Documente Academic

Documente Profesional

Documente Cultură

V-Bearing E

Încărcat de

Rakesh Nair ADescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

V-Bearing E

Încărcat de

Rakesh Nair ADrepturi de autor:

Formate disponibile

Vertical Bearings Series V For Slow and Medium Speed Machines

Type VT

Type VG

RENK vertical bearings, series V, are mainly used with slow to medium speed vertical machines (e. g. pumps, fans, turbines or electrical machines).

Many years of experience in the manufacture of vertical bearings, plus the latest methods of computing bearing performance, together with systematic design improvements, have culminated in the highly successful range of V-bearings.

V-bearings are supplied for thrust loads ranging to 965 kN. The corresponding shaft diameters are from 70 to 425 mm.

For high speed machines we have developed the series EV. Please consult our brochure RH-1021 for further information.

Technical Information

VT-bearings are designed as combined thrust and guide bearings with axial and journal parts; whereas the VG bearings are supplied as guide bearings with journal part only. The bearing housing is designed in accordance with FEM to absorb high axial loads, including shock loads. The journal and axial inserts can be used in combination with housings of different sizes. In the case of slow speed machines the heat dissipation will be natural cooling. In such cases, a relatively small bearing housing will be necessary, since the oil quantity is low and there is no need for space for a water cooler. The same applies to medium speed bearings connected to an external oil system. Due to the higher oil quantity, the medium speed bearings need a larger housing. RENK can offer you the most suitable bearing housing to satisfy each specific application. The bearing housing, made of 3 separate parts (bottom, jacket, cover), is easy to service. Removal or installation of the journal or axial parts is also easy. Axial Part The circular, tilting RD-thrust pads are a major characteristic of the VT bearings. The pads are supported on cup springs which ensure uniform load distribution. The bearings as standard are provided with 12 RD-thrust pads which support downward loads. If required, the bearing shell can be provided with a variable number of RS-thrust pads to take upward axial loads. Journal Part The journal part functions as a guide bearing. The plain cylindrical bore is provided with several lubricating grooves. If

required, the bearing can be provided with a four lobe shell instead of the plain cylindrical bore. This type of shell has a stabilising effect when the shaft is not loaded or only slightly loaded. Heat Dissipation and Lubrication Depending on the application and operating conditions the VT- and VG-bearings are used with - natural cooling - natural cooling with fan, - cooling by external oil circulation, - water cooling or - water cooling plus fan cooling. In the case of a water-cooled bearing the cooler is mounted into the bearing housing. Depending on the water quality, the cooler is made of Cu or CuNi10Fe or titanium (finned tube cooler). The use of a fan makes the application of a natural cooled bearing with higher speeds possible. If a circulating oil system is used, the housing is provided with an overflow weir. The weir maintains a bath of oil within the bearing housing to ensure safe short-term lubrication in the event of an external oil supply failure. Temperature Monitoring For temperature monitoring of the thrust pads or of the guide bearing RENK supplies the especially developed resistance thermometer sensors (PT 100). Oil Flow Control for Circulating Oil Systems We recommend the use of the flow meter type NJV-MI, especially developed for application with slide bearings. These flow meters can be checked visually or, if fitted with a switching device, can be monitored electrically.

Q Series R Type

V vertical bearing T thrust and guide G guide only B thrust and guide with upward thrust face X special design N natural cooling Z lubrication by oil circulation with external oil cooling W water cooling (finned tubes in oil sump) F fan cooling X special cooling systems

S Heat dissipation

and lubrication

T Shape of bore U Bearing cover V Bearing size W Housing size

Example for bearing coding

C plain cylindrical bore V four-lobe bore U non-split G split

QRSTU V W V T N C U 11 - 5 Q R S T U V W

vertical bearing type V thrust and guide bearing heat dissipation by natural cooling cylindrical bore bearing cover non-split bearing size 11 housing size 5

Dimensions of the Bearing Type VTNCU

key size and fit according to DIN 6885 or to suit the customers requirements

oil level

cast lifting hooks for transportation

Bearing size 7 9 11 14 16 18 20 22 25 28 31 40

RD [12 x] 31,5 40 50 63 71 80 90 100 112 125 140 160

FRmin [kN] 0,3 0,4 0,6 1.0 1,3 1,6 2,0 3,0 3,5 4,5 5,5 7,0

FRmax [kN] 6 7,5 12 20 25 31 39 53 68 85 106 138

FAS [kN] 23 37 58 93 118 150 190 235 295 368 461 603

FAB [kN] 28 60 94 149 190 241 305 377 472 589 738 965

drawing shows type VTNCU 18-16

tapped holes for thermometer connection

Final selection of bearing according to the EDP-calculations start load with closed valve upon request Frmin = minimum radial load

