Documente Academic

Documente Profesional

Documente Cultură

The Indirect Composite Resins Were Introduced in An Effort To Address The Disadvantages

Încărcat de

Vinisha Vipin SharmaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

The Indirect Composite Resins Were Introduced in An Effort To Address The Disadvantages

Încărcat de

Vinisha Vipin SharmaDrepturi de autor:

Formate disponibile

The indirect composite resins were introduced in an effort to address the disadvantages, including technique sensitivity, anatomic form,

polymerisation shrinkage, wear and interproximal contacts, of the direct adhesive restoratives. Over the years some manufacturers have attempted corrections or improvements in existing materials, while others have devoted further research efforts aimed at developing new products. In addition to the proven clinical successes of Concept (Ivoclar Vivadent), belleGlass HP (KerrLab), Cristobal+ (DENTSPLY Ceramco), Sculpture (Pentron Laboratory Technologies), and Sinfony (3M ESPE), the future of indirect composites looks promising, with recent additions such as Concept HP (Ivoclar Vivadent), Tescera ATL (Bisco), belleGlass NG (KerrLab), Gradia (GC America), and Sculpture Plus (Pentron Laboratory Technologies). These products incorporate still further modifications in filler size, filler content and methods of curing. This is reportedly in order to improve characteristics such as porosity, the ease of polishing, wear, strength and aesthetics [1]. Everyone involved in patient care must understand the basics of these dental materials. Evaluation of available indirect composite materials and eventual choices should be made with a cooperative laboratory-dentist team approach. In spite of the proven success and improved materials, indirect composites are not as successful as the direct bonded restorations. One factor is the extra chair time involved for a two-visit procedure, along with the laboratory charges that must be passed on to the patient. Another important factor affecting patient and clinician acceptance of indirect composite restorations is related to the schedule of patient benefits provided by many dental insurance plans [1,2]. First generation indirect composites The first generation of the compositebased indirect adhesive restoratives were introduced in the early 1980s. Some of the most popular ones included:

y

y y

SR Isosit in-lay system. This system was first reported in the dental literature in 1983 and was made commercially available in 1986. It is a homogeneously filled composite containing 55% by weight of radiolucent colloidal silica plus 20% radiopaque lanthanium fluoride. Coltene Brilliant. This brilliant aesthetic in-lay/on-lay system incorporates a fine particle size (0.5 mm) hybrid composite containing 78.5% (by mass)of glass fibre [3]. Visio-Gem (ESPE). This was initially introduced as a material suitable for anterior composites veneers, but its use was expanded to include indirect in-lays [3]. The inlays are initially light-cured followed by a 15-minutes light cure under vacuum. Concept (Ivoclar). This is an indirect resin restorative system for aesthetic in-lay and on-lays. It is a highly filled microfill composite, which is heat- and pressurepolymerised extra-orally under 85 psi pressure and at temperatures of 250F (121C) for 10 minutes. The result is a homogeneous in-lay/on-lay with superior aesthetics and excellent resistance to wear [2,3].

These materials were developed in an effort to overcome the polymerisation shrinkage and accelerated wear experienced with direct adhesive restorative materials. However, this first generation of materials suffered from low flexural strength, low modulus of elasticity and low resistance to wear and abrasion. These poor physical properties were the result of low filler load and high matrix load.

