Documente Academic

Documente Profesional

Documente Cultură

2156

Încărcat de

Mohammed AhmedDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2156

Încărcat de

Mohammed AhmedDrepturi de autor:

Formate disponibile

Copyright 2002 IFAC 15th Triennial World Congress, Barcelona, Spain

A GLOBAL APPROACH FOR THE REMOTE PROCESS SIMULATION AND CONTROL

J.L. Dez, M. Valls, A.Valera

Dpto. Ingeniera de Sistemas y Automtica Universidad Politcnica de Valencia Camino de Vera 14, 46022 Valencia (Spain) E-mail: jldiez@isa.upv.es, mvalles@isa.upv.es, giuprog@isa.upv.es

Abstract: Systems Engineering and Control teaching has a problem in common with other technical studies when distance learning is required: laboratory lectures. It is related to the studied concepts in the area and the requirement of using specific software tools (i.e. Matlab) and process. This paper presents a global approach for the remote process simulation and real control using Matlab Web Server (MWS) tool. This work allows the execution of Matlab developed applications from any remote computer having a Web browser. The server obtains configuration parameters from a Web page and runs M-file Matlab programs. Once the simulation or the real process control has finished, MWS returns the output results to the remote computer through a new Web Page. Keywords: Distance-learning, Virtual Laboratory, Remote Laboratory, Digital Computer Applications, Computed Control, Control Education, Data Acquisition.

1. INTRODUCTION For the time being, trend in education (Poindexter, 1998) and, particularly, in control engineering education (Paproch, 1998), is to incorporate Information Technology in learning process. It is due to the increasing amount of computers at home connected to the Internet and decreasing effective teaching hours at University in new undergraduate programmes. They both make necessary an optimisation of educational process. The use of Internet resources leads to an increase in time and space flexibility of the educational process. Clearly, distance education takes more advantage

from new technologies than standard education, but the last can make use of information technologies (when properly used) as an effective support (Paproch, 1998). Based on Internet, two different options can be found for the laboratories developing: virtual laboratories and remote laboratories. A virtual laboratory allows, for example, continuous access to a simulated process in a computer. Under this structure, a remote interaction between the student and the virtual process is possible. Halfway between traditional and virtual laboratories are the remote laboratories that offer a real

experiment to remote users. Incorporating a webcam allows watching real system evolution in addition to variables of interest. Most equipment needed for setting up a virtual/remote laboratory is available in traditional laboratories and only an interface between local application and Web server is the additional part to be developed. MWS is a very powerful tool that helps developing virtual laboratories (Valera, et al., 2001), (Valls, et al., 2001). However, direct process control is not possible if this software is used alone. This paper shows how to implement remote simulation and real process control using Internet platforms. In order to do this, MWS is complemented with some software functions. The hardware configuration is based on PC and industrial data acquisition cards. The software functions allow the low level access from the Matlab environment. In the final part of this paper a real example of industrial process control (a DC motor) is presented in order to show the hardware and software configuration for the proposed remote laboratory.

For an extensive explanation of main features of MWS and commands used in creation of basic applications, (Valls, et al., 2001) is suggested. In this paper, the particular configuration for authors equipment is explained and some remote laboratories examples are presented. The process of creating MWS applications involves usually a combination of Matlab M-files, HTML code and graphics, so that creating these applications consists of generating the following files: An HTML input document for data submission to Matlab. A Matlab M-file to process input data and compute results. An HTML output document for display of Matlabs computations. A test file to validate code before distributing the application over the Web.

2. MATLAB WEB SERVER CONFIGURATION FOR VIRTUAL AND REMOTE INDUSTRIAL PROCESS CONTROL

2.1 Software Configuration Matlab Web Server is an integrated software suite that enables Matlab programmers to create applications that use the capabilities of the World Wide Web to send data to Matlab for computation and to display the results in a Web browser. A set of programs enables remote Web access to Matlab applications (The MathWorks, 1999): matlabserver: Manages the communication between the Web application and Matlab. Matlabserver is a multithreaded server TCP/IP server that runs Matlab programs (M-file) specified in HTML document. The maximum number of simultaneous simulations and port number is specified here. matweb.exe: Located at HTML server is a TCP/IP client of matlabserver that is uses the Common Gateway Interface (CGI) to extract data from HTML documents and transfer it to matlabserver. matweb.m: Calls the M-file that Web application wants to run. matweb.conf: A configuration file that matweb needs for connecting to matlabserver.

