Documente Academic

Documente Profesional

Documente Cultură

27.IJAEST Vol No 7 Issue No 2 Starting Performance Investigation of Self Com Mutating PWM Current Source Inverter Fed Induction Motor Drive With Volts Hz Control Strategy Under MATLAB Environment 337 342

Încărcat de

helpdesk9532Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

27.IJAEST Vol No 7 Issue No 2 Starting Performance Investigation of Self Com Mutating PWM Current Source Inverter Fed Induction Motor Drive With Volts Hz Control Strategy Under MATLAB Environment 337 342

Încărcat de

helpdesk9532Drepturi de autor:

Formate disponibile

Starting Performance Investigation of Self

Commutating PWM Current Source Inverter Fed

Induction Motor Drive with Volts / Hz Control

Strategy under MATLAB Environment

S. M. Tripathi

Assistant Professor

Department of Electrical Engineering

Kamla Nehru Institute of Technology

Sultanpur 228118 (U.P.) India

mani_excel@yahoo.co.in

A. K. Pandey

Associate Professor

Department of Electrical Engineering

M.M.M. Engineering College

Gorakhpur 273010 (U.P.) India

akp1234@gmail.com

A. K. Srivastava

M.Tech. Student

Department of Electrical Engineering

Kamla Nehru Institute of Technology

Sultanpur 228118 (U.P.) India

aankit.srivastava32@gmail.com

AbstractIn this paper, an attempt has been made to investigate

analytically the starting performance of volts / Hz controlled,

self-commutating current source inverter-fed induction motor

drive. The closed-loop mathematical model of the complete drive

system is developed in the synchronously rotating d

e

-q

e

reference

frame. The starting performance of the drive is observed

analytically through MATLAB simulation.

Keywords-Current source inverter, induction motor drive, pulse

width modulation, starting performance, V / f control.

NOMENCLATURE

d, q Direct and quadrature axes

vas, vbs, vcs Phase voltages of the PWM inverter

e

ds

v

d-axis stator voltage in synchronously rotating

reference frame

e

ds

i

d-axis stator current in synchronous rotating

reference frame

e

qs

v

q-axis stator voltage in synchronously rotating

reference frame

e

qs

i

q-axis stator current in synchronously rotating

reference frame

e

dr

i

d-axis rotor current in synchronously rotating

reference frame

e

qr

i

q-axis rotor current in synchronously rotating

reference frame

ias, ibs, ics Line currents of PWM inverter

IDC DC link current

Iact Active component of stator current

*

act

I Reference active component of stator current

Ireact Reactive component of stator current

*

react

I

Reference reactive component of stator current

ee Switching frequency of the inverter

er

Rotor speed of the induction motor

ref

e

Reference speed

esl

Slip speed of the induction motor

*

sl

e

Reference slip speed

Iref Reference DC link current

Vinv Input voltage of the inverter

Vr Rectifier output voltage

Rf Resistance of DC link inductor

Lf Inductance of DC link inductor

R

s

Resistance of stator winding per phase

Ls Self-inductance of stator winding per phase

Rr Resistance of rotor winding per phase

Lr Self inductance of rotor winding per phase

Lm Mutual inductance per phase

L1 Ls Lr - Lm

2

C Capacitance per phase

J Moment of inertia in kg-m

2

B Viscous friction coefficient

| Pulse width of PWM rectifier

VLL Line-to-line input voltage of the rectifier

P Number of poles

Ic Instantaneous phase current of capacitor

Vs Instantaneous stator phase voltage

e

dc

i

d-axis capacitor current in synchronously rotating

reference frame

e

qc

i

q-axis capacitor current in synchronously rotating

reference frame

i

p

k

Proportional gain of current regulator

i

i

k

Integral gain of current regulator

s

p

k

Proportional gain of speed regulator

s

i

k

Integral gain of speed regulator

p Differential operator (d/dt) or complex frequency

k

current link DC

current line inverter l fundamenta of value Maximum

k1 Slope of stator active current (Iact) vs. slip speed (esl)

k2 Slope of stator reactive current vs. slip speed (esl)

k11

2

e

)] ( [ frequency angular Rated

phase per current capacitor of value Rated

I

J

A

E

S

T

S. M. Tripathi* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 7, Issue No. 2, 337 - 342

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 237

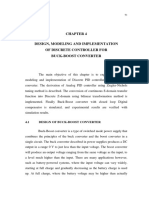

Figure 1. Variable speed self-commutating PWM current source inverter fed induction motor drive

