Documente Academic

Documente Profesional

Documente Cultură

Calculating Financial Impact of Lean Six Sigma Projects

Încărcat de

kbobhateDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Calculating Financial Impact of Lean Six Sigma Projects

Încărcat de

kbobhateDrepturi de autor:

Formate disponibile

Newsletters :: Marketplace :: Job Shop :: Magazine :: iSixSigma Live!

ADVERTISEMENTS

search...

Adv anced Search

Home

New to Six Sigma

Community

Training

Methodology

Implementation

Tools & Templates

Resources

iSixSigma Home > Resources > Financial Analysis > Calculating Financial Impact of Lean Six Sigma Projects

June 19, 2011

Register With iSixSigma!

Register Today for special access to iSixSigma.

Calculating Financial Impact of Lean Six Sigma Projects

font size Rate this item Print E-mail Be the first to comment!

(5 votes)

Already a Member?

Username

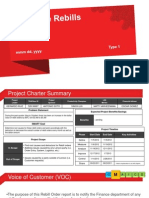

CEOs want to know the return on investment of Lean Six Sigma projects, and CFOs want to compare the real financial Password results to "PowerPoint dollars." A rigorous approach to calculating an improvement project's impact is important to every organization. Remember me Login Forgot login? By Roberto Copercini The benefit to an organization deploying Lean Six Sigma is not limited to immediate financial gain from improvement projects. In fact, the cultural change generated by a fully accepted initiative is probably the best long-term pay back that a company can obtain. Having said this, however, it does not justify a lack of rigor in calculating the financial impact of Lean Six Sigma projects. That rigor is an imperative for the coherence of a data-oriented approach. CEOs and shareholders want to know the return on investment of Lean Six Sigma, and CFOs want to compare the real financial results to those projected "PowerPoint dollars." Additionally, a rigorous approach in defining how to calculate a project's impact can be helpful for the project selection process since the potential financial impact should be a key criteria to select and launch a project. To properly calculate the business impact of a project in a Lean Six Sigma deployment, it is important to have guidelines. These guidelines must be agreed to by the finance department and applied in the same way across the entire business. Technical rules on how to calculate the financial impact can vary depending on the business, however, the main areas to be analyzed and measured are common to almost all businesses. They are: Revenues Costs Risk Customer satisfaction

Channels

Industries Operations Regional Views

iSixSigma Directory

Consultants Customer Surveys Education Organizations Software Training

Lean Six Sigma Curriculum

Need world class training material? Get your free download now.

www.firefly-consultin

iSixSigma Magazine

Revenues

Lean Six Sigma projects are not only related to cost reductions and productivity increases. They also can be aimed a boosting the revenue side of the business. While it is usually Design for Six Sigma (DFSS) projects that are more focused on revenues, DMAIC projects can lead to significant results as well. Revenue can be increased through increased sales volumes as well as the launch of new products or services. Increased volume: Higher volume of an existing product/service sold due to increased customer satisfaction, better offer proposition, improved distribution (geographic coverage, number of shops, higher productivity of existing channels, etc.). The general rule to calculate the increased revenues at the time of successful project closure (N+1) compared to the time before iSixSigma Magazine Subscribe Today! Revenues N+1 - Revenues N = Increased Revenues the project starts (N) is simple:

Stay Connected!

This rule can be easily applied in a situation of constant price and constant cost. If revenue increase is obtained as a result of lower price (volume increase caused by price reduction), it is recommended to measure the impact at margin level. If the result of the project is a cost reduction of the product/service that results in a price reduction, calculate this impact in the

revenue line only for the volume increase (if any). Note: It is not always easy to attribute the revenue increase clearly to a Lean Six Sigma project. Maybe there were other unknown factors or parallel activities that also influenced the increase. New product/service: Revenue generated by a completely (or significantly) new product or service. When this is the result of a Lean Six Sigma project, that project is usually a DFSS project.

