Documente Academic

Documente Profesional

Documente Cultură

Busbar Calculation

Încărcat de

dsilvasaucedoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Busbar Calculation

Încărcat de

dsilvasaucedoDrepturi de autor:

Formate disponibile

Design rules

Busbar calculation

Busbar calculation example

Here is a busbar calculation to check.

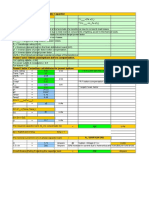

Exercise data

# Consider a switchboard comprised of at least 5 MV cubicles. Each cubicle has 3 insulators(1 per phase). Busbars comprising 2 bars per phase, inter-connect the cubicles electrically.

Busbar characteristics to check:

S d

l : : : : : : : busbar cross-section (10 1) phase to phase distance distance between insulators on the same phase ambient temprature permissible temperature rise

(90-40=50)

10 18 70 40 50

cm2 cm cm C C

n

( - n) profile material

Cellule 1 Cellule 2 Cellule 3 Cellule 4 Cellule 5

flat busbars in copper 1/4 hard, with a permissible strain = 1 200 daN/cm2 edge-mounted

arrangement:

number of busbar(s) per phase:

d d

# The busbars must be able to withstand a rated current Ir = 2,500 A on a permanent basis and a short-time withstand current Ith = 31,500 A rms. for a time of tk = 3 seconds. # Rated frequency fr = 50 Hz # Other characteristics: 5 parts in contact with the busbars can withstand a maximum temperature of max = 100C 5 the supports used have a bending resistance of F = 1 000 daN

1 cm

1 cm

10 cm 5 cm

12 cm

TED300014EN_030_037.

Gamme

Schneider Electric

Design rules

Busbar calculation

0

Lets check the thermal withstand of the busbars!

For the rated current (Ir)

The MELSON & BOTH equation allows us to define the permissible current in the conductor: 0.61 0 .5 0 .39

24.9 ( n ) S p I = K ------------------------------------------------------------------20 [ 1 + ( 20 )]

with:

l : : : : : : permissible current expressed in amperes (A) ambient temperature permissible temperature rise* busbar cross-section busbar perimeter resistivity of the conductor at 20C copper: 1.83 cm

n

( - n) S

40 50 10 22

C C cm2 cm

p

e

p20

temperature coefficient for the resistivity:

0.004

condition coefficient product of 6 coefficients (k1, k2, k3, k4, k5, k6), described below

*(see table V in standard CEI 60 694 pages 22 and 23)

Definition of coefficients k1, 2, 3, 4, 5, 6:

# Coefficient k1 is a function of the number of bar strips per phase for: 5 1 bar (k1 = 1) 5 2 or 3 bars, see table below:

e /a

0.05 0.06 0.08 0.10 number of bars per phase 2 1.63 1.73 1.76 1.80 3 2.40 2.45 2.50 2.55 0.12 0.14 k1 1.83 1.85 2.60 2.63 0.16 1.87 2.65 0.18 1.89 2.68 0.20 1.91 2.70

In our case: e/a = number of bars per phase = giving k1 =

0.1 2 1.80

Schneider Electric

Gamme

AMTED300014EN_030_03

Design rules

Busbar calculation

# Coefficient k2 is a function of the surface condition of the bars: k2 = 1 5 bare: k2 = 1.15 5 painted: # Coefficient k3 is a function of the busbar position: k3 = 1 5 edge-mounted busbars: 5 1 bar flat-mounted: k3 = 0.95 k3 = 0.75 5 several flat-mounted bars: # Coefficient k4 is a function of where the bars are installed: k4 = 1 5 calm indoor atmosphere: 5 calm outdoor atmosphere: k4 = 1.2 5 bars in non-ventilated ducting: k4 = 0.80 # Coefficient k5 is a function of the artificial ventilation: k5 = 1 5 without artificial ventilation: 5 cases with ventilation must be treated on a case by case basis and then validated by testing. # Coefficient k6 is a function of the type of current: 5 for alternatif current at a frequency of 60 Hz, k6 is a function of the number of busbars n per phase and of their spacing. The value of k6 for a spacing equal to the thickness of the busbars:

n k6 1 1 2 1 3 0.98

In our case: n= 2

giving k6 = 1

In fact, we have: k = 1.80 1

0.8

= 1.44

0 . 61 0.5 0 . 39 10 22 24 . 9 ( 90 40 ) I = 1. 44 ---------------------------------------------------------------------------------------------------------------------------------------1 . 83 [ 1 + 0 . 004 ( 90 20 ) ]

0 . 61 0.5 0 . 39 24 . 9 ( n ) S p I = K -----------------------------------------------------------------------------20 [ 1 + ( 20 ) ]

I=

2 689

The chosen solution: is appropriate:

busbars of 10 1 cm per phase either 2 500 A < 2 689 A

Ir < I

TED300014EN_030_037.

Gamme

Schneider Electric

Design rules

Busbar calculation

For the short-time withstand current (Ith)

# we assume that, for the whole duration (3 seconds) : 5 all the heat given off is used to increase the temperature of the conductor 5 the effect of radiation is negligible.

The equation below can be used to calculate the temperature rise due to short-circuit:

0.24 20 I th 2 t k cc = ----------------------------------------------------------2 (n S) c

with: c S

n

specific heat of the metal copper: is the cross section expressed in cm2 number of bars per phase is the short-time withstand current

(rms. value of the maximum shortcircuit current)

0.091 kcal / daNC

10 2 31 500 A rms. cm2

: : :

Ith tk

20

: :

short-time withstand current duration (1 to 3 secs) density of the metal copper: resistivity of the conductor at 20C copper: permissible temperature rise

in secs

8.9 g/cm3

1.83 cm

50 C

( - n) :

5 The temperature rise due to the short circuit is:

1.83 31 500 0.24 1.83 10 ( 31500 ) cc = ----------------------------------------------------------------2 2 ( 2 /1010 ) 0.091 .98.9 0.091

Calculation of t must be looked at in more detail because the required busbars have to withstand Ir = 2 500 A at most and not 2 689 A.

cc =

The temperature t of the conductor after short-circuit will be:

t = n + ( n ) + cc

=

40

50

for I =

2 689

= 94 C (see calculation in the previous pages)

Schneider Electric

Gamme

AMTED300014EN_030_03

Design rules

Busbar calculation

# Let us fine tune the calculation for t for Ir = 2 500 A (rated current for the busbars) 5 the MELSON & BOTH equation (cf: page 31), allows us to deduce the following: I = constant (- n) 0.61 et Ir = constant () 0.61 I therefore = = (-n) Ir ()

2 689 = 2 500

( )

0.61

0.61

( ( ) )

50

50 =

689 ( 22 500 )

1

0.61

50 = 1.126 = 44.3 C 5 temperature t of the conductor after short-circuit, for a rated current Ir = 2 500 A is: t = n + + cc

= =

40

88.3

+ 44.3

C for Ir = 2 500 A

The busbars chosen are suitable because:

t = 88.3 C is less than max = 100 C

(max = maximum temperature that can be withstood by the parts in contact with the busbars).

TED300014EN_030_037.

Gamme

Schneider Electric

Design rules

Busbar calculation

Lets check the electrodynamic withstand of the busbars.