I. INTRODUCTION

The speed control of induction motors is possible over a

wide range by feeding the motor through variable frequency

VSI or CSI. Due to the controlled current operation of the

inverter, slip-regulated CSI is preferred over VSI. The current

source at the front end makes the system naturally capable of

power regeneration [1][4]. In this paper, the closed loop

scheme of self-commutating current source inverter-fed

induction motor drive employing two PI regulators is

discussed.

II. SYSTEM DESCRIPTION

The CSI-fed induction motor drive consists of a three-phase

AC source, a PWM rectifier, a DC link smoothening reactor, a

current-controlled inverter, a three-phase squirrel cage

induction motor, and a three-phase capacitor bank as shown in

Figure 1. A fast-response speed-regulating drive can be

realized by incorporating PI regulators in the feedback loops

[5][8]. Two PI regulators are used one in the speed feedback

loop and the other in the current feedback loop.

The outer speed regulator compares the reference speed and

the actual rotor speed and processes the speed error to obtain

the reference slip speed (

*

sl

e ) which is required to estimate the

reference stator active current (

*

act

I ) and reference stator

reactive current (

*

react

I ) of the induction motor and hence,

reference DC link current (

ref

I ). It is also used in the

calculation of switching frequency (

e

e ) of the inverter. The

following mathematical equations are used:

) (

*

r ref

i

p sl

p

k

k

s

s

e e e

|

|

.

|

\

|

+ = (1)

t constan

*

1

*

+ =

sl act

k I e (2)

t constan

*

2

*

+ =

sl react

k I e (3)

*

sl r e

e e e + = (4)

The current PI regulator is used to regulate the error

between the reference DC link current and the actual DC link

current. The output of current PI regulator decides the pulse

widths of the PWM rectifier pulses and hence, controls the

output voltage of the pulse width modulated rectifier, which in

turn controls the DC link current.

The output voltage of the rectifier in terms of current

regulator parameters is given by the following expression:

) (

DC ref

i

p r

I I

p

k

k V

i

i

|

|

.

|

\

|

+ = (5)

The reference DC link current is determined using the

equation:

( ) ( )

|

|

.

|

\

|

|

.

|

\

|

+ =

k

I I I I

c react act ref

2

.

2

'

*

2

*

(6)

For the f V / control operation of the drive

c

I may be

expressed as

2

11 e c

k I e = (7)

where,

2

) (

) (

11

) (

rated e

rated c

I

k

e

=

I

J

A

E

S

T

S. M. Tripathi* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 7, Issue No. 2, 337 - 342

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 238

III. MATHEMATICAL MODEL OF THE DRIVE

The modeling of the modified CSI-fed induction motor

drive is carried out in synchronously rotating reference frame

for the following:

A. Three-phase PWM rectifier

B. Three-phase PWM inverter

C. DC link

D. Three-phase induction motor with load

E. Three-phase capacitor bank

A. Three-phase PWM Rectifier

The PWM rectifier output voltage depends on the number

of pulses per cycle and their widths. The converter is modeled

for twelve numbers of equal pulses per cycle. It leads to two

pulses per 60 each of | width. The average output voltage of

the PWM rectifier can be expressed as follows:

2

sin )

12

5

sin 4 (

2 3 | t

t

LL r

V V =

(8)

Since | is varied from 10% to 90% of (t/6) radians, it can

be approximated as follows:

sin (|/2 ) ~ (|/2)

Therefore,

) 2 / ( 218 . 5 |

LL r

V V =

(9)

B. Three-phase PWM Inverter

The fundamental component of the line currents of the

three-phase pulse width modulated inverter i

as

, i

bs

, and i

cs

forms

a balanced set of three-phase currents with maximum value as

I

as(max)

and can be expressed as follows:

I

as(max)

