Documente Academic

Documente Profesional

Documente Cultură

Strength of Materials - Simple Stresses - Hani Aziz Ameen

Încărcat de

Hani Aziz AmeenTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Strength of Materials - Simple Stresses - Hani Aziz Ameen

Încărcat de

Hani Aziz AmeenDrepturi de autor:

Formate disponibile

Strength of Materials

Handout No.2

Simple Stresses

Asst. Prof. Dr. Hani Aziz Ameen Technical College- Baghdad Dies and Tools Eng. Dept.

E-mail:haniazizameen@yahoo.com www.mediafire.com/haniazizameen

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

2-1 Introduction

When a load is applied to a member of a machine or structure , the material distorts . The stress intensity ( usually abbreviated to stress) is the load transmitted per unit area of cross-section and the strain is a measure of the resulting distortion .

2-2 Definition of Stress

If a piece of material of cross-sectional area (A) is subjected to equal and opposite axial force (P), either tensile as in Fig.(2-1a) or compressive as in Fig.(2-1b) , then the stress P A force cross sec tional area

i.e.

Fig (2-1) Fig (2-2) From Fig (2-2) it can be explained that the internal force = From the equilibrium

Fy 0 A P=0

P A

The unit of stress is N/m2 , which is called Pascal [Pa]

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

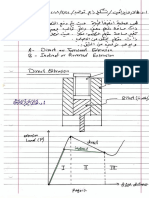

2-3 Kinds of Stresses

2-3-1 Simple Stresses (uniaxial stress) When a force acts on a body in one direction the stresses induced are : tensile stresses . compressive stresses shear stresses torsional stresses ( shear stresses). bending stresses . according to the type of the applied load 2-3-2 Combined Stresses When the forces are in two or more directions ,as shown in Fig (2-3 a,b) the stresses induced are : a) biaxial stress is when the applied loads are in two directions (see Fig 2-3 a)

a) b) c) d) e)

Fig (2-3a) b) Tri axial stress is when the applied loads are in three directions (see Fig 2-3 b)

Fig (2-3b)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

2-4 Tensile , Compressive & Shearing Stresses

The differences between these three stresses are listed below :Item Tensile Stresses 1 Tensile force acting on the body tries to extend the dimension of the body in its direction as shown in Fig(2-4 a) 2 The force is normal to the cross sectional area of the body 3 This type of stress is called normal stress It is represented by: P A Compressive Stresses Compressive force acting on the body tries to shorten the dimension in its direction as shown in Fig(2-4 b) The force is normal to the cross sectional area of the body This type of stress is called normal stress It is represented by: P A Shearing Stress Force acting on body tries to cut the body in its direction as shown in Fig(2-4 c)

The force is tangential to the cross-sectional area This type of stress is called tangential stress It is represented by: P A

-a-

-bFig (2-4)

-c-

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

2-4-1 Special Case of Tensile , Compressive & Shearing Stresses There are other types of stresses: 1-Bearing (Crushing) Stress ( b ) This special case of compressive stress occurs between bodies in contact and is subjected to compressive force. Also it occurs around rivets and bolts in connection joints. (see Fig. 2-5)

Fig (2-5) 2-Classification of Shearing Stress in Bolts It can be stated that shearing stress in the bolts ise single shear stress , double shear stress and multi shear stress are shown in Fig (2-6).

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

Fig (2-6)

2.5

Stress Concentration

The simple formula

P is applied to a member having a A constant cross-section , but when there is a rapid change in the crosssection of the member, this causes the variation of the stress in the member as shown in Fig (2-7)

Fig (2-7) The stress c

max average

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

The reasons for stress concentration are the existence of holes or grooves and any rapid changes in the member . Thus, the simple formula for tension & compression member is modified P K to the form : A

2-6 Examples

The following examples explain the different ideas of simple stress probles Example (2-1) Fig.(2-8) shows a bar of bronze , aluminum & steel subjected to axial loads . Find the stresses in the bronze , aluminum & steel .