(shell with plain cylindrical bore)

FRmax = maximum radial load FAB = axial operational load

FAS Dimensions in mm Size VTN 7-5 9-5 11-5 11-10 14-10 14-16 16-16 16-28 18-16 18-28 18-40 20-28 20-40 22-28 22-40 22-55 25-40 25-55 28-55 28-78 31-55 31-78 40-100 d1 max 70 90 110 110 140 140 160 160 180 180 180 200 200 220 220 220 250 250 280 280 320 320 400 d2 125 140 180 180 225 225 250 250 280 280 280 315 315 375 375 375 425 425 475 475 530 530 600 d3 370 370 370 460 460 580 580 690 580 690 810 690 810 690 810 910 810 910 910 1020 910 1020 1140 d4 440 440 440 540 540 670 670 790 670 790 920 790 920 790 920 1030 920 1030 1030 1150 1030 1150 1280 d5 410 410 410 510 510 640 640 760 640 760 880 760 880 760 880 980 880 980 980 1100 980 1100 1220 d6 250 250 250 250 280 280 320 320 340 340 340 380 380 420 420 420 460 460 500 500 580 580 660 d7 max 75 93 115 115 150 150 170 170 190 190 190 220 220 235 235 235 260 260 310 310 345 345 410 d8 9 9 9 9 9 9 9 11 9 11 11 11 11 11 11 13,5 11 13,5 13,5 13,5 13,5 13,5 17,5 d9 G G G G G G G G G G G G G G G G G G G G G G G 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 1 3/4 1 3/4 1 1 1 1 1 1 1 1 h1 197 200 220 220 265 265 300 300 320 320 320 355 355 400 400 400 435 435 480 480 555 555 625 h2

= axial start up load

h3 70 75 80 80 100 100 115 115 125 125 125 140 140 160 160 160 170 170 200 200 225 225 250

h4 30 30 30 30 30 30 30 30 30 30 34 35 40 37 40 40 40 41 41 41 43 43 46

h5 22 22 22 25 25 25 25 25 25 25 28 30 35 32 35 37 35 38 38 38 40 40 42

h6 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10

z 12 12 12 12 12 18 18 18 18 18 20 18 20 18 20 20 20 20 20 24 20 24 24

w1 [] 15 15 15 15 15 10 10 10 10 10 9 10 9 10 9 9 9 9 9 7,5 9 7,5 7,5

w2 [] 45 45 45 45 45 30 30 30 30 30 27 30 27 30 27 27 27 27 27 22,5 27 22,5 22,5

Weight [kg]1) 85 90 105 145 185 250 270 335 345 410 510 415 510 520 630 770 765 880 1030 1160 1243 1410 1870

Oil quantity [l] 6 5 4 8,5 8 17 18 29 22 29 45 24 42 22 41 57 40 60 53 78 41 77 100

150 150 155 177 180 210 210 242 210 242 270 250 280 255 285 325 285 325 325 345 333 350 390

1) without lubricant filling

Dimensions of the Bearing Type VTWCU

tapped holes for cooling water connections

oil level

space for a water cooler

tapped holes for thermometer connection drawing shows type VTWCU 18-28

Dimensions in mm (for further dimensions please see page 3) Size VTW 7-5 9-5 11-5 11-10 14-10 14-16 16-16 16-28 18-16 18-28 18-40 d10 12 15 15 15 15 15 15 15 15 15 15 h7 40 40 40 50 50 60 60 70 60 70 70 h8 90 90 90 110 110 130 130 160 130 160 180 l1 2 3 3 10 10 10 10 8 10 8 8 w3 [] 15 15 15 15 15 10 10 10 10 10 9 Weight [kg]1) 87 95 110 150 190 260 280 345 350 420 525 Oil quantity [l] 6 5 4 8 7 15 16 26 21 26 39 Size VTW 20-28 20-40 22-28 22-40 22-55 25-40 25-55 28-55 28-78 31-55 31-78 40-100 d10 12 15 15 15 15 15 15 15 22 15 22 22 h7 75 77 77 77 90 77 91 91 90 93 92 110 h8 165 167 167 177 200 177 201 201 206 203 208 250 l1 8 8 8 8 0 8 0 0 -3 0 -3 -5 w3 [] 10 9 10 9 9 9 9 9 7,5 9 7,5 7,5 Weight [kg]1) 425 520 530 645 790 790 900 1050 1190 1220 1430 1900 Oil quantity [l] 21 37 19 36 50 37 55 45 65 35 68 90