= k I

DC

(10)

where k is obtained through Fourier analysis of inverter line

current waveforms, and this is given by the following:

) ( current link D

current line inverter l fundamenta of value maximum

DC

I C

k =

The value of k depends on the operating frequency of the

inverter and varies from 0.8485 to 0.9970 for variation in

operating frequencies from 10 to 50 Hz. Since the inverter

output fundamental current peak is taken along the q

e

axis of

the reference frame, the transformed phase current equations in

the d

e

-q

e

reference frame are as follows:

i

0s

e

= 0 ;

DC

e

qs

kI i = ; 0 =

e

ds

i (11)

Assuming power loss in the inverter to be negligible, i.e.,

input power = output power, we can derive the following:

inv inv

I V =

cs cs bs bs as as

i v i v i v + + = ( )

e

ds

e

ds

e

qs

e

qs

i v i v +

2

3

(12)

Substituting the values of i

qs

e

, i

ds

e

, and I

inv

in terms of I

DC

,

the following equation is obtained:

inv

V =

e

qs

v k 5 . 1 (13)

C. DC Link

The rectifier output voltage V

r

is the sum of the inverter

input voltage

inv

V and DC link voltage, hence

( )

DC f f

e

qs r

I pL R V k V + + = 5 . 1 . (14)

D. Three-phase Induction Motor with Load

The induction motor can be modeled in the d

e

-q

e

reference

frame using the following assumptions:

- The three-phase stator windings of the motor are

balanced and sinusoidally distributed in space.

- The air gap flux is maintained at rated value.

- The motor line currents are sinusoidal due to

capacitor at the motor terminals.

- The DC link current is ripple free.

- The inverter switching transients are ignored.

- There is no core loss in the motor.

The motor can be described by fourth-order matrix equation

in d

e

-q

e

reference frame as follows:

+

+

+

+

=

e

dr

e

qr

e

ds

e

qs

r r r sl m m sl

r sl r r m sl m

m m e s s s e

m e m s e s s

e

ds

e

qs

i

i

i

i

pL R L - pL L

L pL R L pL

pL L - pL R L -

L pL L pL R

v

v

0

0

(15)

The electromagnetic torque equation of the motor is

expressed as follows:

e

T = ( )

e

ds

e

qr

e

dr

e

qs m

i i i i L .

P

.

2 2

3

(16)

The equation of motion of the drive is given by the

following:

r

r

l e

B

dt

d

J T T e

e

+ + =

(17)

The load torque equation is expressed as

( )

base r L l

T T e e . = . (18)

E. Three-phase Capacitor Bank

The capacitor current is related to the stator voltage of the

induction motor, as shown below:

dt

dv

C i

s

c

= (19)

Transforming (19) in the synchronously rotating reference

frame d

e

-q

e

, we have the following:

I

J

A

E

S

T

S. M. Tripathi* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 7, Issue No. 2, 337 - 342

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 239

( ) ( ) t v t v

dt

d

C t i t i

e

e

qs e

e

ds e

e

qc e

e

dc

sin cos sin cos = (20)

Differentiating (20) and comparing the terms on both sides,

d-axis and q-axis currents are expressed as follows:

) v C (pv i

e

qs e

e

ds

e

dc

= (21)

) v (pv C i

e

ds e

e

qs

e

qc

+ = (22)

IV. STARTING PERFORMANCE INVESTIGATION

The starting performance of the drive is investigated

through MATLAB simulation by analyzing the various

response curves of the drive for a step speed command of rated

value (298.29 rad/s) from standstill. The electromagnetic

torque and rotor speed characteristics settle to the steady state

values 1.245 N-m and 298.29 rad/s respectively in 3.24

seconds as depicted in Figures 23. The slip corresponding to

the rated speed (298.29 rad/s) and rated load torque (1.31 N-m)

