Documente Academic

Documente Profesional

Documente Cultură

ELMAG

Încărcat de

thomazfabricioDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ELMAG

Încărcat de

thomazfabricioDrepturi de autor:

Formate disponibile

Elkem AS

Foundry Products Division Hoffsveien 65B P.O. Box 5211 Majorstuen NO-0303 OSLO Tel: +47 22 45 01 00 Fax: +47 22 45 01 52 www.foundry.elkem.com

Product Data Sheet Magnesium Ferrosilicon Nodularisers

1. Alloy Description Magnesium Ferrosilicon (MgFeSi) is a high quality nodulariser with carefully chosen calcium and aluminium contents within the beneficial range for ductile iron production. Calcium helps control the magnesium reactivity during treatment and low aluminium minimises pinhole problems with green-sand moulds. 2. Effect in Iron MgFeSi is the preferred alloy for nodularising ductile iron. For base iron free from harmful impurities, MgFeSi without cerium may be used. However, without the nucleating effect of cerium, chill may form in thin sections. Cerium and other rare earths effectively neutralise the harmful effects from subversive elements which may cause structural defects. 3. Application MgFeSi is produced in a variety of grades, some of which are listed. This allows each foundry the flexibility to select the alloy best suited for their treatment method and other needs. 4. Chemical analysis Elkem offers MgFeSi qualities in a variety of standard chemistries, some of which are shown in the table. Elkem can furthermore offer special qualities on demand. Please contact your local Elkem sales representative with any questions in this regard. 5. Sizes Available in sizes suitable for all foundry methods including ladle, in-the-mould, and flow through processes. 6. Packing The product is available in various forms of packing on request. 7. Physical Data Apparent density Bulk density Melting range Solubility: Water Mineral acids g/cm3 kg/m3 C(liquidus) C (solidus)

4.6 2250 1225 910

: Insoluble : Soluble, releases hydrogen

May form phosphine and arsine gas in contact with water, acids or bases.

Nodulariser %Si %Mg %La %Ca %RE* %Al %MgO Remag 3100 2.75 3.5 0.2 0.5 1.75 2.5 0.4 1.0 Elmag 5800 44 48 5.5 6.2 0.8 1.2 0.8 1.2 0.4 1.0 Lamet 5504 5.0 6.0 0.25 0.4 0.4 0.6 0.8 1.2 Max 0.45

*RE (Rare Earths) contains approximately 50% Ce, 25% La, 15% Nd, 5% Pr, minor amounts of Y and Sm.

1/2 Elmag, Lamet and Remag are registered trademarks owned by Elkem AS. Revised September 2006 Copyright Elkem AS

8. MgFeSi There are many ways to improve magnesium recoveries in ductile iron production. One is to reduce the magnesium content of the nodulariser, another is to increase the uniformity of the structure of the MgFeSi alloy. This is due to the better control of the Mg2Si phase in the nodulariser (see illustration below). By the special technique of casting thin layers in chill molds, Elkem produces a magnesium-ferrosilicon having a uniform magnesium content. This uniform chemistry and sizing ensure reproducibility and high magnesium yield with less flare.

9. Local Elkem representative For further information please contact our sales representative. Our specialists will help you solve any individual problems. 10. Health, Safety and Environment Refer to Elkem Safety Data Sheet No. 103. 11. Brochure See Elkem brochure Magnesium Ferrosilicon

Example of thin cast homogenous microstructure of MgFeSi with 5% Mg, 1% RE and 1% Ca.

