Documente Academic

Documente Profesional

Documente Cultură

Designing and Detailing of Example Chimney

Încărcat de

Lalima ChatterjeeDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Designing and Detailing of Example Chimney

Încărcat de

Lalima ChatterjeeDrepturi de autor:

Formate disponibile

6.

Designing and Detailing of example chimney

6.1 Introduction

In the earlier chapters about analysis of the various loads that are incident on a

chimney, a number of calculations have been performed on some typical chimneys.

Those results will be brought together towards the design of a sample chimney.

Then the detailing of such a chimney is also shown.

In addition the last part of the chapter deals with the design of the footing for the

chimney.

6.2 Design of a chimney

The following table gives the list of the various parameters of a chimney and their

typical values.

Name of parameter Practical range Typical value

Slenderness ratio h/D

o

7-17 11

Taper ratio D

t

/D

o

0.3-1.0 0.6

Base diameter to thickness ratio

D

b

/t

b

20-50 35

Mean, base thickness ratio t

m

/t

b

0.3-0.8 0.55

Top mean thickness ratio t

t

/t

m

0.7-1.0 0.85

Table 6.1 Chimney parameters

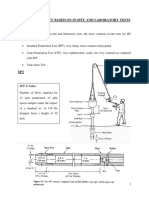

These values determine the section of the chimney which is given below with the

dimensions of the various parameters.

53

13.6 m

Top Thickness

0.3035 m

250 m

Base Thickness

0.65 m

22.72 m

Figure 6.1 The chimney

Checking the viability of the cross section

Taking the values of the forces as follows, which have been calculated in the

earlier chapters. It may be noted that this calculation is for the worst case of the wind

load.

Moment = 1552.8 MNm

Axial force = 175 MN

Calculating the values of m and n to be used in the design charts, assuming

M30 concrete.

m = 3.089

n = 3.955

The parameter value for use in the design charts without the value of the steel

comes to

54

Parameter = 13.83 (percentage of steel)

With 1% steel, using the curve with a parametric value of 15.56 the cross

section is safe.

The design

Fe415 steel

M30 concrete

Steel = 1%

Since the loads and other effects are totally reversible, the steel must be applied

equally on both faces of the chimney shell. Hence each face has 0.5 percent of the steel.

The detailing is done as follows and the figure is given later.

Using bars of 25mm diameter

Area of a meter length (circumferential) of the chimney = 6500mm

2

Area of reinforcing bar = 490.9 mm

2

Number of bars = 6.6

Spacing between the bars = 150 mm

Provide a cover of 75 mm on either face

This is the scheme to be followed for both the horizontal and the vertical

reinforcement at the base of the chimney. The changes to be done are given below

Curtailment

Since the chimney tapers with height, the area of concrete available decreases

along with the reinforcement requirement. Hence the vertical steel needs to be curtailed

in stages. The following scheme may be followed for the same.

Curtail 1 out of every 6 six bars at about a height of 120m. Curtail a second bar

out of the original six (now five) at a height of 200m.

The horizontal steel also needs to be changed with increase in height. Since

increasing the spacing alone is not a good option, keeping in mind the requirements of

55

temperature gradient and for preventing the surface cracks. Hence increase in spacing

needs to be coupled along with decrease in diameter.

Increase spacing to 180mm after a height of 100m. from a height of 150m use

20mm diameter steel bars at the initial spacing of 150mm. From 200m onwards use

20mm bars at 180mm center to center.

The following is a sketch of the reinforcement details at the base of the chimney.

150mm

56

650mm

Figure 6.2 Sectional plan view Vertical Reinforcement

Figure 6.3 Sectional elevation view horizontal Reinforcement

75mm

500mm

75mm

150mm

650mm

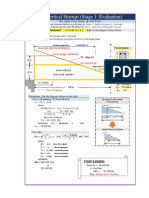

6.3 Design of foundation

Load effects

Deal load = 175 MN

Wind load = 1553 MNm

Earthquake load = 800 MNm (Not Critical)

For no tension design we consider

Z

M

A

W

=

Where the load is W, and the moment is M

The area A is given by

4

2

D

A t =

And the value of Z is

32

3

D

Z t =

Substituting and calculating

Diameter = 70.99m

Adopt a smaller diameter and not go for a no-tension approach.

