Documente Academic

Documente Profesional

Documente Cultură

H R Lift Plan Procedure SSRL LPP 000 r1

Încărcat de

Nenad Ruzic0 evaluări0% au considerat acest document util (0 voturi)

186 vizualizări7 paginiSSRL Lift Plan Procedure describes the process how to use the SSRL hoisting and rigging Lift Plan (HRLP) and conduct safe hoisting activities. A Lift Plan is a document that describes the process of how to use a lifting plan and conduct safe lifting activities. The Lift Plan is used to determine the height of an object to be hoisted and the height of the object to be rigged.

Descriere originală:

Titlu original

h r Lift Plan Procedure Ssrl Lpp 000 r1

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentSSRL Lift Plan Procedure describes the process how to use the SSRL hoisting and rigging Lift Plan (HRLP) and conduct safe hoisting activities. A Lift Plan is a document that describes the process of how to use a lifting plan and conduct safe lifting activities. The Lift Plan is used to determine the height of an object to be hoisted and the height of the object to be rigged.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

186 vizualizări7 paginiH R Lift Plan Procedure SSRL LPP 000 r1

Încărcat de

Nenad RuzicSSRL Lift Plan Procedure describes the process how to use the SSRL hoisting and rigging Lift Plan (HRLP) and conduct safe hoisting activities. A Lift Plan is a document that describes the process of how to use a lifting plan and conduct safe lifting activities. The Lift Plan is used to determine the height of an object to be hoisted and the height of the object to be rigged.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 7

SSRL Lift Plan Procedure Stanford Synchrotron Radiation Laboratory

Lead Author

__________________________________ Date 07/13/2005___________

David A. Ernst Mechanical Service Group Approvals: __________________ Date _____________________

Matt Padilla SSRL Safety Officer

Robert Hettel Accelerator System Department Head

__________________

Date _____________________

Piero Pianetta Beam Line System Department Head

__________________

Date _____________________

Hoist and Rigging Panel Member _______________________________________ Date ______________________

Oct 16, 2006 SSRL Lift Plan Procedure (SSRL-LPP-000-R1) Page 1 of 7

SSRL Lift Plan Procedure Stanford Synchrotron Radiation Laboratory

Index

1 Introduction . 4 1.1 Purpose .. 4 1.2 Scope .. 4 1.3 Recordkeeping .... 4 1.4 Applicability .. 4 1.5 Related Documents ... 4 1.6 Precautions and Limitations .. 4 1.7 Equipment Description 2 Operator qualifications and requirements 5 2.1 Training .. 5 2.2 Job Hazard Analysis and Mitigation (JHAM) .... 5 3 Preparing a Lift Plan ..... 5 3.1 General Information ..... 5 3.2 Equipment Information ... 6 3.3 Personnel Protective Equipment (PPE) .. 6 3.4 Hazards .. 6 3.5 Rigging sketch . 6 3.6 Approvals and Authorization . 6 3.6.1 Approval .... 7 3.6.2 Authorization ... 7 3.7 Deviations from the approved Lift Plan . 7

