Documente Academic

Documente Profesional

Documente Cultură

Clean and Environmentally Sustainable Copper Production

Încărcat de

MajaTrumicTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Clean and Environmentally Sustainable Copper Production

Încărcat de

MajaTrumicDrepturi de autor:

Formate disponibile

CLEAN AND ENVIRONMENTALLY SUSTAINABLE COPPER PRODUCTION

Milan . Trumi, Maja S. Trumi

University of Belgrade, Technical faculty in Bor, VJ 12, p.o. 50, 19210 Bor, Serbia mtrumic@tf.bor.ac.rs

s I

11 ` t

ABSTRACT Faced with a fast degradation of the environment as well as the exploitation of natural resources, people want to make an influence on their future and decide to put their heads together demanding the further economic and industrial development be in accordance with to Sustainable development. The basic idea of Sustainable development is to satisfy the needs of today's generations, without endangering possibilities of future generations to satisfy their own. The strategy for Sustainable development in the mining industry is being reduced to permanent, long-term reduction of consuming primary metals reserves, with the constant increase of the recycling metal production. The intent is to equalize the production with consumption. Traditional mineral processing technologies are being applied in the environmental field for cleanup and recycling processes. This paper presents examples of ways by which crushing and grinding, sizing, magnetic separation, electric separation, gravity and flotation concentration have been effectively used in waste recycling technology - example for cleaner production of copper.

SUSTAINED DEVELOPMENT The generally accepted definition of sustained development is the one which created the Brundthland's commission: The sustained development is the development which satisfies the needs of today's generation without jeopardizing the rights of future generations to satisfy their needs. The main goal of the sustained development is to provide the future generations with as much possibilities as we have had so far. One of the key issues of its sustainability is the awareness of the fact that the natural and material resources on our planet are limited. The cleaner production presents the goal which perfectly fit into the efforts leading to the sustained development. The strategy of sustained development in the field of exploiting mineral raw materials, leads towards a permanent and long-term reduction of using the primary mineral reserves accompanied at the same time by a permanent increase of metal (mineral) production out of the recycling process, leading up to the final goal, that is, to equalize it with its usage. THE CONCEPT AND DEFINITION OF CLEANER PRODUCTION

EXAMPLE OF CLEANER PRODUCTION Mineral resources belong to the group of non-renewable resources. These are exhaustive resources and that is why it is necessary to use them rationally, that is, to save them. The proper way to do it nowadays can be achieved by recycling, substitution and import. For example, in Bor, the average copper content in the ore amounts to around 0,25%. For the production of one tone of cathodic copper, some 999 tones of dangerous waste have been produced. The usage of mineral resources causes a dangerous environmental pollution and it is usually accompanied by the following issues:

soil degradation air pollution pollution of surface and underground water quantities of solid and liquid waste quantities of waste waters Copper can also be obtained from secondary raw materials, for example, from electronic waste. The *High *High *High *High *High

The concept of cleaner production is based on new methods which are supposed to be cleaner, to consume much less energy and not to produce harmful waste products. The aim of this approach is to satisfy human needs without jeopardizing human lives or the wholeness of the ecological system we depend on. The cleaner production is, in fact, a preventive approach. The main aim of the cleaner production is to focus on the prevention or reduction the quantity of waste, as well as the non-efficient usage of energy and resources. In order to achieve all these issues, it is necessary to adopt new technologies and techniques, together with new values and ways for satisfying needs of mankind. Besides, this new approach should be applied to the production process, consumption and supplying goods and services in order to get the same or higher production rate with much less energy and resources consumption. UNEP has defined the cleaner production in the following way: The cleaner production is a conceptual and procedural approach to the production which requires that all phases of life cycle of products should be so processed that it is possible to achieve the main goal: to achieve prevention or minimization of short and long-term risks for people and their environment. In fact, the cleaner production can be explained as:

*Reduction of the quantity of produced waste, or avoidance of its production at all, *More efficient usage of energy and resources, *Production of ecologically acceptable products and services, *Achieving less quantities of produced waste, lower prices and higher profit.