However, MWS does not allow on-line access to the low level hardware. Therefore, remote laboratories and remote industrial process control is not possible under MWS software provided by Mathworks. In order to make possible remote laboratories and remote control of real systems using MWS, an additional configuration with several data acquisition cards have been used and different routines have been programmed to access these cards from the Matlab environment and the web server. Above-mentioned file structure is shown in Figure 1.

Client 1 Inicial HTML HTML results Client n Inicial HTML HTML results

http daemon

matweb matlabserver MATLAB graphics

M-files

Cards drivers

Fig. 1. Remote laboratory file structure. The routines that have been programmed to access these cards from the Matlab environment allows the A/D conversion, the D/A conversion, Encoders

signals management, Digital inputs/outputs accessing and timer programming. All these functions have been programmed using C++ language in order to access to these cards directly in the .m files of the Matlab Web Server applications (available functions from Matlab toolboxes does not fulfil the application requirements). The Matlab executable functions are obtained as DLL files with the mex command, using Visual C++ v6.0 compiler. >> mex read_812.cpp

Scalar variables display The simplest way to show output results is to display a scalar or character string. In order to do so, variable name (between $ signs) have to be written in the HTML output file. Matrix display If Matlab function output is more complex, results can be shown in a matrix. A table, based on information included in a Matlab variable, can be dynamically generated for that purpose by means of HTML command table where autogenerate option corresponds to Matlab variable to display. Graphic display Finally, graphics can be generated when much information must be displayed. MWS generates jpeg graphics from Matlab. An graphic identifier (mlid) must be defined and used subsequently for file name creation.

2.2 Hardware Configuration System configuration (Figure 2) consists of a Web browser running in client workstations, while Matlab, MWS, and the Web server daemon (httpd) are running in another machine. Additionally, several data acquisition cards (DACs) have been used. An Advantech PCL-812 industrial card has been used in order to obtain the analog outputs; another one, PCL-726, has been used for supplying the control actions; and the PCL-833, have been used for reading encoders signals. Finally, a real process has been connected to DACs. DACs and real processes are not necessary if a virtual control is performed.

4. EXAMPLES OF VIRTUAL LABORATORIES Some examples have been developed with MWS and a set of appropriately designed web pages, in order to test tool capabilities and the easy access of the whole simulation framework via the Internet. Nowadays, available virtual laboratories are related to IIR Digital Filter Design and "Controllers Design", both of them quite common in basic control courses [2]. In this way, any student following a subject in which concepts related to developed web pages are taught, can perform proposed virtual laboratory work. The only one requirement is to have a PC connected to the Internet and a Web browser, and no Matlab version is required on the student computer. Developed laboratory structure is as follows: an index.html web main page has hyperlinks to two new main pages, each one corresponding to one of the previously mentioned examples: controller and filter design. Main page for controller design is pract1.html and pract2.html is the same for filter design.

Client (Web Broser)

DACs MATLAB matlabserver httpd

Webcam

Client (Web Broser)

Industrial Process

Fig. 2. Remote laboratory hardware configuration.

3. CREATION OF VIRTUAL APPLICATIONS As stated in section 3.1, three files are needed for executing Matlab applications through the Internet. First, an HTML file for data submission to Matlab is needed. This file have to specify all M-file variables and a submit input for submitting data to the program. Text variable names used at web pages must coincide with Matlab file variables. M-file for processing data input and calculate results must be implemented at computer server. The M-file is a normal Matlab function that accepts input from HTML input document and return results to a HTML output document. Different options exist for showing results and choice must depend on the kind of result.

4.1 IIR Filter Design Laboratory. Once IIR filter design option is chosen, different possibilities exist: signal generation filter design, and filter behaviour test

Signal generation option is in gen_sen1.html file and it allows, by submitting to Matlab sinusoidal signals parameters (amplitude, frequency, phase), generation of a complex signal by addition of

sinusoidal components. Indirectly, the user has acces to sen command. After parameters are introduced at text entry boxes, Enviar (submit) button must be pressed in order to make data arrive at Matlab applications server, where a .m file will process data and results will be sent to client computer. In this example, a time and frequency analysis of generated signal is done (by means of plot and fft commands) and a plot including both is returned. Figures 3 and 4 show input data web page and obtained result, respectively.