1) without lubricant filling

Dimensions of the Bearing Type VTZCU

oil outlet (choice between flange connection or thread connection)

oil inlet pipe

oil level

drawing shows type VTZCU 18-28

tapped holes for thermometer connection

Dimensions in mm (for further dimensions please see page 3) Size VTZ 7-5 9-5 11-5 11-10 14-10 14-16 16-16 16-28 18-16 18-28 18-40 d112) G G G G G G G G G G G 1 1 11/2 11/2 2 2 2 1/2 2 1/2 2 1/2 2 1/2 2 1/2 d12 10 12 18 18 22 22 22 22 28 28 28 h9 95 95 95 105 105 125 130 145 128 150 140 h10 103 103 103 120 117 140 140 160 143 165 160 l2 50 50 50 50 50 50 50 50 60 60 60 w4 [] 15 15 15 15 15 10 10 10 10 10 9 w5 [] 15 15 15 15 15 10 10 10 10 10 9 Weight [kg]1) 85 90 105 145 185 250 270 335 345 410 510 Oil quantity [l] 6 5 4 8,5 8 17 18 29 22 29 45 Size VTZ 20-28 20-40 22-28 22-40 22-55 25-40 25-55 28-55 28-78 31-55 31-78 40-100 d112) G G G G G G G G G G G G 3 3 4 4 4 3 3 4 4 4 4 4 d12 35 35 38 38 38 38 38 38 38 38 38 38 h9 150 165 150 160 180 180 185 190 190 205 205 235 h10 170 185 170 180 200 200 205 210 210 225 225 255 l2 70 70 70 70 70 70 70 70 70 70 70 70 w4 [] 10 9 10 9 9 9 9 9 7,5 9 7,5 7,5 w5 [] 10 9 10 9 9 9 9 9 7,5 9 7,5 7,5 Weight [kg]1) 415 510 520 630 770 765 880 1030 1160 1243 1420 1870 Oil quantity [l] 24 42 22 41 57 40 60 53 78 41 77 100

1) without lubricant filling

2) flange connection upon request

Dimensions of the Bearing Type VGNCU

oil level

tapped holes for thermometer connection

Bearing size 7 9 11 14 16 18 20 22 25 28 31 40

FRmin [kN] 0,3 0,4 0,6 1,0 1.3 1,6 2,0 3,0 3,5 4,5 5,5 7,0

FRmax [kN] 6 7,5 12 20 25 31 39 53 68 85 106 138

Final selection according to the EDP-calculation FRmin = minimum radial load

(shell with plain cylindrical bore)

FRmax = maximum radial load

drawing shows type VGNCU 18-16

Dimensions in mm

Size VGN 7-5 9-5 11-5 14-10 16-16 18-16 20-28 22-28 25-40 28-55 31-55 40-78

d1 max 80 90 125 160 180 200 225 250 315 335 375 425

d2 125 140 180 225 250 280 315 375 425 475 530 600

d3 410 410 410 510 640 640 760 760 880 980 980 1100

d4 450 450 450 550 680 680 800 800 930 1050 1050 1160

d5 370 370 370 460 580 580 690 690 810 910 910 1020

d6 9 9 9 9 9 9 11 11 11 13,5 13,5 13,5

d7 G G G G G G G G G G G G 3/4 3/4 3/4 3/4 3/4 3/4 1 1 1 1 1 1

h1 65 70 80 100 115 125 140 160 170 200 225 250

h2 45 50 50 60 60 75 80 120 120 135 205 235

h3 148 148 148 178 210 210 250 250 280 320 320 340

h4 12 12 12 14 16 16 20 20 23 23 23 25

e1 140 140 140 200 240 240 290 290 320 370 370 420

z 12 12 12 12 18 18 18 18 20 20 20 24

w1 [] 75 75 75 75 50 50 52,5 52,5 47,5 47,5 47,5 54,5

Weight [kg]1) 62 65 75 130 200 230 305 345 515 725 895 1185

Oil quantity [l] 7 8 4 7 16 14 29 33 43 66 69 97

1) without lubricant filling

Dimensions of the Bearing Type VGWCU

oil level

space for a water cooler

tapped holes for thermometer connection

drawing shows type VGWCU 18-16

Dimensions in mm (for further dimensions see page 6) Size VGW 7-5 9-5 11-5 14-10 16-16 18-16 d8 15 15 15 15 15 15 h5 50 50 50 60 90 90 e2 50 50 50 65 60 60 e3 472 472 472 560 588 588 w2 [] 15 15 15 15 10 10 Weight [kg]1) 63 66 76 135 205 235 Oil quantity [l] 6 8 4 7 15 13 Size VGW 20-28 22-28 25-40 28-55 31-55 40-78 d8 15 15 15 15 15 15 h5 100 100 120 130 120 140 e2 80 80 90 100 100 120 e3 692 692 812 514 514 569 w2 [] 10 10 9 9 9 7,5 Weight [kg]1) 310 350 520 730 900 1190 Oil quantity [l] 28 32 42 65 69 96