Fig(2-8) Solution F 10 *103 s A 600 *10 6 F A 5 * 103 1000 * 10 20 * 103 700 * 10 6

6

16.66 MPa (ten.)

al

5 MPa (comp.)

and ,

b

F A

28.6 MPa (comp.)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

Example (2-2) Fig.(2-9 a) shows a cantilever beam tied by the rope from the middle .Find the stress in the rope .

Fig(2-9a) Solution

Fig(2-9b) Applying the equilibirum equation to the Fig( 2-9 b) , yields MA 0 W*3+P*6 S*d=0 Hence , S 3W 6P

d Thus, the stress will be S A 3W 6P A*d

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

Example (2-3) Fig.(2-10) shows a piston & cylinder, where the diameter of the piston is equal to 40 cm & a diameter of shaft ( piston rod) is equal to 5.6 cm. The inside value of gas pressure is 2 MPa . Find the direct tensile stress over the normal cross-section of the piston rod.

Fig(2-10) Solution It can be deduced the force F of the pressure F A*P F (40 2 5.6 2 )P

P is

4 from equilibrium condition Fx 0 F R 0 hence, the stress will be : R A 40 2 4 4 5.6 2 5.6

2

F R

P 100.16MPa

Example (2-4) Fig.(2-11) shows a truss , which is subjected to force P at the joint B . Find the maximum P acting on the truss shown below if max 100 MPa , A= 30*60 mm2 for each section.

Fig(2-11)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

Solution

Taking a joint B

Fx Fy

0 0

S1 sin S1 cos

S2 cos S2 cos

0 P

............................... (i) ................................ (ii)

Solving to get S2 S1 sin sin S1 ................ (iii) , sub. into eq.(ii)

sin cos P sin cos sin sin cos S1 sin S1 cos S1 sin( sin P ) P sin ) sin S1 P

P sin sin(

Sub. into eq. (iii) ,yield

S2

sin sin(

sin sin(

The stress induced in the cross-section is S1 A

max

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

) sin( ) Pmax max .A. sin From tri-geometric relation it can be get

Pmax sin A sin(

max

&

that

82=62+102 2*6*10 cos cos = 0.6 sin sin sin 53.1 26.75 8 6 8 6 cos and sin 30.9 8 180 ( ) 180=26.75+53.1+( +36.9) =63.25 thus Pmax will be sin(63.25 36.9) Pmax 100 * 106 * 30 * 60 * 10 6 sin36.9 and Pmax = 295.3 kN sin 6

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

abcd-

Example (2-5) Fig(2-12) shows a steel coupling connected by bolts and subjected to an axial force of 50 kN .Find Shearing stress in the bolt. Tensile stress in plate Tensile stress in branched part of coupling The bearing stress.

Fig(2-12) Solution a) P1 A P1 A P1 A 50 * 103 2 4 * (15 * 10 ) 50 * 103 50 * 10

3

6 2

136.5 MPa

b)

* 6 * 10

216 MPa

c)

(50 * 103 ) / 2 50 * 6 * 10

6

80.4 MPa

d)

b1

P1 t *d P1 / 2 t *d

50 * 103 6 * 15 * 10

6

536.3 MPa

(50 * 103 ) / 2 6 * 15 * 10

6

b2

268 MPa

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

Example (2-6) Fig.(2-13) shows a rectangular plate fixed at the four corners . A 160 kN is applied at the center of the plate . Find : a) The stress across the lower washer before tightening the nut b) The stress across the upper and lower washers after tightening the nut and the tensile force across the bolt = 5 kN

Fig(2-13) Solution a) 160 = 40 kN 4 hence, the compressive stress , is Load at each corner

F A

40 * 103 (502 222 )

25.3MN / mm 2

b)

4 Stress on upper washer 5

c

5.7 MN / mm 2 322 )

4 and the stress on lower washer can be obtained The total force on the lower washer = 40+5 = 45 kN Thus, 45 28.9MN / mm 2 c (502 222 ) 4

( 402

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

Example (2-7) Fig.(2-14) shows the pin connected structure. Pin C & D each 31.75 mm diameter ; pin C is in single shear and pin D is in double shear. Find the shear stress in the pins C&D and the bearing stress between the pin at A and the plate E . The thickness of the plate E is 6.35 mm .