Costs

The is the area in which most Lean Six Sigma projects are concentrated. Under this saving line, are identify several different types of financial impacts - reduced material costs, productivity increases (labor cost saving), and reduction of the cost of poor quality. Reduced cost: Any cost saving achieved; a reduction of a recurred P&L cost (a certain cost already incurred in the past) can be calculated in this category. The general rule is: Cost N+1 - Cost N = Cost Saving If direct cost, the following rule is applicable: (Cost N+1 x Numb er of Items) - (Cost N x Numb er of Items) = Cost Saving The "number of items" is the count of the items that the cost is related to (i.e., products, invoices, calls, etc). Any reduction in capital used (assets), interest paid, working capital and stocks can be calculated as a reduced cost. Note: Cost avoidance (costs not in P&L and not incurred in the past) cannot be included in this category. In financial businesses it needs to be clearly defined how to calculate the cost of capital. Productivity saving: Refers to the increased amount of output per unit (minutes, hours, days, etc) of labor and is usually calculated in terms of time saved to perform a specific action or to obtain a specific output. It can be achieved as a result of simplification, automation or elimination of tasks (e.g., non-value-added activities). To properly calculate a financial impact from productivity saving one of the following conditions has to be applicable: Headcount reduction: If the productivity saving leads to headcount reduction, the amount saved can be included in the financial impact. Redundancy cost, cost related to headcount reduction, also can be considered. The general rule is: Cost of Lab our x Headcount Unit x Period - Redundancy Cost = Productivity Saving Increased volume: If the business is growing and the time saved (units of labor) is utilized to increase the production, the amount of time saved can be included in the financial impact (up to the effective production increase). Cost of Lab or x Time x Numb er of Units = Productivity Saving No headcount reduction and stable volume: In this case, saving can be calculated only if it can be demonstrated that the time saved will be used in value-added activities not performed before. Cost of Lab or x Time x Activity = Productivity Saving The cost of labor has to be clearly defined, i.e., Standard cost or actual cost? Does it include overhead? Etc. Cost of poor quality: Internal and external failure costs, prevention costs, appraisal costs and others. Many of these costs are hidden and difficult to identify by measurement systems. In order to properly calculate the financial impact it is critical to capture the right measures. Note: See the iSixSigma article "Cost of Quality: Not Only Failure Costs."

Risk

Risk-related projects are becoming more and more critical, mainly in financial businesses. Types of risk-related savings include operational risk reduction and risk provision reduction. Operational risk reduction: Basel Committee on Banking Supervision defines operational risk as "the risk of direct or indirect loss resulting from inadequate or failed internal processes, people and systems or from external events." Operational risk can result in increased write-offs, additional expenses or loss of revenue. One of the best ways to capture operational risk reductions is the project's failure mode and effects analysis in the Control phase. Risk provision reduction: Any reduction in risk provisions allowed as the result of a project (i.e., stable process, higher performances, etc.) must be reflected in risk policies - in other words, better credit collection performances leading to lower provision for unpaid invoices, or higher residual value of assets leading to lower depreciation. Note: Attention needs to be paid to double counting operational risk reduction and cost reduction (i.e., cost savings for

reduced invoice errors counted as cost reduction and risk reduction).

Customer Satisfaction

Customer satisfaction is the declared goal of any Lean Six Sigma initiative. The customer satisfaction index is probably the best leading indicator for a business. Customer retention, customer penetration and customer winning rates are the business-related indicators that reflect customer satisfaction. It is not easy - if not sometimes impossible - to link the impact of a single project to a customer satisfaction indicator or to customer retention, penetration and winning rates. While it is not possible or efficient to capture the one-to-one relationship project/improvement, a cost-effective option is to identify projects and initiatives with impacts in those areas and measure projects overall impact on satisfaction, retention, penetration and winning rate in a defined period. Note: Customer satisfaction index, customer retention, penetration and winning rates - as they are key business indicators have to be clearly defined at business level (operational definitions).

Timing and Financial Impact

All project savings mentioned are calculated for a defined time period. This period is usually 12 months following the project go-live (when improvements are implemented). Based on the type of the business or the amount of investment (such as the launch of a wide Lean Six Sigma initiative), periods of two to three years (or more) can be used. In any case, it is critical to demonstrate that a process management activity is in place with stable process performances to calculate the savings. Any further improvement has to be calculated starting from a clear baseline (in terms of performance and timing). About the Author: Roberto Copercini is a director of Valeocon Management Consulting in Europe. He has a wide range of experience in helping multi-national companies deploying operational excellence programs and improving their strategy execution. Prior to joining Valeocon, he had senior positions at Merrill Lynch and General Electric. He lives in Geneva and can b e reached at rob erto.copercini@valeocon.com .