Second generation indirect composites It was not until the mid-1990s that the second generation of indirect composite restorative were introduced. These new materials included Artglass (Heraeus-Kulzer), BelleGlass HP (Kerr), Targis (Ivoclar), Colombus (Cendres et Mtaux) and Sinfony (ESPE) [3]. The effect on the degree of conversion of heat-curing these newer composite materials was demonstrated by Ferracane and Condon in 1992 [4]. They showed that heat treatment, in addition to a 60-second light cure, would increase the degree of conversion, and this would improve the resistance of indirect composite materials. to fracture This second generation of materials incorporated ceramic fillers with mean particle sizes of less than 1 m diameter, silanised and with a narrow distribution. The filler is commonly barium silica. These materials have a high filler load (70-80% by weight and 50-60% by volume) and they have a lower resin content (approximately 33% resin matrix by volume.) The filler volume and filler load correlate with the strength of a composite resin. The higher filler load will help reduce the polymerisation shrinkage, while it increases the modulus of elasticity [3]. Artglass (Heraeus/Kulzer) Identified by the manufacturer as a nonconventional dental polymer, artglass has been on the market since 1995. During this relatively short period, it has become accepted by a growing number of clinicians. It is most commonly used in in-lays, on-lays and crowns. Although fullcrown restorations are commonly generated in conjunction with a metal substrate, they have also been used without one [5]. While conventional composite resins (such as BIS-GMA or urethane dimethacrylate, or UDMA) commonly contain only bifunctional molecules, the Artglass formulation is considerably more complex. In addition to conventional bifunctional molecules, Artglass contains four to six functional groups. Such a configuration provides the opportunity for more double-bond conversions. This can aid in improving the resistance to wear and other physical and mechanical properties of the resin matrix. The filler component of Artglass is essentially a radiopaque barium glass with a mean particle size of 0.7 m. A moderate amount of colloidal silica is also incorporated to enhance certain handling characteristics [6]. Artglass is photo-cured in a special unit using a xenon stroboscopic light (UnixXS, Heraeus/Kulzer). The system emits a total of 4.5 watts as usable luminous power, while the emission range is between 320 and 500 nanometers. This range is significant because excitation of the initiator, camphor quinone, is optimised at about 470 nm [5]. This material is suitable for metal-free crowns, veneers, in-lays, on-lays or metal supported crowns, bridges and implant supra-structures.Shades are matched to both the Vita Lumin and Chromascop shade guides. BelleGlass HP (Kerr) (Dentron) Belle de St. Claire introduced this indirect restorative material in 1996; the manufacturer characterised it as being aesthetically appealing and highly wear-resistant. The resin matrix is chemically similar to that of the BIS-GMA restorative systems currently on the market. The mechanism of curing associated with BelleGlass HP, however, is considerably different. BelleGlass HP is polymerised under pressure at an elevated temperature and in the presence of nitrogen, an inert gas. The elevated temperature (138C, 280F) increases the polymerisation rate, whereas the increased atmospheric pressure (29 pounds per square inch) reduces the vaporisation potential of the monomers at elevated temperatures. The use of a nitrogen atmosphere during the polymerisation process enables an increase in wear

resistance. In essence, it produces an oxygen-free environment, which, in turn, results in a higher level of polymerisation [5,6]. Oxygen also plays an important role in the apparent translucency or opacity of the cured resin restoration. Its presence as an entrapment in the finalised restoration, regardless of dimension, tends to diffract natural light as it reflects from the surface of the preparation. Removing all of the air causes the restoration to become considerably more translucent. BelleGlass HP achieves a cure of 98.5% through the use of fibre optic light, 140C heat, and 60 psi pressure cured under a nitrogen atmosphere [6]. It is most suitable for traditional in-lays, on-lays, and single crowns extending to three-unit bridges, either metal-free or bonded to metal. BelleGlass works well for the fabrication of anterior veneers due to opalescent and fluorescent additives within the polymer-based glass. Implant reconstructions also benefit from BelleGlass due to the unique effect it has on surrounding periodontium.Shades are matched to both the Vita Lumina and Vita 3D Master shade guide. Sculpture/FibreKor The Sculpture/FibreKor system unites the latest in polymer ceramics and advanced fibre science technology allowing the laboratory technician to create functional and aesthetic restorations. FibreKor is a pre-impregnated fibre-reinforcing material with a modulus of rupture comparable to non-precious alloys (approximately 1000 MPa). FibreKor is used, in place of metal, to reinforce single unit and three-unit bridges. Sculpture is an advanced light, heat, and vacuum cured polymer-glass restorative material that is built on the FibreKor substructure. Sculpture has an extremely low water absorption rate (9-12mg/mm), which prevents unsightly discoloration or staining. A Sculpture restoration has a wear rate similar to that of natural dentitionless than 3 m per year [1,5,6]. The material is suitable for anterior and posterior crowns, full coverage bridges, in-lay/on-lay bridges, and in-lay and on-lay encore bridges. Bridges should not exceed 15 mm in length. Shades are matched to the Vita Lumin shade guide. FibreKor is offered in five shades and two sizes. Cristobal (Ceramco Inc.) Cristobal is an indirect composite system, which is recommended as a replacement for PFM and all-ceramic restorations. Cristobal has a dynamic post-curing polymerisation process that cures quickly, and creates superior strength, hardness and wear. The generalised wear of Cristobal was less than half that of the nearest competitor at 1.6 microns after 100,000 cycles using a three-body wear test. The non-porous, bio-compatible surface of Cristobal is virtually impermeable to microorganisms., and allows superior chair-side polishability. Because Cristobal is mechanically polished as opposed to glazed, the finish will not wear off. The unique Cristobal formula is highly fracture-resistant and shock-absorbent with ideal rebounding characteristics so it is ideal for implants [1,6,7].Cristobal is suitable for 3-unit metal-free/fibre-free bridges through the second premolar, single unit crowns through the first molar, in-lays, on-lays, veneers, implants bonded to metal, and all types of fused-to-metal restorations. Shades are matched to the Vita Lumin shade guide. Gradia (GC Lab Technologies Inc.) Gradia is a light-cured indirect restoration with an innovative hybrid MFR formulation. The unique chemistry of Gradia couples a micro-fine ceramic/pre-polymer filler with a urethane dimethacrylate matrix to produce a superior ceramic composite with exceptionally high strength, wear resistance and superior polishability. Gradia is biocompatible and gentle to opposing teeth. Since polymerisation does not change Gradias colour, technicians see the subtle colours of the final restoration throughout all phases of fabrication [1,2,7]. Gradia is

