Documente Academic

Documente Profesional

Documente Cultură

Ice Blasting

Încărcat de

Abigith BabyDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ice Blasting

Încărcat de

Abigith BabyDrepturi de autor:

Formate disponibile

Seminar Report on Ice Blasting

1. ICE BLASTING

1.1 INTRODUCTION:Ice blasting is a simple process that uses compressed air and ice crystals, shot through a hose and directed with a nozzle, a fine powerful mist is blasted onto a surface, acting like a chisel to remove debris. Ice blasting is a nonabrasive, cleaning process that uses ordinary tap water, compressed air and electricity to create an environmentally friendly, cost effective method to address a variety of cleaning needs.

1.2 HISTORY: The Department of National Defence in Canada contracted Dr. Sam Visaisouk to determine the feasibility of ice blasting for cleaning in confined spaces such as inside ships. The prospect of a dustless abrasive blasting process was very appealing on environmental and worker safety compliance grounds. This effort led to the first operating commercial ice blast machine in 1992. These ice blast machines had complex operating system controls and required frequent defrosting as very cold air was used for fluidizing and transporting ice particles from source to nozzle. At that time, any ice blockages were attributed to partial melting of ice particles, which would favour agglomeration. The use of very cold fluidizing air was deemed absolutely necessary. Periodic system defrosting was required as a result. During this period, other methods of ice blast were introduced elsewhere. Gary Settles of Penn State University patented a process in which a cryogenic fluid froze atomized water in a nozzle for blasting. A French version (briefly licensed by Schlick) utilized liquid nitrogen to freeze small water droplets to form ice particles for blasting. Both of these processes relied on cryogenic fluid at very low temperatures and could not be easily scaled up for robust industrial requirements. In 1996 Sam Visaisouk took a drastic change in the method of producing and fluidizing ice particles that resulted in patent US5, 913,711. He and Norm Fisher later

__________________________________________________________________ 1

Seminar Report on Ice Blasting

produced a working model, patents US6, 001,000 and US6, 270,394. This breakthrough method remains the base of the state of the art ice blast systems to date till 2003.

1.3 BLASTING IN GENERAL

Blasting refers to a high-speed impact of a projectile on a target. The projectile can be either discrete, as in solid media blasting, or continuous, as in water blasting. A simple impact phenomenon involves 2 bodies. The projectile normally called the blast media can be spherical or angular, large or small, hard or soft, solid or liquid and projected at a variety of speed and angle towards the target. In general the user has no choice in terms of nature of target the users choice is in the media property and condition of blasting.

a) Abrasive Blasting

In applications where erosion is to be controlled, solid media of low abrasivity such as plastic media, starch media, glass beads, etc. are used. For solid media of low abrasivity, the impact action is mainly displacement. One aspect of solid media blasting is the generation of dust and secondary solid waste from spent media. Therefore, abrasive blasting is not a cleaning process.

b) Water blasting

Water Blasting is non-abrasive therefore its applications relate mainly to cleaning. Although at very high pressures, water is used for cutting as in water jetting. For effective cleaning, normally detergents or other cleaning chemicals are added to the water. The impact action is primarily rinsing. In many applications the water is recycled, thereby requiring water treatment as additional process and cost. Generally water blast uses a large volume of water, in the range of 1000-2500 Liters per hour. The treatment cost for such a high volume can be considerable.

c) Ice Blasting: Ice blast is a cleaning technology which is essentially a hybrid between abrasive (i.e. sand) and non-abrasive (i.e. water) types. Because ice is

__________________________________________________________________ 2

Seminar Report on Ice Blasting

a phase change material, it cleans as a solid, then deforms on impact and performs a scrubbing and rinsing action. No other blast cleaning material can work in this fashion.

1.4 Ideal Blast - Clean but No Damage

In an ideal cleaning application, the deposit is completely removed with no damage to the substrate. It means that no such process should be used which will have abrasive action on the surface of finished components as it will deteriorate the finished surface of the components of which deburring is to be done.

Fig. 2 Ideal Blasting 1.5 ABOUT ICE BLASTING

1.5.1 Ice as media Ice is a phase change media. Ice starts as a solid and changes into a liquid. Therefore it possesses the combined characteristics of both solid and liquid blasts. Ice is not abrasive, therefore is only marginal in erosion applications. Erosion by ice blast is a result of impact fracture, not abrasive action. Being a phase change material, ice does not generate dust on impact and does not require a large volume to do useful work.

1.5.2 Ice: - A phase changing media Ice particles will change phase at normal working temperatures, therefore are ideally suited as a blast cleaning agent. As a phase change solid, ice particles moving at high speed can perform impact cleaning work before phase change, during phase change and after phase change. Fig. 3 Change of Phase

__________________________________________________________________ 3

Seminar Report on Ice Blasting

1.5.3 Deburring mechanism in ice blasting:-

1. Before Phase Change - Displace

Ice particles are solids possessing momentum to displace contamination on a target. Displacement results when ice particle momentum exceeds the inertia of the contamination.