Social sharing

More in this category:

Ask the Expert: The Topic: Six Sigma and Return on Investment

How to Explain Six Sigma by

Using the Profit Triangle

Add comment

enter your comment here...

Name enter your name... E-mail enter your e-mail address... URL (optional) enter your site URL... Enter the two words you see below

Submit comment back to top

From Our Partners

Free Quality Management E-book Let ASQ take y our career to the next lev el.

Worldwide Leader in Online Six Sigma Training-Earn Your Master Certif icate Enroll Now Classes Fill Quickly Register Today !

Six Sigma Training f rom UL - Global Leader in Certif ication World Class Instruction f rom Industry Practitioners

iSixSigma's 'Best of the Best' Webinar Series DoD Perf ormance Sy mposium, June 27-30

Lean Six Sigma online, classroom, and custom programs. Learn f rom top ASU f aculty . Master Black Belt enrolling now!

Start Your Black Belt E-learning Program Today ! Six Sigma templates f or Green, Black and Master Black Belts

New to Six Sigm a Definition of Six Sigma Design for Six Sigma (DFSS) Dictionary of Lean Six Sigma Terminology DMAIC FAQ Getting Started History How Is Six Sigma Different? Roles & Responsibilities Sigma Level Training

Com m unity Aw ards and Standards Blogs Discussion Forum Events LinkedIn Live! Events Most Read Top-rated Articles New s Submit an Article Tw itter

Training Certification E-learning

Methodology Balanced Scorecard Benchmarking Management (BPM) Design for Six Sigma (DFSS) DMAIC Hoshin Kanri Innovation Kaizen Lean Metrics Plan, Do, Check, Act Project Management Robust Design/Taguchi Method Theory of Constraints Total Quality Management (TQM) VOC/Customer Focus Work-out

Im plem entation Basics Benchmarking Case Studies Deployment Health Financial Analysis Getting Started Metrics Project Selection & Tracking Teams VOC/Customer Focus

Tools and Tem plates 5S Af finity Diagram/KJ Analysis Variance (ANOVA) Analytic Hierarchy Process (AHP) Brainstorming Calculators Capability Indices/Process Capability Cause & Effect Control Charts Design of Experiments (DOE) FMEA Graphical Analysis Charts Hypothesis Testing Kano Analysis Measurement Systems Analysis (MSA)/Gage R&R Normality Pareto Poka Yoke Process Mapping Project Charter QFD/House of Quality RACI Diagram Regression Risk Management Sampling/Data Simulation SIPOC/COPIS Softw are Statistical Analysis Templates Value Stream Mapping Variation

Resources Advertising Aw ards Contact Us Dictionary Directory Job Shop Link to iSixSigma Live! Events Magazine Marketplace New sletters White Papers

Organizations/Providers Business Process Training Materials & Aids

Cox-Box Cartoon Training Events

Change Management Analysis of

2000-2010 iSixSigma. All rights reserved. v3.0lb, 0.0

Legal Information | About iSixSigma | Contact Us | Privacy Policy | Site Map | Submit an Article

S-ar putea să vă placă și

- GE Six SigmaDocument6 paginiGE Six Sigmaimran27pk100% (2)

- Lean Six Sigma in The Service Industry by Alessandro Laureani PDFDocument14 paginiLean Six Sigma in The Service Industry by Alessandro Laureani PDFnaacha457Încă nu există evaluări

- Six Sigma For Managers 185 1Document55 paginiSix Sigma For Managers 185 1Mitul PatelÎncă nu există evaluări

- Adoption of Six Sigma DMAIC To Reduce Cost of Poor QualityDocument26 paginiAdoption of Six Sigma DMAIC To Reduce Cost of Poor QualityFikri Ilham100% (1)

- Six Sigma Black Belt Project On: Reduction in Breakage in BiscuitsDocument42 paginiSix Sigma Black Belt Project On: Reduction in Breakage in BiscuitsHombing Haryanto100% (1)