1) without lubricant filling

Dimensions of the Bearing Type VGZCU

oil level

oil outlet (choice between flange or thread connection)

drawing shows type VGZCU 18-16

Dimensions in mm (for further dimensions please see page 6) Size VGZ 7-5 9-5 11-5 14-10 16-16 18-16 d92) G G G G G G 1 1 1 1 1 2 d10 10 12 12 15 18 18 h8 58 55 70 90 100 100 h9 48 45 60 75 85 85 l1 35 35 38 45 55 55 w3 [] 15 15 15 15 10 10 w4 [] 15 15 15 15 10 10 Weight [kg]1) 62 65 75 130 200 230 Oil quantity [l] 7 8 4 7 16 14 Size VGZ 20-28 22-28 25-40 28-55 31-55 40-78 d92) G G G G G G 2 2 2 2 2 3 d10 18 22 22 22 22 25 h8 120 100 130 140 120 120 h9 105 80 115 125 105 105 l1 55 55 55 50 50 60 w3 w4 Weight [] [] [kg]1) 10 10 305 10 10 345 9 9 515 9 9 725 9 9 895 7,5 7,5 1185 Oil quantity [l] 29 33 43 66 69 97

1/4 1/2 1/2 1/2

1/2 1/2 1/2 1/2

1) without lubricant filling

2) flange connection upon request

Further Types Special Design Bearings

Type VB This bearing type can absorb thrust loads in both directions. The bearing shell can be made to accomodate a variable number of RS-thrust pads to carry the upward thrust load. Upon receipt of the proposed operational duty, we will determine the correct number of RS-thrust pads and the housing size. VBWCU Type V.F Both the natural cooled bearing (N) and the water cooled bearing (W) can be additionally equipped with fan cooling. The fan cooling increases the rate of heat dissipation over the bearing housing.

Bearing size 7 9 11 14 16 18 20 22 25 28 31 40

FAX [kN] 24,5 24,5 45,3 100,5 141,4 157,1 188,5 219,9 299,3 380,1 482,5

VTFCU Type X (special) with hydrostatic jacking To accomodate high axial loads (greater than the catalogue Fas values) from a standing start, the RD-thrust pads can be designed to inject high pressure oil from a hydrostatic jacking system.

VXWCU

Type X (special) with enlarged axial part (FAB ) The admissible axial load can be increased by using bigger RD-thrust pads. In such cases there will be a reduction of the maximum diameter of shaft permitted in way of the stand pipe.

VXWCU

Sealing Systems for V-Bearings

The shaft seals are meant to: - prevent oil getting out of the bearing, - prevent penetration of water or foreign particles such as sand dust, into the bearing.

Based on the modular unit system and depending on the application cases the bearings are equipped with the corresponding sealing systems.

The shaft seals must meet certain requirements, such as for instance, to prevent the penetration of water or foreign particles.

Upon delivery of the operational requirements RENK can determine the necessary sealing system. The customers specifications on protection grade according to DIN 40050 or IEC-529 are extemely useful in selecting the correct sealing arrangement.

Stand pipe with / without pipe seal The stand pipe is attached to the bottom side of bearing and keeps the oil inside the tank. With speeds over 13,5 m/s the journal bearing is provided with a stand pipe seal. The stand pipe seal controls the formation of foam within the oil bath of the bearing. The stand pipe meets with the following protection requirements: Stand pipe with / without seal IP 23.

Single gap seal The single gap seal is mounted on the top and bottom side of the bearing. Fixed to the top of the bearing the gap seal functions as a standard seal. The single gap seal can be fixed to the bottom side of the bearing in addition to the stand pipe (with / without stand pipe seal). The single gap seal corresponds to the following protection grades: single gap seal on the top IP 42 single gap seal on the bottom in addition to the stand pipe with /without stand pipe seal IP 43.

Double seal (DUO-seal) with connections for air seal / pressure compensation The use of the DUO-seal increases the protection grade. Before determining the seal type it is necessary to clarify which side (bottom or top) of the bearing must be protected. The DUO-seal corresponds to the following protection grades: Duo seal on the top IP 44 DUO seal on the bottom additionally to the stand pipe with / without stand pipe seal IP 44.

Labyrinth seal with single gap seal and grease packing This type of seal is mainly used to protect the top of the bearing. Due to the additional grease packing this seal can be used in almost all application field. The labyrinth seal with single gap seal and grease packing corresponds to the protection grade IP 56.