Third (and last) option referring filter design is in apl_fil1.html file and can be used for testing designed filters. In this case, all parameters explained in the two previous options (signal generation and filter design) must be submitted to Matlab. Server output is a plot of time and frequency analysis of original (unfiltered) and filtered signals, where behaviour of designed filter can be easily checked.

4.2 Controller Design Laboratory From index.html global main page, second laboratory main page (pract1.html) can be easily accessed, where different buttons for three different exercises are shown. Available exercises are in this case: open loop system analysis, closed loop system analysis, and controller design

Fig. 3: Input data web page.

Open loop system analysis is managed by "bobert1.html" file. This web page submits to Matlab bobert.m file (located at remote server) numerator and denominator coefficients written by the user at text entry boxes in the same way as explained in previous laboratory example. In this case, remote user has access to dstep Matlab command. Closed loop system analysis exercise works in the same way, being its main page "btancat1.html" file. In this case, the web page submits numerator and denominator coefficients of the system to be analysed to Matlab btancat.m remote file. In this case, remote user has access to rlocus Matlab command. The exercise output (remote server output) is a root locus plot, which will help user in controller design tasks. Finally, controller design exercise is in "control.html" file. This web page submits to Matlab control.m file (located at remote server) numerator and denominator coefficients of the system and the controller (the user have to design this controller) to be tested in a unit feedback configuration. In this way, the user has remote access to conv and dstep Matlab commands. Server output is a plot where closed loop system step answer is shown. Input to the system (step reference) is also plotted, in order to allow easy comparison between signals and control system performance.

Fig. 4: An example of analysis of generated signal. Filter design option is managed by dis_fil1.html file, who submits Matlab bandwidth of the signal that filter will process (in order to choose an appropriate sampling frequency) and design filter parameters: frequency passband edge ripple, frequency stopband edge ripple, passband ripple, stopband ripple, filter type (Butterworth, Chebyshev I, Chebyshev II or Elliptic) and main filter characteristic (lowpass, highpass, bandpass, bandstop). Once parameters are introduced at the menus and text entry boxes, submit (Enviar) button must be pressed and a plot of frequency analysis of designed filter (answer of freqz Matlab command) is shown.

5. REMOTE INDUSTRIAL PROCESS CONTROL BASED ON MATLAB WEB SERVER Two different operating options are available in remote labs: batch and on-line. On-line operation

considers control algorithm at remote computer, being control actions and sensors information transmitted through the Internet. Reference and parameters can be changed while experiment is being carried out, but variable delays appear as a consequence of Internet traffic. Batch operation avoids Internet delays because reference and controller parameters are sent to server before experiment starts and, once finished, process output is sent to remote computer. A remote laboratory in batch operating mode has been done as an example and it has been developed using MWS with additional features explained in section 2 and a set of appropriately designed web pages. In this way, any student having a PC connected to the Internet and a Web browser can control an industrial process, and no Matlab version is required on the student computer. Additionally, a webcam in order to allow watching real system evolution has been included using Windows Media Technologies 7 free software (Microsoft Corp, 2000). A hyperlink to broadcasting has been added to experiment main page (see figure 7) and, when visualisation of experiment is chosen, Windows Media Player is open (figure 5) and real time (with some delay) images are visualised by users.

Matlab, MWS Control Algorithms and Drivers

D/A Converter

DC Motor

A/D Converter

Tachometers

Potentiometers

PC

Process

Fig. 6: Remote Laboratory Setup Technically this control architecture works as follows: The potentiometers and the tachometers give the DC motor position and the velocity. These signals are introduced in the computer server using the A/D converters. Then, the computer server calculates and applies (using the D/A converters) the control action. In order to control more complex systems, other card drivers have been programmed, like the encoders signals and the digital inputs/outputs. All these cards and drivers are used to control an industrial gantry robot. For the implementation of this remote laboratory, an HTML file for data submission to Matlab is needed. This file have to specify all M-file variables and a submit input for submitting data to the program. In this case, initial Web page is control.html file and it submits to Matlab all experiment parameters (reference values, controller parameters and experiment time). Figure 7 shows the input Web page.

Fig. 5. Remote Process visualisation using Webcam.

