafael Ricardo Rubiano PavíaÎncă nu există evaluări

- Republic of The Philippines Legal Education BoardDocument25 paginiRepublic of The Philippines Legal Education BoardPam NolascoÎncă nu există evaluări

- PHP Listado de EjemplosDocument137 paginiPHP Listado de Ejemploslee9120Încă nu există evaluări

- Reinforcing Steel and AccessoriesDocument4 paginiReinforcing Steel and AccessoriesTheodore TheodoropoulosÎncă nu există evaluări

- Learning TheoryDocument7 paginiLearning TheoryIMS AcadÎncă nu există evaluări

- On Evil - Terry EagletonDocument44 paginiOn Evil - Terry EagletonconelcaballocansadoÎncă nu există evaluări

- CS3 Backup 2023 01 31 02 41Document1 paginăCS3 Backup 2023 01 31 02 41Fans Page1Încă nu există evaluări

- TestertDocument10 paginiTestertjaiÎncă nu există evaluări

- Coca-Cola Femsa Philippines, Tacloban PlantDocument29 paginiCoca-Cola Femsa Philippines, Tacloban PlantJuocel Tampil Ocayo0% (1)

- EXPE222Document6 paginiEXPE222K-yanVehraaYomomaÎncă nu există evaluări