10

Product Range

Journal and thrust slide bearings and inserts

Type E Type I Type M Type SN Type SC Type HG Type WG Type DN Type VT and VG Type EV Type G Type SH ROTRIX for electrical machines, fans, compressors, turbines for tube mills and crushers for general mechanical engineering applications aftermost and intermediate bearings for marine applications journal bearings for use with Diesel generators and rolling mills fr Hydrogeneratoren und Elektromotoren in geschweiter Ausfhrung fr Walzwerkantriebe thrust bearings for marine applications complete vertical thrust and guide bearings vertical bearing inserts for electrical machines, pumps and fans plain bearing shells for gears, pumps etc. trunnion bearings for tube mills trunnion bearings Catalogue-No. RH-1009 Catalogue-No. RH-1120 Catalogue-No. RH-1065 Catalogue-No. RH-1202 Catalogue-No. RH-1149 Catalogue-No. RH-1188 Catalogue-No. RH-1155 Catalogue-No. RH-1073 Catalogue-No. RH-1153 Catalogue-No. RH-1021 Catalogue-No. RH-1102 Catalogue-No. RH-1147 Catalogue-No. RH-1089 Catalogue-No. RH-1025 Catalogue-No. RH-1198

RD-thrust bearings standard thrust internals (cup spring supported RS-thrust pads Special bearings standard range thrust pads (ball pivoted) RENK can design and manufacture special bearings for a wide range of industrial applications (e.g. type WG bearings with fabricated housing for rolling mill drives). RENK also manufacture bearings, shells etc. to customers designs and drawings

Couplings

ELCO ELBI AERO flexible compression sleeve coupling flexible coupling for general mechanical engineering pneumatically shifting friction coupling centrifugal clutch overrunning clutch diaphragm clutch special couplings and clutches EDP-computer calculations for slide bearings and ELCO-couplings. Catalogue-No. RH-1008 Catalogue-No. RH- 076 Catalogue-No. RH-1118 Catalogue-No. RH-1014 Catalogue-No. RH-1013 Catalogue-No. RH-1063

11

Sales Organisation

Domestic

Hannover Heidelberg Mnchengladbach

Export

Australia Austria Belgium Brazil Canada Czech Republic Croatia Finland France G.B. and Ireland Hungary India Italy Japan Liechtenstein Luxembourg Mexico Netherlands Norway PR China Slovak Republic Slovenia Republic South Africa South Korea Spain USA

Headquarters and Manufacturing Plant

Assembly and Distribution Centers with Sales and Engineering Support

RH-1153 (11.99) Printed in Germany

RENK AKTIENGESELLSCHAFT Werk Hannover Weltausstellungsallee 21 D-30539 Hannover Telephone: (5 11) 86 01-0 Telefax: (5 11) 86 01-288 e-mail: renk_hannover@renk.de

RENK Corporation 304, Tucapau Road 29334 Duncan S.C. USA Telephone: (1-8 64) 4 33 00 69 Telefax: (1-8 64) 4 33 06 36

MAN B&W (Japan) Ltd. Hibiya Park Building (R. 410) 1-8-1, Yurakucho Chiyoda-ku, Tokyo 100-0006 Japan Telephone: (81-3) 32 15-1310 Telefax: (81-3) 32 84-0867

We reserve the right to changes made in the interests of technical improvement.

S-ar putea să vă placă și

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Aerator PremiumDocument10 paginiAerator PremiumvijaykumarnÎncă nu există evaluări

- 220 2007 EnglischDocument134 pagini220 2007 EnglischropmachadoÎncă nu există evaluări

- ABB MotorsDocument22 paginiABB MotorsKhaled HassanÎncă nu există evaluări

- Slide Bearing For Electricar Machines BrochureDocument6 paginiSlide Bearing For Electricar Machines BrochureGabriel BolívarÎncă nu există evaluări

- Vulcan GoodDocument48 paginiVulcan Goodtanha56313955Încă nu există evaluări

- Introduction About Lafarge:: Lafarge (Jordan Cement Factory)Document6 paginiIntroduction About Lafarge:: Lafarge (Jordan Cement Factory)Hamzeh GhnimatÎncă nu există evaluări

- Eclipse Gearbox Wind TurbineDocument9 paginiEclipse Gearbox Wind TurbinePankaj KatreÎncă nu există evaluări

- HAISUNG Good3 - Cycloid Drive - CatalogDocument92 paginiHAISUNG Good3 - Cycloid Drive - Catalog032indesignÎncă nu există evaluări

- Noble Corporation: Noble Analyst Day Singapore May 17-18, 2011Document27 paginiNoble Corporation: Noble Analyst Day Singapore May 17-18, 2011Andi ayuÎncă nu există evaluări

- RH - Em9seDocument6 paginiRH - Em9seJefa DanarÎncă nu există evaluări

- Drive PerformanceDocument47 paginiDrive PerformanceEduardo VicelisÎncă nu există evaluări

- Tooth Design: Forces Acting On Spur GearsDocument77 paginiTooth Design: Forces Acting On Spur GearsJitendra KumarÎncă nu există evaluări

