Documente Academic

Documente Profesional

Documente Cultură

Covered Electrodes For Stainless Steel: Avesta Electrodes Product Programme

Încărcat de

kamals55Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Covered Electrodes For Stainless Steel: Avesta Electrodes Product Programme

Încărcat de

kamals55Drepturi de autor:

Formate disponibile

Avesta electrodes

product programme

Covered electrodes for stainless steel

Prefabrication welding in workshops, on-site welding, overlay welding

and repair welding are just some of the uses of covered electrodes.

Avesta Weldings wide programme includes electrodes that, for most steel

grades and applications, satisfy the severest requirements in respect

of corrosion resistance and mechanical properties.

Product programme

Avesta Welding produces covered electrodes not only for

all the most commonly used ferritic, martensitic, duplex

and austenitic stainless steels, but also for nickel base

alloys. The programme further includes electrodes for welding dissimilar joints between, for example, stainless steels

and unalloyed steels or nickel base alloys.

Avesta Welding manufactures three categories of electrodes:

Rutile-acid electrodes are designed for normal flat

welding, but can also be used for position welding.

Basic electrodes offer better mechanical properties and

superior penetration. Welding with basic electrodes uses

direct currentand the electrode as the positive terminal

(DC+).

Rutile electrodes are the predecessors of todays rutile-

acid electrodes. Nowadays, rutile coatings are used

almost exclusively for welding more demanding ma-

terials such as 2507/P100 and 254 SFER. In these cases,

properties are given a higher priority than weldability.

Electrode types and designations

Electrode types

EN 1600

Avesta Weldings designations

Martensitic

248 SV

Austenitic

308L/MVR, 308/308H, 308L-LF, 347/MVNb,

316L/SKR, 316/316H, 318/SKNb, 317L/SNR, SLR

Austenitic-ferritic LDX 2101, 2304, 2205, 2507/P100

Fully austenitic

254 SFER, SKR-NF, 316L/SKR-Cryo, 904L,

383, P12-R, P625, P16, P54

Special types

307, 309L, P5, P7, P10, P690

Heat resistant

309, 310, 253 MA, 253 MA-NF, 353 MA

Avesta Welding can also supply electrodes specially

manufactured to meet individual customer requirements

as regards, for example, coating or chemical composition.