5.1 Example: Remote DC-Motor Control In this example, a DC motor that has been used as can be seen at the Figure 7, but any other physical process can be used if the signals (control actions and process outputs) are available. Figure 6 shows the laboratory setup used for this experiment. Fig. 7: Input data page for DC-Motor Velocity Control. After Enviar (submit) button is pressed and the data arrives to the server, Matlab starts with the execution of the M-file associated function (control.m for the motor velocity control). This function is a normal Mfile Matlab function that accepts input data from HTML input document, starts the control experiment and return calculated results to a HTML output

document. With this file, results will be sent to client computer and shown in control2.html file. In this example, a time response of DC-motor to chosen reference is returned in a graphic, as is shown in Figure 8. Another remote control implemented with this DC motor is the position control. In a similar way, the user must specify the reference position and the control parameters and the results are showed in a graphic also.

work, under research project PPI-6-00-20010031 (Proyecto de I+D para Grupos Emergentes).

REFERENCES Johansson M., Gfvert M., Astrm K. J. (1998) "Interactive Tools for Education in Automatic Control", IEEE Control Sytems Magazine, Vol. 18, pp. 33-40. Overstreet J. W., Tzes A. (1999). "An Internet-Based Real-Time Control Engineering Laboratory", IEEE Control Sytems Magazine, Vol. 19, pp. 19-34. Paproch, Kenneth., (1998). Distance Learning: The Ultimate Guide London. Sage Publications. Poindexter S.E., B.S. Heck, (1999) Using the Web in your Courses: What can you do? What should you do?, IEEE Control Sytems Magazine, Vol. 19. Microsoft Corp. (2000). "Microsoft MediaTM JumpStart CD". Windows

Fig. 8: Output of DC-Motor Velocity Control.

The MathWorks Inc. (1999). "Matlab Web Server user' s guide". Valera, ., Valls, M., Tornero, J., (2001) LabConRob: Virtual Laboratory of Real-Time Robot Control, Robotica. 43. ISBN 152701/00. SIN 0874-9019. Pp 40-45 Valls, M., Valera, ., Dez J.L., (2001). Setting up a Virtual Matlab Control Laboratory., Education in Automatic Control EDCOM 2001.

6. CONCLUSIONS Matlab Web Server is an interesting tool for making accessible Matlab applications from any remote computer with a Web browser. In order to do that, the following files must be generated: a HTML input document for data submission to Matlab, a Matlab Mfile to process input data and compute results and a HTML output document for display (text or graphics) Matlabs computations. If remote industrial process control is required, an additional configuration with several data acquisition cards and different routines to access these cards from Matlab environment are needed. A practical example for a simple industrial process control has been presented and the tool behaviour was simple and fast. Finally, as usual in a remote laboratory, a webcam has been incorporated in order to allow watching real system evolution in addition to the graphical information returned by the web application.

Acknowledgements The authors wish to acknowledge the support provided by "Vicerrectorado de Investigacin, Desarrollo e Innovacin" from the Universidad Politcnica de Valencia for partial funding of this

S-ar putea să vă placă și

- Sample Cross-Complaint For Indemnity For CaliforniaDocument4 paginiSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- Google Cloud Platform for Data Engineering: From Beginner to Data Engineer using Google Cloud PlatformDe la EverandGoogle Cloud Platform for Data Engineering: From Beginner to Data Engineer using Google Cloud PlatformEvaluare: 5 din 5 stele5/5 (1)

- HowTo Use CST and Matlab TogatherDocument4 paginiHowTo Use CST and Matlab TogatherOo-baid U-safzai50% (2)

- Using Matlab WebserverDocument6 paginiUsing Matlab WebserverMuhammad Adnan MalikÎncă nu există evaluări

- Matlab DCEDocument21 paginiMatlab DCEbaruaeeeÎncă nu există evaluări

- Development of A Real-Time Digital Control System With A Hardware-in-the-Loop Magnetic Levitation Device For Reinforcement of Controls EducationDocument9 paginiDevelopment of A Real-Time Digital Control System With A Hardware-in-the-Loop Magnetic Levitation Device For Reinforcement of Controls EducationJacobo Javier Cáceres RodríguezÎncă nu există evaluări

- Eng - Using MATLAB Component Object Model With Visual Basic Graphical User Interface (GUI) Application To One Dimensional Diffusion Heat Transfer Equations of Extended Surface (FINS) PDFDocument5 paginiEng - Using MATLAB Component Object Model With Visual Basic Graphical User Interface (GUI) Application To One Dimensional Diffusion Heat Transfer Equations of Extended Surface (FINS) PDFYuriadiÎncă nu există evaluări