- P I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsDocument2 paginiP I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsRonaldÎncă nu există evaluări

- Shaft DesignDocument17 paginiShaft DesignAldrin BernardoÎncă nu există evaluări

- Area Report Raw Mill: Submitted By: Zohaib Ahmed Memon (96658) SMT (Production)Document7 paginiArea Report Raw Mill: Submitted By: Zohaib Ahmed Memon (96658) SMT (Production)Zohaib AhmedÎncă nu există evaluări

- Shaft and House Design PDFDocument3 paginiShaft and House Design PDFm2110100% (1)

- AMITDocument25 paginiAMITThe Fun ExplosionÎncă nu există evaluări

- Marine and Naval Line Shaft BearingsDocument7 paginiMarine and Naval Line Shaft BearingsGuussttÎncă nu există evaluări

- Load Testing of GearboxesDocument4 paginiLoad Testing of Gearboxesvijaykumarn100% (1)

- Basic of GearsDocument35 paginiBasic of Gearskcshieh100% (1)

- AYCCL-Bearing PresentationDocument74 paginiAYCCL-Bearing PresentationKashif Muhammad100% (1)

- Gear Hunting Tooth Recommendations-Frank Kushner - 0419Document2 paginiGear Hunting Tooth Recommendations-Frank Kushner - 0419Rachel AustriaÎncă nu există evaluări

- Renk Bearings RangeDocument2 paginiRenk Bearings Rangehumayun121Încă nu există evaluări

- 1029C1 PDFDocument29 pagini1029C1 PDFAnonymous dPyHoLÎncă nu există evaluări

- On Pelton Efficiency and CavitationDocument10 paginiOn Pelton Efficiency and CavitationJohn RobinsonÎncă nu există evaluări

- Alwasy Step Ahead in TechnologyDocument6 paginiAlwasy Step Ahead in TechnologyDxFx100% (1)

- Earl Logan Jr. Handbook of Turbomachinery 2003-3Document3 paginiEarl Logan Jr. Handbook of Turbomachinery 2003-3irctcsbt6bimblikipil0% (1)

- PBL Series K CatalougeDocument117 paginiPBL Series K CatalougeankitkanujiyaÎncă nu există evaluări

- 4.1 DC Motor SpecificationDocument6 pagini4.1 DC Motor SpecificationAsgher KhattakÎncă nu există evaluări

- Turbines For BFP Drive PDFDocument10 paginiTurbines For BFP Drive PDFShameer Majeed100% (1)

- 300 - CHP - EPA (Final) W-AppsDocument244 pagini300 - CHP - EPA (Final) W-AppsmgkalfasÎncă nu există evaluări

- SL01 397Document2 paginiSL01 397thiseus25Încă nu există evaluări

- Model For Prediction of Churning LossesDocument6 paginiModel For Prediction of Churning LossesSaipriya BalakumarÎncă nu există evaluări

- Rolling Contact Bearings - DMEDocument28 paginiRolling Contact Bearings - DMESumitÎncă nu există evaluări

- Applications of Rotary KilnDocument5 paginiApplications of Rotary KilnVerona OsorioÎncă nu există evaluări

- Agricultural-Tractors New Holland T5000 - Models, Technical Data and CharacteristicsDocument2 paginiAgricultural-Tractors New Holland T5000 - Models, Technical Data and Characteristicsyan_dunrossÎncă nu există evaluări

- Bed PlateDocument5 paginiBed PlateJigar PatelÎncă nu există evaluări

- Design of Main GirderDocument58 paginiDesign of Main GirderovikbasuÎncă nu există evaluări

- Shaft DesignDocument33 paginiShaft DesignMunawwar Abbas0% (1)

- C DodgeDocument42 paginiC DodgeDaniel BolivarÎncă nu există evaluări

- CH 11Document17 paginiCH 11Faysal Qadeer KhanÎncă nu există evaluări

- DominatorDocument4 paginiDominatorPeter AllisonÎncă nu există evaluări

- 2010-05-31 Schunk Carbon-Brush Shaft GroundingDocument7 pagini2010-05-31 Schunk Carbon-Brush Shaft GroundingcorsairsanÎncă nu există evaluări

- Note On Gear BoxDocument32 paginiNote On Gear BoxanupbagÎncă nu există evaluări

- Is-919-Part2-1993-Fits and Tolerences For Holes and ShaftsDocument49 paginiIs-919-Part2-1993-Fits and Tolerences For Holes and ShaftsvijaykumarnÎncă nu există evaluări

- Fluid Coupling NotesDocument13 paginiFluid Coupling NotesDSKÎncă nu există evaluări

- Catalog New Motor 1LG0Document40 paginiCatalog New Motor 1LG0bajricaÎncă nu există evaluări

