Documente Academic

Documente Profesional

Documente Cultură

M48 - Threaded Bar Mech Properties - Daversteels

Încărcat de

ty2onDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

M48 - Threaded Bar Mech Properties - Daversteels

Încărcat de

ty2onDrepturi de autor:

Formate disponibile

FM12954

Welcome

Daver Steels manufacture high strength structural tie rods with a high specification finish for architectural applications. The DST520 tie rod system is produced in carbon and stainless steel, both with characteristic yield strengths of 520 N/mm2.

The DST520 system provides a technical solution to your tie rod requirements. We have a wide range of experience with tie rod systems and can offer assistance to architects, designers and the end user.

English Institute of Sport - Sheffield

As well as the standard range of fittings shown in this publication Daver Steels are happy to manufacture to your specific needs. Please contact us about your bespoke requirements, for example; special machined forks, spades or couplings, special pins, plate connections, fabricated brackets, welded plate spades.

Tie bar arrangements

The options shown here are generic arrangements. Please contact us about bespoke solutions, stainless, carbon steel brackets & glazing fabrications.

Fork to fork

The simplest form of tendon comprises a bar with a left hand and right hand threaded fork at opposite ends. Once installed the tendon can be adjusted in length by turning the bar. See table 3 to ensure that there is sufficient adjustment for the application.

Fork to fork with turnbuckle

Generally for longer length tendons where fork to fork tendons do not give adequate length adjustment or the overall length exceeds the maximum single bar length. A turnbuckle gives +/- 50mm adjustment for M20 and above. Where excessive sag in a horizontal bar is anticipated a welded connection cleat can be made to the turnbuckle for hanger and stay bars to be connected. Longer turnbuckles can also be machined, together with jacking lock covers for applications where the bars need to be stressed after installation. Please contact our sales team for more information.

Fittings

Shown below are the standard range of Daver Steels fittings. Special fittings can be made and supplied upon request.

Fork ends

Threaded fork ends are used to terminate bars and transfer load to the structure. Fork ends are cast components from M12 - M100. The forks are threaded left-hand or right-hand depending on the tie rod arrangement and are generally tapped with a blind hole for corrosion detailing.

Spade ends

The spade design fits within the fork and matches the load criteria. Spades can be used in place of a fork but the effect of bending and single shear upon the pin must be taken into account. Spades are a special order item.

Pins Central connectors

Where tendons cross in a braced bay a central connection disc can be used. Bars and forks are generally threaded left hand/right hand for the central discs. Tendons are usually fork to fork type but where longer adjustments or a pre-tension is required, forkturnbuckle-fork arrangement can be used. Standard pins are supplied as a pin barrel with end caps. The end caps are secured with countersunk socket set screws to provide a flush finish. Other pin details can be machined to your specific project requirements.

Lockcovers

The locking thread cover (lockcover) is a machined fitting which tapers the fork to the diameter of the bar. For the complete architectural look they also hide exposed threads and when tightened against the fork lock the tendon at the set length. Where thread covers are not required standard hexagonal nuts can be used.

Centre discs

Centre discs are used to connect 3 or 4 tendons together at a central point. Standard centre discs are round with a central hole but other shapes can be made on request. Holes are drilled at an angle to suit your application whether for a braced bay or hanger rods.

Turnbuckles

Turnbuckles are left hand and right hand threaded bar connectors which allow in-situ length adjustments. These are machined with a central chamber to give greater length adjustment than can be achieved with the left-hand/righthand fork combination.

DST520 system components

The Daver Steels DST520 tie rod system consists of two basic components; high strength round bar and connecting fittings.

Customs post - Switzerland

Details from Watergrass bridge - Eire

Shoreditch Bridge, London

Bar

DST520 bar is a high strength steel ranging in diameters from 12mm to 100mm. Bars are available upto 12m in a single length (longer lengths available on request) and have metric threads applied by cold rolling the thread form onto the bar. Bar is available in both carbon and stainless steel grades

Carbon steel - grade 520

I I I I 520N/mm2 yield stress a high strength, weldable, structural steel available in long lengths (up to 12m) with rolled threads to BS3643 can be supplied self colour, painted or galvanised

Stainless steel - grade 520

I I I I I 520N/mm2 0.2% proof stress a high strength cold drawn 316 stainless steel or Duplex stainless steel available in lengths up to 7.5m with rolled threads to BS3643 usually offered as a satin equivalent finish bright polished tendons can also be offered

For areas of higher corrosion exposure bright polished stainless steel tendons are recommended.