2. During Phase Change - Scrub

Ice particles exert a pressure against the surface as it deforms, providing a strong icesurface interaction whereby minute amounts of contaminations can be scrubbed away. At a blast pressure of about 7 bar, this scrubbing pressure has been estimated to be approximately 300 bar

3. After phase change Flush

Ice particles melt into water to rinse away removed contamination. The conversion of kinetic energy to pressure energy enables to flush away the scrubbed debris. This conversion adds the features of water deburring to the process. Thus having a two in one effect at the same cost

1.6 WORKING: In ice blast, ice particles are accelerated by a stream of high velocity of air to do impact cleaning work. Ice particles are not free flowing and will pack and agglomerate when stationary. For ice blast to work readily, ice particles must be created and consumed continuously in a dynamic state. An ice blast machine is ready for work within seconds of pushing the start button. Ice particles are produced continuously at a rate of 200 pounds per hour. Using a two hose system, ice particles are transported through a low pressure hose to the blasting nozzle

__________________________________________________________________ 4

Seminar Report on Ice Blasting

where a second higher pressure hose delivers up to 200 psi (pounds per square inch) pressure to accelerate the ice particles towards the target surface. The solid ice particles displace surface contaminants through the energy from the impact and through the lateral deformation of the ice particles. At the heart of the ice blast technology is the scrub and flush cleaning that takes place when the ice crystals impact onto a substrate. Ice crystals deform to scrub on impact, and after impact melt into water to flush away debris. Ice blasting uses up to 20 gallons per hour. Further, upon impact, the ice particles explode, turning approximately half of its solid mass into vapour and the other half into liquid, thus resulting in even less wastewater to contain.

1.6.1 Equipment used for Ice Blasting:A device that couples two commercially reliable items, the ice maker and the ejector nozzle, forms the basis of a continuous ice blast machine. This device contains fractured chips, receives sufficient fluidizing air form one end to balance the suction demand of the ejector on other end to create an induced fluidized flow of the ice chips from source to nozzle. When balanced this process operates indefinitely in a steady-state mode giving the ice blast process unmatched long reliability as an industrial process. Figure 7 shows the process of making ice chips, transporting them to the nozzle and ejecting them towards a target. A blast nozzle of the ejector design creates a vacuum which sucks the ice chips from the ice maker to the nozzle where they are mixed with a high velocity air stream to be ejected from the nozzle. A method of continuously producing a stream of ice particulates comprising continuously freezing water into a thin sheet of ice onto a surface of a rotating refrigerated element while controlling a thickness of the sheet; continuously harvesting the self-fragmenting sheet from the surface of the refrigerated element with a knife blade to form particles; directly entraining the harvested particles into a stream of air with sufficient velocity to fluidize the particles; and continuously ejecting the particles from a nozzle.

1.6.2 Refrigeration and ice making

__________________________________________________________________ 5

Seminar Report on Ice Blasting

Ice blast requires ice particles and compressed air to provide high velocity for impact work. Equipment-wise, it requires refrigeration and ice making. These are the two most reliable industrial components today as our entire food supply infrastructure depends on them. They can operate reliably under harsh climatic and environmental conditions,). In combination, they have the attributes of a robust industrial process that is reliable and costeffective. This is the reason why production of ice crystals by cryogenic fluids is neither cost effective nor reliable in comparison.

1) Refrigeration and ice making: The most reliable ice making process is known as immersed cold drum" a (Figure 8). As is immediately refrigerant cools formed. of

rotating drum surface, a thin sheet of ice Under drum appropriate conditions

diameter, temperature and rotational speed, the ice sheet can be formed with sufficient internal stress that when its Fig. 8 Ice making process

frontal edge impacts a doctor blade, the sheet fractures into small ice fragments similar to the shattering effect of a broken stressed (safety or Pyrex) glass.

2) Moving the Ice particles:

Above the doctor blade is mounted a tube with a longitudinal slot over the entire length of the blade. One end of this tube is connected to a venturi-type nozzle that draws by vacuum the ice fragments from the tube. The other end of the tube is connected to a compressed air source that supplies sufficient air to balance the vacuum caused by the venturi. In this manner, ice fragments are instantly fluidized and moved to the nozzle by the induced flow. 1.7 SALIENT FEATURES a) No mechanical Intervention:-

__________________________________________________________________ 6

Seminar Report on Ice Blasting

In this process design, there is no mechanical intervention within the ice particle production area. This allows ice particles to flow with no interference. This process takes advantage of the natural fragmentation of a stressed ice sheet to create particles and not rely on any mechanical means to size them. b) No dust, minimum waste:As ice particles disintegrate on impact, they create a blast mist, which can help to suppress dust from the operation and to cool the environment for the workers. This is particularly helpful in the summer. Evaporation will normally reduce the net liquid waste to about 50-70 Litres per hour.

