Documente Academic

Documente Profesional

Documente Cultură

Jha of Painting

Încărcat de

Allan Camacho RegaladoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Jha of Painting

Încărcat de

Allan Camacho RegaladoDrepturi de autor:

Formate disponibile

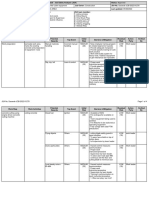

Job Hazard Analysis and Mitigation Form

Task or Employee: <name of Student under 18>

Routine

Non-routine

For instructions on filling out this form, please see the webpage at http://www-group.slac.stanford.edu/esh/general/hazanalysis/ . Routine JHAMs are kept by the employee and supervisor. Non-routine JHAMs are kept until the task is fully closed out (however, in case of an incident, the form is to be kept for use by the review team). All participants should sign in the Acknowledgement section on the last page.

Basic Job Steps

Potential Hazards

Controls & Recommended Actions

Training Associated Depending on length of work Safety Orientation (under 60 days) or Employee Orientation to ESH (EOESH) (over 60 days) If working in RCA area, General Employee Radiological Training required.

General Occupant Issues

1. 2. 3. 4.

egress enter hazardous area fire conserve natural resources

General cleaning activities around machine shop including: - Sweeping inside and outside - General cleaning and straightening up of shop including walls, floors, cabinets, drawers, and

1. Dust when sweeping 2. Objects in eyes when in shop. 3. Metal objects/chips caught on feet. 4. Paint chips in eyes 5. exposure to lead containing paint 6. exposure to paint 7. Disposal of hazardous materials.

1. Discuss with your supervisor the path of egress and where the emergency assembly point is located. Describe what the evacuation alarm for the building sounds like. 2. Discuss with your supervisor the many areas within a building that have entry requirements posted. Look for and comply with these requirements. Examples include safety glasses and closed-toed shoes when in the machine shop, dosimeter required when entering a radiologically controlled area (RCA). 3. In the event of fire, immediately contact 911 or 9-911 from a SLAC phone. 4. Conserve natural resources whenever possible including but not limited to energy, water, paper, fuel. 1. Keep dust to a minimum with sweeping technique. Allow dust to settle periodically. 2. Wear safety glasses and closed toed shoes whenever in the machine shop. 3. Wear closed-toed shoes whenever in the machine shop. 4. Wear safety glasses when scraping paint.

SLAC-I-730-0A06R-002-R001

Form Revision 6/29/2006

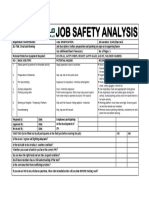

Job Hazard Analysis and Mitigation Form

Basic Job Steps Potential Hazards Controls & Recommended Actions

page 2 of 3

Training Associated

storage lockers. Painting (and prep for paint) of areas including walls, cabinets, lockers, floor, and storage containers.

Excludes any work on a metalworking machine.

Inventory of shop materials 1. Drop material on feet 1. 2. 3. 4. pinch fingers with tool or material carpel tunnel exposure to chemical (alcohol) flying objects in eye from compressed air 5. disposal of alcohol contaminated wipes/rags 6. work around radiological materials

Light Mechanical Inspection - use of calipers - use of micrometers - data entry - clean parts with solvent (alcohol) - clean parts with compressed air (usually canned air) - work area is located within a radiologiacally

5. Any paint that potentially contains lead must be tested prior to sanding or scraping. 6. For any chemical used by the student, review the MSDS with supervisor, and discuss with them how to obtain a copy on-line. Discuss with your supervisor what MSDSs are, why they are written, and how to read them. Ensure that you are fully aware of the health hazards of all materials being used. 7. Discuss with your supervisor the proper disposal of paint and other potentially hazardous waste (oily rags, used brushes, and empty or partly empty chemical and paint cans). If solvent based/epoxy type paint then they must go in a solvent solids debris waste container. 1. Wear closed toed shoes when risk of dropping heavy or sharp item on feet exists. 1. Obtain training from supervisor on the On the Job Training of proper use of tools including a any tools being used. demonstration on how it can pinch. 2. Take periodic breaks from repetitions activities For any chemical used by the student, review the MSDS with supervisor, and discuss with them how to obtain a copy on-line. Discuss with your supervisor what MSDSs are, why they are written, and how to read them. Ensure you