Adopt a diameter of 60m

A rough diagram of the chimney base is shown here

57

Figure 6.4 The foundation (representation)

60m

19m - approx

Apportioning the chimney base

The stress distribution on the base of the chimney is calculated by trial and error

method. The maximum permissible stress of the soil is assumed to be 300 kN/mm

2

(assuming a rock strata)

The force diagram looks like

58

Figure 6.5 Load and eccentricity

The value of the eccentricity is 9.1m

With a liftoff are segment of 4 meters the resistance capacities are

F = 189476 kN

P = 39.18 from the left of the diagram. Hence the eccentricity of 9.1 meters (total

of 30+9.1 = 39.1m) is taken care of.

The loads are calculated keeping in mind the distribution of loads that occur on

the foundation as shown

Figure 6.6 Actual loading pattern

Calculating the maximum moment from the cantilevered part of the chimney

( )

2 2

2

16

3

1 ) ln( 2

8

b a w

a

b

b

a W

M

|

.

|

\

|

+ =

t

e P

Where

2

4

D

W

w

t

=

Moment acting at the base = 11 MNm

Required d

eff

= 1.795m

Assume 75mm cover

Use a total depth of 2m under the shell of the chimney

Taper the thickness of the foundation to 600mm at the end of the chimney

Reinforcement

Although the footing is circular, the reinforcement is provided orthogonal.

Calculating the steel requirement

Pt/100 = 3.5%

Provide 30mm bars at 100mm center to center

The moment acting on the other direction is due to the landfill and is not very

high. Hence providing a nominal reinforcement on the sloping side of the foundation.

Provide 12mm bars at 150 centers.

Also take a local thickening of the shell to take care of transfer of loads. Hence

the final detailing of the foundation and the base connection is given below

59

60

Figure 6.7 The foundation and the connection

Design of Staircase

A staircase of independent tread slabs can be constructed inside or outside the

chimney for the purpose of maintenance and cleaning etc. The cross section of such a

stair is given below. The end of the stair is embedded into the shell.

Figure 6.8 Design of staircase tread

6.4 - Conclusion

The example chimney has been designed and the reinforcement requirements and

other details worked out. The foundation for the chimney has been designed too. The

interaction curves developed were used in the process of design.

24mm bars along with

vertical reinforcement

Top of foundation

12mm @ 150mm c/c

Bottom of foundation

30mm @ 100mm c/c

8mm @ 220mm

310mm

1200mm

3-10mm

300mm

S-ar putea să vă placă și

- Chimney Windshield OperationDocument19 paginiChimney Windshield Operationsimple_aniÎncă nu există evaluări

- Slipformworksby Concretepump: SimplexlafargesonadihteamDocument12 paginiSlipformworksby Concretepump: SimplexlafargesonadihteamVinayaga MoorthiÎncă nu există evaluări

- Boq For BeamsDocument22 paginiBoq For BeamsgopaltryÎncă nu există evaluări

- Column Base Design:: Input DataDocument3 paginiColumn Base Design:: Input DataEng HatemÎncă nu există evaluări

- Boq For Road WorksDocument6 paginiBoq For Road WorksFaisal KhanÎncă nu există evaluări

- Behavior of Sbr-Latex Modified Polypropylene Fibre Einforced Railway SleepersDocument7 paginiBehavior of Sbr-Latex Modified Polypropylene Fibre Einforced Railway SleepersHasnain BukhariÎncă nu există evaluări

- Pre Bored Steel H Piling System Engineering EssayDocument6 paginiPre Bored Steel H Piling System Engineering EssayfieeeeyÎncă nu există evaluări

- Technical Manual 1 Slide Rail SystemDocument48 paginiTechnical Manual 1 Slide Rail SystemLalaine23Încă nu există evaluări

- Presentation On Analysis and Design of Small Reinforced Concrete BuildingsDocument29 paginiPresentation On Analysis and Design of Small Reinforced Concrete BuildingsPuneeth H GowdaÎncă nu există evaluări

- Slipform Chimney ConstructionDocument3 paginiSlipform Chimney ConstructionAniba SalahÎncă nu există evaluări

- Mat Foundation Fem Data: Width L: 9.50M Length: 10.0MDocument6 paginiMat Foundation Fem Data: Width L: 9.50M Length: 10.0MV.m. RajanÎncă nu există evaluări

- Slipform BrochureDocument8 paginiSlipform BrochureRen SalazarÎncă nu există evaluări