__________________________________________________________________ 7

Seminar Report on Ice Blasting

2. BENEFITS AND COMPARISONS

2.1 Benefits Below given are some of the benefits of ice blasting that will definitely prove its importance in the current finishing process scenario.

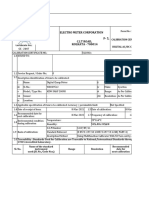

Table No.1

Feature Unique 'Displace-Scrub-Flush'-deburring mechanism Using only 100 litre of (normal tap) water per hour Benefits Superior cleanliness Non-abrasive, no damage to surface Very efficient and effective cleaning: speed Minimal waste - lower waste management costs Minimal waste - environmental friendly Widely available, minimal logistical costs Relative low pressure; maximum of 12 bar No generation of dust Safe working environment No damage to substrate Low maintenance costs No use of chemicals No certification procedures required Environmental friendly Safe working environment Very reliable Ice making process No additional costs Proven reliability worldwide, decades The above statements show that ice blasting is far better process than other deburring methods which involves the use of soaps, chemicals and water based solutions for deburring of finished components. This means, the process of ice blasting helps the user to get the lustrous finish that he always demands from components on which various manufacturing and finishing operations have been performed, but is not free from burr. A used for

__________________________________________________________________ 8

Seminar Report on Ice Blasting

comparative study of Ice blasting process with the other blasting processes has been explained here to stress the need of this process in the industry.

DISADVANTAGES:1 It is necessary that the surface temperature of the object being ice blasted is always above 0 C as ice particles melt on impact. 2. Ice blasting will not remove deep rust or metal burrs as it is less abrasive.

2.2 COMPARISON (Ice blasting & Dry Ice Blasting): Table No. 2 Features Blast Media Purchase Logistical cost for media Continuous operation Waste generated Blasting surface Airborne particulates Blasting in confined space Typical max hose length temperature at Ice Blast Dry Ice Blast (CO2) Minimum; less then 1 per Yes: 30-50 per hour hour Yes; 10-20% of media No purchase Yes No Minimum; app. 60 liter per None hour app. +34F/+1C Low; suppressed by mist Yes 70 meters app. -100F or -75C High; Explode on

impact Must have ventilation and air monitoring 20 meters

2.3 Problems faced with Dry Ice blasting a) Dry-Ice and Ice Blast are totally different technologies

The biggest similarity of Dry-Ice Blast and Ice Blast is probably the name! Both technologies use compressed air to move the media but they are totally distinct on all other aspects.

b) Different cleaning mechanism, different results

__________________________________________________________________ 9

Seminar Report on Ice Blasting

Dry Ice pellets 'explode on impact' or the dry-ice pellets change directly from solid to gas without going through a wet liquid stage. Ice Blast is based on the DisplaceScrub-Flush Cleaning Mechanism. The impact on the substrate is totally different resulting in different level of cleanliness.

c) Not buying media makes the (cost) distinction Dry-ice pellets must be bought or produced in advanced. Depending on the consumption of Dry-Ice pellets the cost varies between 30-50 per hour. It requires skilful matching of workload and media purchase to control cost because unused Dry-Ice pellets will become useless. Ice Blast requires only normal tap water, an ideal media, which is widely available at minimal cost in most of the world.

2.4 Comparison (Ice blasting & Water Blasting): Table No. 3

Features Blasting pressure Water consumption Waste generated Ice Blast 5-12 Bar High Pressure Water 700 bar, up to 2000 bar

and higher 100 litre per hour 1000-3000 liter per hour Minimal; app. 60 liter per 1000-3000 liter per hour High High Required to lower the waste management costs Optional

hour Safety requirements Normal Maintenance costs Low Recycling or Water None / Optional treatment Chemical/solvents/soap usage None

2.5 Problems faced while cleaning with water:

The number of cleaning systems in industry has increased significantly during the last decades. Cleaning with water has been optimized with chemicals, water pressure, water volume and better equipment. The use of chemicals has further been limited by environmental concerns. In essence the performance has been maxed out.

a) Increasing the pressureHigh Pressure Water cleaning systems with increasing working pressures have been developed to extend the market opportunities. More pressure means more cleaning power

__________________________________________________________________ 10

Seminar Report on Ice Blasting

but at a cost: less safe working environment, more maintenance costs and increased indirect costs. b) Pressures up to 2000 Bar / 37000 PSI are not an exception these days. On the other hand using Ice Blast at 12 Bar / 180 PSI to clean grease or crude oil gives the same or better results.

c) Consuming more and more water- Swelling the volume of water has been another

attempt to increase the performance of high pressure water cleaning. Consuming 1000 Liter per hour per nozzle (and much more) is nothing special. Waste management costs have become a major cost and will continue to increase. In contrast Ice Blast uses 100 liter water per hour, only 10% or less, meaning 10% or less waste management costs.Ice Blast is a cost saver!

d) Washing parts, using chemicals -In most today's production environment washers are

still the most common method for both degreasing and cleaning parts in the manufacturing process. Over the years many changes and additions have been made to improve their performance: increasing the water temperature, increasing the water chemicals, using more water, etc. pressure, adding

e) Increasing complexity means increasing cost- Manufacturers have to meet lower

and lower contamination specifications. This leads to more water and chemicals use resulting in increasing water reprocessing costs. Trends in environmental regulations favour lower use of both. To compromise more sophisticated water treatment systems are installed to meet the latest standards.