Fig(2-14) Solution. From Equilibrium conditions

MD 0 MA 0

H *1.82 27 *1.22 0 H 17.8kN 17.8 * 3.65 F *1.22 0 F 53.4kN

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

The resultant reaction at pin C= (17.8) 2 Pin C acting in single shear , hence , The resultant reaction at pin D= (8.9) 2 Pin, D acts in double shear , hence,

(53.4) 2

56.26kN 71MPa

2

56.25 * 103

(31.75) 4 (53.4) 2 54.08kN 54.08 * 103

2

35.16MPa

2 * (31.75) 4 The resultant reaction at pin A= ( 4.448) 2 (35.6) 2 35.85 kN Half of this reaction acts at the upper plate and the other half acts at the lower plate E, thus the bearing stress will be : (35.85 *103 ) / 2

b

6.35 *10

* 31.75 *10

89MPa

Example (2-8) Fig (2-15) shows a lever keyed to a shaft and subjected to the forces. Find the length L of the key for an allowable shearing stress of 69 MPa

Fig(2-15) Solution Torque acting on the shaft ,T, can be calculated T =2*355.84*304.8*10 3 = 216.92 kN.m

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

T = F*r 216.92 = F*(25.4/2) F = 17 kN Hence , the shear stress will be : F 17 * 103 A 6.35L 17 * 103 69 * 106 L 39.11mm 6.35L Example (2-9) Fig.(2-16) shows the wooden truss, the allowable shearing stress parallel to the grains is 0.6895 MPa and the allowable bearing stress is 3.44 MPa . The cross-sectional area of each member is 152.4 mm*152.4 mm . Find the distance a & b .

Fig(2-16) Solution From the Equilibrium condition

MA 0 R2*L1+61.6*103 * L2 * cos30=0 .............(i) substituting L1 = L2/cos30 into eq.(i) , gives

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

R2 = 46.22 kN , and R1 = 61.6 46.22 R1 = 15.4 kN From Section a-a 46.22*L3*cos60 + FAB* L * sin60 = 0 Mc 0 FAB = 26.7 kN (ten.) Hence , the shear stress will be P , P = H = FAB = 26.7 kN A And the shearing area A = 152.4*a mm2 Thus, 26.7 * 103 6 0.6895 * 10 a 254mm 152.4 * 10 3 * a P Then , the bearing stress is , P = H = 26.7 kN bearing A And the bearing area A = 152.4*b Thus 26.7 * 103 3.44 * 106 b 50.8mm 152.4 * 10 3 * b Example (2 10) Fig (2-17) shows a flat bar having the dimensions and geometric shape shown in the Fig. is subjected to a tensile force P . Find the following ,with r= 6.35 mm a) the average stresses at the critical sections when the applied load P= 22.24 kN and the thickness of the bar t= 12.7 mm b) the max. stress at the change in the cross section accounting for the stress concentration also, sketch the stress distribution and show the computed values on a sketch The stress concentration factor are K= 2.45 for circular hole K= 2.15 for the semi-circular grooves K= 1.7 for the fillets

Fig(2-17)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

Solution a) b) P 22.24 * 1000 45.98 MPa A 12.7 * 12.7 * 10 6 The max. stress are : P 2.45 * 45.98 112.67MPa K max ) circular hole A 2.15 * 45.98 98.6MPa max )Semicircul ar

av hole

max ) fillet

1.7 * 45.98 77.9 MPa

Example (2-11) Fig.(2-18) shows a bar having the force P=30 kN acting axially . Find the max. stress for the fillet for K=1.63, K=1.97, and K =2.46 Solution P 30000 62.5MPa A 48 * 10 thus , the max. stress will be K av 1.63 * 62.5 102MPa max max 1.97 * 62.5 123MPa 2.46 * 62.5 154MPa max

av

Fig(2-18)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

2.7 Problems

2-1) Fig (2-19) shows a bar with variable cross- section with axial load P = 10kN , and L = 0.3 m , d = 0.01 m, dx = (0.01+x2) m , Find x at x = 0 , x = L / 6 & x = L/3.