Oct 16, 2006 SSRL Lift Plan Procedure (SSRL-LPP-000-R1) Page 2 of 7

SSRL Lift Plan Procedure Stanford Synchrotron Radiation Laboratory

Revision/Modification List

Rev/Mod Number R0 Description Original document

updated Safety Officer

Author /Signature Date D. Ernst 07/22/2005

R1

A.Mueller 10/16/06

Oct 16, 2006 SSRL Lift Plan Procedure (SSRL-LPP-000-R1) Page 3 of 7

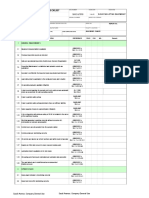

SSRL Lift Plan Procedure Stanford Synchrotron Radiation Laboratory

1 Introduction 1.1 Purpose This procedure describes the process of how to use the SSRL hoisting and rigging lift plan (HRLP) and conduct safe hoisting & rigging activities within the Stanford Synchrotron Radiation Laboratory (SSRL). 1.2 Scope The introduction of the SSRL hoisting and rigging lift plan document (SSRLHRLP-000-R0). This Lift Plan can be used to perform all routine hoisting & rigging activities not covered by the already validated SSRL lifting procedure (SLP). SLP procedures will still be completed for non-routine and hoisting and rigging activities requiring special lift fixtures and processes. 1.3 Recordkeeping This procedure requires the preparation and approval of a Lift Plan for each lifting activity. Lift Plans have unique document numbers, which are assigned by the HRLP excel spread sheet located on the V:\SSRL\CAD_Archive\SSRL Hoisting & Rigging. Copies of approved lift plans must remain on file with the area supervisor during the job in progress and later added to the engineering document archive in the V:\SSRL\CAD_Archive\SSRL Hoisting & Rigging\doc_Files HRLP\PDF folder. 1.4 Applicability This procedure applies to all routine hoisting & rigging activities performed by SSRL personnel. 1.5 Related Documents SSRL Hoisting & Rigging Lift Plan template (SSRL-HRLP-000-R0) SSRL Hoisting & Rigging Lift Procedure template (SSRL-SLP-000-R0) ES&H Chapter 41 Hoisting and Rigging describes the SLAC hoisting & rigging program and lists all of the controlling regulations for the program. ES&H Bulletin 59A Changes to the Hoisting & Rigging Program ES&H Bulletin 71 Hoisting and Rigging Bobs Overhead Crane & Rigging Handbook (training reference only)

Oct 16, 2006 SSRL Lift Plan Procedure (SSRL-LPP-000-R1) Page 4 of 7

SSRL Lift Plan Procedure Stanford Synchrotron Radiation Laboratory

1.6 Precautions and Limitations Ensure that below-the hook lifting devices; and cranes, hoists, and other lifting equipment are never loaded beyond their rated capacity. 1.7 Equipment Description The types of lifting equipment covered by this procedure include: Overhead cranes: common names used to describe these include bridge, gantry, mobile gantry, monorail, jib, floor-operated, and wall mounted cranes. Shop cranes, engine hoists, and cherry pickers. Forklifts - when used with rigging gear. 2 Operator qualifications and requirements 2.1 Training SSRL Personnel who operate cranes and hoists must be current in ES&H Course 280 Hoisting & Rigging training. 2.2 Job Hazard Analysis and Mitigation (JHAM) Personnel who are involved in hoisting & rigging activities must have hazard analysis documentation (routine or non-routine JHAM) that addresses hoisting & rigging activities. Many elements of the JHAM process (hazard identification and mitigation) are included in this procedure, and do not need to be repeated in a JHAM. 3 Preparing a Lift Plan This procedure requires that a Lift Plan be prepared and approved for all routine hoisting & rigging activities. A Lift Plan provides a formal mechanism to plan, document, and perform hoisting & rigging activities. Lift plans can be re-used for identical tasks. Lift plans must be prepared using the Hoisting and Rigging Lift Plan template (SSRL-HRLP-000-R0). The Lift plan template can be found on the V:\SSRL\CAD_Archive\SSRL Hoisting & Rigging\doc_Files HRLP folder. 3.1 General Information The following general information should be included in the Lift Plan: Unique document number Author of lift plan A general description of the load and the lift activity. Indication of radioactivity or hazardous materials that could be released if the load were dropped. Indication if the load is irreplaceable or very costly to replace if damaged. Oct 16, 2006 SSRL Lift Plan Procedure (SSRL-LPP-000-R1) Page 5 of 7