Weld metal composition Standard designations

Electrode designations Coating type Chemical composition, typical values, %

Typical

EN

AWS

Avesta Welding

Si

Mn

Cr

Ni

248 SV

308L/MVR-2D

308L/MVR-3D

308L/MVR-4D

308L/MVR basic

308L/MVR-VDX

308/308H AC/DC

308L-LF

347/MVNb-3D

347/MVNb basic

316L/SKR-2D

316L/SKR-3D

316L/SKR-4D

316L/SKR basic

316L/SKR-VDX

316/316H AC/DC

318/SKNb AC/DC

317L/SNR AC/DC

SLR AC/DC

LDX 2101-3D

2304-3D

2205-2D

2205-3D

2205-4D

2205 basic

2507/P100-4D

2507/P100

254 SFER

316L/SKR-Cryo

904L AC/DC

904L-PW

383 AC/DC

P12-R

P625

P16

P54

307 AC/DC

309L-3D

309L-4D

309L basic

P5-2D

P5-3D

P5-4D

P5 basic

P5-VDX

P7 AC/DC

P10

P690

309 AC/DC

310 AC/DC

253 MA AC/DC

253 MA-NF

353 MA

0.03

0.03

0.02

0.02

0.03

0.02

0.06

0.03

0.02

0.06

0.03

0.02

0.02

0.03

0.02

0.06

0.02

0.02

0.02

0.04

0.02

0.02

0.02

0.02

0.03

0.03

0.03

0.03

0.03

0.02

0.02

0.02

0.02

0.02

0.01

0.02

0.07

0.02

0.02

0.03

0.03

0.02

0.02

0.03

0.02

0.09

0.03

0.03

0.05

0.10

0.08

0.08

0.07

0.5

0.7

0.8

0.8

0.4

0.7

0.7

0.3

0.8

0.2

0.8

0.8

0.8

0.4

0.7

0.8

0.8

0.7

0.8

0.8

0.8

0.8

0.8

0.8

0.5

0.8

0.5

0.8

0.4

0.7

1.0

0.9

0.4

0.5

0.1

0.2

0.8

0.8

0.8

0.2

0.8

0.8

0.7

0.2

0.9

0.8

0.3

0.4

0.8

0.5

1.5

0.7

0.7

3.0

0.9

0.6

0.6

1.5

0.8

1.1

1.8

0.8

1.7

0.8

0.7

0.7

1.7

0.7

1.0

0.8

0.9

1.0

0.7

0.8

0.7

0.7

0.7

1.2

0.8

1.3

4.5

2.4

1.2

1.2

0.9

0.4

0.2

0.2

2.6

4.0

0.8

1.0

1.9

1.0

0.8

1.0

2.0

0.9

0.8

7.0

3.0

1.0

2.1

0.7

1.0

1.4

16.0

20.0

19.5

19.5

20.0

19.0

20.0

18.5

19.5

19.5

18.0

18.5

18.0

18.5

18.5

19.0

18.5

19.0

18.5

23.5

24.5

22.5

23.0

23.0

23.5

25.0

25.5

25.5

17.5

20.5

20.0

27.0

21.5

21.5

23.5

25.5

19.5

23.0

23.5

24.0

22.0

23.0

23.0

22.5

22.5

29.0

16.0

30.0

24.0

26.0

22.0

19.0

27.5

5.5

1.2

10.5

10.0

10.5

10.0

10.0

10.0

10.5

10.0

10.0

12.0

2.8

12.0

2.7

12.0

2.6

12.0

2.8

12.5

2.8

12.0

2.8

12.0

2.8

13.0

3.7

13.5

4.0

7.0

0.3

9.0

9.5

3.0

9.5

3.0

9.5 3.0

9.0 3.0

9.3 3.6

10.0 3.6

22.5 2.4

13.8 2.5

25.0

4.5

24.5

4.5

32.0

3.7

Bal.

9.5

Bal.

9.5

Bal.

15.5

25.5

5.0

10.5 0.8

13.0

13.0

13.0

13.5 2.7

13.0 2.5

13.0 2.5

13.0 2.7

13.5 2.5

9.5

Bal.