- Foundation DesignDocument84 paginiFoundation DesignIngeniero Estructural100% (2)

- Footing Calculation Rev1Document17 paginiFooting Calculation Rev1RobbyTeresaÎncă nu există evaluări

- STAAD PRO V8i Continuous BeamDocument6 paginiSTAAD PRO V8i Continuous BeamAnonymous nwByj9LÎncă nu există evaluări

- Footing Design According To BS8110 CodeDocument4 paginiFooting Design According To BS8110 CodeMohit VatsÎncă nu există evaluări

- Design Guidelines For Timber Ceiling Structures With Asbestos Cement Sheets or Light Timber Planks by Prof. S.R. de S. Chandrakeerthy 2005Document8 paginiDesign Guidelines For Timber Ceiling Structures With Asbestos Cement Sheets or Light Timber Planks by Prof. S.R. de S. Chandrakeerthy 2005ishanÎncă nu există evaluări

- Reference Description of Problem Values Units: Infomile SolutionsDocument3 paginiReference Description of Problem Values Units: Infomile SolutionsdhawanaxitÎncă nu există evaluări

- LintelsDocument3 paginiLintelsSA023Încă nu există evaluări

- Stabilization of Black Cotton Soil by Using Fly AshDocument52 paginiStabilization of Black Cotton Soil by Using Fly AshManohar ManuÎncă nu există evaluări

- Upn (Unp) European Standard U Channels, Upn Steel Profile Specifications, Dimensions, PropertiesDocument3 paginiUpn (Unp) European Standard U Channels, Upn Steel Profile Specifications, Dimensions, PropertiesshankerÎncă nu există evaluări

- Mechanical Columns Buckling FailureDocument19 paginiMechanical Columns Buckling FailurePraful Patil100% (1)

- Comparing Theoretical and Experimental Plastic Bending Moments of Steel Beams Under Different Support ArrangementsDocument12 paginiComparing Theoretical and Experimental Plastic Bending Moments of Steel Beams Under Different Support ArrangementsJohn Diete-Koki100% (1)

- Pile Cap DesignDocument4 paginiPile Cap DesignMohamed RifdyÎncă nu există evaluări

- 5.slab Design PDFDocument6 pagini5.slab Design PDFepe civilÎncă nu există evaluări

- RC Retaining Wall NoteDocument17 paginiRC Retaining Wall NoteMat Zoul100% (2)

- Steel Case Structure Design CalculationDocument21 paginiSteel Case Structure Design CalculationDe Dao Van100% (1)

- Analysis and Design of Elevated Rectangular Water Tank Using STAAD.ProDocument3 paginiAnalysis and Design of Elevated Rectangular Water Tank Using STAAD.ProHilary WatsonÎncă nu există evaluări

- Introduction to Pile FoundationsDocument34 paginiIntroduction to Pile FoundationsJake BloggerÎncă nu există evaluări

- BS8110 Simply Supported Slab DesignDocument8 paginiBS8110 Simply Supported Slab DesignRavish RavindraÎncă nu există evaluări

- STAAD ProDocument1 paginăSTAAD ProkamalnitrrÎncă nu există evaluări

- Software VerificationDocument621 paginiSoftware VerificationAngel Simon DiazÎncă nu există evaluări

- MOS Trial Trench WorkDocument20 paginiMOS Trial Trench Workg.chandra mohanÎncă nu există evaluări

- Schedule of Rates For ROAD WORKS With New ItemsDocument161 paginiSchedule of Rates For ROAD WORKS With New ItemsShabbir1989Încă nu există evaluări

- Project Output ESTIMATEDocument21 paginiProject Output ESTIMATEedgezy07Încă nu există evaluări

- Analysis of Bearing Capacity Driven PileDocument22 paginiAnalysis of Bearing Capacity Driven PileGEOMAHESHÎncă nu există evaluări

- Foundation Piles GuideDocument38 paginiFoundation Piles GuidediaidrisÎncă nu există evaluări

- Bearing Capacity Estimation from SPT and Settlement CalculationDocument14 paginiBearing Capacity Estimation from SPT and Settlement CalculationmazharÎncă nu există evaluări

- Calculation Summary of Pile FoundationDocument24 paginiCalculation Summary of Pile FoundationdedydarwisÎncă nu există evaluări

- BAR BENDING SCHEDULE FOR BRIDGE SLABDocument2 paginiBAR BENDING SCHEDULE FOR BRIDGE SLABTheodore Teddy KahiÎncă nu există evaluări

