Documente Academic

Documente Profesional

Documente Cultură

5 1

Încărcat de

gabrieltinDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5 1

Încărcat de

gabrieltinDrepturi de autor:

Formate disponibile

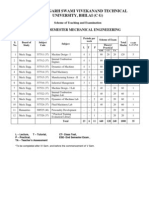

94 5.1 RATIONALE This subject is in continuation to Auto Engine-I. It covers diesel engines and other types of engines.

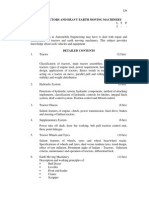

It also includes combustion, performance of engine. Engine pollutants and its control. Brief description of engines of modern vehicles has also been included in this subject. DETAILED CONTENTS 1. High Speed Diesel Engine (10 hrs) AUTO ENGINE-II L T P 3 - -

Theory of diesel engine operation. Difference between petrol & diesel engine. Advantages and disadvantages. Fuel filters-primary and secondary, priming & fuel feed pumps. Fuel injection pumps- plunger and barrel type, distributor type. Fuel injectors and solid injection, CRDI (Common rail direct Injection). Type of nozzles. Governing and type of governors. 2. Combustion Phenomenon of combustion in C.I engines and S.I engines, phases of combustion and after burning . Methods producing turbulence. Various type of combustion chambers for petrol and diesel engines. Detonation and knocking, octane and cetane number,, swirl and squish. 3. Different Types of Engine (8 hrs) (8 hrs)

Super charged engines. Turbo charged engines, power absorbed by super charger. Location of super charger. Wankel engine Free piston engine Gas turbines and jet propulsion Alternate fuels operative engines like L.P.G, C.N.G operated. Working principle of Hybrid car, fuel cell car/duel fuel operated engines. 4. Performance of Engine Effect on engine performance due to atmospheric temperature, pressure, compression ratio, engine speed, working conditions, dirt, desert, hills, injection timing/spark timing. Air fuel ratio. Their remedial measures. Two stroke engine scavenging definition and types (6 hrs)

95 5. Engine Pollutants and its control Sources of engine pollutants of S.I and C.I engine. Effect of pollutants on human and environment. Methods of Control Crank case, fuel tank ventilation, carburetion and recirculation. Redesigning of various engine system, V.V.R. Exhaust gas recirculation systems. Catalytic converters. Close loop feed back electronic integrated engine management system. Emission rules and regulations. Euro I, II, III 6. Modern Vehicles Brief description of constructional features of engine used in automobiles such as Hero Honda, Maruti, Tata and Leyland and Volvo trucks. (6 hrs) (10 hrs)

RECOMMENDED BOOKS 1. 2. 3. Automobile Engineering by Dr. Kirpal Singh Automobile Engineering by R.B. Gupta I.C. Engines by M.L. Mathur and R.P Singh.

96 5.2 RATIONALE Chassis, body and transmission forms the core of automobile engineering. The subject aims at imparting knowledge and skills regarding chassis and body viz, clutch system, transmission system, drive system, steering mechanism, suspension system, braking system and safety of vehicles DETAILED CONTENTS 1. Clutch Constructional details and working of centrifugal, semi centrifugal clutches and fluid coupling. 2. Transmission Necessity, functions. Epicyclic gear box and automatic transmission, free wheel mechanism, auxiliary gear box torque converter, description and operation of transfer gear box, common faults and remedies. 3. Steering Power steering - necessity, types, salient features of construction and working. Common steering system troubles and remedies. 4. Suspension System Function, types- independent, rigid axle suspension springs, functions and types coil, leaf and torsion bar, sprung and un-sprung weight. Characteristic of spring materials, leaf ends, spring eye, upturned and down turned bushes, variable rate spring, helper leaf, leaf section, rubber pads, pressure block, spring covers interleaf inserters pneumatic suspension system. Pneumatic suspension system. Function and construction of hydraulic dampers (shock absorbers). Diagnosis of common faults and their rectification, silent-bloc bushing. 5. Power Brakes Air, air-hydraulic, hydro-vac brakes-their construction and working details. Brake tests, common faults and their rectification. (6 hrs) (12 hrs) (8 hrs) (10 hrs) (8 hrs) CHASSIS, BODY AND TRANSMISSION-II L T P 3 - -