Bal. 0.3

13.5

21.0

10.5

10.0

33.0

Rutile

Rutile-acid

Rutile-acid

Rutile-acid

Basic

Rutile-acid

Rutile-acid

Rutile

Rutile-acid

Basic

Rutile-acid

Rutile-acid

Rutile-acid

Basic

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Basic

Rutile-acid

Rutile

Rutile

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Basic

Basic

Basic

Basic

Rutile-acid

Rutile-acid

Rutile-acid

Basic

Rutile-acid

Rutile-acid

Rutile-acid

Basic

Rutile-acid

Rutile-acid

Basic

Basic

Rutile-acid

Rutile-acid

Rutile-acid

Rutile-acid

Basic

Mo

Other

ferrite*

N 0.12

10 FN

10 FN

5 FN

5 FN

5 FN

5 FN

0 FN

Nb10xC** 8 FN

Nb10xC** 5 FN

10 FN

10 FN

8 FN

5 FN

5 FN

5 FN

10 FN

Nb10xC**

10 FN

10 FN

N 0.14

45 FN

N 0.12

30 FN

N 0.15

30 FN

N 0.15

30 FN

N 0.15

30 FN

N 0.16

40 FN

N 0.22

30 FN

N 0.23

30 FN

N 0.16 0 FN

0 FN

Cu 1.5 0 FN

Cu 1.5 0 FN

Cu 1.0 0 FN

Nb 2 Fe 3 0 FN

Nb 3.5 Fe 1.5 0 FN

0 FN

N 0.35 Cu 0.8 0 FN

5 FN

15 FN

15 FN

15 FN

20 FN

15 FN

20 FN

15 FN

20 FN

40 FN

Nb 2.2 Fe 5 0 FN

Nb 1.5 Fe 9 0 FN

15 FN

0 FN

N 0.18 REM

10 FN

N 0.16 REM 0 FN

REM 0 FN

E 19 9 L R

E 19 9 L R

E 19 9 L R

E 19 9 L B

E 19 9 L R

E 19 9 R

E 19 9 L R

E 19 9 Nb R

E 19 9 Nb B

E 19 12 3 L R

E 19 12 3 L R

E 19 12 3 L R

E 19 12 3 L B

E 19 12 3 L R

E 19 12 2 R

E 19 12 3 Nb R

E 19 13 4 N L R

E 22 9 3 N L R

E 22 9 3 N L R

E 22 9 3 N L R

E 22 9 3 N L B

E 25 9 4 N L R

E 25 9 4 N L R

E 25 22 2 N L R

E 20 25 5 Cu N L R

E 20 25 5 Cu N L R

E 27 31 4 Cu L R

ENiCr21MoFeNb

ENiCr22Mo9Nb

ENiCr23Mo16

E 18 9 Mn Mo R

E 23 12 L R

E 23 12 L R

E 23 12 L B

E 23 12 2 L R

E 23 12 2 L R

E 23 12 2 L R

E 23 12 2 L B

E 23 12 2 L R

E 29 9 R

E Ni Cr 15 Fe 6 Mn

E Ni Cr 30 Fe 9 Nb

E 25 20 R

E308L-17

E308L-17

E308L-17

E308L-15

E308L-17

E308H-17

E308L-15

E347-17

E347-15

E316L-17

E316L-17

E316L-17

E316L-15

E316L-17

E316H-17

E318-17

E317L-17

E2209-17

E2209-17

E2209-17

E2209-15

E2594-17

E2594-17

E316L-17

E385-17

E383-17

ENiCrMo-12

ENiCrMo-3

ENiCrMo-13

E307-17

E309L-17

E309L-17

E309L-15

E309MoL-17

E309MoL-17

E309MoL-17

E309MoL-15

E309MoL-17

(E312-17)

ENiCrFe-3

ENiCrFe-7

E309-17

E310-17

* The ferrite content of pure weld metal. FN 0 18 in Schaeffler-DeLong, FN >18 in WRC-92. ** Max. 1.0% Nb.

Avesta 2D electrodes

high productivity in the flat position

Avesta 2D high-recovery electrodes give a metal recovery

of up to 150%. The deposition rate can be as much as

30% better than that of corresponding standard products.

Because weld beads are generally considerably longer

when using 2D electrodes, there is minimum starting and

stopping. This improves both cost efficiency and quality.

2D electrodes can be used for: horizontal-vertical and flat

fillet welds; flat butt welds; and, various types of overlay

welding. Suitable metal thicknesses are 5 mm upwards.

Avesta 3D electrodes

the perfect all-round electrodes

Avesta 3D electrodes have been specially developed

for flexible welding in all common welding positions.

Because 3D electrodes have a very wide parameter box,

they have a large working range and can be used for

all types of joints. 3D electrodes have extremely good

weldability and give a stable arc. Both the slag and the

weld pool are easy to control. Suitable metal thicknesses

are 3 mm upwards. For thinner materials, Avesta 4D

electrodes are recommended.

Mechanical properties, typical values

Electrode

Rp0.2

N/mm2

Rm

N/mm2

A5

%

Impact strength, KV, J

+20C Lgtemp

248 SV

308L/MVR-2D

308L/MVR-3D

308L/MVR-4D

308L/MVR basic

308L/MVR-VDX

308/308H

308L-LF

347/MVNb-3D

347/MVNb basic

316L/SKR-2D

316L/SKR-3D

316L/SKR-4D

316L/SKR basic

316L/SKR-VDX

316/316H

318/SKNb

317L/SNR

SLR

LDX 2101-3D

2304-3D

2205-2D

2205-3D

2205-4D

2205 basic

2507/P100-4D

2507/P100

254 SFER

316L/SKR-Cryo

904L

904L-PW

383

P12-R

P625

P16

P54

307

309L-3D

309L-4D

309L basic

P5-2D

P5-3D

P5-4D

P5 basic

P5-VDX

P7

P10

P690

309

310

253 MA

253 MA-NF

353 MA

510

395

470

420

420

450

450

420

470

520

420

445

480

430

480

470

470

485

490

640

640

640

620

630

645

700

700

440

440

400

400

410

480

480

550

500

465

450

460

440

450

490

530

465

545

620

380

400

435

430

535

470

385

760

550

570

520

560

600

605

570

620

680

575

590

590

565

630

615

605

615

635

800

780

825

810

820

840

880

900

660

550

565

600

620

730

770

780

700

605

550

590

570

625

640

660

615

685

810

630

640

580

625

725

630

565

30

115

41 65

37 60

35 54

38 70

35 55

37 55

39 85

35 55

30 80

37 55

36 55

34 60

34 70

30 50

35 50

34 60

32 45

31 45

25 45

23 40

33 55

25 45

25 45

26

100

24 40

26 80

32 55

37 75

34 70

35 70

33 55

37 90

30 60

35 60

20 50

35 45

35 50

29 50

30 50

30 35

30 30

28 40

30 50

30 40

18 25

39 115

35 110

30 45

35 80

37 60

35 70

33 85

55 (40C)