- Backstop For ConveyorDocument28 paginiBackstop For ConveyorabdulscribdÎncă nu există evaluări

- Technical Parameter of Spiral ClassifierDocument1 paginăTechnical Parameter of Spiral ClassifierTerancen RajuÎncă nu există evaluări

- Elecon High Speed Gearbox PDFDocument14 paginiElecon High Speed Gearbox PDFgaurang3005Încă nu există evaluări

- Alignment Shaft Thermal GrowthDocument6 paginiAlignment Shaft Thermal Growthmmcsw6624Încă nu există evaluări

- Gear Tooth Contact PatternsDocument3 paginiGear Tooth Contact PatternsToua YajÎncă nu există evaluări

- Structural Health MonitoringDe la EverandStructural Health MonitoringDaniel BalageasÎncă nu există evaluări

- Imo Ace PumpsDocument12 paginiImo Ace Pumpsrentz76Încă nu există evaluări

- Marine Propulsion English Status January 2011Document20 paginiMarine Propulsion English Status January 2011Jodiel CoelhoÎncă nu există evaluări

- B3887BHF1Document4 paginiB3887BHF1xianmingÎncă nu există evaluări

- Ship Steering GearDocument8 paginiShip Steering Gear123habib123fikri67% (3)

- ID Fan Dodge BRGDocument4 paginiID Fan Dodge BRGjhanduÎncă nu există evaluări

- Rakesh. A: Professional SynopsisDocument5 paginiRakesh. A: Professional SynopsisRakesh Nair AÎncă nu există evaluări

- Maxwell Stress TensorDocument5 paginiMaxwell Stress TensorRakesh Nair AÎncă nu există evaluări

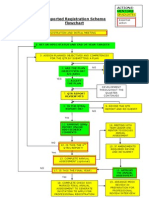

- Supported Registration Scheme Flowchart: 2. Set Uk-Spec Status and End of Year TargetsDocument1 paginăSupported Registration Scheme Flowchart: 2. Set Uk-Spec Status and End of Year TargetsRakesh Nair AÎncă nu există evaluări

- Iimc Epgbm BrochureDocument3 paginiIimc Epgbm BrochureRakesh Nair AÎncă nu există evaluări

- Bearing ClearancesDocument2 paginiBearing ClearancesRakesh Nair AÎncă nu există evaluări

- Deflection of ShaftDocument2 paginiDeflection of ShaftRakesh Nair AÎncă nu există evaluări

- Introduction To Finite Element Analysis: A Brief HistoryDocument3 paginiIntroduction To Finite Element Analysis: A Brief HistoryAndy ChongÎncă nu există evaluări

- Strain Energy in BendingDocument5 paginiStrain Energy in BendingRakesh Nair A100% (1)

- Moment of Inertia of Stepped ShaftsDocument11 paginiMoment of Inertia of Stepped ShaftsRakesh Nair A100% (2)

- Vertical Sleeve BearingsDocument6 paginiVertical Sleeve BearingsRakesh Nair A100% (1)

- Ceramic BearingsDocument16 paginiCeramic BearingsmanaschoudhuryÎncă nu există evaluări

- General Bearing DesignDocument99 paginiGeneral Bearing DesignDr_M_Soliman100% (1)

- Horizontal Sleev BearingsDocument2 paginiHorizontal Sleev BearingsRakesh Nair AÎncă nu există evaluări

- GroundingDocument1 paginăGroundingRakesh Nair AÎncă nu există evaluări

- Shaft and Bearing CalculationDocument24 paginiShaft and Bearing CalculationArul Gnana JohnÎncă nu există evaluări

- Cooling CoilDocument2 paginiCooling CoilRakesh Nair AÎncă nu există evaluări

- BearingsDocument23 paginiBearingsRakesh Nair AÎncă nu există evaluări

- General Bearing DesignDocument99 paginiGeneral Bearing DesignDr_M_Soliman100% (1)

- Sleeve Vs Antifriction Bearings Selection of The Optimal BearingDocument13 paginiSleeve Vs Antifriction Bearings Selection of The Optimal BearingKamal Arab0% (1)

- Bearing Load CalculationDocument9 paginiBearing Load CalculationRakesh Nair AÎncă nu există evaluări

- RamjetDocument13 paginiRamjetbalajgnÎncă nu există evaluări

- Plastic Hinge Lengths of Normal and High-Strength Concrete in FlexureDocument7 paginiPlastic Hinge Lengths of Normal and High-Strength Concrete in FlexureNikola JankovicÎncă nu există evaluări

- PTM - Pilot Training ManualBKPDocument415 paginiPTM - Pilot Training ManualBKPRonaldo Passanha100% (1)