3. APPLICATIONS

__________________________________________________________________ 11

Seminar Report on Ice Blasting

3.1 Scope

Ice blasting covers a wide variety of products right from environmental cleaning, industrial cleaning, and applications as given below.

Cleaning Type

Precision Cleaning

Examples of Potential Application

Involves removing surface contaminants and/or light deburring to defined tolerance, typically in a repetitive production setting where quality control are closely measured and monitored. Include a range of auto components (Transmission components & cases, valve bodies & housing, engine & cylinder head cast part, armatures, magnesium casting, etc.) Manufacturing equipment, industrial plant of all kinds (petro-chemicals beverage, power station, pulp & paper, etc.) plastics molds & dunnage, turbines , yard Equipments Building structure, in particular lead paint Removal from steel bridges & asbestos abatement in building structures. Nuclear decontamination, aerospace, marine, food & services.

Competition

Water glass bead, manual labour & chemicals.

Rationale For Adoption

Superior cleaning , fewer rejects , dustless, highly reliable , reduced floor space environmental benige , lower maintenance, monitoring, and operating costs.

Industrial Cleaning

Water, dry ice, soda, abrasives, manual labour & chemicals.

Environmental Cleaning

Manual labor, chemicals, water, dry ice, abrasives.

Superior cleaning , reduced waste & cleanup, dustless, low operating costs, no damage to fiberglass or materials, simple field implementation. Minimal waste, no dust (no need for class A containment areas), improved worker health, simple implementation.

Other

3.1 EXAMPLE OF INDUSTRIAL CLEANING GEAR DEBURRING 3.1.1 The process

__________________________________________________________________ 12

Seminar Report on Ice Blasting

The Gear cleaning process lifts and rotates the part as the blast nozzle moves over the part. The gear is being lifted and rotating. The nozzle, on the left, directs the ice on the gear teeth. At its uppermost position, the bottom of the gear is exposed to the blast stream. The top and inside of the gear is cleaned when the gear is in the lower position (Figure 9). This two-axis lift-and-rotate movement allows the part be cleaned both inside and outside, Fig 9:-Gear Deburring Process to

and all around in a very short time. The Blast nozzle pivots and follows the gear as it is lifted. The gear rotates at low RPM so that it is blasted all the way around. The normal process includes a dwell in the lift and nozzle movement so that at least two revolutions of ice blast are concentrated on the gear teeth themselves. This insures the removal of any chips or residue that may have been caught in the root of the gear tooth.

3.1.2 Ice Blast Gear Deburring

The Ice Blast cleaning cell (Fig.10) is designed in modules. The available modules are: a) Ice Blast lift-and-rotate unit- The Ice Blast lift and rotate is the heart of the process. This is where the part is cleaned. b) Clean water rinse, optional -When lower Fig. 10 Deburring Cell

contamination requirements are needed the rinse system is included to wash off any airborne particles which may resettle on the part after blasting. c) Rust preventative application - If the work part is made of steel, a rust inhibitor will need to be applied to the part. When the gear manufacturing process includes an automatic gear checker of the master gear variety, a separate rust preventative application booth is added to the line after the gauging operation.

d) Hot air drying - The final module is the hot air, part dryer. This can be either

electric or steam heat. The parts emerge from the unit completely dry and clean.

__________________________________________________________________ 13

Seminar Report on Ice Blasting

Before

After

Fig. 11 Gear Deburring Before / After

Some Interesting Facts about Ice Blasting:1 The surface temperature of the object being ice blasted is always above 0 C as ice particles melt on impact. 2 Ice particles produce a blast mist, which helps to suppress dust or airborne particulates to minimize unintended dispersion. 3. In warm climates, essential complete evaporation can take place, leaving only damp blast debris. The aspect of ice blast is of particular interest to those concerned with waste generation & disposal, especially in the cleaning hazardous chemicals. 4. The surface cleanliness depends on the quality of water & air used. 5. The injector nozzle used in ice blast allows introduction of additives into the ice stream. For example, disinfectant can be metered into the iced stream for cleaning of food processing equipments.

4. CASE STUDY

__________________________________________________________________ 14

Seminar Report on Ice Blasting

This case study includes the implementation of a new technology in the manufacture of fuel pump valve housing components at the Robert Bosch Corporation Anderson sc facility. The process qualification include a technical evaluation of ice blast technology for deburring and cleaning the development of a production parts approval process the development of a continuous ice blast system and implementation. Part I provides a technical introduction to ice blast technology. Part II describes some technical evaluation result and development of qualified process.