Forces between parallel-mounted conductors

Electrodynamic forces due to the short-circuit current are given by the equation:

F1 = 2 l d

ldyn2 G 10-8

(see drawing 1 at the start of the calculation example)

l d k

: : :

distance between insulators in the same phase phase to phase distance

70 18

cm cm

2.5

for 50 Hz according to IEC

Idyn :

peak value of short-circuit current = k / lth = 2.5 / 31 500 = 78 750 A

F1 = 2 / (70/18) / 78 7502 /10-8 = 482.3 daN Forces at the head of the supports or busducts

Equation to calculate forces on a support :

F = F1 G H + h H

with

F H h : : : force expressed in daN insulator height distance from the head of the insulator to the busbar centre of gravity

12 5

cm cm

Calculating a force if there are N supports

# The force F absorbed by each support is at most equal to the force F1 that is calculated multiplied by a coefficient kn which varies according to the total number N of equi-distant supports that are installed. 5 number of supports 5 =N 5 we know N, let us define kn using the table below:

N kn 2 0.5 3 1.25 4 1.10

5 1,14 daN

giving F = 683

(F1)/ 1.14 (kn) =

778

The supports used have a bending resistance F = 1 000 daN calculated force F = 778 daN. The solution is OK

Schneider Electric

Gamme

AMTED300014EN_030_03

Design rules

Busbar calculation

Mechanical strength of the busbars

Assuming that the ends of the bars are sealed, they are subjected to a bending moment whose resultant strain is: F1 l v = ----------- -- -

12

with

l : : is the resultant strain in daN/cm2 distance between insulators in the same phase : is the modulus of inertia of a busbar or of a set of busbars

(value chosen in the table below)

70

cm

I/v

14.45 cm3

1 = 482.3--70 --------- - -- --------- - 12 14.45 = 195 daN / cm2 The calculated resultant strain ( = 195 daN / cm2) is less than the permissible strain for the copper busbars 1/4 hard (1200 daN / cm2) : The solution is OK Busbar dimensions (mm)

100 x 10 Arrangement

x

S m daN/cm I

cm2 Cu A5/L cm4 cm3 cm4 cm3 cm4 cm3 cm4 cm3 cm4 cm3 cm4 cm3

10 0.089 0.027 0,83 1.66 83.33 16.66 21.66 14.45 166.66 33.33 82.5 33 250 50

x x

I/v I

x x

I/v I

x x

I/v I

x x

I/v I

x x

I/v I

I/v

TED300014EN_030_037.

Gamme

Schneider Electric

Design rules

Busbar calculation

Let us check that the chosen busbars do not resonate.

Inherent resonant frequency

The inherent resonant frequencies to avoid for busbars subjected to a current at 50 Hz are frequencies of around 50 and 100 Hz. This inherent resonant frequency is given by the equation: EI f = 112 -----------m l4

f E : : frequency of resonance in Hz modulus of elasticity for copper = linear mass of the bar length between 2 supports or busducts moment of inertia of the busbar section relative to the axis xx perpendicular to the vibrating plane

1.3 106 daN/cm2

m l

: :

0.089 70

daN/cm

cm

21.66

cm4

(choose m and l on the table on the previous page)

6 21.66 f = 112 1.3------------- --- --10---------- - 0.089 70 4 f = 406 Hz

f is outside of the values that have to be avoided, in other words 42 to 58 Hz and 80 to 115 Hz:

The solution is OK

In conclusion

The busbars chosen, i.e. Ith = 31.5 kA 3 sec.

bars of 10 1 cm per phase, are suitable for an Ir = 2 500 A and

2

Schneider Electric

Gamme

AMTED300014EN_030_03

S-ar putea să vă placă și

- Panel Busbar Sizing Calculations - Thomas and RataDocument4 paginiPanel Busbar Sizing Calculations - Thomas and Ratakapil100% (12)

- Bus Bar Calculation - RequirementDocument20 paginiBus Bar Calculation - Requirementsrigirisetty208100% (2)

- HDD Crossing Calculation 2Document26 paginiHDD Crossing Calculation 2Denstar Ricardo Silalahi93% (29)

- Busbar DesignDocument25 paginiBusbar DesignHans De Keulenaer100% (20)

- Copper Busbar Ampacity TablesDocument3 paginiCopper Busbar Ampacity TablesedgarcooÎncă nu există evaluări

- Power Factor Correction SpreadsheetDocument1 paginăPower Factor Correction Spreadsheetirwanchandra50% (2)