Form Revision 6/29/2006

SLAC-I-730-0A06R-002-R001

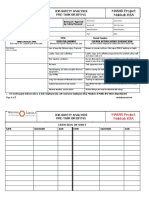

Job Hazard Analysis and Mitigation Form

Basic Job Steps Potential Hazards Controls & Recommended Actions

page 3 of 3

Training Associated

controlled area (RCA)

(Add rows by placing cursor in the right box of the last row and entering a tab.)

are fully aware of the health hazards of all materials being used. Wear safety glasses when using compressed air Ask supervisor where to dispose of alcohol contaminated wipes/rags. Must wear dosimeter when in area.

Acknowledgements

Print Name Supervisor: Participants: Signature Date

SLAC-I-730-0A06R-002-R001

Form Revision 6/29/2006

S-ar putea să vă placă și

- JSA Pipe Installation 2012Document2 paginiJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 paginiJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganÎncă nu există evaluări

- Sarawak JSA for Concrete CuttingDocument4 paginiSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailÎncă nu există evaluări

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Document4 paginiJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSÎncă nu există evaluări

- Job Safety Analysis for Brick Work, Tile and Glass RemovalDocument4 paginiJob Safety Analysis for Brick Work, Tile and Glass RemovalSushil Kumar YadavÎncă nu există evaluări

- JHA PaintingDocument9 paginiJHA Paintingperquino oasan100% (1)

- Bricks Messonary Work Job Hazard AnalysisDocument2 paginiBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 paginiJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyÎncă nu există evaluări

- JSA FOR Concerate PlacementDocument1 paginăJSA FOR Concerate Placementwahyu nugrohoÎncă nu există evaluări

- Jsa Grinding Welding Gas CuttingDocument3 paginiJsa Grinding Welding Gas CuttingRyanÎncă nu există evaluări

- Diesel Filling JSADocument6 paginiDiesel Filling JSAMohammed Ali QaziÎncă nu există evaluări

- Jsa For The Installation of I EamDocument5 paginiJsa For The Installation of I EamMohammed MinhajÎncă nu există evaluări

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocument3 paginiJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiÎncă nu există evaluări

- Rohan Builders (i) Pvt.Ltd. - Job Safety Analysis for Compound Wall PaintingDocument2 paginiRohan Builders (i) Pvt.Ltd. - Job Safety Analysis for Compound Wall PaintingEka100% (1)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 paginiJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelÎncă nu există evaluări

- Job Hazard Analysis (Earth Mounted Tank)Document8 paginiJob Hazard Analysis (Earth Mounted Tank)jay RÎncă nu există evaluări

- JS A Excavation Work For Electrical CableDocument3 paginiJS A Excavation Work For Electrical CableMohammed MinhajÎncă nu există evaluări

- Jsa PaintDocument2 paginiJsa PaintKhalid NaseemÎncă nu există evaluări

- Job Safety Analysis - Cone ErectionDocument7 paginiJob Safety Analysis - Cone ErectionMohammed MinhajÎncă nu există evaluări

- Job Hazard AnalysisDocument10 paginiJob Hazard AnalysisDave ImpresoÎncă nu există evaluări

- Maintaining Structural Beams SafelyDocument1 paginăMaintaining Structural Beams SafelySajith C PauloseÎncă nu există evaluări

- Jsa PaintingDocument1 paginăJsa Paintingclynne despiÎncă nu există evaluări

- JHA Handling Materials - ROMODocument3 paginiJHA Handling Materials - ROMOazroyremyÎncă nu există evaluări

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 paginiPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834Încă nu există evaluări

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 paginiJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- JHA PaintingDocument12 paginiJHA Paintingeast100% (1)

- JSA-010 Excavation Sampling PDFDocument5 paginiJSA-010 Excavation Sampling PDFArgaYurIstiawanÎncă nu există evaluări

- Jsa For Operating A BobcatDocument2 paginiJsa For Operating A Bobcatsoubhagya100% (2)

- SAND FILLING JSADocument5 paginiSAND FILLING JSAOgunwa Emmanuel0% (1)

- JSA For Lifting of RebarsDocument5 paginiJSA For Lifting of RebarsNiraÎncă nu există evaluări