- Development of Control Algorithms in Matlab/Simulink: SciencedirectDocument5 paginiDevelopment of Control Algorithms in Matlab/Simulink: SciencedirectJunn Ree MontillaÎncă nu există evaluări

- Digital Modulation Using MATLABDocument7 paginiDigital Modulation Using MATLABWeehao SiowÎncă nu există evaluări

- A Power Quality Monitoring System Based On MATLAB Server PagesDocument13 paginiA Power Quality Monitoring System Based On MATLAB Server Pagesbukit_guestÎncă nu există evaluări

- Control 2Document8 paginiControl 2engrodeÎncă nu există evaluări

- Remote MonitoringDocument4 paginiRemote Monitoringshabbir_ahmed5023Încă nu există evaluări

- Matlab Project FileDocument27 paginiMatlab Project FileHimanshu ShisodiaÎncă nu există evaluări

- Báo CáoDocument6 paginiBáo CáoBẢO ĐẶNG THÁIÎncă nu există evaluări

- Mod1 Part3Document12 paginiMod1 Part3SOSHYA V CÎncă nu există evaluări

- Gridmpc: A Service-Oriented Grid Architecture For Coupling Simulation and Control of Industrial SystemsDocument8 paginiGridmpc: A Service-Oriented Grid Architecture For Coupling Simulation and Control of Industrial SystemsIrfan Akbar BarbarossaÎncă nu există evaluări

- Learn Mat Lab On WebDocument3 paginiLearn Mat Lab On WebTony StarkÎncă nu există evaluări

- Ministry of Higher Education and Scientific Research Diyala University College of EngineeringDocument5 paginiMinistry of Higher Education and Scientific Research Diyala University College of Engineeringحسين ساشهÎncă nu există evaluări

- Practical File of SCDocument27 paginiPractical File of SCKapil SoniÎncă nu există evaluări

- IPACT - 025 - PID5829727 - Indra Gandhi PDFDocument6 paginiIPACT - 025 - PID5829727 - Indra Gandhi PDFGvj VamsiÎncă nu există evaluări

- Web Base ManufacturingDocument40 paginiWeb Base ManufacturingJoeb DsouzaÎncă nu există evaluări

- Introduction of MatlabDocument9 paginiIntroduction of MatlabKind GroupÎncă nu există evaluări

- Matrimonial Portal DocumentDocument11 paginiMatrimonial Portal DocumentthangatpÎncă nu există evaluări

- The Advantages of MATLAB Over Other Programing LanguagesDocument1 paginăThe Advantages of MATLAB Over Other Programing Languageskprk414Încă nu există evaluări

- Requirements Engineering 1.1general: Operating SystemsDocument50 paginiRequirements Engineering 1.1general: Operating SystemserodeiframeÎncă nu există evaluări

- Real Time DSPDocument4 paginiReal Time DSPMuhammadÎncă nu există evaluări

- Running Labview in MatlabDocument5 paginiRunning Labview in MatlabelfrichÎncă nu există evaluări

- E FarmingDocument59 paginiE Farminggsrawat123Încă nu există evaluări

- Data Soket 2Document12 paginiData Soket 2Manu@777Încă nu există evaluări

- Struts+Notes+ (1) UnlockedDocument211 paginiStruts+Notes+ (1) Unlockedchakri007ajayÎncă nu există evaluări

- Maple Link To Grid: Dana Petcu, Diana Dubu and Marcin PaprzyckiDocument7 paginiMaple Link To Grid: Dana Petcu, Diana Dubu and Marcin PaprzyckiRyanÎncă nu există evaluări

- Online Tracking SystemDocument87 paginiOnline Tracking SystemJaldeepÎncă nu există evaluări

- CN Lab ManualDocument34 paginiCN Lab ManualChaya Bsvrj75% (4)

- Chapter 3 DroneDocument12 paginiChapter 3 DroneZero MrÎncă nu există evaluări

- MadonaDocument4 paginiMadonahappy meÎncă nu există evaluări

- NI CaseStudy Cs 13453Document7 paginiNI CaseStudy Cs 13453Anonymous C6PQv75QZÎncă nu există evaluări