recommended for crown and bridge, in-lays, on-lays and veneers. Shades are matched to the Vita Lumin shade guide. Herculite XR & XRV (Kerr) Herculite XR & XRV are Bis-GMA microhybrid light-activated composites with an average particle size of 0.6 m. They are available in Vita Shades in two levels of dentin and enamel transparencies. Herculite simulates light refraction, fluorescence and translucency of natural dentition [1,2,6].The material is recommended for all anterior and posterior applications. Excellent handling properties allow anatomical shaping without composite slumping. Fiveyear in-the-mouth-clinical trials demonstrate reliability as well as proven durability. Shades are matched to the Vita Lumin shade guide. Indirect ceromers The introduction and adoption of heat-and-pressure-cured restorations (Concept, Ivoclar Williams, Amherst, NY) highlighted the functional and aesthetic limitations of metal and metal-supported restorations. However, a metal-free veneering and framework system has been introduced (Targis System, Ivolclar Williams, Amherst, NY) which could replace conventional ceramic-fused-to-metal restorations of single or multiple teeth. The material is easy to fabricate, has a natural colour, marginal integrity and the wear and fracture resistance of its component materials, Ceromers (CERamic Optimised polymers) and fibre-reinforced composites [7,8]. Targis ceromer Ceromers are a specific combination of the latest in ceramic filler technology and advanced polymer chemistry that provide enhanced function and aesthetics. They are composed of specially developed and conditioned homogeneous, three-dimensional fine-particle ceramic fillers of submicrometer size (0.04 and 1.0m) which are densely packed (approximately 80% in weight) and embedded in an advanced organic matrix with optimum light-and heatcuring potentials. Whereas some conventional composite resins contain only bi-functional molecules of Bis-GMA, Ceromer technology is considerably more complex, containing polyfunctional groups. Such configurations provide the potential for a higher level of crosslinking and more double-bond conversion, which result in the enhanced strength of the material [8]. Monaco C et al evaluated the clinical acceptability of ceromers for in-lay and on-lay restorations in single- or multi-surface cavities of posterior teeth, and concluded that over an 18-month period the Targis restorative system had good clinical service [9]. Wear is quite low according to the manufacturer. BelleGlass is reported by the manufacturer as having a wear of 1.2 m for 1 year. In 1998 different findings were reported: Belleglass was shown to wear at 62 m, Targis at 106 m, and Artglass at 77 m per year [8,9]. Suzuki S et al evaluated the wear characteristics of seven indirect composite restoratives and compared them with a type III gold alloy by means of an in vitro wear test. They concluded that some indirect composite restoratives have similar wear resistance to the type III gold alloy tested. Antagonistic enamel was abraded more by highly filled composite materials [10]. Fibre-reinforced sub-structure indirect composites This second generation of indirect composite resins may be combined with a fibre-reinforced