- Jsa No-01 Container UnloadingDocument4 paginiJsa No-01 Container Unloadingsumith sÎncă nu există evaluări

- DewateringDocument1 paginăDewateringChandruÎncă nu există evaluări

- JSA-Construction Right of WayDocument3 paginiJSA-Construction Right of Wayfrancis_e_tan100% (5)

- 11 - JSA (Tower Crane) 12-9-06Document11 pagini11 - JSA (Tower Crane) 12-9-06sattiÎncă nu există evaluări

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 paginăJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- JSA For Scissor Lift, Rev-6Document2 paginiJSA For Scissor Lift, Rev-6Mahamudul HasanÎncă nu există evaluări

- JSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewDocument8 paginiJSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewHSE RHIÎncă nu există evaluări

- JHA - Survey WorksDocument3 paginiJHA - Survey WorksNazirul Syazwan100% (3)

- JSA - Foam RefillingDocument13 paginiJSA - Foam RefillingMuhammad Umar GondalÎncă nu există evaluări

- Rebar Job Hazard AnalysisDocument1 paginăRebar Job Hazard Analysisjoker batmanÎncă nu există evaluări

- MITISA HOLDINGS PILE CAP JSADocument8 paginiMITISA HOLDINGS PILE CAP JSAknabpshoÎncă nu există evaluări

- JSA - Installation of U G PipingDocument11 paginiJSA - Installation of U G PipingOws Anish100% (1)

- JSA Erection of Gathering TentDocument12 paginiJSA Erection of Gathering TentMuhammad Tariq100% (2)

- S/N Sequence of Basic Steps Potential Hazards Hazards Control Action byDocument7 paginiS/N Sequence of Basic Steps Potential Hazards Hazards Control Action byjavithÎncă nu există evaluări

- JSA for Drain Line ReplacementDocument5 paginiJSA for Drain Line ReplacementMadhan KannanÎncă nu există evaluări

- Job Hazard Analysis - Granite Surface PlateDocument2 paginiJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriÎncă nu există evaluări

- Form JSA Lifting CraneDocument6 paginiForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA ScaffoldingDocument2 paginiJSA ScaffoldingHrishikesh UnnikrishnanÎncă nu există evaluări

- 0 JsaDocument54 pagini0 JsaRavi AmarlapudiÎncă nu există evaluări

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 paginiJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadÎncă nu există evaluări

- JOB SAFETY ANALYSIS FOR VEHICLE REPAIR AND MAINTENANCEDocument4 paginiJOB SAFETY ANALYSIS FOR VEHICLE REPAIR AND MAINTENANCEba ratnaparkheÎncă nu există evaluări

- Jsa Tank CleaningDocument5 paginiJsa Tank CleaningASLAM MULANIÎncă nu există evaluări

- Installing Pneumatic Rubber Fenders Job Safety AnalysisDocument3 paginiInstalling Pneumatic Rubber Fenders Job Safety AnalysisIhwan AsrulÎncă nu există evaluări

- Lifting Bridge JSADocument8 paginiLifting Bridge JSAeslamÎncă nu există evaluări

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 paginiEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- JSA FORMAT For Materials LoadingDocument2 paginiJSA FORMAT For Materials LoadingVikky KumarÎncă nu există evaluări

- Work at Height Safety AnalysisDocument2 paginiWork at Height Safety AnalysiszebmechÎncă nu există evaluări

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 paginiJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrÎncă nu există evaluări

- BargeDocument4 paginiBargeanon_222140886Încă nu există evaluări

- Xxxpol / 65° Az 17.3 / 17.0 / 17.3 Dbi: DiplexedDocument2 paginiXxxpol / 65° Az 17.3 / 17.0 / 17.3 Dbi: DiplexedMahamoud HamoudÎncă nu există evaluări

- NJAPA-PaveXpress V2 PresentationDocument75 paginiNJAPA-PaveXpress V2 PresentationLuis MogrovejoÎncă nu există evaluări

- Espectrómetro FT-IR Nicolet Is 10Document1 paginăEspectrómetro FT-IR Nicolet Is 10Adriano BludegardÎncă nu există evaluări