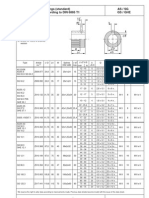

Table 1 DST520 range of bar diameters and mechanical properties

Grade 520 Carbon steel bar Yield load (design load) Nominal bar dia: Maximum single bar length: kN mm m M12 30 12 6 M16 82 16 6 M20 127 19 12 M24 184 22 12 M30 292 28 12 M36 425 34 12 M42 583 39 12 M48 766 45 12 M56 1,056 52 12 M64 1,392 60 12 M76 1,999 72 12 M90 2,879 85 12 M100 3,605 97 12

Grade 520 Stainless steel bar Yield load (design load) Nominal bar dia: Maximum single bar length: kN mm m

M12 44 11 6

M16 82 15 6

M20 127 18 7.5

M24 184 22 7.5

M30 292 27 7.5

M36 425 33 7.5

M42 583 39 7.5

M48 677 45 6

M56 933 52 6

All dimensions in mm for full design details see pages 14-15

M20 - M24 - M42 - M90

Fittings design data

A variety of fittings can be supplied to match your requirements. All fittings are designed to the requirements of BS5950. All fittings exceed the capacity of the bar. Fittings are supplied self colour, painted, galvanised or in stainless steel (satin or bright polished).

Table 2 Fork and spade assembly dimensions

M12 Nominal bar diameter: Fork assembly length: Spade assembly length: Thickness: Jaw gap (fork only) +0/-2mm: Spade thickness: Width: Overall pin length: Lfa Lsa W2 T2 T1 D1 Lp 12 115 115 24 14 10 32 34.5 M16 16 138 138 28 16 12 43 38 M20 19 172 172 35 19 15 51 48 M24 22 200 200 42 24 20 62 55 M30 28 239 239 52 30 25 79 73 M36 34 272 272 64 36 30 93 84 M42 39 303 303 74 39 35 107 99 M48 45 326 326 84 44 40 121 110 M56 56 388 388 95 49 45 145 120 M64 60 433 458 120 59 55 167 149 M76 72 511 536 148 76 70 199 183 M90 85 624 649 170 86 80 246 213 M100 97 709 734 181 91 85 287 223

All dimensions in mm for full design details see pages 14-15

Lfa

Bar

W2

T2

Lsa

FORK ASSEMBLY

Bar

W2

Lp

SPADE ASSEMBLY

T1

D1

Lp

Bar

D1

2 D

Stainless steel fork with isolated pin

Table 3 Turnbuckles

M12 Nominal bar diameter: Turnbuckle assembly length: Diameter: Lta W1 12 130 18 M16 16 150 24 M20 19 300 29 M24 22 322 35 M30 28 344 43 M36 34 366 52 M42 39 398 60 M48 45 420 68 M56 52 442 80 M64 60 464 91 M76 72 504 108 M90 85 596 129 M100 97 635 143

Tendon pin-pin length adjustment Fork - fork: Per turnbuckle: +/- mm +/- mm

M12 15 25

M16 15 25

M20 15 50

M24 20 50

M30 20 50

M36 20 50

M42 25 50

M48 25 50

M56 50

M64 50

M76 50

M90 50

M100 50

All dimensions in mm for full design details see pages 14-15

Bar

Lta

TURNBUCKLE ASSEMBLY

Chiswick Park

Madrid airport

Lloyds TSB

W1

10

Surface finishes

The DST520 tie bar system can be finished to suit specified requirements:

Self Colour

Galvanised

Shot blast & painted

Carbon steel

For carbon steel systems, the options are: I shot blast and primed; painted piece small and reassembled for site top coat I galvanised; bar threads are brushed after galvanising in accordance with BS EN 1461 and fitting threads are cut after galvanising to ensure free running. Alternatively, bar threads can be applied after galvanising and cold zinc applied I galvanised and painted I self colour NB: if shot blasting, painting or galvanising is performed by others please ensure that all threads are protected, Daver Steels cannot accept any responsibility for free running of threads once treated by others.