substructure [Table 1]. Fibre reinforcement of polymer resins has been available for many years but has only recently become very popular in dentistry for fixed prosthetics. Silanetreated glass fibres are commonly used, as are plasma-treated polyethylene, often in a woven form. Unlike glass fibres, which are commonly used due to their high elasticity, polyethylene fibres do not appreciably increase the stiffness of the structure. Instead, they strengthen and toughen composites for single and multiple unit restorations. The woven fibres are usually impregnated with a lightly-filled or heavily-filled resin, the latter being easier to accomplish by the manufacturer and supplied as such to the operator. Wetting of the fibres by the resin and homogeneous distribution of the resin between the fibres are critical to successful reinforcement [8,11]. This technology was used for periodontal splinting as well as temporary bridge reinforcement prior to its introduction as reinforcement for indirect composite restoratives. The fibres used for this purpose are composed of carbon Kevlar, polyethylene and glass fibres. The revolutionary fibre-reinforced composite (FRC) has high flexural strength, and the breaking load of Targis and Vectris similar to PFM. The modulus of elasticity is similar to dentin [11,12]. These fibres may be silanised and pre-impregnated with resin. This provides a cohesive bond to the resin matrix [13,14]. Fibres can be unidirectional, woven or laminar in orientation. Vectris FRC Fibre-reinforced composite technology has long been utilised in industry. In dentistry the rationale for using FRC is to combine different materials to achieve superior properties and synergistic effects. The FRC material comprises several layers of pre-impregnated, homogeneous glass fibre wafers, in addition to uniaxially-oriented fibre bundles. These silanised glass fibres are reinforced with the polymer matrix utilised in the Ceromer veneering material,Targis. This advanced technology enables a metal-free, highly functional framework for anterior and posterior bridges, and full-coverage crown restorations [13,14]. Comparison with porcelain In-lays and On-lays. When comparing indirect composites and porcelain concerning wear of the opposing enamel, indirect composites have a definite advantage [15]. Some studies suggest that indirect composite in-lays and on-lays also hold the edge with respect to the long-term quality of margins. Margins are still one of the keys to restorative success. The longevity of indirect restorations of any type depends on the integrity of the margins at placement. In a 8-year in vivo study of fired ceramic in-lays, the margins were observed to have 22% visual microfractures and 77% micro-fractures observed with scanning electron microscopy [15]. Another study of pressed-glass ceramic in-lays and on-lays showed, after six years in vivo, that 94% had margin deficiencies [16]. In contrast, the margins of indirect composites seem to be faring much better. A recent 3-year study compared direct composites with indirect composites. It concluded that the margins of indirect composites were rated consistently higher than direct composites [17]. Conclusion Indirect composite restorations can be an excellent choice for patients. For optimal success, it is vital to have sufficient knowledge of the material, and to choose a laboratory that creates the restoration with aesthetic and functional excellence. Treatment plans should reflect the differences in an individual clinicians abilities as well as the patients varying aesthetic desires and functional needs.

Because there is no ideal one-fits-all restorative system, it continues to be the dentists responsibility to apply his/her knowledge to select the appropriate materials and techniques for each patient. Using indirect composite resin for a restorative procedure requires more than a rudimentary understanding of the material. Progress in adhesive technology and composite material systems allows for the preservation and reinforcement of tooth structure, while improving natural aesthetics and wear resistance. These indirect composite systems complement and broaden the scope of restorative alternatives that are available to assist the patient, technician and the dentist in making an informed selection for different clinical situations. References: 1. Landman P. Alpha Omegan 1994;87(4):49-54 2. Jackson RD. Curr Opin Cosmet Dent 1994, 30-39. 3. Sikri VK. Textbook of Operative Dentistry, Ist ed. CBS Publis hers, 2002 4. Ferracane JL, Condon JR. Dent Mater 1992; 8: 290-295. 5. Depew TE, Sorensen JA. J Dent Res 1998; 77 (Special Issue B): abstract 900. 6. Kowalski BJ. www.benco.com/aesthetics.pdf 7. Leinfelder KF. J Am Dent Assoc 1997;128:573-580. 8. Newton Falb Jr.,Casellin RC. . Signature 1997; 6: 7-13. 9. Monaco C et al. Int J Prosthodont 2001;14(1):81-6 10. Suzuki S et al. IJ Prosthet Dent 2002 Oct;88(4):431 -6 11. Ferracane JL. Oper Dent 2001; 6:199-209. 12. Cesar PF, Miranda WG Jr, Braga RR. J Prosthet Dent 2001;86(3):289-96 13. Freilich MA. Quintessence Int 1998; 29: 689-696. 14. Weitao Jia, 20080250974. Fiber -Reinforced Composite Dental Materials and Method of Manufacture 10-16-2008. 15. Hayashi M et al. Oper Dent. 2000;25:473-481. 16. Frankenberger R, Petschelt A, Kramer N. Oper Dent 2000;25:459-465. 17. Manhart J et al. J Prosthet Dent 2000;84:289-296.