97 6. Automotive safety systems Preventive design, designing for minimum injury in accident, seat belts, air bags, electronic vehicle stability and occupant protection systems. (4 hrs)

RECOMMENDED BOOKS 1. Automobile Engineering, Vol. I by Dr. Kirpal Singh, Standard Publishers 2. Automotive Chassis and Body by PL Kohli 3. Automobile Engineering by GBS Narang, Khanna Publishers, Delhi 4. Automobile Engineering by CP Nakra

98 5.3 RATIONALE Management of garages forms an important function of automobile technicians. To perform such functions, knowledge of service station equipment, tuning equipment, engine repair tools, electrical repair equipment and reconditioning and fabrication of equipment is very essential. Hence the subject. DETAILED CONTENTS 1. General Tools Specifications and applications of Screw drivers Spanners and wrenches Pliers Hammers Chisels Files Hacksaw Tools for tubes flaring Taps and dies Reamers Soldering tools Measuring tools- vernier calipers, inside and outside micrometers 2. General Equipment Specifications and applications of Drilling machine Bench grinder Air compressor Hydraulic and electric hoists Car washer Oil sprayers Grease Guns-manual and bucket type, pneumatic Tyre inflation gauge (Manual and Digital type automatic) Tyre Changer (Manual and Automatic) Creepers Electric and gas welding equipment Fire extinguisher First aid box (12 hrs) (6 hrs) GARAGE EQUIPMENT L T P 4 - -

99 3. Turning and Testing Equipment Specifications and applications of Vacuum Gauge Compression Gauge (Pressure Gauge) Distributor Tester cam (dwell) angle tester, r.p.m. tester. Battery Tester Spark lug cleaner and tester Ignition timing light Fuel injector tester Fuel consumption tester 4. Engine Repair Tools/Measuring and Testing Equipment Specifications and applications of Torque wrench, pneumatic wrench Piston ring compressor Valve lifter and valve spring tester Piston ring files, groove cleaner Scrappers Piston ring remover Cylinder Dial gauge Smokemeter Exhaust gas analyzer Engine Analyser/Scanner 5. Electrical Repair Equipment Specifications and uses of Electrical Test Bench Battery Charger Head Lights Beam Aligner and Tester (Electronic and Digital type) Growler 6. Chassis, Body of Reconditioning/Testing Equipment Use of Brake Efficiency Tester (Chassis Dynamometer) Clutch Fixtures and Brake Line Rivetters, pop riveting gun Crane and Chain Pulley Block Jacks mechanical, hydraulic, trolley type Paint chamber Paint Spray Gun Paint Drying Equipment (6 hrs) (6 hrs) (12 hrs) (10 hrs)

100 Computerized wheel balancer- Static and Dynamic Computerized wheel alignment Equipment 7. Engine Reconditioning and Testing Equipment Specifications and use of Cylinder Boring Machine and Honing Machine Crankshaft Machine and Camshaft Grinding Machine Connecting Rod Aligner Line Boring Machine and Arbor Press Nozzle Grinding and Lapping Machine Fuel Injection Pump Calibrating Machine Valve Refacer, Valve Seat Cutting and Grinding Radiator Tester RECOMMENDED BOOKS 1. 2. 3. Automotive Mechanics by WH Crouse and Donald Anglin; and Tata Mc Graw Hill Publishing Co. Ltd., Delhi. Auto Mechanics Fundamentals by MW Stockel, Goodheart Wilcox Publishers. Automobile Engineering Vol. I and II by Dr. Kirpal Singh; Standard Publishers, Delhi. (12 hrs)