- Fatigue Strength in Laser Welding of The Lap Joint: S.-K. Cho, Y.-S. Yang, K.-J. Son, J.-Y. KimDocument12 paginiFatigue Strength in Laser Welding of The Lap Joint: S.-K. Cho, Y.-S. Yang, K.-J. Son, J.-Y. KimbnidhalÎncă nu există evaluări

- Thermochemistry: Purpose of The ExperimentDocument20 paginiThermochemistry: Purpose of The ExperimentAngel LacsonÎncă nu există evaluări

- 2021 International Construction Benchmark Yearbook SAMPLE 1Document10 pagini2021 International Construction Benchmark Yearbook SAMPLE 1Familia GonzalezÎncă nu există evaluări

- Fire Load CalculationDocument6 paginiFire Load CalculationGunvant Patel91% (11)

- Projection Achievement ReportDocument8 paginiProjection Achievement ReportPskaruppiah KarupsÎncă nu există evaluări

- Drum Unloading SystemDocument2 paginiDrum Unloading SystemJas SumÎncă nu există evaluări

- High Precision Ball Bearings SolutionsDocument71 paginiHigh Precision Ball Bearings SolutionsTravis DavisÎncă nu există evaluări

- Corrosion Types and Prevention Methods in 40 CharactersDocument75 paginiCorrosion Types and Prevention Methods in 40 CharactersCipri Croitor0% (1)

- Commsys 2 2012 4Document47 paginiCommsys 2 2012 4AnuÎncă nu există evaluări

- Debug 1214Document15 paginiDebug 1214manhlong2009Încă nu există evaluări

- Nylatron GSM Technical Data SheetDocument1 paginăNylatron GSM Technical Data SheetgovindsrÎncă nu există evaluări

- List of Organisations SAR147 Apr2012Document2 paginiList of Organisations SAR147 Apr2012Tan Lian KiatÎncă nu există evaluări

- Strength Calculation and Dimensioning of Joints: Prepared By: Samson Yohannes Assistant ProfessorDocument45 paginiStrength Calculation and Dimensioning of Joints: Prepared By: Samson Yohannes Assistant ProfessorBK MKÎncă nu există evaluări

- Ms-Mech-10, Ms Fabrication of PipingDocument13 paginiMs-Mech-10, Ms Fabrication of PipingBabar Manzoor GhauriÎncă nu există evaluări

- Physics 110A: Electromagnetism: 1 Introduction and OverviewDocument4 paginiPhysics 110A: Electromagnetism: 1 Introduction and OverviewJoshua LinÎncă nu există evaluări

- What Is Transmission Channel ?Document12 paginiWhat Is Transmission Channel ?tusharÎncă nu există evaluări

- ASTM D5199 Nominal ThicknessDocument4 paginiASTM D5199 Nominal ThicknessCharleneTaneoÎncă nu există evaluări

- XT316 Air SockerDocument4 paginiXT316 Air Sockeryudiar djamaldilliahÎncă nu există evaluări

- Boiler FormulasDocument5 paginiBoiler FormulasAnonymous 6Mb7PZjÎncă nu există evaluări

- Michlaski Light Ultraviolet and InfraredDocument21 paginiMichlaski Light Ultraviolet and Infraredm_bohnÎncă nu există evaluări

- Barco RLM g5 PDFDocument114 paginiBarco RLM g5 PDFRainer AdelsbergerÎncă nu există evaluări

- Smart Test Series: 1-Circle The Correct Answer. (12x1 12)Document4 paginiSmart Test Series: 1-Circle The Correct Answer. (12x1 12)Dr. AyshaÎncă nu există evaluări

- 9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by LayoutDocument7 pagini9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by Layoutsuresh100% (1)

- A Review of Heat Transfer Enhancement Using Twisted Tape With and Without PerforationDocument9 paginiA Review of Heat Transfer Enhancement Using Twisted Tape With and Without PerforationIJIERT-International Journal of Innovations in Engineering Research and TechnologyÎncă nu există evaluări

- DISJUNTOR DE MÉDIA TENSÃO COOPER VN2-24E+Brochure PDFDocument16 paginiDISJUNTOR DE MÉDIA TENSÃO COOPER VN2-24E+Brochure PDFedmarrobÎncă nu există evaluări

- SSP421 Body BasicsDocument76 paginiSSP421 Body Basicsmamuko100% (3)