- Manual Compressor CSD 102, EnglishDocument108 paginiManual Compressor CSD 102, EnglishАлександр ЩербаковÎncă nu există evaluări

- F-CD-19 Pipe and Weld Book 26-Abr-19Document84 paginiF-CD-19 Pipe and Weld Book 26-Abr-19Jorge Isaac Lara RamosÎncă nu există evaluări

- 747 400 Boeing: ATA 36 PneumaticDocument138 pagini747 400 Boeing: ATA 36 Pneumaticazadair100% (1)

- 00 Calculator Techniques 02Document5 pagini00 Calculator Techniques 02Sealtiel1020Încă nu există evaluări

- Gravitation Class 9 Notes PDFDocument6 paginiGravitation Class 9 Notes PDFHemlata BendsureÎncă nu există evaluări

- Jump Start Shell TubeDocument14 paginiJump Start Shell TubetrantheanÎncă nu există evaluări

- Specification Sheet 400Document3 paginiSpecification Sheet 400moh_ichwanuddinÎncă nu există evaluări

- 8M-003 Operation Manual For Purifier (SJ80F, SJ40F)Document291 pagini8M-003 Operation Manual For Purifier (SJ80F, SJ40F)Leonid KolesnikovÎncă nu există evaluări

- Dramix Setting The Standard SDocument8 paginiDramix Setting The Standard SwilmanesÎncă nu există evaluări

- Current To Pressure (I/P) Converter Principle: Inst ToolsDocument6 paginiCurrent To Pressure (I/P) Converter Principle: Inst ToolsMinhthien NguyenÎncă nu există evaluări

- VRV HSDocument17 paginiVRV HSAnthony WoenarwanÎncă nu există evaluări

- Chapter 4 PDFDocument56 paginiChapter 4 PDFArpitRanderia0% (1)

- University Thermodynamics Laboratory Report (Ratio of Volume)Document5 paginiUniversity Thermodynamics Laboratory Report (Ratio of Volume)Jackson KcÎncă nu există evaluări

- NASA SP36 ExtractoDocument82 paginiNASA SP36 ExtractoDiego Guerrero VelozÎncă nu există evaluări

- ECIV 728 Chapter 1-2023Document33 paginiECIV 728 Chapter 1-2023Bren GedsÎncă nu există evaluări

- 1998 - The Measurement and Control of Blast Induced Damage of Final Pit Walls in Open Pit Mining - W. Adamson, C.Scherpenisse - ISEE-1998Document18 pagini1998 - The Measurement and Control of Blast Induced Damage of Final Pit Walls in Open Pit Mining - W. Adamson, C.Scherpenisse - ISEE-1998Elías Bravo CortésÎncă nu există evaluări

- Jis C3771Document2 paginiJis C3771bkprodhÎncă nu există evaluări

- Refrigeration and Air ConditioningDocument24 paginiRefrigeration and Air ConditioningUtsav ParsanaÎncă nu există evaluări

- MCM 5.7LXDocument148 paginiMCM 5.7LXGoran JedrejčićÎncă nu există evaluări

- North American Fire - All Dual-Fuel Burners: CombustionDocument3 paginiNorth American Fire - All Dual-Fuel Burners: CombustionJose Antonio Jose Antonio SilveiraÎncă nu există evaluări

- Bda 5 25Document34 paginiBda 5 25oÎncă nu există evaluări

- MSI08 Force in A Statically Indeterminate Cantilever TrussDocument8 paginiMSI08 Force in A Statically Indeterminate Cantilever TrussWong Ngiik Kwang100% (1)

- M-4-2 Diesel Generator Engine Type 5DC-17Document410 paginiM-4-2 Diesel Generator Engine Type 5DC-17Sharadkumar R ChavanÎncă nu există evaluări

- 590 - Turbo Loader Backhoe (01/88 - 12/91) 06 - Power Train 6-12 - Transaxle Assembly, Power Shuttle, Input Shaft and Forward ClutchDocument4 pagini590 - Turbo Loader Backhoe (01/88 - 12/91) 06 - Power Train 6-12 - Transaxle Assembly, Power Shuttle, Input Shaft and Forward ClutchJESUSÎncă nu există evaluări

- MCQ Failure TheoriesDocument46 paginiMCQ Failure TheoriesfdsfsdfsdfsfsÎncă nu există evaluări

- The NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsDocument33 paginiThe NSCP 2015 Provisions On The Use of QT TMT Reinforcing BarsFritze Hansteen OngÎncă nu există evaluări

- Vendor Document / Document Front Sheet: Diesel Engine Generator Set Overall Piping & Instrumentation DiagramDocument11 paginiVendor Document / Document Front Sheet: Diesel Engine Generator Set Overall Piping & Instrumentation Diagramshoghi wisesa100% (1)