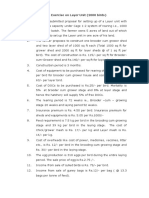

average copper content in printed circuit boards amounts to around 9,7%. The content of precious metals is also higher in these printed boards (Ag~0,06%, Au~0,023%, Pd~0,01%) in relation to their content in mineral raw materials, consequently all of these facts point to the economical importance of recycling. As an IC board contains a high copper concentration, it can be directly sent to the plant for smelting without any previous treatment. However, by smelting process it is not possible to obtain plastics and ceramics, which are present with some 30% in the printed circuit boards and which, during the melting process, cause the formation of dioxine and fuaran which pollute air and have a negative influence on the environment. If these materials are extracted in some other pretreatment (by a mechanical procedure), they can be applied in the civil-engineering industry. For the pretreatment of printed circuit board (IC) there are the whole series of different technological processes, but the things that are of special interest for mineral processing engineers are that the majority of them are based on the procedures and technologies of mineral processing. By means of these processes, it is possible to achieve the metal recovery of 80%. A great variety of materials, which are used in electric production, have a direct influence on the complexity of technologies of the mechanic recycling of these products. The mere technology of the mechanic recycling can be devided into two unities, and these are communitation and separation of integrated materials. The first step in recycling the printed circuit boards is communition. Communition has been mainly performed into several phases. The equipment that is used for communition is based on cutting and crushing the raw material and, in fact, these are universal cutters (granulators) and impact crushers of various designs (hammer mills). The transport of raw materials between the phases of communition, has been carried out by pneumatic pipelines, and each device for communition has got the dust separator and it is of particular importance thanks to its dust harmfulness. If we want the recycling technology to be successful, the communition process must provide the highest possible free movement of materials. Separation of integral materials of electronic devices is a very complex and complicated industrial process. A great number of various materials and elements, which are used in producing electronic devices, of ten require the combination of different separation methods. The most common separation methods in the recycling process of electronic devices-printed circuit boards-are: magnetic concentration, electric concentration, gravity concentration, flotation concentration. Methods of mineral processing, which have been used in the processes of IC boards recycling and shown on the flow-sheet- Figure 1, achieve higher recovery of the present metals, and in accordance with the fact that there is no water or chemical additions in combination with this procedure, there is no problem of waste waters and it is the proper thing that makes this process economically more convenient, and what is more, for the environment more acceptable than the metallurgical processes. FINAL CONSIDERATION The metal and power consumption in the world has got a terrifying rate of increase. Reserves are being used quickly. Metal waste present a very important secondary resource, and if it is being collected and returned into the process of a new treatment, we will reduce the usage of primary resources, prolong the life of their reserves and reduce the pollution of the environment. The mineral reprocessing from waste, as well as the general reprocessing of some other materials (RECYCLING), present the future, which can be accomplished only by an integral approach to the problem and which in its essence tends towards the sustained development. The clear example, which confirms the previous statements, is given in the following tables:

The power savage by using recycling materials Materials (%) Copper 85 Lead 65 Zink 60 Aluminum 95 Iron and steel 74 Magnesium 98 Titanium 58 Paper 64 Plastics 80

As it has been noticed from this table, metal waste is a very rich raw material compared to the mere ore; what is more, the transport and handling are much cheaper. The investment expenses for building up the facilities for waste processing and metal production amounts only 16 to 20% out of the costs necessary for building up facilities for processing the primary material-ore. Besides, the processing, technologies based on processing the secondary minerals (metals), are much simpler and even more convenient for the environment, and these statements can be noticed clearly on the examples of iron and steel in the following table.

Conveniences of using iron and steel out of waste ore materials Conveniences (%) 74 Power savage 90 Savage of materials obtained from ore 86 Reduced air pollution 40 Reduced water consumption 76 Reduced water pollution Reduced mining waste (waste rock) 97

Figure 1. Technological flow sheet of the physical separation of old IC boards

Acknowledgements This work was supported by the Ministry of Education and Science of the Republic of Serbia within the framework of the Project number TR 33007

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Cmvli DigestsDocument7 paginiCmvli Digestsbeth_afanÎncă nu există evaluări

- HB 76 SummaryDocument4 paginiHB 76 SummaryJordan SchraderÎncă nu există evaluări

- Naseer CV Dubai - 231017 - 215141-1Document2 paginiNaseer CV Dubai - 231017 - 215141-1krachinaseebbiryaniÎncă nu există evaluări

- Case Exercise On Layer Unit (2000 Birds)Document2 paginiCase Exercise On Layer Unit (2000 Birds)Priya KalraÎncă nu există evaluări