Fig(2-19) 2-2) Fig.(2-20) shows a round bar subjected to a tensile load of 150 kN. If the stress 215 MPa , find the diameter of the middle portion.

Fig(2-20) 2-3) Fig(2-21) shows a cast column of the section 2 m high and it supports a load of 20kN , in addition to its own weight. Find the max. compressive stress in the column . The density of cast iron is 7200 kg/m3 .

Fig(2-21)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

2-4)

Fig(2-22) shows the plates fixed with a bolt , subjected to an axial load P where P=39240 N, 157MPa , 117.7MPa , bearing 314MPa , Find d , t , a & b.

Fig(2-22) 2-5) Fig (2-23) shows a member is subjected to a force 31392 N , the stresses are 9.81MPa , = 0.7 , b=2 . Find t , d, b , do .

Fig(2-23)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

2-6) Fig.(2-24) shows a mechanism supports the hydraulic cylinder and weighs 26688 N and the average normal stress in the 19mm diameter plunger of hydraulic cylinder . Find the average shearing stress in the 12.7mm diameter pin at A

Fig(2-24) 2-7) Fig.(2-25) shows a mechanism, the hub of the pulley is 12mm thick . Find the shearing stress in the 6 mm diameter pin at the pulley and the average bearing stress between the pulley and the pin

Fig(2-25)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

2-8) Fig.(2-26) shows a knuckle joint in a tie bar allowing stresses of 105, 75 and 150 MPa for tension , shearing and bearing respectively. Find suitable dimensions for D , d 1, t and d2 . if the load on the rod is 125 kN.

Fig(2-26) 2-9) Fig(2-27) shows the beam BE is used for hoisting machinery . It is anchored by two bolts at B, and C , it rests on a parapet wall . The essential details are given in the fig. Note that the bolts are threaded as shown in Fig. with d=16 mm at the root of the threads . If this arrangement is used to lift equipment of 10 kN , find the stress in the bolts BD and the bearing stress at C . Assume that the weight of the beam is negligible in comparison with the loads handled .

Fig(2-27)

Strength of Material -Handout No.2 - Simple Stresses - Dr. Hani Aziz Ameen

2-10) Fig.(2-28) shows a tower used for a highline. If it is subjected to a horizontal force of 540 kN and the allowable stresses are 100 MPa in compression and 140 MPa in tension , what is the required cross- sectional area of each member? All members are pinconnected .

Fig(2-28)

S-ar putea să vă placă și

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDe la EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionÎncă nu există evaluări

- Strength of Materials - Shear Stress in Beams - Hani Aziz AmeenDocument40 paginiStrength of Materials - Shear Stress in Beams - Hani Aziz AmeenHani Aziz Ameen100% (2)

- Uniaxial Stress SystemDocument36 paginiUniaxial Stress SystemKhalid YousafÎncă nu există evaluări

- CAE Lab ManualDocument40 paginiCAE Lab ManualBeesam Ramesh KumarÎncă nu există evaluări

- Fatigue Life Analysis of RIMS (Using FEA)Document4 paginiFatigue Life Analysis of RIMS (Using FEA)raghavgmailÎncă nu există evaluări

- Strength of Materials - Torsion of Non Circular Section - Hani Aziz AmeenDocument8 paginiStrength of Materials - Torsion of Non Circular Section - Hani Aziz AmeenHani Aziz Ameen100% (2)

- Strength of Materials - Deflection of Beams - Hani Aziz AmeenDocument25 paginiStrength of Materials - Deflection of Beams - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Material Science and Testing LabDocument26 paginiMaterial Science and Testing LabJitendra JangidÎncă nu există evaluări

- CAE Fatigue and Fracture Seminar - CZM For WebDocument21 paginiCAE Fatigue and Fracture Seminar - CZM For WebdamnkaushikÎncă nu există evaluări

- AnsysDocument15 paginiAnsysginupaulÎncă nu există evaluări

- Linearizing StressDocument6 paginiLinearizing Stressbo cambellÎncă nu există evaluări