SSRL Lift Plan Procedure Stanford Synchrotron Radiation Laboratory

3.2 Equipment Information Equipment ID (hoist #, forklift #, Building crane#) and custodian. Rated capacity and operator capacity if applicable different from rated capacity. 3.3 Personnel Protective Equipment (PPE) The plan must identify the potential hazards to personnel, and the personnel protective equipment required to mitigate those hazards. 3.4 Hazards Identify additional hazards associated with the lift and describe how they will be mitigated. Examples of hazards/mitigations to consider include: Obstacles in the operator or load path (walk load path and remove obstacles prior to lift). Foot traffic around load (barricade work zone). Special hazards or precautions of rigging equipment. 3.5 Rigging sketch The rigging sketch is a critical element of the lift plan. It diagrams all of the rigging details for the activity. All rigging gear used in the lift must be sufficiently rated to withstand the forces that will be applied to it during the lift. The rigging sketch must contain enough information to demonstrate this. Note: If the

physical characteristics (size, weight, or configuration) of the item changes significantly during the manufacturing process, or if you will be handling the item is various positions, a rigging sketch may be required for each configuration.

3.6 Approvals and Authorization Lift plans must be approved for use as described below. Once a lift plan has been approved, specific personnel are authorized to use the plan.

Oct 16, 2006 SSRL Lift Plan Procedure (SSRL-LPP-000-R1) Page 6 of 7

SSRL Lift Plan Procedure Stanford Synchrotron Radiation Laboratory

3.6.1 Approval The level of review and approval required for a Lift Plan depends on the load being lifted and the nature of the lift. All lift plans must be reviewed and approved by the supervisor(s) who will be authorizing personnel to use the Lift Plan. If the lift involves rolling or flipping of the load, the lift plan must also be reviewed and approved by the SSRL Hoisting and Rigging Panel member. If the lift involves a load that, if dropped, could release radioactivity or hazardous materials or a load that is irreplaceable or very costly to replace if damaged must be reviewed and approved by the SSRL Safety Officer or Department Head and a member of the SSRL Hoisting & Rigging Panel. The SSRL Safety Officer or Department Head can require additional approvals at their discretion. 3.6.2 Authorization Lift Pans must include documentation of personnel authorized to use the plan. Documentation will include the name, signature, and date of the employee and their supervisor. Supervisors must approve the plan before they authorize any personnel to use the plan. 3.7 Deviations from the approved Lift Plan Even the best planned activity may need adjustments. The impact of any change to the Lift Plan must be evaluated and noted on the plan. If the changes are minor the impact must be determined, documented on the lift plan, and initialed by all personnel involved. Example: changed from 4-foot slings to 5-foot slings need to determine new sling angles, reduction factors, and ratings). Major changes will likely require the completion of a new rigging sketch. Such changes must be reviewed by everyone who approved the initial Lift Plan. Supervisor will discuss the lift process with lift team members after task is complete and record any additional feedback and improvement if applicable.

Oct 16, 2006 SSRL Lift Plan Procedure (SSRL-LPP-000-R1) Page 7 of 7

S-ar putea să vă placă și

- Hoisting Guide Lift PlanDocument3 paginiHoisting Guide Lift PlanPera HarlizonÎncă nu există evaluări

- Hoisting and Rigging - Lift Planning and Control For Ordinary LiftsDocument5 paginiHoisting and Rigging - Lift Planning and Control For Ordinary Liftscyno21Încă nu există evaluări

- Crane Lift PlanDocument4 paginiCrane Lift PlanAmin HatimiÎncă nu există evaluări

- Instructions For Crane Lift PlanDocument2 paginiInstructions For Crane Lift PlanAndrianoÎncă nu există evaluări

- API 17 TR14 Ballot Draft PDFDocument128 paginiAPI 17 TR14 Ballot Draft PDFStoyan StoyanovÎncă nu există evaluări

- P314.414 Cranes and Mobile Cranes PDFDocument11 paginiP314.414 Cranes and Mobile Cranes PDFJahel LootiÎncă nu există evaluări

- Lifting Plan HVACDocument10 paginiLifting Plan HVACFMU KSAÎncă nu există evaluări

- Rp-205 Crane Operation, Maintenance and TestingDocument30 paginiRp-205 Crane Operation, Maintenance and TestingWilman Barrera Grados100% (1)

- PD 05011015Document15 paginiPD 05011015Malik Uzair ZafarÎncă nu există evaluări