11

Stainless steel

Stainless steel systems can be offered as: I satin finish - forks - electro polished - locking thread covers & pins - fine machined - bar - 240 Grit machine finish I bright polished - forks & fittings hand polished to a bright finish - bar machined finish to a bright polish Stainless steel is corrosion resistant. However it is not completely maintenance-free in all environments. For example in coastal, swimming pool and leisure environments stainless steel requires cleaning with a proprietary cleaner to remove light surface corrosion. The time interval between cleaning will be determined by the severity of the exposure.

M20 Stainless steel tie bars

The DST520 stainless steel system should only be used in a chlorine environment after full consideration of the associated risks of stress corrosion cracking.

Where stainless steel fittings are in contact with carbon steel bi-metallic corrosion may take place under certain conditions. To prevent this isolation coatings and washers can be supplied for the pins at request. Please contact our technical team for more information.

12

Site installation

For rapid installation on site, DST520 tendons are pre-assembled in the factory and set to their nominal pin-to-pin length. The tendons are then ready for immediate incorporation into the structure and generally require no site assembly, saving valuable time. To install follow the steps below.

Fork to fork tendon

1. back off lock covers 2. install tie rods and pins 3. adjust to length - torque to required value if necessary 4. tighten lock covers For extra security the pin end caps can be secured using a chemical locking compound (such as Loctite) on the counter sunk set screws. Forks are generally drilled with a blind hole to prevent any run-off from the bars. The lock cover/bar opening can be sealed with a proprietary exterior silicon sealant if required.

Reebok stadium, Bolton

Fork to fork tendon with turnbuckle

1. back off turnbuckle locking thread covers 2. install tie rods and pins, tighten fork lock covers 3. adjust tendon length with turnbuckle - torque to required value if necessary 4. tighten turnbuckle lock covers Tendons longer than 12m will be split into transportable lengths and some site assembly will be required. Ensure all components are fitted to the bar and the nominal pin-to-pin length has been set. Follow the steps indicated above.

13

Site pre-stressing

Certain applications may require tendons to be prestressed after installation. This can be performed provided jacking turnbuckles have been specified. Daver Steels offer a robust and easy-to-use range of jacking equipment to provide a simple solution to the stressing of tendons which can be performed by most competent steel erectors. Please contact our sales department for further information.

Daver Steels jacking frame on location

Daver Steels jacking frame

14

Table 4 DST520 System mechanical properties

Grade 520 Carbon steel bar Yield load (design load) Ultimate load (break load): Nominal bar dia: Stress area: Yield stress: Ultimate stress: Elongation: Maximum single bar length: Bar specification: kN kN mm mm2 N/mm2 N/mm2 % m M12 30 51 12 84 355 610 20 6 M16 82 102 16 157 520 650 19 6 M20 127 159 19 245 520 650 19 12 M24 184 229 22 353 520 650 19 12 M30 292 364 28 561 520 650 19 12 M36 425 531 34 817 520 650 19 12 M42 583 729 39 1,121 520 650 19 12 M48 766 958 45 1,473 520 650 19 12 M56 1,056 1,320 52 2,030 520 650 19 12 M64 1,392 1,739 60 2,676 520 650 19 12 M76 1,999 2,528 72 3,889 520 650 19 12 M90 2,879 3,634 85 5,591 520 650 19 12 M100 3,605 4,547 97 6,995 520 650 19 12

Bar specification:Grade 520 bars to BS EN 10267:1998, fine grained micro alloyed steel with enhanced mechanical properties as detailed M12 bars to BS EN 10025-1, type S355J2. All carbon steel bar is fully weldable.