55 (40C)

38 (40C)

55 (40C)

40 (40C)

50 (40C)

35 (196C)

45 (40C)

60 (40C)

55 (40C)

55 (40C)

55 (20C)

50 (40C)

35 (40C)

50 (40C)

30 (40C)

28 (40C)

25 (40C)

40 (40C)

35 (40C)

35 (40C)

75 (40C)

30 (46C)

55 (40C)

35 (196C)

70 (196C)

50 (40C)

40 (40C)

30 (70C)

45 (40C)

35 (40C)

80 (196C)

100 (196C)

35 (196C)

Approvals*

Brinell

TV

DNV

CWB

CE

Other

hardness

260

210

200

210

200

210

210

200

225

255

210

210

210

210

210

210

220

210

225

260

260

240

240

240

240

250

250

200

200

200

200

200

220

220

220

220

200

210

210

210

220

220

220

230

225

270

180

220

210

190

215

210

200

x

x

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

x

X

X

X

X

X

X

X

X

x

X

X

X

X

X

X

X

X

X

X

X

X

X

x

x

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

DB

DB

DB

DB

DB

DB, LR, GL, RINA

DB

DB, LR, GL, RINA

DB

* For detailed information, contact Avesta Welding.

Avesta 4D electrodes

for extreme position welding of sheet and pipes

The weldability of 4D electrodes is extremely good

and the arc and weld pool are both stable. The thin

coating gives a small weld pool. However, the slag is

very compliant and easy to control. A short arc is to be

used for welding. The slag is self-releasing and leaves

an even, beautiful weld finish.

Several of the rutile-acid electrodes are manufactured with

the coating specially adapted for specific purposes:

PW electrodes, predecessors to our 3D and 4D electrodes,

have a rutile-acid coating specially developed for position

welding.

VDX electrodes, predecessors to 4D electrodes, have a

rutile-acid coating and are to be used for the vertical-down

welding of joints that have no gaps, e.g. lap welds.

Current, A

Overhead (PE)

Current, A

mm

Current, A

Rutile-acid

Basic*

1.6

2.0

2.5

3.25

4.0

5.0

2.0

2.5

3.25

4.0

5.0

1.6

2.0

2.5

3.25

4.0

5.0

2630

2630

2630

2630

2630

2630

2427

2427

2427

2427

2427

2224

2224

2224

2224

2224

2224

30 50

30 40

35 45

35 60

35 50

40 50

50 80

50 60

60 70

80120

80 95

95105

100160

160220

35 55

35 40

35 45

50 75

50 60

55 65

70100

70 80

90100

100140 100115 125135

140190

30 40

30 35

30 40

35 55

35 40

40 50

50 75

50 60

60 70

70110

70 80

95105

100150 100120 120135

140190

Rutile

10707EN-GB, Centrumtryck, Avesta 2007

Welding recommendations, typical values

Coating type

Diameter

Voltage

Flat (PA)

Vertical-up (PF)

* A slightly lower current is recommended for nickel base electrodes such as P10, P12 and P16.

Quality assurance and marking

Further information

Avesta Weldings covered electrodes are supplied

with 3.1 certificates. These give the chemical analyses

of the supplied items. Each electrode is marked with

the product name, lot number and, where there is one,

standard designation.

Further information about Avesta Weldings products

is available at www.avestawelding.com and in various

publications, e.g.:

The Avesta Welding manual

Product brochures

Product data sheets

How to weld a series of brochures with welding

recommendations for special steels.

Each capsule has the following markings:

Avesta Weldings product name

Lot number

Weight

Standard designation

Approvals

Recommended welding parameters

Warning text

All Avesta electrodes can be supplied manufactured in

accordance with the relevant parts of the requirements

set out by the nuclear power industry in ASME code

section III and KTA 1408.