- Quick Start Summary 1 Who Needs To Know About These RequirementsDocument58 paginiQuick Start Summary 1 Who Needs To Know About These Requirementsjapv_pasÎncă nu există evaluări

- Lifting Code of PracticeDocument18 paginiLifting Code of PracticeOnaFajardoÎncă nu există evaluări

- Crane Lift Plan: InstructionsDocument2 paginiCrane Lift Plan: InstructionsAndrianoÎncă nu există evaluări

- Lifting Code of PracticeDocument34 paginiLifting Code of Practiceakubestlah67% (3)

- Licence To Erect ScaffoldDocument12 paginiLicence To Erect ScaffoldMustafa IdrisÎncă nu există evaluări

- 01 - Lifting Personnel Basket - ADNOCDocument4 pagini01 - Lifting Personnel Basket - ADNOCEmad ZakiÎncă nu există evaluări

- Crane Tata SteelDocument39 paginiCrane Tata Steelbabu maheshÎncă nu există evaluări

- Lifting Plan FF - Sprinkler ActivitiesDocument9 paginiLifting Plan FF - Sprinkler ActivitiesFMU KSAÎncă nu există evaluări

- G01CRANESDocument11 paginiG01CRANESjessaniÎncă nu există evaluări

- Sparrows Crane Offshore Crane Operator and Banksman Integrated Safe Operating ProceduresDocument64 paginiSparrows Crane Offshore Crane Operator and Banksman Integrated Safe Operating ProceduresTrần T Như Quyên78% (9)

- HR Chapter 03Document24 paginiHR Chapter 03Metallurgist007Încă nu există evaluări

- Lifting PlanDocument17 paginiLifting PlanzaimÎncă nu există evaluări

- 1740 - 9 NasaDocument113 pagini1740 - 9 NasaEngr Fawad WaliÎncă nu există evaluări

- QP Reg Rev 4Document92 paginiQP Reg Rev 4Murthy MullapudiÎncă nu există evaluări

- OSHA Crane Inspection GuidelinesDocument11 paginiOSHA Crane Inspection Guidelinesmisu110382100% (1)

- Crane N RiggingDocument34 paginiCrane N RiggingRajuÎncă nu există evaluări

- Hse Directive 4 Lifting OperationsDocument80 paginiHse Directive 4 Lifting Operationssea_manÎncă nu există evaluări

- Appointed Person: Planning and Regulatory RequirementsDocument6 paginiAppointed Person: Planning and Regulatory RequirementssamÎncă nu există evaluări

- OSHA Technical ManualDocument102 paginiOSHA Technical ManualthugpanditÎncă nu există evaluări

- Code of Practice Safe Lifting Operations Revised 2014Document36 paginiCode of Practice Safe Lifting Operations Revised 2014AhmedA.Hassan100% (1)

- OHDC Lifting ProcedureDocument12 paginiOHDC Lifting ProcedureHamid Ali100% (1)

- K-CW-HS-ST-007 Lifting Operations 18.0Document3 paginiK-CW-HS-ST-007 Lifting Operations 18.0Faizan AliÎncă nu există evaluări

- Standard Lift Plan ChecklistDocument9 paginiStandard Lift Plan ChecklistPablo Alejandro JrÎncă nu există evaluări

- Latest WSH Requirements On Safe Lifting Operation - MR SatishkumarDocument22 paginiLatest WSH Requirements On Safe Lifting Operation - MR SatishkumarThanThanscc100% (1)

- Some Aspects of The Roll-Over Protective Structures Evaluation, Using Shock Loading SimulationDocument8 paginiSome Aspects of The Roll-Over Protective Structures Evaluation, Using Shock Loading SimulationAldo Javier GalicÎncă nu există evaluări

- Lifting PlanDocument30 paginiLifting PlanYusuf Jappie33% (3)

- Lift Planning & Hoist ProcedureDocument34 paginiLift Planning & Hoist ProcedureAdham Abo bakrÎncă nu există evaluări

- Contractor Lift Plan Sep 1509Document9 paginiContractor Lift Plan Sep 1509Saju JosephÎncă nu există evaluări