- Bus Bar Design Calculations For Busduct MarsDocument8 paginiBus Bar Design Calculations For Busduct MarsKamesh1977Încă nu există evaluări

- Busbar Sizing CalculationDocument1 paginăBusbar Sizing CalculationJanardhanan Palani100% (3)

- Busbar Calculation For Current Carrying Capacity 1000 A With 50 X 12 CuDocument1 paginăBusbar Calculation For Current Carrying Capacity 1000 A With 50 X 12 Cudipak_eee8291% (22)

- Workshop On EC4 - CompositeDocument53 paginiWorkshop On EC4 - CompositePeyman MznÎncă nu există evaluări

- Cambridge IGCSE™ Physics Workbook (Heather Kennett)Document82 paginiCambridge IGCSE™ Physics Workbook (Heather Kennett)sfaezali09Încă nu există evaluări

- Solved - A Carnot Refrigerator Has Tetrafluoroethane As The Work...Document4 paginiSolved - A Carnot Refrigerator Has Tetrafluoroethane As The Work...MingÎncă nu există evaluări

- HT2Document178 paginiHT2dhruvÎncă nu există evaluări

- Bus Bar CalculationDocument8 paginiBus Bar CalculationSubhash ChekkaÎncă nu există evaluări

- Electrical - Bus Bar SizingDocument9 paginiElectrical - Bus Bar SizingsbpathiÎncă nu există evaluări

- 3 Bus Bar Sizing CalculationDocument42 pagini3 Bus Bar Sizing CalculationAnonymous OKkHA0NzÎncă nu există evaluări

- Copper Busbar Sizing CalculationDocument5 paginiCopper Busbar Sizing CalculationAnantharamakrishnan VenkatramanÎncă nu există evaluări

- Aluminium Busbar Sizing Software OutputDocument3 paginiAluminium Busbar Sizing Software Outputkapil100% (4)

- Busbar Sizing CalculationDocument4 paginiBusbar Sizing CalculationRahul Bhattacharyya100% (1)

- MCC Bus Bar Sizing CalculationDocument12 paginiMCC Bus Bar Sizing Calculationerkamlakar223483% (6)

- Busbar Calulation For 2000a Copper BusbarsDocument3 paginiBusbar Calulation For 2000a Copper Busbarsbalaallied100% (5)

- Busbar Sizing CalculationDocument13 paginiBusbar Sizing CalculationPower Solution100% (2)

- MV Design Guide Design RulesDocument34 paginiMV Design Guide Design RulesAhmed IbraheemÎncă nu există evaluări

- Parameters: Calculation For Al Bus Bar Suitable For 50ka Fault LevelDocument1 paginăParameters: Calculation For Al Bus Bar Suitable For 50ka Fault Levelanand_girgaonkarÎncă nu există evaluări

- 17july10 WDC Busbar SizingDocument8 pagini17july10 WDC Busbar Sizingtceterex100% (1)

- Short Circuit CalculationDocument4 paginiShort Circuit CalculationAnonymous SrVaQYÎncă nu există evaluări

- Busbar RatingDocument64 paginiBusbar RatingAbdulla Nashith100% (1)

- Busbar Sizing CalculationDocument7 paginiBusbar Sizing Calculationchenshiva100% (1)

- Busbar Trunking SystemDocument21 paginiBusbar Trunking SystemJordan Ansh50% (2)

- Cable CalculationDocument6 paginiCable CalculationparameshvkrÎncă nu există evaluări

- Short CKT Calculation MCCDocument3 paginiShort CKT Calculation MCCshaikhsajid242Încă nu există evaluări

- LV Cable SizingDocument9 paginiLV Cable Sizingsrsureshrajan100% (1)

- Design Calculation - 5000A LT BusductDocument5 paginiDesign Calculation - 5000A LT BusductNatarajan Ramakrishnan50% (2)