101 5.4 RATIONALE A diploma holder will have to conduct time and motion study to improve the methods/system. This subject impart valuable skills to plan and understand plant layout, and production planning and control. DETAILED CONTENT 1. Production and Productivity Production, production functions, productivity, factors affecting productivity, measurement of productivity, causes of decrease in productivity, difference between production and productivity. 2. Plant Location, Layout and Material Handling Plant location, factors affecting plant location, concept of plant layout, types of layout, their characteristics, factors affecting plant layout, work station design, factors considered while designing a work station, introduction, need and objective of material handling, factors considered while selecting a material handling device, safety concept of material handling equipment. 3. Work Study Definition and scope of work study; areas of application of work study in industry, Role of work study in improving productivity, Objectives, needs and methods of method study, information collection, recording techniques, process symbols, charts and diagrams, critical examination, development, installation and maintenance of improved methods, work measurement objectives, needs and methods of work measurement, time study, various allowances, calculation of time, work sampling, standard data and its use. Application of engineered time standards and work sampling Ergonomics, concept and advantages. 4. Job Evaluation and Incentives Introduction, objectives, needs of job evaluation, job definition, job analysis, data source, job evaluation methods such as ranking method, grade description method, point system and factor comparison method, hybrid system. (12 hrs) (12 hrs) (8 hrs) (6 hrs) INDUSTRIAL ENGINEERING L T P 4 - -

102 Incentive-definition and concept, incentive and productivity relation, types of incentives such as financial, non financial. Individual and group incentives, pre requisites for incentives, characteristics of a good incentives plan 5. Production Planning and Control Introduction, objectives and components (functions) of P.P.C, Advantages of production planning and Production Control, stages of P.P.C, process planning, routing, scheduling, dispatching and follow up, routing purpose, route sheets, scheduling purpose, machine loading chart, Gantt chart, dispatching purpose, and procedure, follow up purpose and procedure. CPM/PERT technique, drawing of simple networks and critical time calculation. Production Control in job order, batch type and continuous type of productions. Difference between these controls. 6. Estimation and Costing Introduction, purpose/functions of estimating, costing concept, ladder and elements of cost, difference between estimation and costing. Overheads and their types, estimation of material cost, estimation of cost for machining processes, numerical problems. (12 hrs) (14 hrs)

RECOMMENDED BOOKS 1. 2. 3. 4. 5. Industrial Engineering by O.P. Khanna; Dhanpat Rai and Sons, New Delhi. Industrial Engineering by S.C. Sharma; Khanna Publisher. Industrial Engineering and Management by T.R. Banga. Elements of work study by Suresh Dalela. Production Management by Jain and Aggarwal.

103 5.5 AUTO ELECTRICAL AND ELECTRONICS EQUIPMENT L T P 4 - RATIONALE Diploma holders in Automobile Engineering have to deal with different types of batteries, their changing and testing and electronic regulators, ignition system, lighting system and various other electrical accessories used in Automobile Engineering. Hence the subject of automotive electrical & electronic equipment is very essential for these technicians. DETAILED CONTENTSS 1 Introduction Various electrical and electronics circuit components and their symbols as used and their functions. HT & LT, their specifications, wiring harness. 2. Lead Acid and other Batteries Construction, working, material used, electrolyte and its strength, effect of added plate area and temperature, rating, capacity, efficiency, temperature characteristics, terminal voltages, charging & discharging, maintenance- free batteries. Battery testing Electrolyte testing hydrometer, voltage test, high discharge and cadmium test. Battery charging: Constant potential and constant current, Initial charging, normal charging, trickle charging, intermittent charging, Boost charging. Battery Defects: Sulphation, plates decay, erosion, cracking, sedimentation, separator defects, short circuits, over charging. Alkaline Batteries: Principles of working, merits and demerits of Ni-Fe, NiCd, Ag-Zn cells. Fuel cells: Types, principles of working and use of fuel cells. (12 hrs) (6 hrs)