- Raft Foundations Bearing Capacity and Settlement Report PDFDocument9 paginiRaft Foundations Bearing Capacity and Settlement Report PDFixynnuddoÎncă nu există evaluări

- UNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNDocument7 paginiUNDER-REAMED PILES: KEY FACTS ABOUT CONSTRUCTION AND DESIGNAnonymous nwByj9LÎncă nu există evaluări

- Concrete Pull Out Check PDFDocument1 paginăConcrete Pull Out Check PDFMaliki MuhammedÎncă nu există evaluări

- Stair Geometry and TypesDocument13 paginiStair Geometry and TypesMakongoro MagembeÎncă nu există evaluări

- How to fix STAAD.Pro warnings and errorsDocument5 paginiHow to fix STAAD.Pro warnings and errorsMohdDanishÎncă nu există evaluări

- 5-Design of Raft FoundationDocument2 pagini5-Design of Raft FoundationheshamÎncă nu există evaluări

- Base Connection DesignDocument7 paginiBase Connection Designmsiddiq1Încă nu există evaluări

- Cost Comparison Between RCC Slab Steel Composite Slab Structure of G 5 Storied BuildingDocument4 paginiCost Comparison Between RCC Slab Steel Composite Slab Structure of G 5 Storied BuildingSuman PolleyÎncă nu există evaluări

- Calculation of Pile Bearing CapacityDocument3 paginiCalculation of Pile Bearing Capacityhayder1974Încă nu există evaluări

- TOS 5 Unit 3 Design of Columns Across Multiple FloorsDocument9 paginiTOS 5 Unit 3 Design of Columns Across Multiple FloorsKshitijaÎncă nu există evaluări

- Steel Tutorial 2,3,4,5,6,7Document7 paginiSteel Tutorial 2,3,4,5,6,7Sankalp LamaÎncă nu există evaluări

- Design of Portal Frames: by Dr. G.S.Suresh, Professor, Civil Engineering Department, NIE, MysoreDocument22 paginiDesign of Portal Frames: by Dr. G.S.Suresh, Professor, Civil Engineering Department, NIE, MysoreS Muneer HussainÎncă nu există evaluări

- Homework2 Confined RC Section AnalysisDocument13 paginiHomework2 Confined RC Section AnalysisQingzhi Liu100% (1)

- 7-Lecture-7 One Way Continuous SlabDocument39 pagini7-Lecture-7 One Way Continuous SlabRubab ZahraÎncă nu există evaluări

- Axial Load Column CapacityDocument3 paginiAxial Load Column Capacityaditya2053100% (1)

- ANNA UNIVERSITY M.E./M.Tech. DEGREE PRACTICAL EXAMINATION MAY/JUN 2012 ANALYSIS AND SIMULATION LABORATORYDocument10 paginiANNA UNIVERSITY M.E./M.Tech. DEGREE PRACTICAL EXAMINATION MAY/JUN 2012 ANALYSIS AND SIMULATION LABORATORYHareesh R IyerÎncă nu există evaluări

- Ce010 601 Design of Steel Structures Ce PDFDocument5 paginiCe010 601 Design of Steel Structures Ce PDFPrakash rubanÎncă nu există evaluări

- RC Stirrups DesignDocument11 paginiRC Stirrups DesignJaireÎncă nu există evaluări

- Column Base Design Types Slab Gusseted Transmit Loads FoundationsDocument6 paginiColumn Base Design Types Slab Gusseted Transmit Loads FoundationsPrantik MitraÎncă nu există evaluări

- RC2009 University of HongKong Reinforced Concrete DesignDocument29 paginiRC2009 University of HongKong Reinforced Concrete DesignApril IngramÎncă nu există evaluări

- Randolph1981 PDFDocument13 paginiRandolph1981 PDFSaeedÎncă nu există evaluări

- Strain Definition and Stress-Strain Diagram AnalysisDocument26 paginiStrain Definition and Stress-Strain Diagram AnalysisLuckyÎncă nu există evaluări

- Tianhong Yu 4196881Document331 paginiTianhong Yu 4196881Jad Antonios JelwanÎncă nu există evaluări

- Physics: Force and MotionDocument29 paginiPhysics: Force and MotionGoce Totti KuzeskiÎncă nu există evaluări