2/2

S-ar putea să vă placă și

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocument8 paginiRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazÎncă nu există evaluări

- S.G IronDocument6 paginiS.G IronQasim BarkatÎncă nu există evaluări

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocument2 paginiPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646Încă nu există evaluări

- Selection of Inoculants For Grey Cast IronDocument2 paginiSelection of Inoculants For Grey Cast Ironarnaldorcr8646Încă nu există evaluări

- SG Iron ProductionDocument20 paginiSG Iron ProductionShreyashri Nayak100% (1)

- S.G. Iron : MouldingDocument11 paginiS.G. Iron : MouldingsureshbabuamalaÎncă nu există evaluări

- MagnesiumDocument3 paginiMagnesiumIsidoro LópezÎncă nu există evaluări

- SG Iron CompositionDocument5 paginiSG Iron CompositionamirgukharÎncă nu există evaluări

- Technical InformationDocument78 paginiTechnical InformationCarlos Barrachina Martínez100% (2)

- Fading of Nodularity in Ductile IronDocument2 paginiFading of Nodularity in Ductile Ironarnaldorcr8646100% (4)

- Common Metallurgical Defects in Ductile Iron English (1Document1 paginăCommon Metallurgical Defects in Ductile Iron English (1sateeshkori100% (2)

- Elkem 13 Compacted Graphite IronDocument2 paginiElkem 13 Compacted Graphite Ironmarcotulio123Încă nu există evaluări

- Elkem 07 Magnesiun Contents in Ductile IronDocument2 paginiElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123Încă nu există evaluări

- Factors Influencing The Recovery and Addition of MagnesiumDocument4 paginiFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Încă nu există evaluări

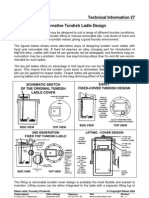

- Elkem 10 Tundish Cover Ladle NodularizationDocument2 paginiElkem 10 Tundish Cover Ladle Nodularizationmarcotulio123Încă nu există evaluări

- Late Metal Stream InoculationDocument2 paginiLate Metal Stream Inoculationarnaldorcr8646Încă nu există evaluări

- Elkem 05 Inoculation MechanismsDocument2 paginiElkem 05 Inoculation Mechanismsmarcotulio123Încă nu există evaluări

- Alternative Tundish Ladle DesignDocument2 paginiAlternative Tundish Ladle Designarnaldorcr8646Încă nu există evaluări

- Sampling of Liquid Cast IronDocument2 paginiSampling of Liquid Cast Ironarnaldorcr8646Încă nu există evaluări

- Seminar S.G IronDocument32 paginiSeminar S.G Ironravikataria02Încă nu există evaluări

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFDocument23 pagini1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Ferroalloy Storage Bin DesignDocument2 paginiFerroalloy Storage Bin Designarnaldorcr8646Încă nu există evaluări

- O HC HCDocument101 paginiO HC HCIndustrial Infra Jobs100% (1)

- Common Metallurgical Defects in Grey Cast IronDocument9 paginiCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- Shrinkage in Ductile IronDocument5 paginiShrinkage in Ductile Ironkarthikkanda100% (1)

- Chunky GraphiteDocument16 paginiChunky GraphitesachinguptachdÎncă nu există evaluări

- Oxidation of Ferrosilicon Alloys During StorageDocument1 paginăOxidation of Ferrosilicon Alloys During Storagearnaldorcr8646Încă nu există evaluări

- Magnesium Contents in Ductile IronDocument2 paginiMagnesium Contents in Ductile Ironarnaldorcr8646Încă nu există evaluări

- Shrinkage in Iron CastingsDocument10 paginiShrinkage in Iron CastingskarthikkandaÎncă nu există evaluări

- Cast Iron SolidificationDocument12 paginiCast Iron Solidificationkatchani123100% (1)

- Surface Graphite Degeneration in Ductile Iron CastDocument8 paginiSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarÎncă nu există evaluări

- Effect of Minor and Trace Elements in Cast IronDocument2 paginiEffect of Minor and Trace Elements in Cast IronsachinguptachdÎncă nu există evaluări

- AntiSegregation HopperDocument5 paginiAntiSegregation Hoppermecaunidos7771Încă nu există evaluări

- Effect of Minor and Trace Elements in Cast IronDocument2 paginiEffect of Minor and Trace Elements in Cast IronsachinguptachdÎncă nu există evaluări

- Home About Us Products Quality Control Representation Useful Links Contact UsDocument5 paginiHome About Us Products Quality Control Representation Useful Links Contact Ustushak mÎncă nu există evaluări