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Diff Betwn Inlay and Amalgam CavityDocument7 paginiDiff Betwn Inlay and Amalgam CavityVinisha Vipin Sharma100% (1)

- Criteria of SelectionDocument12 paginiCriteria of SelectionVinisha Vipin SharmaÎncă nu există evaluări

- Mechanical Preparation Updated May2017 Prof Marco VersianiDocument159 paginiMechanical Preparation Updated May2017 Prof Marco VersianiVinisha Vipin SharmaÎncă nu există evaluări

- Non Surgical Management of Periapical Lesions Using Calcium HydroxideDocument6 paginiNon Surgical Management of Periapical Lesions Using Calcium HydroxideVinisha Vipin SharmaÎncă nu există evaluări

- Acupuncture in Dentistry PDFDocument73 paginiAcupuncture in Dentistry PDFVinisha Vipin SharmaÎncă nu există evaluări

- Challenges in Working Length DeterminationDocument101 paginiChallenges in Working Length DeterminationVinisha Vipin SharmaÎncă nu există evaluări

- Eaat 14 I 1 P 217Document6 paginiEaat 14 I 1 P 217Vinisha Vipin SharmaÎncă nu există evaluări

- Content ServerDocument5 paginiContent ServerVinisha Vipin SharmaÎncă nu există evaluări

- Glide Path PreparationDocument5 paginiGlide Path PreparationVinisha Vipin SharmaÎncă nu există evaluări

- Show TextDocument1 paginăShow TextVinisha Vipin SharmaÎncă nu există evaluări

- PRISMA-P Statement - Moher Sys Rev Jan 2015Document9 paginiPRISMA-P Statement - Moher Sys Rev Jan 2015Vinisha Vipin SharmaÎncă nu există evaluări

- Some Basics of LasersDocument102 paginiSome Basics of LasersVinisha Vipin SharmaÎncă nu există evaluări

- Laser in Conservative Dentistry & EndodonticsDocument75 paginiLaser in Conservative Dentistry & EndodonticsVinisha Vipin SharmaÎncă nu există evaluări

- Dentin HypersensitivityDocument62 paginiDentin HypersensitivityVinisha Vipin Sharma100% (1)

- Content ServerDocument6 paginiContent ServerVinisha Vipin SharmaÎncă nu există evaluări

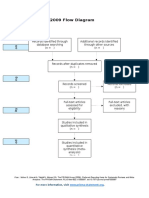

- PRISMA 2009 Flow Diagram: For More Information, VisitDocument1 paginăPRISMA 2009 Flow Diagram: For More Information, VisitVinisha Vipin SharmaÎncă nu există evaluări

- Practice: Radiographic Evidence of Postoperative Healing 12 Years Following Root Canal Treatment - A Case ReportDocument5 paginiPractice: Radiographic Evidence of Postoperative Healing 12 Years Following Root Canal Treatment - A Case ReportVinisha Vipin SharmaÎncă nu există evaluări

- EchsDocument20 paginiEchsVinisha Vipin SharmaÎncă nu există evaluări

- Ceramic Restorations: Bonded Porcelain Veneers - Part 1: PerspectiveDocument5 paginiCeramic Restorations: Bonded Porcelain Veneers - Part 1: PerspectiveVinisha Vipin SharmaÎncă nu există evaluări

- Nanodentistry: New Buzz in Dentistry: Review ArticleDocument5 paginiNanodentistry: New Buzz in Dentistry: Review ArticleVinisha Vipin SharmaÎncă nu există evaluări

- Esthetic Alternatives To AmalgamDocument15 paginiEsthetic Alternatives To AmalgamVinisha Vipin SharmaÎncă nu există evaluări

- Pin Retained RestorationDocument31 paginiPin Retained RestorationVinisha Vipin SharmaÎncă nu există evaluări