- Cable Sizing For Main Cable - DBDocument8 paginiCable Sizing For Main Cable - DBDharmenderSinghChoudharyÎncă nu există evaluări

- L&T Busbar Trunking SystemDocument19 paginiL&T Busbar Trunking SystemUmerÎncă nu există evaluări

- Busbar Sizing CalculationDocument19 paginiBusbar Sizing Calculationhemant kumar100% (1)

- Bus Bar CalculationDocument20 paginiBus Bar CalculationAnirban Sen100% (2)

- Busbar Sizing CalculationDocument8 paginiBusbar Sizing CalculationCode Jon100% (1)

- Medium Voltage Swgr4Document3 paginiMedium Voltage Swgr4kjfensÎncă nu există evaluări

- A684 Cable Sizing Calculations PDFDocument1 paginăA684 Cable Sizing Calculations PDFamrit100% (1)

- An Example How To Calculate Voltage Drop and Size of Electrical Cable - EEP PDFDocument8 paginiAn Example How To Calculate Voltage Drop and Size of Electrical Cable - EEP PDFtatianaÎncă nu există evaluări

- Calculating Short-Circuit Current - IAEI MagazineDocument13 paginiCalculating Short-Circuit Current - IAEI MagazineMohamedAhmedFawzy100% (1)

- Busbar Clearance BarrierDocument2 paginiBusbar Clearance BarrierSundaresan Sabanayagam100% (1)

- Busbar CalculationDocument8 paginiBusbar Calculationd_rosembergÎncă nu există evaluări

- Medium Voltage Swgr9Document3 paginiMedium Voltage Swgr9kjfensÎncă nu există evaluări

- Merlin Gerin Medium VoltageDocument10 paginiMerlin Gerin Medium VoltagekjfenÎncă nu există evaluări

- Merlin Gerin Medium VoltageDocument10 paginiMerlin Gerin Medium VoltagekjfenÎncă nu există evaluări

- Busbar Calculation: Design RulesDocument3 paginiBusbar Calculation: Design RuleskjfensÎncă nu există evaluări

- Single-Phase Transformer DesignDocument7 paginiSingle-Phase Transformer DesignAids SumaldeÎncă nu există evaluări

- Busbar Calculation: Design RulesDocument3 paginiBusbar Calculation: Design RuleskjfensÎncă nu există evaluări

- Below Ground & Above Ground Earthing CalculationDocument8 paginiBelow Ground & Above Ground Earthing CalculationPramod B.Wankhade0% (1)

- Earthing CalculationDocument14 paginiEarthing CalculationNatarajan Ramakrishnan100% (18)

- Client: - M/ P C H P - L - ProjectDocument5 paginiClient: - M/ P C H P - L - Projectgirishprabhu19840% (1)

- Earth Mat CalculationDocument5 paginiEarth Mat CalculationSOUMEN100% (2)

- Elec CalculationDocument12 paginiElec CalculationVs PkdÎncă nu există evaluări

- HV Cable SizingDocument11 paginiHV Cable SizingPallab MukherjeeÎncă nu există evaluări

- PelajariDocument26 paginiPelajaribambangÎncă nu există evaluări

- SPL Bsts Jandaha Earthmat - Cal 005Document11 paginiSPL Bsts Jandaha Earthmat - Cal 005rahulnegi19170% (1)

- Electrical Installation DesignDocument27 paginiElectrical Installation DesignLasantha AbeykoonÎncă nu există evaluări

- MV CalDocument11 paginiMV CalrezaqesÎncă nu există evaluări

- 7SS522 CT RequirementDocument4 pagini7SS522 CT RequirementAnonymous 9EV0OmkÎncă nu există evaluări

- Circuit BreakerDocument50 paginiCircuit BreakerDeanna GrahamÎncă nu există evaluări

- On AC ResistanceDocument4 paginiOn AC ResistancesreedharÎncă nu există evaluări