- A Fictitious Six Sigma Green Belt Part IDocument19 paginiA Fictitious Six Sigma Green Belt Part IhalilpashaÎncă nu există evaluări

- FEIGENBAUM + Ishikawa + TaguchiDocument7 paginiFEIGENBAUM + Ishikawa + Taguchiaulia rakhmawatiÎncă nu există evaluări

- Online Lean Six Sigma Champion Belt Training: Quality - Support - InnovationDocument2 paginiOnline Lean Six Sigma Champion Belt Training: Quality - Support - InnovationkolehÎncă nu există evaluări

- Green Belt ProjectDocument5 paginiGreen Belt ProjectIeva ValpētereÎncă nu există evaluări

- Six Sigma Project WorkDocument34 paginiSix Sigma Project WorkDrpallavi NanavatiÎncă nu există evaluări

- TQM Versus Six SigmaDocument16 paginiTQM Versus Six Sigmaapi-3751356Încă nu există evaluări

- Lean-Implementation A25 MakrandDocument12 paginiLean-Implementation A25 MakrandKolekarMakrandMahadeoÎncă nu există evaluări

- Master BB 2017 VersionDocument29 paginiMaster BB 2017 VersionSN SharmaÎncă nu există evaluări

- 5S in Service IndustriesDocument34 pagini5S in Service IndustriesHVD87100% (1)

- Lean Vs Six SigmaDocument23 paginiLean Vs Six SigmabowbeforeallahÎncă nu există evaluări

- Improving Bank Call Centre Operations Using Six Sigma: Rahul GautamDocument8 paginiImproving Bank Call Centre Operations Using Six Sigma: Rahul Gautamsajeeby100% (1)

- Six SigmaDocument27 paginiSix SigmaagarwalsaurabhhÎncă nu există evaluări

- Primer On Lean Six Sigma - NRCDocument54 paginiPrimer On Lean Six Sigma - NRCJim WolfeÎncă nu există evaluări

- THE EFFECTIVENESS OF SIX SIGMA IN SERVICES SECTORS-libre PDFDocument26 paginiTHE EFFECTIVENESS OF SIX SIGMA IN SERVICES SECTORS-libre PDFsarahÎncă nu există evaluări

- IASSC Yellow Belt Body of Knowledge1 PDFDocument3 paginiIASSC Yellow Belt Body of Knowledge1 PDFShivam SharmaÎncă nu există evaluări

- 2 The 20 Keys MethodologyDocument14 pagini2 The 20 Keys Methodologymilou88Încă nu există evaluări

- Lean ImplementationDocument28 paginiLean ImplementationJacob EdwardsÎncă nu există evaluări

- 6 SigmaDocument5 pagini6 SigmajaisonguruÎncă nu există evaluări

- Conversion Gate01 PDFDocument48 paginiConversion Gate01 PDFVenkatesh RadhakrishnanÎncă nu există evaluări

- Six Sigma Black Belt Case StudyDocument37 paginiSix Sigma Black Belt Case StudyHimang Jain0% (1)

- SIPOCDocument27 paginiSIPOCEliot Juarez100% (1)

- Agile Suitability FiltersDocument11 paginiAgile Suitability FiltersbinvinÎncă nu există evaluări

- An Evolutionary Model of Continuous Improvement Behaviour: John Bessant, Sarah Caffyn, Maeve GallagherDocument11 paginiAn Evolutionary Model of Continuous Improvement Behaviour: John Bessant, Sarah Caffyn, Maeve GallagherNathalia Cáceres100% (1)

- Green Belt Class NotesDocument11 paginiGreen Belt Class NotesPankaj LodhiÎncă nu există evaluări

- BPR MethodologiesDocument29 paginiBPR MethodologiesOsamah S. Alshaya100% (1)

- Six Sigma Black Belt Story BoardDocument7 paginiSix Sigma Black Belt Story BoardChantel DeniseÎncă nu există evaluări

- Six Sigma Seminar on Definition, History, Implementation and MethodsDocument19 paginiSix Sigma Seminar on Definition, History, Implementation and MethodsNishika chopra100% (2)