104 3. Charging system Circuits, function of various components, Dynamo, Alternator-types, construction, working, advantages and disadvantages. Cut out relay. Regulation: Necessity of regulation, construction and working of regulators for dynamos and alternators. 4. Starting systems Starting requirements of an S.I. engines, principle, types and construction details of starter motor, starter switches, starter drives - their types and working. 5. Ignition system Working of point type electrical coil ignition system and function of its various components. Working of point less inductive type systems, pulse generator, Hall switch optical switch. Electronic ignition advance, distributorless ignition system, testing of ignition circuits and various system components. 6. Lighting system Various lighting terms, lighting circuits, head lamp type and constructional details. Sealed beam, double filaments, asymmetric and dual units., vertical and side control of lamps, fog light, sidelight, brake light, instrument light, indicator light, reversing light, ultraviolet head light, LED lighting. Wiring: Cable colour code, cable connectors, wiring diagram of cars and twowheelers, fuses, faults and rectification. Multiplexed wiring system. 7. Electrical Accessories Fuel gauges:- Bimetallic and balancing coil type, Air pressure gauges, temperature gauges, warning lights, spedometer, wind Screen wipers, horns, horn-relay, electrical fuel pump, heaters, defrastors, power locks, window controllers, faults and rectification. RECOMMENDED BOOKS 1. 2. 3. 4. 5. Automobile Engineering. Vol II - by Dr. Kirpal Singh, Standard Publishers, Delhi. Automotive Electrical Equipment by P.L. Kohli, Tata McGraw Hill, Delhi Automotive Electronics and Electrical equipment by William H. Crouse and DL. Anglin, McGraw Hill company. Automobile Engineering by R.B. Gupta, Satya Prakash, New Delhi Automobile Electric and Electronic Systems by Tom Denton, Arnold London. (14 hrs) (8 hrs) (8 hrs) (8 hrs) (8 hrs)

105 5.6 RATIONALE Testing and trouble shooting of various electrical components and systems of automotive vehicle is an area where a diploma holder must have proficiency. He should be fully aware about the procedures of overhauling of engines, gearbox, differential. He should be trained in using various components while driving on road, in plains and hilly areas. That is why, this subject has been introduced. LIST OF PRACTICALS 1. 2 3. 4. Testing of battery with hydrometer, high rate discharge tester, charging of Batteries. Testing and setting of ignition timing with timing light, cam angle tester, and dwell angle tester. Testing and Cleaning of spark plug. Testing of field winding, testing of armature winding and comutator for shortcircuit. For alternator. 5. 6. 7. 8. 9. Testing of voltage and current regulator. Head light and beam setting. Testing and setting of horn, relay, dipper switch, flasher unit and indicator circuits. Diagnosing electronic ignition systems, magneto ignition system. Colour codes and sketching of complete wiring circuits of an Indian automobile. AUTO WORKSHOP AND DRIVING PRACTICE L T P - - 18

10. Overhauling of petrol engine. 11. Overhauling of diesel engine. 12. Overhauling of gearbox. 13. Overhauling of differencial. 14. Inside and out inspection/checking of vehicle, checking of engine oil, horn, starter, coolant before starting of engine. 15. Starting of engine and warming up. 16. Fuel injection pump calibration on calibration machine. 17. Clutch operation of engaging and disengaging on the road. 18. Gear changing from low to high and high to low speed on the road. 19. Braking and use of brakes on ground/road. 20. Practice on general road safety, road and traffic signals and driving regulations. 21. Driving practice on road for steering control.

106 22. Reversing practice on vehicle on the ground. 23. Driving on gradient. 24. Driving practice on a scooter/motor cycle. 25. Painting practice on vehicles to change colour from base. 26. Servicing of suspension system, lead springs, independent suspension, coil spring, torsion bar, telescopic shock absorber.

RECOMMENDED BOOKS 1. 2. 3. 4. 5. Automobile Engineering by Kirpal Singh. Automobile Electrical and Electronic System by Tom Denton; Arnold, London, Automotive Electrical Equipment by P.L. Kohli. Automotive Electrical Equipment by William H. Crouse. Automobile Engineering by R.B. Gupta.