- 137684-1980-Serrano v. Central Bank of The PhilippinesDocument5 pagini137684-1980-Serrano v. Central Bank of The Philippinespkdg1995Încă nu există evaluări

- 04 Chapter 3Document13 pagini04 Chapter 3Danica Marie Baquir PadillaÎncă nu există evaluări

- Soal Soal ERPDocument31 paginiSoal Soal ERPAnggitÎncă nu există evaluări

- Mastery Problem (L04, 5, 6), 27: 2,500 500 0 200 100 1,300 1,500 (Expense) 2,000 0 200 100 1,300 1,000Document2 paginiMastery Problem (L04, 5, 6), 27: 2,500 500 0 200 100 1,300 1,500 (Expense) 2,000 0 200 100 1,300 1,000Paulina OlivaresÎncă nu există evaluări

- Case LawsDocument4 paginiCase LawsLalgin KurianÎncă nu există evaluări

- Test Bank - Chapter 16Document25 paginiTest Bank - Chapter 16Jihad NakibÎncă nu există evaluări

- 006 2014 Hans TjioDocument17 pagini006 2014 Hans TjioarshadtabassumÎncă nu există evaluări

- Kuki KukaDocument3 paginiKuki KukaDikiÎncă nu există evaluări

- How To Cite Legal Materials PDFDocument2 paginiHow To Cite Legal Materials PDFNadine AbenojaÎncă nu există evaluări

- Lecture 1Document15 paginiLecture 1Skyy I'mÎncă nu există evaluări

- Rhode Island College: M.Ed. in TESL Program Language Group Specific Informational ReportsDocument14 paginiRhode Island College: M.Ed. in TESL Program Language Group Specific Informational ReportsAdrian KrebsÎncă nu există evaluări

- Deanne Mazzochi Complaint Against DuPage County Clerk: Judge's OrderDocument2 paginiDeanne Mazzochi Complaint Against DuPage County Clerk: Judge's OrderAdam HarringtonÎncă nu există evaluări

- Oracle IRecruitment Setup V 1.1Document14 paginiOracle IRecruitment Setup V 1.1Irfan AhmadÎncă nu există evaluări

- Universalism and Cultural Relativism in Social Work EthicsDocument16 paginiUniversalism and Cultural Relativism in Social Work EthicsEdu ArdoÎncă nu există evaluări

- DigestDocument9 paginiDigestOliveros DMÎncă nu există evaluări

- Strategic Action Plans and Alignment GuideDocument13 paginiStrategic Action Plans and Alignment GuideAbeer AzzyadiÎncă nu există evaluări

- Abbreviations Related To Hotel Management 14.09.2018Document5 paginiAbbreviations Related To Hotel Management 14.09.2018Anonymous BkRbHIeyqnÎncă nu există evaluări

- Causes of The Fall of Rome 1Document8 paginiCauses of The Fall of Rome 1api-334241910Încă nu există evaluări

- HirarchaddonDocument5 paginiHirarchaddonawe_emÎncă nu există evaluări

- Basic Features of Jaimini AstrologyDocument3 paginiBasic Features of Jaimini AstrologyVd Vivek SharmaÎncă nu există evaluări

- Power Sector Assets v. CIR GR 198146 8 Aug 2017Document19 paginiPower Sector Assets v. CIR GR 198146 8 Aug 2017John Ludwig Bardoquillo PormentoÎncă nu există evaluări

- CLAT UG Merit List - Rank 10001-15000Document100 paginiCLAT UG Merit List - Rank 10001-15000Bar & BenchÎncă nu există evaluări

- Exam 6 PrimariaDocument5 paginiExam 6 PrimariaEdurne De Vicente PereiraÎncă nu există evaluări

- S. 1964 Child Welfare Oversight and Accountability ActDocument27 paginiS. 1964 Child Welfare Oversight and Accountability ActBeverly TranÎncă nu există evaluări

- Manajemen Rantai Pasok Tugas Studi Kasus Seven-Eleven: OlehDocument11 paginiManajemen Rantai Pasok Tugas Studi Kasus Seven-Eleven: OlehRane ArthurÎncă nu există evaluări

- Week 5 6 Diass 3.0Document7 paginiWeek 5 6 Diass 3.0Jonathan ReyesÎncă nu există evaluări