Thread specification: Length tolerance:

Rolled metric threads to BS3643 + / - 3mm for M12 to M100

Grade 520 Stainless steel bar Yield load (design load) Ultimate load (break load): Nominal bar dia: Stress area: Yield stress: Ultimate stress: Maximum single bar length: Bar specification: Thread specification: Length tolerance: kN kN mm mm2 N/mm2 N/mm2 m

M12 44 55 11 84 520 660 6

M16 82 104 15 157 520 660 6

M20 127 162 18 245 520 660 7.5

M24 184 233 22 353 520 660 7.5

M30 292 370 27 561 520 660 7.5

M36 425 539 33 817 520 660 7.5

M42 583 740 39 1,121 520 660 7.5

M48 677 898 45 1,473 460 610 6

M56 933 1,238 52 2,030 460 610 6

Grade 316 stainless steel, cold drawn bar to BS970 or Duplex stainless steel Rolled metric threads to BS3643 + / - 3mm for M12 to M56

Table 5 Fork and spade dimensions

M12 Yield load (design load) Fork length: Spade length: Diameter: Thickness: Jaw gap (fork only) +0/-2mm: Spade thickness: Width: Pin hole diameter: Projection: Jaw depth (fork only): All dimensions in mm kN Lf Ls W1 W2 T2 T1 D1 D2 L1 L2 30 90 90 18 24 14 10 32 13 21 25 M16 56 112 112 22 28 16 12 43 17 27 30 M20 112 132 132 29 35 19 15 51 21 33 42 M24 162 155 155 35 42 24 20 62 25 41 50 M30 258 189 189 43 52 30 22 79 31 52 59 M36 375 217 217 52 64 36 30 93 37 61 68 M42 515 243 243 60 74 39 35 107 43 69 78 M48 677 266 266 68 84 44 40 121 50 78 87 M56 933 313 313 80 95 49 45 145 58 96 105 M64 1,231 348 373 91 120 59 55 167 66 110 120 M76 1,768 420 445 108 148 76 70 199 78 131 141 M90 2,547 498 523 129 170 86 80 246 96 161 171 M100 3,188 575 600 143 181 91 85 287 111 188 197

Lf L1

D 2

Ls L2 L1

D 2

L2

W2

W1

T2

W1

W2

D1

D1

FORK END

SPADE END

T1

15

Table 6 Accessories

Connection plates Thickness: Pin hole diameter: Projection: Clearance: Grade plate to BS EN 10025: T1 D2 L1 L3 M12 10 13 21 32 S355 M16 12 17 27 38 S355 M20 15 21 33 52 S355 M24 20 25 41 62 S355 M30 25 31 52 74 S355 M36 30 37 61 87 S355 M42 35 43 69 97 S355 M48 40 49 78 107 S355 M56 45 57 96 125 S355 M64 55 65 110 140 S355 M76 70 78 131 161 S355 M90 80 96 161 196 S355 M100 85 111 188 222 S355

ensure clearance for paint/galvanising Centre discs Thickness: Overall diameter: Central hole: Pin hole diameter: PCD: Grade plate to BS EN 10025: All dimensions in mm T1 T1 OD ID D2 PCD M12 10 145 50 13 110 S355 M16 12 185 60 17 140 S355 M20 15 245 70 21 180 S355 M24 20 285 90 25 210 S355 M30 25 350 100 31 260 S355 M36 30 420 120 37 310 S355 M42 35 490 140 43 360 S355 M48 40 560 160 49 410 S355 M56 45 660 200 57 480 S355

ensure clearance for paint/galvanising

ID

T1 ANGLE TO SUIT (min 45) OD D2

PCD D2

L1

L3

CENTRE DISC

CONNECTING PLATE FOR HOST STRUCTURE

Table 7 Accessories

Pinsets Pin diameter: Pin body length: End cap diameter: End cap thickness: Lock Covers Lockcover diameter: Fork lockcover length: Turnbuckle lockcover length: Turnbuckles/Couplers Coupler length: Coupler/turnbuckle diameter: Turnbuckle length: All dimensions in mm L3 W1 L4 37 18 70 45 24 85 53 29 144 64 35 155 75 43 170 89 52 180 100 60 195 115 68 210 135 80 230 145 91 240 165 108 268 195 129 290 215 143 315 W1 L5 L6 18 25 30 24 26 33 29 40 78 35 45 84 43 50 87 52 55 93 60 60 102 68 60 105 80 75 106 91 85 112 108 91 118 129 126 153 143 134 160 D3 W2 D4 C M12 12 24 20 3 M16 16 28 25 5 M20 20 36 32 6 M24 24 43 35 6 M30 30 53 50 10 M36 36 64 55 10 M42 42 75 60 12 M48 48 86 60 12 M56 56 96 70 12 M64 64 121 86 14 M76 76 153 100 15 M90 94 173 120 20 M100 109 183 140 20