S-ar putea să vă placă și

- Auto Engine Course Document SummaryDocument13 paginiAuto Engine Course Document SummaryDineshNewalkarÎncă nu există evaluări

- 15me655 AeDocument2 pagini15me655 Aeyoussef ibrahimÎncă nu există evaluări

- Automobile - Full Notes - 6TH PDFDocument179 paginiAutomobile - Full Notes - 6TH PDFShailesh RajuÎncă nu există evaluări

- ENGINEERING TITLEDocument37 paginiENGINEERING TITLEferiha khanÎncă nu există evaluări

- Chhattisgarh Technical University B.E. Mechanical 5th Sem Subject SchemeDocument14 paginiChhattisgarh Technical University B.E. Mechanical 5th Sem Subject Schemeveer_sÎncă nu există evaluări

- Ae Mod1 5@azdocuments - inDocument188 paginiAe Mod1 5@azdocuments - inBhargav AngadiÎncă nu există evaluări

- B. TEch 7th SemDocument24 paginiB. TEch 7th SemrajeshÎncă nu există evaluări

- Untitled NotesDocument149 paginiUntitled NotesShashank BiligiÎncă nu există evaluări

- Automobile Systems - 9057Document5 paginiAutomobile Systems - 9057Khushbu JoshiÎncă nu există evaluări

- 6.1 Tractors and Heavy Earth Moving MachineryDocument16 pagini6.1 Tractors and Heavy Earth Moving MachineryEr Rajesh Bura100% (1)

- Automobile Engineering Course OverviewDocument16 paginiAutomobile Engineering Course OverviewHIMANSHU KUMARÎncă nu există evaluări

- Auto-Syllab MTech Admission 2012-13Document25 paginiAuto-Syllab MTech Admission 2012-13Ratnakar PatilÎncă nu există evaluări

- Mce 401 Computer Integrated Manufacturing Systems: Secti On-ADocument24 paginiMce 401 Computer Integrated Manufacturing Systems: Secti On-ArajeshÎncă nu există evaluări

- Syllabus Automobile EngineeringDocument54 paginiSyllabus Automobile EngineeringmechanzsÎncă nu există evaluări

- List of Open Electives Offered by Automobile Engg BoardDocument15 paginiList of Open Electives Offered by Automobile Engg BoardpurnaÎncă nu există evaluări

- ELEMENTS OF MECHANICAL ENGINEERING AND HYDRAULICSDocument5 paginiELEMENTS OF MECHANICAL ENGINEERING AND HYDRAULICSnavitgmÎncă nu există evaluări

- B.E Mechnical2009Document64 paginiB.E Mechnical2009akshaybj4396Încă nu există evaluări

- Lesson Plan AutomobileDocument7 paginiLesson Plan AutomobileKalaiselvan Punniyamoorthy50% (2)

- Eme-701: Computer Aided Design (Cad) LTP 3 1 0 Unit-IDocument5 paginiEme-701: Computer Aided Design (Cad) LTP 3 1 0 Unit-IKaiser AnjumÎncă nu există evaluări

- Unit 2: Vehicle Engine Principles, Operation, Service and RepairDocument12 paginiUnit 2: Vehicle Engine Principles, Operation, Service and RepairsaiemÎncă nu există evaluări

- AutoDocument30 paginiAutoVarunÎncă nu există evaluări

- Rto 2 Syllabus PDFDocument11 paginiRto 2 Syllabus PDFParthÎncă nu există evaluări

- B.Tech. Mechanical Engineering Course ScheduleDocument12 paginiB.Tech. Mechanical Engineering Course ScheduleShrikant KhatingÎncă nu există evaluări

- Piston Engine (Autopesaved)Document4 paginiPiston Engine (Autopesaved)Mohan ChetriÎncă nu există evaluări

- M.E. AutomobileDocument33 paginiM.E. AutomobileJeyaram KumarÎncă nu există evaluări

- AutomobileDocument33 paginiAutomobilemarinerajesh3022Încă nu există evaluări

- RGPV Syllabus 5th SemDocument4 paginiRGPV Syllabus 5th SemavantikasankhyainÎncă nu există evaluări

- AU201 SI Engines and CombustionDocument3 paginiAU201 SI Engines and CombustionvaisakmctÎncă nu există evaluări

- IC Engines & Jet Propulsion Course OutlineDocument2 paginiIC Engines & Jet Propulsion Course OutlineSubash AppuÎncă nu există evaluări

- 7th Semester UET TaxilaDocument4 pagini7th Semester UET TaxilaRameez AnwarÎncă nu există evaluări

- Learning Vehicle MaterialsDocument74 paginiLearning Vehicle MaterialsYUCABETHÎncă nu există evaluări