- Ductile Dross Formation MonitoringDocument27 paginiDuctile Dross Formation MonitoringsachinguptachdÎncă nu există evaluări

- Heat Conservation in Liquid IronDocument2 paginiHeat Conservation in Liquid Ironarnaldorcr8646Încă nu există evaluări

- Common Metallurgical Defects in Ductile Iron EnglishDocument1 paginăCommon Metallurgical Defects in Ductile Iron EnglishedgarestevessÎncă nu există evaluări

- Recommended Target Analysis For Ductile IronDocument2 paginiRecommended Target Analysis For Ductile Ironarnaldorcr8646100% (2)

- Effect of Bismuth in Ductile IronDocument4 paginiEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Elkem 19 Aluminum in Cast IronDocument2 paginiElkem 19 Aluminum in Cast Ironmarcotulio123Încă nu există evaluări

- Carbide Dissolution in Thin Wall Ductile Iron PDFDocument8 paginiCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdÎncă nu există evaluări

- Niobium in Cast IronDocument13 paginiNiobium in Cast IronTayyab HussainÎncă nu există evaluări

- Elkem 10 Tundish Cover Ladle Nodularization PDFDocument2 paginiElkem 10 Tundish Cover Ladle Nodularization PDFAnonymous iztPUhIiÎncă nu există evaluări

- Elkem 04 Inoculation PracticesDocument2 paginiElkem 04 Inoculation Practicesmarcotulio123Încă nu există evaluări

- Grey Cast IronDocument43 paginiGrey Cast IronVasanth PrasadÎncă nu există evaluări

- 26-ELKEM Poster-Graphite Structures in Cast IronsDocument1 pagină26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENÎncă nu există evaluări

- Offsetting Macro-Shrinkage in Ductile IronDocument13 paginiOffsetting Macro-Shrinkage in Ductile IronmetkarthikÎncă nu există evaluări

- Lecture - Magnesium Alloys - Hue'sDocument29 paginiLecture - Magnesium Alloys - Hue'sMurali ManuÎncă nu există evaluări

- 23 Factors Influencing The Recovery and Addition of Magnesium in Ductile Iron Ladle Treatment Processes PDFDocument4 pagini23 Factors Influencing The Recovery and Addition of Magnesium in Ductile Iron Ladle Treatment Processes PDFSIDDHARTH GOYALÎncă nu există evaluări

- Mapa MetalograficoDocument1 paginăMapa MetalograficoBreno DellaÎncă nu există evaluări

- T-18 - Recommended Target Analysis For Ductile IronsDocument2 paginiT-18 - Recommended Target Analysis For Ductile Ironscrazy dÎncă nu există evaluări

- 3 Inoculant Alloy CompositionDocument2 pagini3 Inoculant Alloy CompositionAdams GodoyÎncă nu există evaluări

- Composition of Grey Cast IronDocument2 paginiComposition of Grey Cast IronPranil GhatageÎncă nu există evaluări

- S.G.Iron GuidelinesDocument28 paginiS.G.Iron GuidelinesTarun Chakraborty100% (3)

- Compression MountingDocument12 paginiCompression MountingEden HazardÎncă nu există evaluări

- Effect of Aloying Elements in Cast IronDocument2 paginiEffect of Aloying Elements in Cast IronsachinguptachdÎncă nu există evaluări

- Continuous casting The Ultimate Step-By-Step GuideDe la EverandContinuous casting The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Production Aspects of Spheroidal Graphite Iron: CAFP - 2008 Special Metal Casting and Forming ProcessesDocument14 paginiProduction Aspects of Spheroidal Graphite Iron: CAFP - 2008 Special Metal Casting and Forming ProcessesAswini Kumar DashÎncă nu există evaluări

- Megaworld CanopyDocument6 paginiMegaworld CanopyNanam ZaerÎncă nu există evaluări

- Aker Drilling Riser Brazil: Presenter Marcelo Coraça Project Manager June/2010Document45 paginiAker Drilling Riser Brazil: Presenter Marcelo Coraça Project Manager June/2010Tiago Sten FreitasÎncă nu există evaluări