- Lab Report Example 2Document20 paginiLab Report Example 2MECHANICAL ENGINEERINGÎncă nu există evaluări

- ES13 - 2SAY15-16 - Torsion - StudentsDocument68 paginiES13 - 2SAY15-16 - Torsion - Studentsmaracelis0220% (1)

- Strength of Materials - Stresses in Thin Walled Cylinder - Hani Aziz AmeenDocument13 paginiStrength of Materials - Stresses in Thin Walled Cylinder - Hani Aziz AmeenHani Aziz Ameen100% (1)

- ANSYS Analysis of Single Phase Induction Motor - Hani Aziz AmeenDocument74 paginiANSYS Analysis of Single Phase Induction Motor - Hani Aziz AmeenHani Aziz Ameen50% (2)

- C E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural NgineeringDocument27 paginiC E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural Ngineeringhend mahmoudÎncă nu există evaluări

- Energy Elastic Strain EnergyDocument14 paginiEnergy Elastic Strain EnergyamirwmÎncă nu există evaluări

- Bolt Pattern Force Distribution - MechaniCalcDocument8 paginiBolt Pattern Force Distribution - MechaniCalcdomesÎncă nu există evaluări

- Mechanical DesignDocument51 paginiMechanical DesignsafaozhanÎncă nu există evaluări

- Torsional Vibrations and Torsion ModulusDocument5 paginiTorsional Vibrations and Torsion ModulusJose Galvan100% (1)

- Fatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresDocument9 paginiFatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresAndreyÎncă nu există evaluări

- Lecture 8 & 9 - TorsionDocument12 paginiLecture 8 & 9 - TorsionHowell TungolÎncă nu există evaluări

- Strain EnergyDocument10 paginiStrain EnergyJayakumar VenkataramanÎncă nu există evaluări

- CE2155 - Combined LoadingsDocument21 paginiCE2155 - Combined LoadingsJuliaÎncă nu există evaluări

- Tips For FEA AnalysisDocument6 paginiTips For FEA Analysissagar1503Încă nu există evaluări

- Fatigue Failure CriteriaDocument17 paginiFatigue Failure CriteriaAmrMashhourÎncă nu există evaluări

- ANSYS Stress LinearizationDocument15 paginiANSYS Stress LinearizationTiago CandeiasÎncă nu există evaluări

- Mechanics of SolidDocument100 paginiMechanics of SolidasgharÎncă nu există evaluări

- Material PropertiesDocument42 paginiMaterial PropertiesDr_M_Soliman100% (2)

- Composite FEMDocument14 paginiComposite FEMbookdigitÎncă nu există evaluări

- (Fatigue Test) : Strength Lab Report Experiment #Document12 pagini(Fatigue Test) : Strength Lab Report Experiment #john rozz bbÎncă nu există evaluări

- Statics and Strength of Materials 7th Edition Ebook PDFDocument41 paginiStatics and Strength of Materials 7th Edition Ebook PDFwendy.ramos733Încă nu există evaluări

- Redistribution of MomentsDocument29 paginiRedistribution of MomentsShita AlemieÎncă nu există evaluări

- FatigueDocument20 paginiFatiguevivekÎncă nu există evaluări

- Good Solid Modeling Bad FeaDocument9 paginiGood Solid Modeling Bad FeaDeepak ChachraÎncă nu există evaluări

- Fracture Project PresentationDocument16 paginiFracture Project Presentationdhillon_rsdÎncă nu există evaluări

- Stresses in Machine ElementsDocument18 paginiStresses in Machine ElementsthirumalaikumaranÎncă nu există evaluări

- Evaluation and Comparison of Several Multi Axial Fatigue CriteriaDocument9 paginiEvaluation and Comparison of Several Multi Axial Fatigue CriteriaEbrahim AlvandiÎncă nu există evaluări

- COMSOL Cohesive Zone DebondingDocument22 paginiCOMSOL Cohesive Zone DebondingAaqib AliÎncă nu există evaluări