- Clarks Cavity PreparationDocument10 paginiClarks Cavity PreparationVinisha Vipin SharmaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- TRM34 Preparation of Calculations Rev5Document5 paginiTRM34 Preparation of Calculations Rev5TuanÎncă nu există evaluări

- Krunker ModMenuDocument10 paginiKrunker ModMenuCody Kartavya0% (1)

- Nachi Special SteelsDocument20 paginiNachi Special SteelsBambang MulyantoÎncă nu există evaluări

- BX 3010 (0C)Document362 paginiBX 3010 (0C)Lâm Hồ Ngọc HãnÎncă nu există evaluări

- Large Volume PoursDocument7 paginiLarge Volume PoursgordonÎncă nu există evaluări

- Company Profile Traya Lintas PersadaDocument24 paginiCompany Profile Traya Lintas PersadaAyu Catra KastaraÎncă nu există evaluări

- Experiment 1Document5 paginiExperiment 1Cheng BauzonÎncă nu există evaluări

- Hoses & AppliancesDocument92 paginiHoses & Appliancestheguy 21100% (1)

- Gogostemcells StudentpagesDocument2 paginiGogostemcells Studentpagesapi-356824125Încă nu există evaluări

- 1 5 1Document5 pagini1 5 1daemsalÎncă nu există evaluări

- Top Gun I-ARC 130Document9 paginiTop Gun I-ARC 130Tom PleysierÎncă nu există evaluări

- Lab Manual - DEDocument41 paginiLab Manual - DEAnkur Giri100% (2)

- SLM 1 CARPENTRY 10 Revalidated and Language 1st QuarterDocument8 paginiSLM 1 CARPENTRY 10 Revalidated and Language 1st Quarterash hshsÎncă nu există evaluări

- SRI FireFighting Equipments 2012 PDFDocument46 paginiSRI FireFighting Equipments 2012 PDFsullamsÎncă nu există evaluări

- KinematicsDocument33 paginiKinematicsErik MagnoÎncă nu există evaluări

- KNS2163 Week1Document32 paginiKNS2163 Week1Nurul QurratuÎncă nu există evaluări

- Assessment of Rotational Capacity Test Procedure FINALDocument21 paginiAssessment of Rotational Capacity Test Procedure FINALzaheerahmed77Încă nu există evaluări

- Instalación Zapata Case 9010Document5 paginiInstalación Zapata Case 9010Miguel Angel Herrera MartinezÎncă nu există evaluări

- Foreword by Brett Queener - Agile Product Management With Scrum - Creating Products That Customers LoveDocument3 paginiForeword by Brett Queener - Agile Product Management With Scrum - Creating Products That Customers LoveJoao Paulo MouraÎncă nu există evaluări

- Johnloomis Org Ece563 Notes Geom Resize ImresizeDocument10 paginiJohnloomis Org Ece563 Notes Geom Resize ImresizeAdrian Jose Costa OspinoÎncă nu există evaluări

- BITS Herald Summer Issue 2013Document23 paginiBITS Herald Summer Issue 2013Bits Herald100% (1)

- Design of Well FoundationDocument31 paginiDesign of Well FoundationAshish Karki97% (32)

- Ford's PHEV Fact SheetDocument1 paginăFord's PHEV Fact SheetFord Motor Company100% (2)

- Alien Legacy-Manual PDFDocument93 paginiAlien Legacy-Manual PDFMark BallingerÎncă nu există evaluări

- Deception & Detection-On Amazon Reviews DatasetDocument9 paginiDeception & Detection-On Amazon Reviews Datasetyavar khanÎncă nu există evaluări

- 023 POL902.00 CB1Q3934en 01 ModBusDocument4 pagini023 POL902.00 CB1Q3934en 01 ModBusEvandroRodriguesÎncă nu există evaluări

- Toshiba Satellite L650 12Q Laptop ManualDocument229 paginiToshiba Satellite L650 12Q Laptop ManualTasos KachpanisÎncă nu există evaluări

- Cathodic Protection System Inspection and Test PlanDocument10 paginiCathodic Protection System Inspection and Test PlanNoor A QasimÎncă nu există evaluări

- Math 1030 Working in The YardDocument4 paginiMath 1030 Working in The Yardapi-313345556Încă nu există evaluări

- Sub Test Mole Concept PDFDocument7 paginiSub Test Mole Concept PDFVIKAS GARGÎncă nu există evaluări