W2 C

L5

L6

L3

L4

D3

D4

W1

W1

W1

PIN SET

FORK LOCKCOVER

TURNBUCKLE LOCKCOVER

COUPLER

W1

TURNBUCKLE

MMXI daversteels limited - all rights reserved

address Daver Steels Ltd 395 Petre Street Sheffield South Yorkshire S4 8LN United Kingdom

telephone +44 (0) 114 261 1999 facsimile +44 (0) 114 261 1888

e.mail sales@daversteels.co.uk website www.daversteels.co.uk

This data sheet gives the design parameters currently used by Daver Steels Ltd. in the design of its components. The company reserves the right to amend technical details as and when necessary in line with its policy of continuous development. Design by Loop Print

S-ar putea să vă placă și

- Dextra Tie Rods Rev14 Y13M10D30Document10 paginiDextra Tie Rods Rev14 Y13M10D30siva_ar100% (1)

- Reinforcing Bar CouplersDocument9 paginiReinforcing Bar CouplersAWAKSEORANGÎncă nu există evaluări

- Ancon Tapered Thread Couplers International Version PDFDocument16 paginiAncon Tapered Thread Couplers International Version PDFAhmadHamdyÎncă nu există evaluări

- Steel Work SectionDocument22 paginiSteel Work SectionbijukoottalaÎncă nu există evaluări

- VSL Thread Bar Systems BrochureDocument16 paginiVSL Thread Bar Systems BrochureFida GÎncă nu există evaluări

- Viking Johnson Dismantling Joint+BrochureDocument13 paginiViking Johnson Dismantling Joint+BrochureecocadecÎncă nu există evaluări

- Rul and Disk Coupling 2006Document8 paginiRul and Disk Coupling 2006DarkedgeÎncă nu există evaluări

- Tie Rod BrochureDocument20 paginiTie Rod Brochuremech_abhiÎncă nu există evaluări

- Macalloy 500Document4 paginiMacalloy 500Karen BarmakiÎncă nu există evaluări

- Halfen Coupler Mechanical Rebar SplicingDocument33 paginiHalfen Coupler Mechanical Rebar Splicingcarlosfilipegomes3994Încă nu există evaluări

- 2010walkway Expanded MetalDocument2 pagini2010walkway Expanded MetalthorenÎncă nu există evaluări

- H Rod DatasheetDocument2 paginiH Rod DatasheetJohnnie StrydomÎncă nu există evaluări

- Boltzen - Trade Range Catalogue FinalDocument10 paginiBoltzen - Trade Range Catalogue FinalSalith MoosaÎncă nu există evaluări

- Sikla Product GuideDocument6 paginiSikla Product GuideMohamed AdelÎncă nu există evaluări

- Glulam SupplementDocument24 paginiGlulam SupplementLee Ager100% (1)

- Trelleborg Bollard GuideDocument9 paginiTrelleborg Bollard Guidenmh43Încă nu există evaluări

- Tech in Fast Catalogue EnglishDocument42 paginiTech in Fast Catalogue Englishsharklasers12Încă nu există evaluări

- 26 HHW Katalog 2010 Eng UniversaleDocument10 pagini26 HHW Katalog 2010 Eng Universalecos2012Încă nu există evaluări

- VJ Flexlock BroDocument9 paginiVJ Flexlock BroAhmad ShakeelÎncă nu există evaluări

- 25 Rebar CouplerDocument4 pagini25 Rebar CouplerNivedhan GandhiÎncă nu există evaluări

- The Nelson System Catalouge Version 2 2017 Shear StudsDocument8 paginiThe Nelson System Catalouge Version 2 2017 Shear StudsMacÎncă nu există evaluări

- Lintech CatalogDocument75 paginiLintech CatalogElectromateÎncă nu există evaluări

- Ancon CouplersDocument32 paginiAncon CouplersNuno Telmo LopesÎncă nu există evaluări