4.1 Introduction

Ice blast technology is relatively new process in manufacturing. Its ability to provides superior cleanliness has been documented in the development of a process for the manufacture of gear in automobile industry as given in application. In search of process to deburr / deflash and clean zinc die cast valve housing component for its fuel pump manufacturing, Bosch decided to evaluate ice blast technology because it offered the promise to deburr and clean while not causing any dimensional or surface quality changes. Furthermore the environmental purity of the process was appealing. Prototype parts were ice blasted examination and evaluation. The viability of the process was confirmed. A continuous ice blast cleaning process developed leading to the submission of production parts approval process document. To date over one million parts have been processed by ice blast technology. This paper presents the entire process from curiosity to qualification for production

4.2 PART I 4.2.1 Ice blast technology

Fundamentals of ice blast technology have been discussed in a prior part certain aspects of ice blast impact phenomena that are relevant to this paper are presented here for completeness. Near room temperature ice is a phase change material. Therefore small ice particles at high velocity can perform work in solid form as well as in liquid form. From this point of view ice blast is a hybrid of solid media blast and water blast but without the solid waste normally generated from solid media blast. This work done by solid ice participles is of the

__________________________________________________________________ 15

Seminar Report on Ice Blasting

displacement type. To deburr or deflash solid ice particles must have sufficient momentum to overcome the inertia of the target material. An intuitive and cost effective way to maximize momentum is to use ice particles that have large average size hence large mass. The formula for the impact force confirms this size dependence as shown in figure 12 F = R2 V 1.2 cos. .................................... (1) Thus we can say that to get the desired force we should vary the angle and it can be found out by = cos 1 (F / R2 V 1.2)............................. (2) So it can be seen that optimal angel of attack is typically in the direction of the intended displacement, seen by the cos. dependence Thus, the work done by ice particle in liquid form is rinsing. Debris from the blast impact action is conveniently rinsed away. As is obvious now, ice blast is more than the combination of solid and liquid blast. This is because the impact action takes a finite time during which ice particles deform. The deformation exerts a pressure force on the surface. As a result, ice particles perform frictional scrubbing work on the surface during its phase change. This phase-change is unique to ice, therefore only ice particle can provide frictional scrubbing work without damage to the surface. The optimal angle of attack is normal to the surface to be cleaned, as described by the following formula: P=V1.2sin................................................... (3) However, scrubbing requires motion parallel to the surface. Optimal scrubbing action therefore requires a slight oblique angle attack. There is no such scrubbing action from water blast; therefore it cannot offer the same level of cleanliness, even at much more elevated blast pressures and at much higher volumes.

4.3 PART II 4.3.1 Deburring Evaluation

The burrs to be removed from the housing part are shown in figure 12. The burrs from the injector pins pose a particular problem as they are nearly hidden from the line of sight of the ice blast stream, and they are oriented perpendicular to the optimal direction for the displacement deburrs.

__________________________________________________________________ 16

Seminar Report on Ice Blasting

Selected prototype parts were photographed before and after ice blasting. Typical results are shown in figure 13 in the photographs. They represent large and small burrs. The small burrs are particularly difficult to remove as they have small frontal areas and long hinge sections. Note the deburred parts take on a clean, sparking appearance. These tests confirmed the deburring capability of ice blast. Figures before and after comparison of ice blasted parts containing a large and small burr are as shown.

4.3.2 Implementation

Upon validation of deburring efficiency, a process was developed to deburr and clean parts on a continuous basis. To meet the final QA requirement, a line consisting of an ice blast station, rinsing station and drying station was developed. This is shown schematically as figure 14 below.

Fig. 14 Station Layout

__________________________________________________________________ 17

Seminar Report on Ice Blasting

It was determined that the part must be ice blasted from both sides and the total ice blast operation was 4 seconds. With fixed nozzles fanned to cover the entire height of the parts, the parts transfer speed was 5 feet/min.. In order to track quality and provide quality assurance, a production parts approval process was developed, as shown.

4.4 PART III 4.4.1 Comparison with alternative processes

For fuel pump assembly three parameters are judged important in terms of acceptability of process for deburring and cleaning of valve housing:

1) Air leak test - The pump need to be tested at desired pressure to pump the fluid but due

to presence of burr no effective cleaning is possible thus resulting in improper assembly accusing air leaks & cavitations. Fig. 15 Air Leakage Test Graph

2) 14 day leak test In this test the fuel is filled in the pump assembly and after 14 days

the volume remaining in checked for leakages. This % is less in case of pump with no proper assembly due to presence of burr. Fig. 16:--14 day Leak Test

__________________________________________________________________ 18

Seminar Report on Ice Blasting

5 CONCLUSIONS

Based on these results, the acid etching process produced unacceptable leak-down results while the vibrating deburring process failed on excessive air leaks. In summary, ice blast offers the most desirable results of the three tested processes. In practice, ice blast offers a cleaner and offers infinitely lower chance of contamination which is a major issue faced by many automotive component suppliers. In a Ice blast is also used in more conventional deburring applications such as transmission valve body parts where fine burrs from machining and milling must be removed.. manufacturing environment, ice blast deburring and cleaning offer the following benefits: 1. 2. 3. 4. 5. 6. 7. 8. 9. high deburring efficiency superior cleanliness low waste generation simple equipment requiring little maintenance compact size of equipment no recycling/waste water processing requirements low operating cost low capital cost environmentally sound

The main objective of this seminar was to give others an overview of new trends in Deburring process i.e. Ice blasting.