is realized 5% as shown in Figure 4. The actual DC link current

acquires the reference value near the steady state as shown in

Figure 5. At steady state the DC link current is found to be

5.506 A. The V / f ratio is estimated from Figure 6 to be about

2.5322 volts / Hz except during transients for aforesaid rated

load torque condition. The RMS stator current / phase is found

to be 7.932 A during starting and settles to a value 3.108 A in

steady state as shown in Figure 7. Figure 8 shows the d-axis

and q-axis stator currents of which steady state values are

found 3.9342 A and -1.9609 A respectively. Similarly, the

RMS rotor current / phase is found to be 6.798 A during

starting and settles to a value 1.869 A in steady state as

depicted in Figure 9. Figure 10 shows the d-axis and q-axis

rotor currents of which steady state values are found -2.4725 A

and -0.9343 A respectively. Further, as shown in Figure 11, the

RMS capacitor current / phase is found to be 5.9567 A in

steady state. Figure 12 shows the d-axis and q-axis capacitor

currents / phase of which steady state values are found to be

-3.9342 A and 7.4504 A respectively. The RMS inverter output

current / phase is established 3.8811 A in steady state as shown

in Figure 13. The d-axis inverter output current is zero whereas

the q-axis inverter output current at steady state is found to be

5.4895 A as shown in Figure 14.

Figure 2. Electromagnetic torque vs. time

Figure 3. Rotor speed vs. time

Figure 4. Percentage slip vs. time

Figure 5. Reference DC link current vs. time (RED) and actual DC link

current vs. time (BLUE)

Figure 6. V / f ratio vs. time

I

J

A

E

S

T

S. M. Tripathi* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 7, Issue No. 2, 337 - 342

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 240

Figure 7. RMS stator current / phase vs. time

Figure 8. d-axis stator current vs. time (RED) and q-axis stator current vs.

time (BLUE)

Figure 9. RMS rotor current / phase vs. time

Figure 10. d-axis rotor current vs. time (RED) and q-axis rotor current vs.

time (BLUE)

Figure 11. RMS capacitor current / phase vs. time

Figure 12. d-axis capacitor current / phase vs. time (RED) and q-axis

capacitor current / phase vs. time (BLUE)

Figure 13. RMS inverter output current / phase vs. time

Figure 14. d-axis inverter output current vs. time (RED) and q-axis inverter

output current vs. time (BLUE)

I

J

A

E

S

T

S. M. Tripathi* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 7, Issue No. 2, 337 - 342

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 241

V. CONCLUSIONS

A closed-loop scheme incorporating speed and current PI

regulators for self-commutating PWM CSI-fed induction motor

drive with volts / Hz control strategy has been discussed. The

starting performance curves have been obtained through

MATLAB simulation. The settling time of the drive during

starting for the selected values of regulator parameters and

reference speed command of rated value (298.29 rad/s) has

been observed 3.24 seconds. The analysis of the starting

performance curves confirmed the satisfactory and fast

operation of the proposed closed-loop scheme of the drive

during starting.

APPENDIX

Name plate ratings of induction motor

1 hp, three-phase, 400 V, 50 Hz, four-pole, 1425 r.p.m., star

connected

Induction motor parameters

R

s

= 3.520 O R

r

= 2.780 O L

s

= 0.165 H

L

r

= 0.165 H L

m

= 0.150 H J = 0.01289 kg-m

2

DC link parameters

R

f

= 0.250 O, L

f

= 0.040 H

REFERENCES

[1] P. Agarwal and V. K. Verma, Performance Evaluation of Current

Source Inverter-fed Induction Motor Drive, Journals of Institution of

Engineers, Vol.72, pp. 209-217, February 1992.

[2] P.N. Enjeti, P.D. Ziogas and J.F. Lindsay, Programmed PWM

Technique to Eliminate Harmonics: A Critical Evaluation, IEEE

Transactions on Industry Applications, Vol. 26, No. 2, pp. 302-315,

March/April 1990.

[3] S.R. Bowes and R.I. Bullough, Optimal PWM Microprocessor

Controlled Current Source Inverter Drives, IEEE Proceedings, Vol.

135, Pt. B, No. 2, pp. 59-75, March 1988.

[4] Y. Xiao, B. Wu, S. Rizzo and R. Sotuden, A Novel Power Factor

Control Scheme for High Power GTO Current Source Converter,

Conference Record IEEE-IAS, pp. 865-869, 1996.