- Ramset Specifiers Anchoring Resource Book ANZ Chemical Anchoring Anchor StudsDocument59 paginiRamset Specifiers Anchoring Resource Book ANZ Chemical Anchoring Anchor StudsjlolhnpÎncă nu există evaluări

- Cutting Edge BrochureDocument2 paginiCutting Edge BrochureKen SmithÎncă nu există evaluări

- MC Series MNDocument33 paginiMC Series MNnvkjayanthÎncă nu există evaluări

- Spiral Wound Gaskets PDFDocument4 paginiSpiral Wound Gaskets PDFSumit ChaurasiaÎncă nu există evaluări

- Bollard Guide TrelleborgDocument9 paginiBollard Guide Trelleborgcost_engineer100% (2)

- DEFNUT - Nituri TubulareDocument28 paginiDEFNUT - Nituri Tubularepaula09Încă nu există evaluări

- Reinforcement: Types of ReinforcementsDocument7 paginiReinforcement: Types of ReinforcementsymanfasÎncă nu există evaluări

- VSL Threadbar SystemsDocument16 paginiVSL Threadbar SystemsNguyen Chau LanÎncă nu există evaluări

- Ancon MBT Couplers International Version PDFDocument14 paginiAncon MBT Couplers International Version PDFAhmadHamdyÎncă nu există evaluări

- Non Standarad Dowel PinDocument4 paginiNon Standarad Dowel Pinjaskaran singhÎncă nu există evaluări

- Weldlok GratingDocument16 paginiWeldlok Gratingnovadistributors100% (3)

- Walkway GratingDocument2 paginiWalkway Gratingbijukoottala100% (1)

- Cold Rolled Steel StripDocument40 paginiCold Rolled Steel StripshelarsanjayÎncă nu există evaluări

- Arcing DevicesDocument10 paginiArcing DevicessalvandyÎncă nu există evaluări

- BestalMetal Catalogue 2013Document28 paginiBestalMetal Catalogue 2013Chan Kam Chu100% (1)

- Fastenr GradesDocument5 paginiFastenr GradesVipul ShereÎncă nu există evaluări

- Weldlok Steel GratingDocument16 paginiWeldlok Steel GratingDivyang241088Încă nu există evaluări

- Parallel Groove ClampsDocument5 paginiParallel Groove ClampsN.PalaniappanÎncă nu există evaluări

- Rawlbolt: Shield Anchor Loose BoltDocument2 paginiRawlbolt: Shield Anchor Loose BoltBappy IslamÎncă nu există evaluări

- SFS Suruburi Panouri Sandwich EngDocument26 paginiSFS Suruburi Panouri Sandwich EngMircea BotezÎncă nu există evaluări

- Bossard Taptite Self Tapping Screw CatalogueDocument10 paginiBossard Taptite Self Tapping Screw CataloguepmlmkpÎncă nu există evaluări

- ECE 2211 CIVIL ENGINEERING DRAWING III Lecture 5Document24 paginiECE 2211 CIVIL ENGINEERING DRAWING III Lecture 5Stanley MwangiÎncă nu există evaluări

- Din 7500 enDocument10 paginiDin 7500 enCălin Bălăiţă100% (1)

- Dywidag High Strength BarsDocument4 paginiDywidag High Strength Barsnishchint100% (1)

- Reinforcement: Industrial Training Report Tudawe Brothers LimitedDocument8 paginiReinforcement: Industrial Training Report Tudawe Brothers Limitedymanfas100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Spot Welding Interview Success: An Introduction to Spot WeldingDe la EverandSpot Welding Interview Success: An Introduction to Spot WeldingÎncă nu există evaluări

- High-Performance GM LS-Series Cylinder Head GuideDe la EverandHigh-Performance GM LS-Series Cylinder Head GuideEvaluare: 4.5 din 5 stele4.5/5 (2)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderDe la EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderEvaluare: 5 din 5 stele5/5 (2)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDe la EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkÎncă nu există evaluări

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDe la EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Shailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpDocument7 paginiShailendra - Yadav - R.F Design and Optimization Engineer - 5.10 - Yrs ExpGaurav TiwariÎncă nu există evaluări