__________________________________________________________________ 19

Seminar Report on Ice Blasting

6. REFERENCES

a) Books / research papers

1. Herb, Brett and Sam Visaisouk, Ice Blast Technology for Precision Cleaning, Precision Cleaning 96 Proceedings, Anaheim CA, May 14-16, 1999, pp172-179. 2. Herb, Brett, Cleaning Process for Enhancing the Bond Integrity of Multi-Layered Zirconium and Zirconium Alloy Tubing, U.S. Patent no. 5, 483, 563, January 9, 1999. 3. Tonello, Tony, Ice Blast : New Technology for An Old Problem, ATCO Team Review, Ford Motor Company, Volume, Number 1,February 2002, p6. 4. Gear Technology Magazine, Article - Cleaning gears with Ice Chips and Nothing Else, May-June 2002.

b) Web- sites.

1. www. powertransmission.com 2. www. geartechnology .com 3. www. howlett research.com 4. www. iceblast .net 5. http://www.strahlverfahren.de

__________________________________________________________________ 20

Seminar Report on Ice Blasting

__________________________________________________________________ 21

Seminar Report on Ice Blasting

__________________________________________________________________ 22

S-ar putea să vă placă și

- Dry Ice PDFDocument18 paginiDry Ice PDFAli AtwaÎncă nu există evaluări

- Catalogo Industrias Ing0420Document16 paginiCatalogo Industrias Ing0420SameerKhanÎncă nu există evaluări

- On Dry Ice BlastingDocument29 paginiOn Dry Ice BlastingPratik pagar50% (2)

- Dry Ice-Blasting Is A Form ofDocument3 paginiDry Ice-Blasting Is A Form ofrajashekaraiahÎncă nu există evaluări

- CESCO Technical ProposalDocument2 paginiCESCO Technical ProposalthmaraishriÎncă nu există evaluări

- Seminar Dry Ice Example Presentation InternetDocument79 paginiSeminar Dry Ice Example Presentation InternetMirela-Elena PopaÎncă nu există evaluări

- SOP-Attachment 3d - CNL JV - SWP 404 - Confined Space Entry - Dec10Document33 paginiSOP-Attachment 3d - CNL JV - SWP 404 - Confined Space Entry - Dec10tomychalilÎncă nu există evaluări

- Robots in Shipbuilding Industry (1160) PDFDocument9 paginiRobots in Shipbuilding Industry (1160) PDFWahyu WahyurachmatdhaniÎncă nu există evaluări

- Instruction Manual: Serial No.: Voltage: 230 V Phase: 1 HZ: 50/60Document30 paginiInstruction Manual: Serial No.: Voltage: 230 V Phase: 1 HZ: 50/60Muhammad Haris BaigÎncă nu există evaluări

- Ultra Filtration SystemDocument5 paginiUltra Filtration SystemAbdul SamadÎncă nu există evaluări

- Dry Ice Pelletizer A30P D3Document4 paginiDry Ice Pelletizer A30P D3Zoran TatarevicÎncă nu există evaluări

- Cat Loading by Sock Method in Inert AtmosphereDocument5 paginiCat Loading by Sock Method in Inert Atmospherevishal bailurÎncă nu există evaluări

- Technical Specification For Clarifier: Document Type: SpecDocument17 paginiTechnical Specification For Clarifier: Document Type: SpecgffÎncă nu există evaluări

- 400 MM Digital Clamp Meter Make-Kyoritsu Model-KEW SNAP 2009R, SL No-W8039512Document20 pagini400 MM Digital Clamp Meter Make-Kyoritsu Model-KEW SNAP 2009R, SL No-W8039512Ashutosh MondalÎncă nu există evaluări

- 2000 Rigsafe Air Booster CompressorDocument2 pagini2000 Rigsafe Air Booster CompressorLauren'sclub EnglishBimbel Sd-sma100% (1)

- Method Statement For Ultrasonic Testing: DCSM Project 2019Document5 paginiMethod Statement For Ultrasonic Testing: DCSM Project 2019Thinh NguyenÎncă nu există evaluări

- PS Series Tensioner BrochureDocument4 paginiPS Series Tensioner BrochureAbdullah Muhamad ZahdiÎncă nu există evaluări

- PR-IMS-042 Chemical Management ProcedureDocument18 paginiPR-IMS-042 Chemical Management ProcedureBlister PatchÎncă nu există evaluări

- Standard Operating Procedure For Centrifuge OperationDocument4 paginiStandard Operating Procedure For Centrifuge OperationSiti Nunung NurlelaÎncă nu există evaluări