- MSBTE - Final Copy DTDocument6 paginiMSBTE - Final Copy DTnavneetkpatil8409Încă nu există evaluări

- Sem 6Document11 paginiSem 6Er Inderjeet DhillonÎncă nu există evaluări

- Engineering Services Examination 2020 Important DatesDocument3 paginiEngineering Services Examination 2020 Important DatessanthoshÎncă nu există evaluări

- Internal Combustion EnginesDocument2 paginiInternal Combustion EnginesDhaval PanchalÎncă nu există evaluări

- Mech 6th Sem SyllabusDocument14 paginiMech 6th Sem SyllabusArun ManoÎncă nu există evaluări

- Pass Marks: - 40: Detail Syllabus For Automobile EngineerDocument7 paginiPass Marks: - 40: Detail Syllabus For Automobile EngineerSaurav AdhikariÎncă nu există evaluări

- Automobile Engineering FundamentalsDocument74 paginiAutomobile Engineering FundamentalsAbhimanyuravi CrÎncă nu există evaluări

- Internal Combustion EnginesDocument3 paginiInternal Combustion EnginescharulapÎncă nu există evaluări

- Btech Viii Sem Syallbus 21-22030622124052Document16 paginiBtech Viii Sem Syallbus 21-22030622124052Manish NayakÎncă nu există evaluări

- Automobile Engineering I: 1. Introductory TopicsDocument2 paginiAutomobile Engineering I: 1. Introductory TopicsjigarÎncă nu există evaluări

- Vehicle NotesDocument74 paginiVehicle NotesYUCABETHÎncă nu există evaluări

- BASICS OF MECHANICAL ENGINEERING SYLLABUSDocument2 paginiBASICS OF MECHANICAL ENGINEERING SYLLABUSJerin CyriacÎncă nu există evaluări

- S8Document7 paginiS8Gopu KrishnaÎncă nu există evaluări

- ME413 - Key concepts in engineering management and entrepreneurshipDocument22 paginiME413 - Key concepts in engineering management and entrepreneurshipMurali Krishna GbÎncă nu există evaluări

- AU212 Automobile Power PlantDocument3 paginiAU212 Automobile Power PlantvaisakmctÎncă nu există evaluări

- Vocational Teacher (Maintenance and Repairs of Automobiles)Document7 paginiVocational Teacher (Maintenance and Repairs of Automobiles)Brandon AllenÎncă nu există evaluări

- Automobile EngineeringDocument4 paginiAutomobile EngineeringRita KalaniÎncă nu există evaluări

- Automobile TechnologyDocument7 paginiAutomobile Technologypurusottam2765Încă nu există evaluări

- 6 THDocument19 pagini6 THyoyotoyoÎncă nu există evaluări

- Automobile Engineering Course OverviewDocument74 paginiAutomobile Engineering Course Overviewarulmurugu100% (1)

- MPSC Non Gazetted Services Syllabus of Group C Mains Exam 2023 UpdatedDocument4 paginiMPSC Non Gazetted Services Syllabus of Group C Mains Exam 2023 UpdatedPRATIK MALAVEÎncă nu există evaluări

- Systems and Methodology Used in Automobiles: Automobile EngineeringDocument2 paginiSystems and Methodology Used in Automobiles: Automobile EngineeringM.ThirunavukkarasuÎncă nu există evaluări

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionDe la EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionEvaluare: 5 din 5 stele5/5 (3)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryDe la EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryÎncă nu există evaluări

- Major Process Equipment Maintenance and RepairDe la EverandMajor Process Equipment Maintenance and RepairEvaluare: 4 din 5 stele4/5 (4)

- Manual CastingDocument64 paginiManual CastingDjRacksÎncă nu există evaluări

- 72 Names of God in HasidimDocument16 pagini72 Names of God in HasidimFrancesco VinciguerraÎncă nu există evaluări

- Exercise - 8.1 NewDocument24 paginiExercise - 8.1 NewAkriti Sharma 757Încă nu există evaluări

- Section 09 - Traction Electrification SystemDocument47 paginiSection 09 - Traction Electrification SystemAbu Monsur Ali100% (1)