- BP Cat Plan Risk AssesDocument36 paginiBP Cat Plan Risk AssesErwinalex79100% (2)

- 4818 DB1 OpsMan R0Document661 pagini4818 DB1 OpsMan R0sep650cengrÎncă nu există evaluări

- Plan de Izaje StandarDocument15 paginiPlan de Izaje StandarOmar MaturanaÎncă nu există evaluări

- HR Chapter 13Document19 paginiHR Chapter 13Anonymous Clyy9NÎncă nu există evaluări

- Guide Suspended Swing Stage ScaffoldsDocument14 paginiGuide Suspended Swing Stage Scaffoldsahmed rafeeq100% (1)

- Lifting Operations and Rigging: 1. PurposeDocument27 paginiLifting Operations and Rigging: 1. PurposeFaiyazÎncă nu există evaluări

- Liting PlansDocument28 paginiLiting PlansFirdaus Ismail Jr.Încă nu există evaluări

- Mil STD 1388 1aDocument121 paginiMil STD 1388 1aalvarezkev100% (1)

- Project Technical Plan For Heavy Lifts and PipelinesDocument14 paginiProject Technical Plan For Heavy Lifts and PipelinesMitchellgrany100% (1)

- Model 6 - OSHADocument19 paginiModel 6 - OSHAManoj JaiswalÎncă nu există evaluări

- Crane Hoist Safety ProgramDocument11 paginiCrane Hoist Safety ProgramAssawin AnonuÎncă nu există evaluări

- Procedure For Lifting Operations Over Live Process Are AsDocument11 paginiProcedure For Lifting Operations Over Live Process Are Aszam110Încă nu există evaluări

- Critical Lift ChecklistDocument4 paginiCritical Lift ChecklistUdha Pengen SuksesÎncă nu există evaluări

- DOE/RL-92-36, Hanford Site Hoisting and Rigging Manual Chapter 13.0 - Overhead and Gantry Cranes March 21, 2013 Rev 1 PageDocument6 paginiDOE/RL-92-36, Hanford Site Hoisting and Rigging Manual Chapter 13.0 - Overhead and Gantry Cranes March 21, 2013 Rev 1 PageAnonymous NUn6MESxÎncă nu există evaluări

- Rigging and Lifting (Rev.1)Document33 paginiRigging and Lifting (Rev.1)windell Patalinghug100% (2)

- Cs S 15ingaa CSCG Pipeloading Unloading During Construction PDFDocument10 paginiCs S 15ingaa CSCG Pipeloading Unloading During Construction PDFSham AranÎncă nu există evaluări

- SAFETY IN PETROLEUM FACILITIES TURNAROUND MAINTENANCEDe la EverandSAFETY IN PETROLEUM FACILITIES TURNAROUND MAINTENANCEÎncă nu există evaluări

- Turnaround Management for the Oil, Gas, and Process Industries: A Project Management ApproachDe la EverandTurnaround Management for the Oil, Gas, and Process Industries: A Project Management ApproachEvaluare: 2 din 5 stele2/5 (1)

- Spacecraft Dynamics and Control: The Embedded Model Control ApproachDe la EverandSpacecraft Dynamics and Control: The Embedded Model Control ApproachEvaluare: 5 din 5 stele5/5 (1)

- Advanced Gear Manufacturing and Finishing: Classical and Modern ProcessesDe la EverandAdvanced Gear Manufacturing and Finishing: Classical and Modern ProcessesEvaluare: 3.5 din 5 stele3.5/5 (2)

- Nigeria Factories Act, 1987Document56 paginiNigeria Factories Act, 1987Ethelbert AkwuruahaÎncă nu există evaluări

- Abus Electric Chain HoistDocument32 paginiAbus Electric Chain HoistراموندولدولاوÎncă nu există evaluări

- Load Chart GRT 880 - 236006-1Document18 paginiLoad Chart GRT 880 - 236006-1mohamedÎncă nu există evaluări

- Boat Lift SystemDocument44 paginiBoat Lift Systemteccvm50% (2)