- Failure Theories, Static LoadsDocument15 paginiFailure Theories, Static LoadsLuiz CordeiroÎncă nu există evaluări

- 7structural Analysis of Crane Hook PDFDocument4 pagini7structural Analysis of Crane Hook PDFMohankumarÎncă nu există evaluări

- Abaqus Analysis User PDFDocument19 paginiAbaqus Analysis User PDFmohammadhossein ramezani100% (1)

- Stress AnalysisDocument8 paginiStress Analysisram vomÎncă nu există evaluări

- Deflection On The Cantilever BeamDocument11 paginiDeflection On The Cantilever BeamArif AzizAnÎncă nu există evaluări

- CH01 IntroductionDocument17 paginiCH01 IntroductionRanjit Koshy AlexanderÎncă nu există evaluări

- Pre-Lab #5 - Thin Walled Pressure VesselDocument1 paginăPre-Lab #5 - Thin Walled Pressure VesselAvraham FeldmanÎncă nu există evaluări

- CH 08Document49 paginiCH 08LeonardoMadeira11Încă nu există evaluări

- 84 TOP MOST Strength of Materials - Mechanical Engineering Multiple Choice Questions and Answers Mechanical Engineering Multiple Choice QuestionsDocument24 pagini84 TOP MOST Strength of Materials - Mechanical Engineering Multiple Choice Questions and Answers Mechanical Engineering Multiple Choice QuestionsJagadish MekaÎncă nu există evaluări

- Me2404 Set2Document11 paginiMe2404 Set2என் கருத்துÎncă nu există evaluări

- Annex B2-Recommendations For Linearization of Stress Results ForDocument20 paginiAnnex B2-Recommendations For Linearization of Stress Results ForMarlon VillarrealÎncă nu există evaluări

- Strength of Materials - Principal Stresses - Hani Aziz AmeenDocument32 paginiStrength of Materials - Principal Stresses - Hani Aziz AmeenHani Aziz Ameen100% (1)

- S-N Curve and Stress Concentration Factor (Week-02) PDFDocument17 paginiS-N Curve and Stress Concentration Factor (Week-02) PDFMuhammad TalhaÎncă nu există evaluări

- Finite Element Modeling and Analysis Do's and Don'tsDocument37 paginiFinite Element Modeling and Analysis Do's and Don'tsSory DembeleÎncă nu există evaluări

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 paginiFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Finite Element Method: Project ReportDocument15 paginiFinite Element Method: Project ReportAtikant BaliÎncă nu există evaluări

- Stress Analysis DesignDocument5 paginiStress Analysis DesignWan NorfarhanaÎncă nu există evaluări

- Shear Force and Bending MomentDocument17 paginiShear Force and Bending MomentLuis NunesÎncă nu există evaluări

- Basics of Finite Element AnalysisDocument121 paginiBasics of Finite Element AnalysisChetan The game changerÎncă nu există evaluări

- Strength of Materials - Deformation Due To Axial Load - Hani Aziz AmeenDocument32 paginiStrength of Materials - Deformation Due To Axial Load - Hani Aziz AmeenHani Aziz Ameen91% (32)

- Formability of Laser WeldingDocument9 paginiFormability of Laser WeldingHani Aziz AmeenÎncă nu există evaluări

- 7-Blanking and Piercing-Prof - Dr.hani AzizDocument4 pagini7-Blanking and Piercing-Prof - Dr.hani AzizHani Aziz AmeenÎncă nu există evaluări

- Rolling Process-Prof - Dr.hani Aziz AmeenDocument18 paginiRolling Process-Prof - Dr.hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- 4-Extrusion Process-Prof - Dr.hani Aziz AmeenDocument42 pagini4-Extrusion Process-Prof - Dr.hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- 2-Wire Drawing-Prof - Dr.Hani Aziz Ameen PDFDocument15 pagini2-Wire Drawing-Prof - Dr.Hani Aziz Ameen PDFHani Aziz AmeenÎncă nu există evaluări