[5] A.K. Pandey, Pramod Agarwal and V.K. Verma, Optimal Capacitor

Selection for Modified Self-commutated CSI-fed Induction Motor

Drive, IEEE ISIE 2006, Montreal, Quebec, Canada, pp. 1166-1171,

July 9-12, 2006.

[6] P. Agarwal and V.K. Verma, Parameter Coordination of

Microcomputer Controlled CSI-fed Induction Motor Drive, IE (I)

Journal EL, Vol. 88, December 2007.

[7] Pramod Agarwal, V.K. Verma and A.K. Pandey, Performance

Evaluation of a Self-commutating CSI-fed Induction Motor Drive for

Different Operating Conditions, IETE Journal of Research, Vol. 54,

Issue 4, July/Aug. 2008.

[8] Pramod Agarwal, A.K. Pandey and V.K. Verma, Performance

Investigation of Modified Self-commutated CSI-fed Induction Motor

Drive, Asian Power Electronics Journal Vol. 3, No. 1, pp. 21-29, Sept

2009.

BIOGRAPHIES

Saurabh Mani Tripathi is presently working as

Assistant Professor of Electrical Engineering at

Kamla Nehru Institute of Technology, Sultanpur,

(U.P.), India. He obtained his B.Tech. degree in

Electrical & Electronics Engineering in 2006 and

did his M.Tech. in Electrical Engineering in 2009

from U.P. Technical University, Lucknow. He has

authored several books on Modern Control

System and Basic System Analysis. His areas of

current interest include electrical machines, control

systems, power electronics and electric drives.

Ashok Kumar Pandey received his Ph.D. degree in

Electrical Engineering from Indian Institute of

Technology, Roorkee in 2003. He did his M.Tech. in

Power Electronics, Electrical Machines and Drives

from Indian Institute of Technology, Delhi in 1995.

Currently, he is working as an Associate Professor

with the Department of Electrical Engineering at

M.M.M. Engineering College, Gorakhpur, (U.P.),

India. His areas of interest include power electronics,

electrical machines, and drives. He is a fellow of

Institution of Engineers (IE), India and Institution of Electronics and

Telecommunication Engineers (IETE), India.

Ankit Kumar Srivastava received his B.Tech.

degree in Electrical Engineering in 2008 from the

VBS Purvanchal University, Jaunpur (U.P.), India.

Currently, he is pursuing M.Tech. in Power

Electronics and Drives from Kamla Nehru Institute

of Technology, Sultanpur, (U.P.), India, affiliated to

G.B. Technical University Lucknow (U.P.), India.

His interests are in the area of power electronics

and drives.

I

J

A

E

S

T

S. M. Tripathi* et al. / (IJAEST) INTERNATIONAL JOURNAL OF ADVANCED ENGINEERING SCIENCES AND TECHNOLOGIES

Vol No. 7, Issue No. 2, 337 - 342

ISSN: 2230-7818 @ 2011 http://www.ijaest.iserp.org. All rights Reserved. Page 242

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- LS TTL DataDocument274 paginiLS TTL Datajfk777Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- DC DC ConverterDocument25 paginiDC DC ConverterpugazhendiraÎncă nu există evaluări

- 128 Pid 105 PDFDocument2 pagini128 Pid 105 PDFNaing Min Htun100% (1)

- Air Variable Capacitor From Scrap Aluminum SheetsDocument22 paginiAir Variable Capacitor From Scrap Aluminum SheetsEmilio EscalanteÎncă nu există evaluări

- Geopathic StressDocument17 paginiGeopathic Stressitounos100% (1)

- Bizhub Pro 920Document640 paginiBizhub Pro 920Abdul WahabÎncă nu există evaluări

- S000e Pakscan Systems GlossyDocument16 paginiS000e Pakscan Systems Glossyhizbi7Încă nu există evaluări

- 17.IJAEST Vol No 8 Issue No 1 Design, Simulation & Optimization of On Chip Amplifier For CCD Array 107 112Document6 pagini17.IJAEST Vol No 8 Issue No 1 Design, Simulation & Optimization of On Chip Amplifier For CCD Array 107 112helpdesk9532Încă nu există evaluări