- Cable Tray ExcellentDocument27 paginiCable Tray Excellentraja kumarÎncă nu există evaluări

- Mathematics: Pearson Edexcel International Advanced LevelDocument32 paginiMathematics: Pearson Edexcel International Advanced LevelAhmed ZakkariaÎncă nu există evaluări

- SMA 431 Differential GeometryDocument96 paginiSMA 431 Differential GeometryJoshua AnnÎncă nu există evaluări

- Four-Point Bending Test of Determining Stress-StrainDocument4 paginiFour-Point Bending Test of Determining Stress-StrainyasminaÎncă nu există evaluări

- Product Design and Developmen T Project: Electric Facial Cleanser (Efc)Document50 paginiProduct Design and Developmen T Project: Electric Facial Cleanser (Efc)111 122Încă nu există evaluări

- NTS ATC Past PaperDocument7 paginiNTS ATC Past PaperBilal Maroof100% (1)

- 〈1229.1〉 Steam Sterilization by Direct ContactDocument3 pagini〈1229.1〉 Steam Sterilization by Direct ContactAhckarawinThummaneeÎncă nu există evaluări

- Enhancement of Natural Convection Heat Transfer FRDocument13 paginiEnhancement of Natural Convection Heat Transfer FRanfal amerÎncă nu există evaluări

- Non-Abelian Gradings of Lie AlgebrasDocument20 paginiNon-Abelian Gradings of Lie AlgebrasРоманÎncă nu există evaluări

- Flow Enhancement Tools: CentralizersDocument60 paginiFlow Enhancement Tools: Centralizersفؤاد ابوزيدÎncă nu există evaluări

- Chemical Energetics: Fill in The BlanksDocument13 paginiChemical Energetics: Fill in The BlanksAyush ChouhanÎncă nu există evaluări

- PHY5901 Final Presentation Yap Siew Hong GS59405Document24 paginiPHY5901 Final Presentation Yap Siew Hong GS59405Yap ChristinÎncă nu există evaluări

- Engleski Jezik Amar AscericDocument10 paginiEngleski Jezik Amar AscericArminÎncă nu există evaluări

- Miba Eddy GroovesDocument14 paginiMiba Eddy GroovesCésarÎncă nu există evaluări

- General Mathematics Paper 2, WASSCE (SC), 2017Document2 paginiGeneral Mathematics Paper 2, WASSCE (SC), 2017Emmanuel ThaddeusÎncă nu există evaluări

- EMW QuizDocument7 paginiEMW QuizNaresh Kumar100% (3)

- DESIGN OF CONCRETE STRUCTURES IIDocument100 paginiDESIGN OF CONCRETE STRUCTURES IIMd. Abdullah Al ArafatÎncă nu există evaluări

- Solutions Manual Modern Physics 6th EditDocument12 paginiSolutions Manual Modern Physics 6th EditUlisses OliveiraÎncă nu există evaluări

- ATLAS Smartrac SquareWave RFID Wet Inlay (M750) Data SheetDocument3 paginiATLAS Smartrac SquareWave RFID Wet Inlay (M750) Data SheetFREE BREADÎncă nu există evaluări

- Surface Vehicle Information: Rev. AUG81Document76 paginiSurface Vehicle Information: Rev. AUG81anupthattaÎncă nu există evaluări

- Computer Simulation of Ground Penetrating Radar Propagation Through A FreshwaterDocument22 paginiComputer Simulation of Ground Penetrating Radar Propagation Through A FreshwaterMahfooz HafezÎncă nu există evaluări

- Construction and Design of G+18 Apartment Building Using Tunnel Formwork Technology and Aluminium Formwork For Monolithic ConstructionDocument40 paginiConstruction and Design of G+18 Apartment Building Using Tunnel Formwork Technology and Aluminium Formwork For Monolithic ConstructionRahul KasaudhanÎncă nu există evaluări

- 13 Stress Strain 1Document20 pagini13 Stress Strain 1Razell RuizÎncă nu există evaluări

- ICC-ES Evaluation Report ESR-3904: - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilDocument15 paginiICC-ES Evaluation Report ESR-3904: - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilManuel TravezanÎncă nu există evaluări

- 30 Mainline Hydrotesting 111Document25 pagini30 Mainline Hydrotesting 111rexÎncă nu există evaluări

- Dge TXT ReducersDocument18 paginiDge TXT ReducersDênis DáyolÎncă nu există evaluări