- 8-High Rate Enfergy Forming-Prof - Dr.haniDocument7 pagini8-High Rate Enfergy Forming-Prof - Dr.haniHani Aziz AmeenÎncă nu există evaluări

- Stess Elasticity Prof - Dr.hani Aziz AmeenDocument53 paginiStess Elasticity Prof - Dr.hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Deep Drawing - Prof - Dr.hani Aziz AmeenDocument17 paginiDeep Drawing - Prof - Dr.hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- RESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenDocument14 paginiRESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Experimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenDocument9 paginiExperimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 paginiThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 paginiFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- شهادة تقديرية - دكتور هاني عزيز أمين PDFDocument1 paginăشهادة تقديرية - دكتور هاني عزيز أمين PDFHani Aziz AmeenÎncă nu există evaluări

- The Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenDocument21 paginiThe Effect of Coupled Field On The Vibration Characteristics and Stresses of Turbomachinery System - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Static and Dynamic Characteristics of Slotted Cylinder SpringDocument12 paginiStatic and Dynamic Characteristics of Slotted Cylinder SpringHani Aziz AmeenÎncă nu există evaluări

- Effect of Post-Buckling On The Stiffness and Stress of Plate - Hani Aziz AmeenDocument16 paginiEffect of Post-Buckling On The Stiffness and Stress of Plate - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Effect of Loading Path On Stress DistributionDocument12 paginiEffect of Loading Path On Stress DistributionHani Aziz AmeenÎncă nu există evaluări

- Professor DR Hani Aziz AmeenDocument1 paginăProfessor DR Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Slotted Cylinder SpringDocument11 paginiSlotted Cylinder SpringHani Aziz AmeenÎncă nu există evaluări

- Finite Element Analysis of The Dish Multi-Point FormingDocument10 paginiFinite Element Analysis of The Dish Multi-Point FormingHani Aziz AmeenÎncă nu există evaluări

- Ansys Analysis of Concrete Planter Round PDFDocument6 paginiAnsys Analysis of Concrete Planter Round PDFHani Aziz AmeenÎncă nu există evaluări

- Manufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Document19 paginiManufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Hani Aziz AmeenÎncă nu există evaluări

- ANSYS of Groundwater Flow Problem-Hani Aziz AmeenDocument10 paginiANSYS of Groundwater Flow Problem-Hani Aziz AmeenHani Aziz Ameen100% (2)

- Manufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Document19 paginiManufacturing Cosine Die Profile For Tubes Hydroforming Test (Bulging)Hani Aziz AmeenÎncă nu există evaluări

- Hani Aziz Ameen هاني عزيز امينDocument3 paginiHani Aziz Ameen هاني عزيز امينHani Aziz AmeenÎncă nu există evaluări

- PDF Created With Pdffactory Pro Trial VersionDocument1 paginăPDF Created With Pdffactory Pro Trial VersionHani Aziz AmeenÎncă nu există evaluări

- Hani Aziz Ameen هاني عزيز امينDocument3 paginiHani Aziz Ameen هاني عزيز امينHani Aziz AmeenÎncă nu există evaluări

- Moving and Repeating Load in Ansys APDL - Hani Aziz AmeenDocument4 paginiMoving and Repeating Load in Ansys APDL - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Hani Aziz Ameen هاني عزيز امينDocument3 paginiHani Aziz Ameen هاني عزيز امينHani Aziz AmeenÎncă nu există evaluări

- PDF Created With Pdffactory Pro Trial VersionDocument1 paginăPDF Created With Pdffactory Pro Trial VersionHani Aziz AmeenÎncă nu există evaluări

- Specific Heat Capacity Lab Report2Document6 paginiSpecific Heat Capacity Lab Report2milayosores100% (2)

- Group A Rawat Lab Presentation FinalDocument96 paginiGroup A Rawat Lab Presentation Finalumair100% (3)

- TOEFL Prediction Test 2: Mohon Materi Tes Ini Tidak Diberikan Kepada SiapapunDocument6 paginiTOEFL Prediction Test 2: Mohon Materi Tes Ini Tidak Diberikan Kepada Siapapunbatpersero12100% (1)