- BMC 2250 ManualDocument120 paginiBMC 2250 ManualMuhammad Rifqi Anindito100% (1)

- SS 497 Code of Practice For Design Safe Use and Maintenance of Gantry Cranes PDFDocument20 paginiSS 497 Code of Practice For Design Safe Use and Maintenance of Gantry Cranes PDFWang EnhaiÎncă nu există evaluări

- PagesDocument56 paginiPagesRichard LondoñoÎncă nu există evaluări

- Trafalgar Place - CEMPDocument38 paginiTrafalgar Place - CEMPBermondsey Bill OwenÎncă nu există evaluări

- ABUS Product Overview PDFDocument15 paginiABUS Product Overview PDFNguyen Duc CuongÎncă nu există evaluări

- Komatsu PC09 1 SEBM026102 SM 01990 PDFDocument199 paginiKomatsu PC09 1 SEBM026102 SM 01990 PDFRavinder SinghÎncă nu există evaluări

- Mci/P P L .: 4-V2-2210-GN-MAN-125003Document545 paginiMci/P P L .: 4-V2-2210-GN-MAN-125003Alvaro ArancibiaÎncă nu există evaluări

- HYVA Spare PartsDocument97 paginiHYVA Spare PartsduocÎncă nu există evaluări

- Commercial Catalogue Jib Cranes Low ResDocument32 paginiCommercial Catalogue Jib Cranes Low Resstalin vÎncă nu există evaluări

- 2507 Planetgear 7000 Speed Reducers CatalogDocument88 pagini2507 Planetgear 7000 Speed Reducers Catalogjonbird12Încă nu există evaluări

- Scissor Lift Truck Safety and Operating ProcedureDocument7 paginiScissor Lift Truck Safety and Operating Procedurenatuan74Încă nu există evaluări

- Eiac Certificate Safety ZoneDocument4 paginiEiac Certificate Safety ZoneHAREESH PÎncă nu există evaluări

- Specifications of 40T EOT Crane (Rev00) For 70 Block-1Document11 paginiSpecifications of 40T EOT Crane (Rev00) For 70 Block-1doss mÎncă nu există evaluări

- Manual For HSZ-622 Chain BlockDocument4 paginiManual For HSZ-622 Chain Blockjogioscarsinaga9679Încă nu există evaluări

- Saic-U-7010 - Side Boom Tractor-Cranes-2023Document8 paginiSaic-U-7010 - Side Boom Tractor-Cranes-2023محمد ممدوحÎncă nu există evaluări

- Demag DMR (Brochure)Document20 paginiDemag DMR (Brochure)MadhaneÎncă nu există evaluări

- AM-01.01.084 Main En.d.1Document453 paginiAM-01.01.084 Main En.d.1Michael CraneÎncă nu există evaluări

- MOM - Inspection Req Lifting Equipment PDFDocument1 paginăMOM - Inspection Req Lifting Equipment PDFKannan KamalÎncă nu există evaluări

- Controllers and Controller StationsDocument65 paginiControllers and Controller StationsLucian ChorusÎncă nu există evaluări

- 270D Brazo LargoDocument32 pagini270D Brazo LargoDanny M Hurtado TaypeÎncă nu există evaluări

- Load Chart LTM1300-1Document418 paginiLoad Chart LTM1300-1Calle OlofssonÎncă nu există evaluări

- CK25-1 Webm007000 PDFDocument306 paginiCK25-1 Webm007000 PDFMagdalena BujaraÎncă nu există evaluări

- The Gujarat Factories Rules 1963 PDFDocument365 paginiThe Gujarat Factories Rules 1963 PDFAlpesh ValaÎncă nu există evaluări

- 3938Document23 pagini3938Ritu Saroa0% (1)

- SLT160 (L5523-12) Service ManualDocument74 paginiSLT160 (L5523-12) Service ManualAlbert FaragÎncă nu există evaluări

- OFERTADocument6 paginiOFERTAEpure GabrielÎncă nu există evaluări