- Web-Based Flow Control of A Three-Tank SystemDocument6 paginiWeb-Based Flow Control of A Three-Tank SystemessameldinÎncă nu există evaluări

- GRID NETWORKING (WWW - Ebookmaterials.blogspot - Com)Document15 paginiGRID NETWORKING (WWW - Ebookmaterials.blogspot - Com)VeerubglrKumarÎncă nu există evaluări

- Matlab Programming Environment Based On Web: Liu YuDocument4 paginiMatlab Programming Environment Based On Web: Liu YudanyÎncă nu există evaluări

- Controls Lab FinalDocument40 paginiControls Lab FinalSomil JainÎncă nu există evaluări

- Online Java CompilerDocument3 paginiOnline Java CompilerMayank S PatelÎncă nu există evaluări

- Bank Management SystemDocument36 paginiBank Management Systemnidihnrv2007100% (7)

- Certificate: Vaibhav Gaur, Students of Semester 4Document44 paginiCertificate: Vaibhav Gaur, Students of Semester 4Varun KadianÎncă nu există evaluări

- CS211 Getting Started With MATLAB Part 2Document20 paginiCS211 Getting Started With MATLAB Part 2Jackson MtongaÎncă nu există evaluări

- Towards Open Systems: A PSCAD/EMTDC To MATLAB InterfaceDocument5 paginiTowards Open Systems: A PSCAD/EMTDC To MATLAB InterfacejhoferlocoÎncă nu există evaluări

- Matlab: MATLAB (An Abbreviation of "Matrix Laboratory") Is A Proprietary MultiDocument2 paginiMatlab: MATLAB (An Abbreviation of "Matrix Laboratory") Is A Proprietary MultiSravan JanardhananÎncă nu există evaluări

- A Parallel Controls Software Approach For Pep Ii: Aida & Matlab Middle LayerDocument3 paginiA Parallel Controls Software Approach For Pep Ii: Aida & Matlab Middle LayerbaruaeeeÎncă nu există evaluări

- Online Teaching SystemDocument43 paginiOnline Teaching System20BIT008RAJKUMARÎncă nu există evaluări

- Java ProjectDocument37 paginiJava ProjectSonu Dhangar67% (3)

- MATLAB Overview and ApplicationsDocument14 paginiMATLAB Overview and ApplicationsnyenookeÎncă nu există evaluări

- Why I Use MATLAB For Forensic Image ProcessingDocument6 paginiWhy I Use MATLAB For Forensic Image ProcessingGayathri ShainaÎncă nu există evaluări

- Applications of MATLAB in Science and EngineeringDocument522 paginiApplications of MATLAB in Science and EngineeringNicoleta100% (1)

- A Web-Based Tool For Design of Simulink Models: L'Uboš Cirka, Martin KalúzDocument6 paginiA Web-Based Tool For Design of Simulink Models: L'Uboš Cirka, Martin KalúzOmo NaijaÎncă nu există evaluări

- Study On Web-Based Network Electrical Machine Control: Colloquium-2K8Document11 paginiStudy On Web-Based Network Electrical Machine Control: Colloquium-2K8ranga247Încă nu există evaluări

- Electricity Billing System (Akshi, Abdul Kadir, Abhishek Jain) Group - 18Document9 paginiElectricity Billing System (Akshi, Abdul Kadir, Abhishek Jain) Group - 18Realme SubscriberÎncă nu există evaluări

- From MATLAB To Embedded C: News&NotesDocument4 paginiFrom MATLAB To Embedded C: News&NotesOmar Milián MorónÎncă nu există evaluări

- Robo Mitsubishi RV m1 JournalDocument4 paginiRobo Mitsubishi RV m1 JournalTiagoGomesÎncă nu există evaluări

- Mastering ASP.NET: Building Powerful Web ApplicationsDe la EverandMastering ASP.NET: Building Powerful Web ApplicationsÎncă nu există evaluări

- Java / J2EE Interview Questions You'll Most Likely Be AskedDe la EverandJava / J2EE Interview Questions You'll Most Likely Be AskedÎncă nu există evaluări

- Accelerating MATLAB with GPU Computing: A Primer with ExamplesDe la EverandAccelerating MATLAB with GPU Computing: A Primer with ExamplesEvaluare: 3 din 5 stele3/5 (1)