- 6.ijaest Vol No 8 Issue No 1 Water Audit 039 048Document10 pagini6.ijaest Vol No 8 Issue No 1 Water Audit 039 048helpdesk9532Încă nu există evaluări

- 28.IJAEST Vol No 7 Issue No 2 An Intelligent Energy Efficient QoS Routing Scheme For WSN 343 346Document4 pagini28.IJAEST Vol No 7 Issue No 2 An Intelligent Energy Efficient QoS Routing Scheme For WSN 343 346helpdesk9532Încă nu există evaluări

- 29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354Document8 pagini29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354helpdesk9532Încă nu există evaluări

- Performance Analysis of Wireless MIMO System by Using Alamouti's Scheme and Maximum Ratio Combining Technique PDFDocument6 paginiPerformance Analysis of Wireless MIMO System by Using Alamouti's Scheme and Maximum Ratio Combining Technique PDFHikmah MiladiyahÎncă nu există evaluări

- 30.IJAEST Vol No 7 Issue No 2 An Intelligent Mobile Robot Navigation Technique Using RFID Technology 356 364Document10 pagini30.IJAEST Vol No 7 Issue No 2 An Intelligent Mobile Robot Navigation Technique Using RFID Technology 356 364helpdesk9532Încă nu există evaluări

- 14.IJAEST Vol No 8 Issue No 1 A New Image Encryption Approach Using Block Based Transformation Algorithm 090 096Document7 pagini14.IJAEST Vol No 8 Issue No 1 A New Image Encryption Approach Using Block Based Transformation Algorithm 090 096helpdesk9532Încă nu există evaluări

- 16.IJAEST Vol No 8 Issue No 1 Design of Matlab Based Automatic Speaker Recognition and Control System 100 106Document7 pagini16.IJAEST Vol No 8 Issue No 1 Design of Matlab Based Automatic Speaker Recognition and Control System 100 106helpdesk9532Încă nu există evaluări

- 15.ijaest Vol No 8 Issue No 1 Probability Analysis of Detection 097 099Document3 pagini15.ijaest Vol No 8 Issue No 1 Probability Analysis of Detection 097 099helpdesk9532Încă nu există evaluări

- 9.IJAEST Vol No 8 Issue No 1 THE ENHANCEMENT OF POWER QUALITY CONTROL STRATERGY FOR SINGLE PHASE INVERTERS IN DISTRIBUTED GENERATION SYSTEMS 058 064Document7 pagini9.IJAEST Vol No 8 Issue No 1 THE ENHANCEMENT OF POWER QUALITY CONTROL STRATERGY FOR SINGLE PHASE INVERTERS IN DISTRIBUTED GENERATION SYSTEMS 058 064helpdesk9532Încă nu există evaluări

- 12.IJAEST Vol No 8 Issue No 1 An Overview of Software Testing in Medical System and Medical Device Testing 080 085Document6 pagini12.IJAEST Vol No 8 Issue No 1 An Overview of Software Testing in Medical System and Medical Device Testing 080 085helpdesk9532Încă nu există evaluări

- 2.IJAEST Vol No 8 Issue No 1 "Bio Oxidation of Anaerobically Treated Dairy Wastewater" 010 018Document9 pagini2.IJAEST Vol No 8 Issue No 1 "Bio Oxidation of Anaerobically Treated Dairy Wastewater" 010 018helpdesk9532Încă nu există evaluări

- Ijaest: Adaptation of Watt's Indicator Mechanism in Altitude MeasurementDocument4 paginiIjaest: Adaptation of Watt's Indicator Mechanism in Altitude Measurementhelpdesk9532Încă nu există evaluări

- 11.IJAEST Vol No 8 Issue No 1 Wireless Sensor Network For Brain Computer Interface 075 079Document5 pagini11.IJAEST Vol No 8 Issue No 1 Wireless Sensor Network For Brain Computer Interface 075 079helpdesk9532Încă nu există evaluări

- 8.ijaest Vol No 8 Issue No 1 Synthesis of Nano Particle 054 057Document4 pagini8.ijaest Vol No 8 Issue No 1 Synthesis of Nano Particle 054 057helpdesk9532Încă nu există evaluări