- Lean Six Sigma Green Belt OrientationDocument18 paginiLean Six Sigma Green Belt OrientationJyoti Thonte-BukkapatilÎncă nu există evaluări

- Application of Lean Six Sigma Methodology Application in Banking FINALDocument58 paginiApplication of Lean Six Sigma Methodology Application in Banking FINALimran24Încă nu există evaluări

- Lean Six Sigma PDFDocument28 paginiLean Six Sigma PDFMohammed Said MaamraÎncă nu există evaluări

- DFSS PDFDocument47 paginiDFSS PDFRajkumar VijÎncă nu există evaluări

- Lean IT Foundation Publication v1.0 PDFDocument14 paginiLean IT Foundation Publication v1.0 PDFracringandhiÎncă nu există evaluări

- 1.0 LSS Quality Files Define OpportunitiesDocument113 pagini1.0 LSS Quality Files Define OpportunitiesMurrell J RizonÎncă nu există evaluări

- Lean Six Sigma Green Belt Body of KnowledgeDocument5 paginiLean Six Sigma Green Belt Body of KnowledgeShijuÎncă nu există evaluări

- Six Sigma in Healthcare Value ChainDocument30 paginiSix Sigma in Healthcare Value ChainChowdhury Golam Kibria100% (2)

- Six Sigma Questions PDFDocument5 paginiSix Sigma Questions PDFramvamsyÎncă nu există evaluări

- Literature review on theories of agility and lean managementDocument21 paginiLiterature review on theories of agility and lean managementSundar Ranju0% (1)

- Six Sigma at Ford: Achieving World Class Performance through Reduced VariabilityDocument31 paginiSix Sigma at Ford: Achieving World Class Performance through Reduced Variabilitydaredevil19901Încă nu există evaluări

- Six Sigma Interview Questions and Answers UpdatedDocument14 paginiSix Sigma Interview Questions and Answers UpdatedVyas ZÎncă nu există evaluări

- ExcelTemplates Pareto-ChartDocument2 paginiExcelTemplates Pareto-ChartCristhian Junior Acosta ParadaÎncă nu există evaluări

- Concepts of Precision and Accuracy: Precise Process Is One With Accurate Process Is One WhichDocument27 paginiConcepts of Precision and Accuracy: Precise Process Is One With Accurate Process Is One WhichsareenaikbalÎncă nu există evaluări

- Yellow BeltDocument11 paginiYellow BeltRoberto BismarckÎncă nu există evaluări

- Gri 203 Indirect Economic Impacts 2016 PDFDocument9 paginiGri 203 Indirect Economic Impacts 2016 PDFIlhamAkbarN.NasutionÎncă nu există evaluări

- L3 Define GB VOC, Goals Metrics LadderDocument28 paginiL3 Define GB VOC, Goals Metrics Ladderhaidar khadourÎncă nu există evaluări

- 03 - BB Manual - Measure - v12 - 4 PDFDocument154 pagini03 - BB Manual - Measure - v12 - 4 PDFRicardo BravoÎncă nu există evaluări

- Six Sigma For Chemical Engineers: George LiebermannDocument39 paginiSix Sigma For Chemical Engineers: George LiebermannDave CÎncă nu există evaluări

- Measure Phase Quiz - Student December 2017Document8 paginiMeasure Phase Quiz - Student December 2017Mireya RochaÎncă nu există evaluări

- Value Stream Mapping Software A Complete Guide - 2020 EditionDe la EverandValue Stream Mapping Software A Complete Guide - 2020 EditionÎncă nu există evaluări

- Customer Satisfaction Levels A Complete Guide - 2020 EditionDe la EverandCustomer Satisfaction Levels A Complete Guide - 2020 EditionEvaluare: 1 din 5 stele1/5 (1)

- Process Improvement Simplified: A How-to-Book for Success in any OrganizationDe la EverandProcess Improvement Simplified: A How-to-Book for Success in any OrganizationÎncă nu există evaluări

- Intro to Financial Management Chapter 1 SummaryDocument11 paginiIntro to Financial Management Chapter 1 SummaryweeeeeshÎncă nu există evaluări

- Khandelwal Intern ReportDocument64 paginiKhandelwal Intern ReporttusgÎncă nu există evaluări