- Cost Confirmation Table: Final Exams Assignment ModelDocument7 paginiCost Confirmation Table: Final Exams Assignment ModelJewelyn C. Espares-CioconÎncă nu există evaluări

- SAP MM (Procurement) FUNCTIONAL CONSULTANT - Support ProjectDocument2 paginiSAP MM (Procurement) FUNCTIONAL CONSULTANT - Support Projectsonu8700Încă nu există evaluări

- Cerrejón Achieves World-Class Coal Mining With End-To-End Gemcom Minex SolutionDocument3 paginiCerrejón Achieves World-Class Coal Mining With End-To-End Gemcom Minex SolutionJorge Eliecer Acevedo SilvaÎncă nu există evaluări

- Bking Process SopDocument4 paginiBking Process Sopjoly67% (6)

- 06 Festool Catalog Final 72Document100 pagini06 Festool Catalog Final 72demo1967Încă nu există evaluări

- Infra GDocument10 paginiInfra GMeynard AspaÎncă nu există evaluări

- S6-Fintech Case PDFDocument17 paginiS6-Fintech Case PDFVRÎncă nu există evaluări

- Q1 Reconciliation by SKUsDocument38 paginiQ1 Reconciliation by SKUsErineÎncă nu există evaluări

- Sample Welding Summary FormatDocument1 paginăSample Welding Summary Formatalex sanjanÎncă nu există evaluări

- IhhbbvDocument8 paginiIhhbbvvanÎncă nu există evaluări

- AS9100 in Plain EnglishDocument30 paginiAS9100 in Plain EnglishhimanshunepalÎncă nu există evaluări

- CODEMagazine 2019 SeptemberOctoberDocument76 paginiCODEMagazine 2019 SeptemberOctoberAnonymous ze7rq2QKyÎncă nu există evaluări

- Wire Rope DefectsDocument5 paginiWire Rope DefectsAnonymous ntE0hG2TPÎncă nu există evaluări

- Offshore Pipeline Construction Volume TwoDocument339 paginiOffshore Pipeline Construction Volume Twobregaing100% (12)

- P-Mech Exhibitors ListDocument5 paginiP-Mech Exhibitors Listsuraj pandeyÎncă nu există evaluări

- Industrial Compressor Seires PDFDocument6 paginiIndustrial Compressor Seires PDFabhi_mohit2005Încă nu există evaluări

- Application Design Course BookDocument228 paginiApplication Design Course BookSabrian JufelindoÎncă nu există evaluări

- IKEA Industry Energy Saving Handbook PDFDocument133 paginiIKEA Industry Energy Saving Handbook PDFMARIUS GOVOREANUÎncă nu există evaluări

- Shaktivell M.letchumanan Dd160012 ReportDocument56 paginiShaktivell M.letchumanan Dd160012 ReportShaktivell LetchumananÎncă nu există evaluări

- NZS 3104 - Specification For Concrete ConstructionDocument43 paginiNZS 3104 - Specification For Concrete ConstructionRihab AbukhdairÎncă nu există evaluări

- Opm IV ModuleDocument18 paginiOpm IV ModuleSharma VishnuÎncă nu există evaluări

- EClerx Corporate Presentation - KMDocument15 paginiEClerx Corporate Presentation - KMSantanu S JoshiÎncă nu există evaluări

- Orlaco CatalogueDocument10 paginiOrlaco CataloguencthanhckÎncă nu există evaluări

- Pipeline Integrity ManagementDocument44 paginiPipeline Integrity Managementnani1983100% (4)

- SCA121T-D09 Product Specification 8270700A0Document5 paginiSCA121T-D09 Product Specification 8270700A0Crystal KingÎncă nu există evaluări

- Writing A Quality Policy StatementDocument2 paginiWriting A Quality Policy StatementKannan EsakkimuthuÎncă nu există evaluări

- Max Carporate ProfileDocument35 paginiMax Carporate ProfileSachin KothariÎncă nu există evaluări

- Manual M250 M370 M400Document222 paginiManual M250 M370 M400Carlos Quispe100% (1)