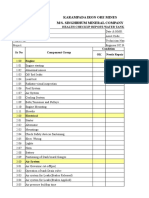

- Lista de Precios Agosto 2022Document9 paginiLista de Precios Agosto 2022RuvigleidysDeLosSantosÎncă nu există evaluări

- BECIL Registration Portal: How To ApplyDocument2 paginiBECIL Registration Portal: How To ApplySoul BeatsÎncă nu există evaluări

- List of The Legend of Korra Episodes - Wikipedia PDFDocument27 paginiList of The Legend of Korra Episodes - Wikipedia PDFEmmanuel NocheÎncă nu există evaluări

- Invoices For UEG IstanbulDocument7 paginiInvoices For UEG IstanbulIesaw IesawÎncă nu există evaluări

- Homework 1Document8 paginiHomework 1Yooncheul JeungÎncă nu există evaluări

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 paginăSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarÎncă nu există evaluări

- Zygosaccharomyces James2011Document11 paginiZygosaccharomyces James2011edson escamillaÎncă nu există evaluări

- PreviewpdfDocument83 paginiPreviewpdfJohana GavilanesÎncă nu există evaluări

- Morse Potential CurveDocument9 paginiMorse Potential Curvejagabandhu_patraÎncă nu există evaluări

- Toi Su20 Sat Epep ProposalDocument7 paginiToi Su20 Sat Epep ProposalTalha SiddiquiÎncă nu există evaluări

- DxDiag Copy MSIDocument45 paginiDxDiag Copy MSITạ Anh TuấnÎncă nu există evaluări

- Lab 2 - Using Wireshark To Examine A UDP DNS Capture Nikola JagustinDocument6 paginiLab 2 - Using Wireshark To Examine A UDP DNS Capture Nikola Jagustinpoiuytrewq lkjhgfdsaÎncă nu există evaluări

- Test Bank For Macroeconomics For Life Smart Choices For All2nd Edition Avi J Cohen DownloadDocument74 paginiTest Bank For Macroeconomics For Life Smart Choices For All2nd Edition Avi J Cohen Downloadmichaelmarshallmiwqxteyjb100% (28)

- BS en Iso 06509-1995 (2000)Document10 paginiBS en Iso 06509-1995 (2000)vewigop197Încă nu există evaluări

- LM2TB8 2018 (Online)Document252 paginiLM2TB8 2018 (Online)SandhirÎncă nu există evaluări

- CoSiO2 For Fischer-Tropsch Synthesis Comparison...Document5 paginiCoSiO2 For Fischer-Tropsch Synthesis Comparison...Genesis CalderónÎncă nu există evaluări

- 3M 309 MSDSDocument6 pagini3M 309 MSDSLe Tan HoaÎncă nu există evaluări

- Nutrition Great Foods For Getting Vitamins A To K in Your DietDocument1 paginăNutrition Great Foods For Getting Vitamins A To K in Your DietDhruv DuaÎncă nu există evaluări

- Teks Drama Malin KundangDocument8 paginiTeks Drama Malin KundangUhuy ManiaÎncă nu există evaluări

- Water Tanker Check ListDocument8 paginiWater Tanker Check ListHariyanto oknesÎncă nu există evaluări

- ICD10WHO2007 TnI4Document1.656 paginiICD10WHO2007 TnI4Kanok SongprapaiÎncă nu există evaluări

- Hetal Patel: Team Leader - SalesDocument2 paginiHetal Patel: Team Leader - SalesPrashant kumarÎncă nu există evaluări

- 10 Essential Books For Active TradersDocument6 pagini10 Essential Books For Active TradersChrisTheodorou100% (2)

- PCI Bridge ManualDocument34 paginiPCI Bridge ManualEm MarÎncă nu există evaluări

- Protection in Distributed GenerationDocument24 paginiProtection in Distributed Generationbal krishna dubeyÎncă nu există evaluări

- Code ExplanantionDocument4 paginiCode ExplanantionVivek JadiyaÎncă nu există evaluări

- Redirection & PipingDocument16 paginiRedirection & PipingPraveen PatelÎncă nu există evaluări

- Financial Accounting 1: Chapter 5 Cash and Short Term InvestmentDocument31 paginiFinancial Accounting 1: Chapter 5 Cash and Short Term InvestmentCabdiraxmaan GeeldoonÎncă nu există evaluări