- Iron FoundationsDocument70 paginiIron FoundationsSamuel Laura HuancaÎncă nu există evaluări

- Gambaran Kebersihan Mulut Dan Karies Gigi Pada Vegetarian Lacto-Ovo Di Jurusan Keperawatan Universitas Klabat AirmadidiDocument6 paginiGambaran Kebersihan Mulut Dan Karies Gigi Pada Vegetarian Lacto-Ovo Di Jurusan Keperawatan Universitas Klabat AirmadidiPRADNJA SURYA PARAMITHAÎncă nu există evaluări

- MEE2041 Vehicle Body EngineeringDocument2 paginiMEE2041 Vehicle Body Engineeringdude_udit321771Încă nu există evaluări

- Cloud Computing Basics and Service ModelsDocument29 paginiCloud Computing Basics and Service ModelsBhupendra singh TomarÎncă nu există evaluări

- Lab 5: Conditional probability and contingency tablesDocument6 paginiLab 5: Conditional probability and contingency tablesmlunguÎncă nu există evaluări

- AccentureDocument11 paginiAccenturecentum1234Încă nu există evaluări

- Hamlet's Seven Soliloquies AnalyzedDocument3 paginiHamlet's Seven Soliloquies Analyzedaamir.saeedÎncă nu există evaluări

- Simple Future Vs Future Continuous Vs Future PerfectDocument6 paginiSimple Future Vs Future Continuous Vs Future PerfectJocelynÎncă nu există evaluări

- Julian's GodsDocument162 paginiJulian's Godsअरविन्द पथिक100% (6)

- Dreams FinallDocument2 paginiDreams FinalldeeznutsÎncă nu există evaluări

- Part 4: Implementing The Solution in PythonDocument5 paginiPart 4: Implementing The Solution in PythonHuỳnh Đỗ Tấn ThànhÎncă nu există evaluări

- Character Interview AnalysisDocument2 paginiCharacter Interview AnalysisKarla CoralÎncă nu există evaluări

- Puberty and The Tanner StagesDocument2 paginiPuberty and The Tanner StagesPramedicaPerdanaPutraÎncă nu există evaluări

- Inflammatory Bowel DiseaseDocument29 paginiInflammatory Bowel Diseasepriya madhooliÎncă nu există evaluări

- Future42 1675898461Document48 paginiFuture42 1675898461Rodrigo Garcia G.Încă nu există evaluări

- Application Performance Management Advanced For Saas Flyer PDFDocument7 paginiApplication Performance Management Advanced For Saas Flyer PDFIrshad KhanÎncă nu există evaluări

- DSA Interview QuestionsDocument1 paginăDSA Interview QuestionsPennÎncă nu există evaluări

- The Forum Gazette Vol. 2 No. 23 December 5-19, 1987Document16 paginiThe Forum Gazette Vol. 2 No. 23 December 5-19, 1987SikhDigitalLibraryÎncă nu există evaluări

- SS2 8113 0200 16Document16 paginiSS2 8113 0200 16hidayatÎncă nu există evaluări

- Inver Powderpaint SpecirficationsDocument2 paginiInver Powderpaint SpecirficationsArun PadmanabhanÎncă nu există evaluări

- Chapter 1Document11 paginiChapter 1Albert BugasÎncă nu există evaluări

- Virtuoso 2011Document424 paginiVirtuoso 2011rraaccÎncă nu există evaluări

- Grade 1 English For KidsDocument4 paginiGrade 1 English For Kidsvivian 119190156Încă nu există evaluări

- Komoiboros Inggoris-KadazandusunDocument140 paginiKomoiboros Inggoris-KadazandusunJ Alex Gintang33% (6)

- CSEC Geography June 2014 P1Document14 paginiCSEC Geography June 2014 P1Josh Hassanali100% (1)

- String length recommendations and brace height advice for Uukha bowsDocument1 paginăString length recommendations and brace height advice for Uukha bowsPak Cik FauzyÎncă nu există evaluări

- Multidimensional ScalingDocument25 paginiMultidimensional ScalingRinkiÎncă nu există evaluări

- M2M RF - RHNDocument3 paginiM2M RF - RHNNur Nadia Syamira Bt SaaidiÎncă nu există evaluări