- Viscotaq Application Manual English April 2011 PDFDocument40 paginiViscotaq Application Manual English April 2011 PDFhenry307Încă nu există evaluări

- Turbodrain EnglDocument8 paginiTurbodrain EnglIonut BuzescuÎncă nu există evaluări

- Design - R.O - System - PPTX Filename - UTF-8 - Design R.O SystemDocument22 paginiDesign - R.O - System - PPTX Filename - UTF-8 - Design R.O SystemabdallahÎncă nu există evaluări

- Tank Cleaning Robotic ServicesDocument2 paginiTank Cleaning Robotic ServicesgmitsutaÎncă nu există evaluări

- H 05893Document4 paginiH 05893gplese0Încă nu există evaluări

- Eagle Burgmann API PlanDocument43 paginiEagle Burgmann API PlanONURÎncă nu există evaluări

- eBroc-FRP Custom Cooling Towers, YWCTDocument28 paginieBroc-FRP Custom Cooling Towers, YWCTJurizal Julian Luthan100% (1)

- Installation Instructions For Commercial RO SystemsDocument22 paginiInstallation Instructions For Commercial RO SystemsMfundo DlaminiÎncă nu există evaluări

- MSDS - Hydraulic OilDocument14 paginiMSDS - Hydraulic OilArdan RnÎncă nu există evaluări

- Literature Review On Design & Fabrication of Oil Measuring & Despensing MachineDocument2 paginiLiterature Review On Design & Fabrication of Oil Measuring & Despensing MachineIJIRSTÎncă nu există evaluări

- Presentation For INDUSTRIAL Cleaning Services PHRCDocument26 paginiPresentation For INDUSTRIAL Cleaning Services PHRCMOSES EDWINÎncă nu există evaluări

- Thermal Desorption PDFDocument29 paginiThermal Desorption PDFShafiaÎncă nu există evaluări

- Centrifuge: CentrifugesDocument6 paginiCentrifuge: CentrifugesMuhammad UsamaÎncă nu există evaluări

- Rock Catchment Dam With Self-Closing WatertapDocument90 paginiRock Catchment Dam With Self-Closing WatertapGreen Action Sustainable Technology GroupÎncă nu există evaluări

- Desalination Plant of TobrukDocument21 paginiDesalination Plant of TobrukMotaz ZgogoÎncă nu există evaluări

- Viscosity Measurement So Easy, Yet So Difficult by Janet L. Lane and Kenneth O. HendersonDocument7 paginiViscosity Measurement So Easy, Yet So Difficult by Janet L. Lane and Kenneth O. HendersonLuis VilchezÎncă nu există evaluări

- Long Term Preservation ProcedureDocument2 paginiLong Term Preservation Procedureiyappan i.p.sÎncă nu există evaluări

- 14 Procedure For Shop and Field PaintingDocument24 pagini14 Procedure For Shop and Field PaintingdnbinhÎncă nu există evaluări

- Christ NishotechDocument42 paginiChrist Nishotechdepardieu1973Încă nu există evaluări

- 2018-01-15 Kasuari WTP Erection & Installation ProcedureDocument6 pagini2018-01-15 Kasuari WTP Erection & Installation ProcedureavriamandaÎncă nu există evaluări

- Desalination EngineeringDocument8 paginiDesalination EngineeringShafayet A SiddiqueÎncă nu există evaluări

- YSTRAL Disperser & Homogenizer Machines PDFDocument4 paginiYSTRAL Disperser & Homogenizer Machines PDFMiguel Angel Pérez GascaÎncă nu există evaluări

- Keranol Fu 320Document2 paginiKeranol Fu 320shankarkl100% (1)

- Quality Management System Procedure Manual: Maintenance (Electrical)Document3 paginiQuality Management System Procedure Manual: Maintenance (Electrical)sourajpatelÎncă nu există evaluări

- Surface Preparation Guide PDFDocument13 paginiSurface Preparation Guide PDFait.koufiÎncă nu există evaluări

- MSDS - Polyelectrolyte, CleartechDocument7 paginiMSDS - Polyelectrolyte, CleartechBazil BoliaÎncă nu există evaluări

- Procedure For Inspection and Sterilisation of Water Storage TanksDocument4 paginiProcedure For Inspection and Sterilisation of Water Storage TanksMuhammad Hussain BilalÎncă nu există evaluări

- SA04C2-MS-MET-AAG-0009 Method Statement of Pneumatic Test For SS and GRE PipesDocument11 paginiSA04C2-MS-MET-AAG-0009 Method Statement of Pneumatic Test For SS and GRE PipesABAID ULLAHÎncă nu există evaluări

- Caf Gasket SpecificationsDocument4 paginiCaf Gasket SpecificationsKARTHIGEYAN.R100% (1)

- Why Is "Cold Cutting" Superior To Plasma Cutting?Document9 paginiWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedÎncă nu există evaluări