- 7.IJAEST Vol No 8 Issue No 1 An Improvised Methodology For Hardware Software Co Verification of USB Subsystem 049 053Document5 pagini7.IJAEST Vol No 8 Issue No 1 An Improvised Methodology For Hardware Software Co Verification of USB Subsystem 049 053helpdesk9532Încă nu există evaluări

- 28.IJAEST Vol No 7 Issue No 2 An Intelligent Energy Efficient QoS Routing Scheme For WSN 343 346Document4 pagini28.IJAEST Vol No 7 Issue No 2 An Intelligent Energy Efficient QoS Routing Scheme For WSN 343 346helpdesk9532Încă nu există evaluări

- 1.IJAEST Vol No 8 Issue No 1 "Biomethanation of Dairy Waste Water Through UASB at Mesophilic Temperature Range" 001 009Document9 pagini1.IJAEST Vol No 8 Issue No 1 "Biomethanation of Dairy Waste Water Through UASB at Mesophilic Temperature Range" 001 009helpdesk9532Încă nu există evaluări

- 29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354Document8 pagini29.IJAEST Vol No 7 Issue No 2 Disposal of Solid Waste For Black Cotton Soil Stabilization 347 354helpdesk9532Încă nu există evaluări

- 26.IJAEST Vol No 7 Issue No 2 WAY TO IMPROVE K MEANS ALGORITHM BY USING VARIOUS ATTRIBUTES 330 336Document7 pagini26.IJAEST Vol No 7 Issue No 2 WAY TO IMPROVE K MEANS ALGORITHM BY USING VARIOUS ATTRIBUTES 330 336helpdesk9532Încă nu există evaluări

- 5.IJAEST Vol No 8 Issue No 1 Robotic Control Systems Based On Bio Inspired Multi Agent Systems 032 038Document7 pagini5.IJAEST Vol No 8 Issue No 1 Robotic Control Systems Based On Bio Inspired Multi Agent Systems 032 038helpdesk9532Încă nu există evaluări

- 30.IJAEST Vol No 7 Issue No 2 An Intelligent Mobile Robot Navigation Technique Using RFID Technology 356 364Document10 pagini30.IJAEST Vol No 7 Issue No 2 An Intelligent Mobile Robot Navigation Technique Using RFID Technology 356 364helpdesk9532Încă nu există evaluări

- 25.IJAEST Vol No 7 Issue No 2 Design Consideration of Interleaved Boost Converter For Fuel Cell Systems 322 329Document7 pagini25.IJAEST Vol No 7 Issue No 2 Design Consideration of Interleaved Boost Converter For Fuel Cell Systems 322 329helpdesk9532Încă nu există evaluări

- 24.IJAEST Vol No 7 Issue No 2 Imaging of Ionospheric Electron Density Profile Using The Modified Spherical Harmonic Analysis 319 322Document4 pagini24.IJAEST Vol No 7 Issue No 2 Imaging of Ionospheric Electron Density Profile Using The Modified Spherical Harmonic Analysis 319 322helpdesk9532Încă nu există evaluări

- 23.IJAEST Vol No 7 Issue No 2 Active Power Filter Based On Cascaded Transformer Multilevel Inverter 313 318Document6 pagini23.IJAEST Vol No 7 Issue No 2 Active Power Filter Based On Cascaded Transformer Multilevel Inverter 313 318helpdesk9532Încă nu există evaluări

- 22.IJAEST Vol No 7 Issue No 2 Simulation Studies On Dynamic Contact Force Between Mobile Robot Manipulator and Surrounding Environment 305 312Document8 pagini22.IJAEST Vol No 7 Issue No 2 Simulation Studies On Dynamic Contact Force Between Mobile Robot Manipulator and Surrounding Environment 305 312helpdesk9532Încă nu există evaluări

- 21.IJAEST Vol No 7 Issue No 2 A Comparison of Different Detection Algorithms in A MIMO System 301 304Document4 pagini21.IJAEST Vol No 7 Issue No 2 A Comparison of Different Detection Algorithms in A MIMO System 301 304helpdesk9532Încă nu există evaluări