- Low Cycle Fatigue in AnsysDocument20 paginiLow Cycle Fatigue in AnsysSuvarnaÎncă nu există evaluări

- Lab 16 - Hollow LensDocument2 paginiLab 16 - Hollow Lensapi-408463795Încă nu există evaluări

- Chapter 15Document27 paginiChapter 15anastark100% (6)

- ESB 2018 Abstract Proceedings 4Document1.099 paginiESB 2018 Abstract Proceedings 4Alan PolancoÎncă nu există evaluări

- DNA Structure + Function 12-1Document31 paginiDNA Structure + Function 12-1Jalajarani AridassÎncă nu există evaluări

- Stack Effect in High Rise Buildings A ReviewDocument13 paginiStack Effect in High Rise Buildings A ReviewAhmedBadrÎncă nu există evaluări

- Nanodrop PDFDocument2 paginiNanodrop PDFVinay TejaÎncă nu există evaluări

- Unit1 Chapter 28 29Document27 paginiUnit1 Chapter 28 29teeradonpat.sÎncă nu există evaluări

- Mark Scheme (Results) Summer 2010: IGCSE Chemistry (4335) Paper 1FDocument16 paginiMark Scheme (Results) Summer 2010: IGCSE Chemistry (4335) Paper 1FCoolman PoonÎncă nu există evaluări

- Konelab 20Document2 paginiKonelab 20mrashrafi100% (1)

- Class X - Holiday HWDocument6 paginiClass X - Holiday HWSaritamaheshÎncă nu există evaluări

- ABB Epoxy PoleDocument11 paginiABB Epoxy Poleminsoo11Încă nu există evaluări

- Sensitometry: Describing Photographic PerformanceDocument55 paginiSensitometry: Describing Photographic PerformanceilloÎncă nu există evaluări

- AMLTM.00.092-00-Iss1 Tape Adhesion Test For Paints and CoatingsDocument6 paginiAMLTM.00.092-00-Iss1 Tape Adhesion Test For Paints and CoatingsalbertoÎncă nu există evaluări

- Urban Drainage Hydraulic CalculationsDocument1 paginăUrban Drainage Hydraulic CalculationsImran AzizÎncă nu există evaluări

- 110 WS Solutions KeyDocument2 pagini110 WS Solutions Keyshanmugam karthickÎncă nu există evaluări

- Growth Kinetic Models For Microalgae Cultivation A ReviewDocument16 paginiGrowth Kinetic Models For Microalgae Cultivation A ReviewJesús Eduardo De la CruzÎncă nu există evaluări

- Brochure Hapro Seecret-Skin RejuvenationDocument16 paginiBrochure Hapro Seecret-Skin RejuvenationwobblegobbleÎncă nu există evaluări

- General Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsDocument12 paginiGeneral Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsHazel EncarnacionÎncă nu există evaluări

- Physics11 WorkEnergy PDFDocument143 paginiPhysics11 WorkEnergy PDFKeith Ryan LapizarÎncă nu există evaluări

- The Presentation ON: Satus of The PSF Plant OperationDocument24 paginiThe Presentation ON: Satus of The PSF Plant OperationKaushik SinghaÎncă nu există evaluări

- NEET Syllabus 2023Document7 paginiNEET Syllabus 2023Shaik AmjadÎncă nu există evaluări

- CHM3201 Tutorial 1 Basic ConceptsDocument3 paginiCHM3201 Tutorial 1 Basic ConceptsAkmalZharifAbdullahÎncă nu există evaluări

- Manual FM200 PDFDocument44 paginiManual FM200 PDFDIOGO FRANCO PUREZAÎncă nu există evaluări

- 2 SonicScope SchlumbergerDocument19 pagini2 SonicScope SchlumbergersudiptodattaÎncă nu există evaluări

- Insert.C.f.a.s. Lipids.03018415001.V7.enDocument2 paginiInsert.C.f.a.s. Lipids.03018415001.V7.enGuneyden Guneyden100% (1)

- Ow-En AirpelDocument4 paginiOw-En AirpelmuppetscrapÎncă nu există evaluări