- Technical Service Bulletin: Commissioning Procedure For HydracapDocument10 paginiTechnical Service Bulletin: Commissioning Procedure For HydracapValesh MonisÎncă nu există evaluări

- Falsh Vessel RVDocument5 paginiFalsh Vessel RVJallu PratamaÎncă nu există evaluări

- DRY ICE Tube CleaningDocument7 paginiDRY ICE Tube CleaningJay LawsonÎncă nu există evaluări

- Pigging in Pipelines.Document14 paginiPigging in Pipelines.john saju malyackalÎncă nu există evaluări

- Power Plant Maintenance 3.0Document25 paginiPower Plant Maintenance 3.0MariusDragoescuÎncă nu există evaluări

- Ice BlastingDocument22 paginiIce BlastingSAr AThÎncă nu există evaluări

- 1 Dsce, Bangalore M.Tech 2 Sem (Cim)Document13 pagini1 Dsce, Bangalore M.Tech 2 Sem (Cim)Mallinath ShettyÎncă nu există evaluări

- Eastern Visayas State University Tacloban CityDocument7 paginiEastern Visayas State University Tacloban CityRonaldÎncă nu există evaluări

- Research Status of Ice-Storage Air-Conditioning System Research Status of Ice-Storage Air-Conditioning SystemDocument7 paginiResearch Status of Ice-Storage Air-Conditioning System Research Status of Ice-Storage Air-Conditioning Systemsiddique27Încă nu există evaluări

- Application of Ice Particles For Surface Decontamination: IDS 2000 June 13-16, 2000, Knoxville, TNDocument5 paginiApplication of Ice Particles For Surface Decontamination: IDS 2000 June 13-16, 2000, Knoxville, TNma qÎncă nu există evaluări

- Design and Fabrication of An Ice Cube Making MachineDocument7 paginiDesign and Fabrication of An Ice Cube Making MachineJunjun AguirreÎncă nu există evaluări

- DRY ICE Tube CleaningDocument7 paginiDRY ICE Tube CleaningJay LawsonÎncă nu există evaluări

- The Complete CO2 SolutionDocument15 paginiThe Complete CO2 SolutionAl HattanÎncă nu există evaluări

- Ice BlastingDocument22 paginiIce BlastingAbigith Baby100% (1)

- April 2014Document84 paginiApril 2014Cleaner MagazineÎncă nu există evaluări

- Dry Ice Pelletizer A30P D3Document4 paginiDry Ice Pelletizer A30P D3Zoran TatarevicÎncă nu există evaluări

- Maintenance Manual Oil & Gas DownstreamDocument55 paginiMaintenance Manual Oil & Gas DownstreamSuraj M Sethu100% (1)

- Dry Ice Blasting Research PaperDocument6 paginiDry Ice Blasting Research Paperliwas0didov3100% (1)

- Paint Removal - AGARD Report 791Document144 paginiPaint Removal - AGARD Report 791iskandarmeranÎncă nu există evaluări

- Seminar Dry Ice Example Presentation InternetDocument79 paginiSeminar Dry Ice Example Presentation InternetMirela-Elena PopaÎncă nu există evaluări

- Catalogo Industrias Ing0621Document20 paginiCatalogo Industrias Ing0621victor guajardoÎncă nu există evaluări

- Dry Ice Cleaning - Frequently Asked Questions: WWW - Optimumdryiceblasting.co - UkDocument5 paginiDry Ice Cleaning - Frequently Asked Questions: WWW - Optimumdryiceblasting.co - Uksales putrariÎncă nu există evaluări

- Dry Ice Blasting 1Document5 paginiDry Ice Blasting 1samer8saifÎncă nu există evaluări

- Dry Ice Blasting BrochureDocument4 paginiDry Ice Blasting BrochureDivya GurukumarÎncă nu există evaluări

- Dry Ice Blasting As Pretreatment of Aluminum SurfacesDocument11 paginiDry Ice Blasting As Pretreatment of Aluminum SurfacesliquidideasÎncă nu există evaluări

- Horizontal HRSG CleaningDocument19 paginiHorizontal HRSG CleaningHung NguyenÎncă nu există evaluări

- KG30 SupremeManual 12-26-12 CompleteDocument116 paginiKG30 SupremeManual 12-26-12 CompleteDavid Oswaldo Nino BohorquezÎncă nu există evaluări

- Dry Ice BlastingDocument6 paginiDry Ice Blastingsoubhadra nagÎncă nu există evaluări

- Safety Documentation SystemDocument165 paginiSafety Documentation SystemPieter HerbstÎncă nu există evaluări

- Instruction Manual: Serial No.: Voltage: 230 V Phase: 1 HZ: 50/60Document30 paginiInstruction Manual: Serial No.: Voltage: 230 V Phase: 1 HZ: 50/60Muhammad Haris BaigÎncă nu există evaluări

- Company Profile PetracarbonDocument32 paginiCompany Profile PetracarbonTien Tran Kha TienÎncă nu există evaluări