- 19.IJAEST Vol No 7 Issue No 2 A New Approach To Diagnosis of Power Quality Problems Using Expert System 290 297Document8 pagini19.IJAEST Vol No 7 Issue No 2 A New Approach To Diagnosis of Power Quality Problems Using Expert System 290 297helpdesk9532Încă nu există evaluări

- 20.IJAEST Vol No 7 Issue No 2 Comparing Architecture Based Reliability Models 298 300Document3 pagini20.IJAEST Vol No 7 Issue No 2 Comparing Architecture Based Reliability Models 298 300helpdesk9532Încă nu există evaluări

- Strain Gauge Based Accelerometer PDFDocument13 paginiStrain Gauge Based Accelerometer PDFMarcell LandryÎncă nu există evaluări

- TeSys D - LC1D65AP7Document6 paginiTeSys D - LC1D65AP7PdfÎncă nu există evaluări

- 2.PID6281995 - IEEE PDF Express PassedDocument6 pagini2.PID6281995 - IEEE PDF Express PassedRitwik ChowdhuryÎncă nu există evaluări

- Cold-Junction-Compensated K-Thermocouple-to-Digital Converter (0°C To +1024°C)Document8 paginiCold-Junction-Compensated K-Thermocouple-to-Digital Converter (0°C To +1024°C)Виктор АнатольевичÎncă nu există evaluări

- Adjustable Frequency Dielectric Resonator Antenna: (Scientific Note)Document3 paginiAdjustable Frequency Dielectric Resonator Antenna: (Scientific Note)Liju TrÎncă nu există evaluări

- LG 32SL8000 Chassis LD91KDocument50 paginiLG 32SL8000 Chassis LD91KBiju PrestcomÎncă nu există evaluări

- KVS Study Modules for Class XII PhysicsDocument87 paginiKVS Study Modules for Class XII Physicspappu khanÎncă nu există evaluări

- Tv21usp Ee PDFDocument1 paginăTv21usp Ee PDFodilonsouzaÎncă nu există evaluări

- Alamada Electrical PlanDocument17 paginiAlamada Electrical PlanFedilino P. FornollesÎncă nu există evaluări

- Prosonic S FMU95: Technical InformationDocument24 paginiProsonic S FMU95: Technical InformationCarlos MoraÎncă nu există evaluări

- Extended Life Computer Grade CapacitorDocument2 paginiExtended Life Computer Grade CapacitorАндрей ПоляковÎncă nu există evaluări

- FY B.Tech Lab ManualDocument63 paginiFY B.Tech Lab ManualPranav GawaiÎncă nu există evaluări

- GW - HT 1500V - Datasheet-ENDocument2 paginiGW - HT 1500V - Datasheet-ENGabooÎncă nu există evaluări

- Test ReportDocument3 paginiTest ReportAnkur Chopra0% (1)

- A Smoke Detector Is A Smoke Sensing Device That Indicates FireDocument4 paginiA Smoke Detector Is A Smoke Sensing Device That Indicates FireshahroozÎncă nu există evaluări

- TdepDocument26 paginiTdepNitin Maurya75% (4)

- Clean Energy Trainer Experiment GuideDocument9 paginiClean Energy Trainer Experiment GuidePantheia DadpouÎncă nu există evaluări

- ESP Schedule for Shree Singaji TPP Units 3&4Document4 paginiESP Schedule for Shree Singaji TPP Units 3&4Director CommercialÎncă nu există evaluări

- Undergraduate Laboratory Examples For The Rtds Real-Time Digital SimulatorDocument59 paginiUndergraduate Laboratory Examples For The Rtds Real-Time Digital SimulatorLucas CasemiroÎncă nu există evaluări

- Valvulas Saturno 2011 PDFDocument2 paginiValvulas Saturno 2011 PDFJose Ignacio Ancalaf RainÎncă nu există evaluări

- Electrical Fuse MCQ Ebook PDFDocument26 paginiElectrical Fuse MCQ Ebook PDFshukla dhavalÎncă nu există evaluări

- Supervision RelayDocument3 paginiSupervision RelayBassem Mostafa100% (1)