- June 2023 BillingDocument10 paginiJune 2023 BillingEsther AkpanÎncă nu există evaluări

- CSS9 TQ PT 3rd4thDocument8 paginiCSS9 TQ PT 3rd4thJevan Hope BaltazarÎncă nu există evaluări

- Picard's Existence and Uniqueness TheoremDocument2 paginiPicard's Existence and Uniqueness Theoremmanjoy dasÎncă nu există evaluări

- Contact Details For Medical Schools by PostcodeDocument13 paginiContact Details For Medical Schools by PostcodeHeena R ModiÎncă nu există evaluări

- Price List Grand I10 Nios DT 01.05.2022Document1 paginăPrice List Grand I10 Nios DT 01.05.2022VijayÎncă nu există evaluări

- Heidegger On Destruction - Chung ChinDocument16 paginiHeidegger On Destruction - Chung ChinAprilo DielovaÎncă nu există evaluări

- Bep Rev.c-New 20 MLD WTP, NathavaliDocument380 paginiBep Rev.c-New 20 MLD WTP, NathavaliAnonymous 7l8AIyq2Încă nu există evaluări

- Plant Seedling Classification Using CNNDocument12 paginiPlant Seedling Classification Using CNNYugal Joshi0% (1)

- BT Word FormsDocument11 paginiBT Word FormsNguyên TrungÎncă nu există evaluări

- 2008 Company Performance 2008 Company Performance & 2009 Business Outlook & 2009 Business OutlookDocument30 pagini2008 Company Performance 2008 Company Performance & 2009 Business Outlook & 2009 Business OutlookKakasÎncă nu există evaluări

- Table of PenaltiesDocument2 paginiTable of PenaltiesEzekiel FernandezÎncă nu există evaluări

- 28 2001 04 0007Document1 pagină28 2001 04 0007Fernando FanteÎncă nu există evaluări

- RUDDER PLATING DIAGRAMDocument1 paginăRUDDER PLATING DIAGRAMMuhammad Ilham AlfiansyahÎncă nu există evaluări

- Design of Goods & Services: Tanweer Ascem KharralDocument10 paginiDesign of Goods & Services: Tanweer Ascem KharralHadeed GulÎncă nu există evaluări

- Potensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliDocument8 paginiPotensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliNuyul FaizahÎncă nu există evaluări

- Elcometer Wet-Film Gage 115 Spec SheetDocument2 paginiElcometer Wet-Film Gage 115 Spec SheetMary CasillasÎncă nu există evaluări

- 06 Scaffold Erection and Dismantling (JHA-JSA)Document4 pagini06 Scaffold Erection and Dismantling (JHA-JSA)AmanÎncă nu există evaluări

- Actividad 3.1B-Xport-Model-Exercises-SCMDocument5 paginiActividad 3.1B-Xport-Model-Exercises-SCMDante Rivera SalinasÎncă nu există evaluări

- English Idea BookDocument2 paginiEnglish Idea Bookapi-551731988Încă nu există evaluări

- Khalid DL 01 ProfileDocument2 paginiKhalid DL 01 ProfileRipunjay MishraÎncă nu există evaluări

- Interaction of Radiation With Matter: Dhruba GuptaDocument36 paginiInteraction of Radiation With Matter: Dhruba GuptaHala SweetÎncă nu există evaluări

- Greek MathemaDocument6 paginiGreek MathemaSebastian GhermanÎncă nu există evaluări

- Chapter 6 Exercises (Bonds & Interest)Document2 paginiChapter 6 Exercises (Bonds & Interest)Shaheera SuhaimiÎncă nu există evaluări

- FMDocument12 paginiFMGajera HarshadÎncă nu există evaluări

- RepairManual NEF M100 M150 P3D32N003E Mar06Document172 paginiRepairManual NEF M100 M150 P3D32N003E Mar06manuel segovia100% (1)

- Design Basis Events FOR Pressurised Heavy Water Reactor: Aerb Safety Guide No - Aerb/Sg/D-5Document36 paginiDesign Basis Events FOR Pressurised Heavy Water Reactor: Aerb Safety Guide No - Aerb/Sg/D-5Anuj DeoÎncă nu există evaluări