- TUPT AdmissionDegreeLadderizedDocument1 paginăTUPT AdmissionDegreeLadderizedromerqazwsxÎncă nu există evaluări

- Yaesu VR 120Document44 paginiYaesu VR 120Chema MelidaÎncă nu există evaluări

- Using Spreadsheets For Steel DesignDocument4 paginiUsing Spreadsheets For Steel DesignAmro Ahmad AliÎncă nu există evaluări

- A5 MSMD 400WDocument1 paginăA5 MSMD 400WInfo PLSÎncă nu există evaluări

- AC 29 2cincorporatedDocument1.109 paginiAC 29 2cincorporatedzzudhirÎncă nu există evaluări

- Arzator Rooftop ApenDocument44 paginiArzator Rooftop ApenEu TuÎncă nu există evaluări

- Padma Vibhushan Dr. G. Madhavan NairDocument7 paginiPadma Vibhushan Dr. G. Madhavan NairjishnusajiÎncă nu există evaluări

- Density and Concentration Transmitter: Installation GuideDocument40 paginiDensity and Concentration Transmitter: Installation GuideOmid GhÎncă nu există evaluări

- BS en 00480-6-2005 PDFDocument8 paginiBS en 00480-6-2005 PDFShan Sandaruwan AbeywardeneÎncă nu există evaluări

- 22KW Hydraulic Power Unit GADocument1 pagină22KW Hydraulic Power Unit GAGabi GabrielÎncă nu există evaluări

- Chapter 3: Operating-System StructuresDocument31 paginiChapter 3: Operating-System StructuresDiamond MindglanceÎncă nu există evaluări

- Chip Tuning Remaping Book Engine Fuel Map DesignDocument13 paginiChip Tuning Remaping Book Engine Fuel Map Designopenjavier5208100% (10)

- 300B Parallel SET AmplifierDocument8 pagini300B Parallel SET Amplifierandree wÎncă nu există evaluări

- kp-57-65wv600 SONYDocument33 paginikp-57-65wv600 SONYdjcamdtvÎncă nu există evaluări

- PTX PRM PGL T5 750929eDocument382 paginiPTX PRM PGL T5 750929eListiyo Imam SantosoÎncă nu există evaluări

- 7.sieve Analysis AhmedDocument9 pagini7.sieve Analysis AhmedJin AhmedÎncă nu există evaluări

- Maintenance ManualDocument6 paginiMaintenance ManualHuda LestraÎncă nu există evaluări

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Document1 paginăAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeÎncă nu există evaluări

- Double Effect EvaporatorDocument4 paginiDouble Effect EvaporatorAditiJain100% (1)

- 01-25 OB Bbs 3 Year Preboard 2076Document1 pagină01-25 OB Bbs 3 Year Preboard 2076Reestam SD100% (1)

- Practice Test 3Document13 paginiPractice Test 3Ngân Hà NguyễnÎncă nu există evaluări

- 1 1 6 A-VariableRolesIIDocument5 pagini1 1 6 A-VariableRolesIIRocket FireÎncă nu există evaluări

- Technical Service Bulletin 6.7L - Illuminated Mil With Dtcs P1291, P1292, P0191 And/Or P06A6 - Engine Harness Chafe 19-2231Document4 paginiTechnical Service Bulletin 6.7L - Illuminated Mil With Dtcs P1291, P1292, P0191 And/Or P06A6 - Engine Harness Chafe 19-2231Yaniss AlgeriaÎncă nu există evaluări

- Know The Escalation Matrix To ReportDocument1 paginăKnow The Escalation Matrix To ReportHemal GandhiÎncă nu există evaluări

- Pavilion Design Workshop + Competition: Uni - Xyz/competitionsDocument14 paginiPavilion Design Workshop + Competition: Uni - Xyz/competitionsNikunj DwivediÎncă nu există evaluări

- Rajasthan BrochureDocument31 paginiRajasthan BrochureMayank SainiÎncă nu există evaluări

- Draw 224-1Document8 paginiDraw 224-1Alther Dabon33% (3)

- Silver Nano ParticleDocument70 paginiSilver Nano Particleasad ullah100% (1)

- Security Officer/GuardDocument2 paginiSecurity Officer/Guardapi-121358674Încă nu există evaluări