- Topic 9 ThermodynamicsDocument4 paginiTopic 9 ThermodynamicsTengku Lina IzzatiÎncă nu există evaluări

- Rubber Isolator 1921Document10 paginiRubber Isolator 1921Mario Daniel MLÎncă nu există evaluări

- DCS800 Winder DescriptionDocument53 paginiDCS800 Winder DescriptionAndré Carlos CorenzanÎncă nu există evaluări

- Equilibrium Ratio Prediction and CalculationDocument31 paginiEquilibrium Ratio Prediction and CalculationaliÎncă nu există evaluări

- Porque Eres AsiDocument75 paginiPorque Eres AsiEisthen PCÎncă nu există evaluări

- CP1d-SP1d Velocity V Time Graphs Worksheet AJDocument1 paginăCP1d-SP1d Velocity V Time Graphs Worksheet AJSouleymane Jakiteh 9Încă nu există evaluări

- Temporal Stability of Inviscid Incompressible Flows: SabhileshDocument34 paginiTemporal Stability of Inviscid Incompressible Flows: SabhileshSabhilesh SinghÎncă nu există evaluări

- A InstantonDocument61 paginiA InstantonbayareakingÎncă nu există evaluări

- 1 - Shear and Moment in Beams Cest 412: Theory of Structures 1 Engr. S. OlarteDocument7 pagini1 - Shear and Moment in Beams Cest 412: Theory of Structures 1 Engr. S. OlarteSam OlarteÎncă nu există evaluări

- Final Exam - SampleDocument4 paginiFinal Exam - SampleAhmed MashhoorÎncă nu există evaluări

- Klystron TubeDocument21 paginiKlystron TubeRavi Kapatel100% (1)

- TutorialDocument32 paginiTutorialCorrado MulasÎncă nu există evaluări

- Bolt Preload Calculation PDFDocument2 paginiBolt Preload Calculation PDFTimon2005Încă nu există evaluări

- PHYS1001 MechanicsDocument23 paginiPHYS1001 MechanicsYeÎncă nu există evaluări

- CIVE1129 - Lecture Notes - Consolidation PDFDocument23 paginiCIVE1129 - Lecture Notes - Consolidation PDFLee Tin YanÎncă nu există evaluări

- Chapter 1Document199 paginiChapter 1Mohd Syafiq AkmalÎncă nu există evaluări

- YPV Series Universal Servo Drive Instruction Manual: Ye-Li Electric& Machinery Co., LTDDocument69 paginiYPV Series Universal Servo Drive Instruction Manual: Ye-Li Electric& Machinery Co., LTDAhmed100% (1)

- AGADocument5 paginiAGARizky Padutama100% (1)

- Welded C ChannelDocument3 paginiWelded C ChannelНемања Караклајић100% (1)

- Structural Analysis TYS Exp 249Document39 paginiStructural Analysis TYS Exp 249BIJAY KRISHNA DASÎncă nu există evaluări

- 2-Hydrodynamic Methods (Sedimentation, Centrifugation and UltracentrifugationDocument24 pagini2-Hydrodynamic Methods (Sedimentation, Centrifugation and UltracentrifugationEKAÎncă nu există evaluări

- Influence Line PDFDocument4 paginiInfluence Line PDFpronab kumarÎncă nu există evaluări

- Questions Physics XIIDocument137 paginiQuestions Physics XIIChandra Prashad SharmaÎncă nu există evaluări

- Parallel Plate WaveguideDocument7 paginiParallel Plate WaveguideGourab Chatterjee100% (1)

- Old-Exam.Questions-Ch-15 (Dr. Gondal, Phys101) : θ 0.08cos 4.43 tDocument3 paginiOld-Exam.Questions-Ch-15 (Dr. Gondal, Phys101) : θ 0.08cos 4.43 tmukesh3021Încă nu există evaluări

- Gec 223 AssignmentDocument6 paginiGec 223 AssignmentDaniel AgbajeÎncă nu există evaluări