Avesta Welding AB

P.O. Box 501, Koppardalen

SE- 774 27 Avesta, sweden

Tel: +46 (0) 226 815 00

Fax: +46 (0) 226 815 75

info@avestawelding.com

www.avestawelding.com

S-ar putea să vă placă și

- Lesson 14 WelderQuals - New2Document80 paginiLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Aws WJ 201402Document150 paginiAws WJ 201402aperezm361Încă nu există evaluări

- Differences Between AC Welding and DC WeldingDocument2 paginiDifferences Between AC Welding and DC WeldingDevarakonda KondayyaÎncă nu există evaluări

- Cswip QuestionDocument3 paginiCswip Questionfasith9534Încă nu există evaluări

- ASTM Standards 1Document4 paginiASTM Standards 1balajiÎncă nu există evaluări

- Weld Defect Wall ChartDocument6 paginiWeld Defect Wall ChartMuhammad Attaulla KhanÎncă nu există evaluări

- VT Acceptance Criteria Vs ASMEDocument1 paginăVT Acceptance Criteria Vs ASMEAnonymous EkfqSPÎncă nu există evaluări

- Weld Repair ProcedureDocument51 paginiWeld Repair Proceduremohd as shahiddin jafriÎncă nu există evaluări

- Specification For Visula Welding InspectionsDocument5 paginiSpecification For Visula Welding InspectionsAhmed Shaban KotbÎncă nu există evaluări

- Structure and PropertiedDocument43 paginiStructure and PropertiedJalaj GaurÎncă nu există evaluări

- Daily Report-31 (Su Jinlong)Document3 paginiDaily Report-31 (Su Jinlong)sujinlongÎncă nu există evaluări

- How To Read Welding Gauges PDFDocument5 paginiHow To Read Welding Gauges PDFjimbox88Încă nu există evaluări

- 316LNDocument3 pagini316LNGanesh KcÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Welding Procedure Specification For GTAWDocument9 paginiWelding Procedure Specification For GTAWraja reyhanÎncă nu există evaluări

- A Tig Welding MainsDocument37 paginiA Tig Welding Mainshiya mistryÎncă nu există evaluări

- Er 100 S 1Document1 paginăEr 100 S 1Oliver Quezada Inostroza100% (1)

- Supervisory Development Programme-I (SDP-I) Topic: Non Destructive Testing (NDT) Faculty: Naveen SethDocument54 paginiSupervisory Development Programme-I (SDP-I) Topic: Non Destructive Testing (NDT) Faculty: Naveen SethvcpÎncă nu există evaluări

- Welding Drying OvenDocument2 paginiWelding Drying OvenAsad AliÎncă nu există evaluări

- Material Inspection Report: Project Name Date InspDocument22 paginiMaterial Inspection Report: Project Name Date InspRafiqKuÎncă nu există evaluări

- Duplex Stainless SteelDocument17 paginiDuplex Stainless SteelthunderÎncă nu există evaluări

- Asme 1325-18 (2007)Document1 paginăAsme 1325-18 (2007)Matthew TaylorÎncă nu există evaluări

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 paginăTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarÎncă nu există evaluări

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 paginiCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONÎncă nu există evaluări

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 paginiA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableÎncă nu există evaluări

- Approved Weld Procedure SpecificationsDocument38 paginiApproved Weld Procedure SpecificationsJohan0001Încă nu există evaluări

- Wel 13 HDocument8 paginiWel 13 HWilly Uio100% (1)

- Difference Between Stainless Steel Grade SS316 & SS316LDocument1 paginăDifference Between Stainless Steel Grade SS316 & SS316LSableen SinghÎncă nu există evaluări

- WPS & SmawDocument12 paginiWPS & Smawnuke apriyaniÎncă nu există evaluări

- General Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelsDocument14 paginiGeneral Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelspawanÎncă nu există evaluări

- LamelerDocument5 paginiLamelerPrasetyaOne NugraHantoeÎncă nu există evaluări

- MetallurgyDocument25 paginiMetallurgyPandu Damay PutraÎncă nu există evaluări

- DVS 2207-3Document12 paginiDVS 2207-3gura9054Încă nu există evaluări

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 paginiN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliÎncă nu există evaluări

- WIS Plate ExeDocument26 paginiWIS Plate ExeArdi ManaluÎncă nu există evaluări

- Inspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationDocument3 paginiInspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationKhaled GamalÎncă nu există evaluări

- Weld Cleaning MethodsDocument7 paginiWeld Cleaning MethodsTrần Thùy LinhÎncă nu există evaluări

- Cold Tap Coating Report 2Document1 paginăCold Tap Coating Report 2Jamal BakhtÎncă nu există evaluări

- Ferrite Content MeasurementDocument5 paginiFerrite Content MeasurementFasil Paruvanath100% (1)

- Duplex Ss in API, NSF and AwwaDocument16 paginiDuplex Ss in API, NSF and AwwajoseritoÎncă nu există evaluări

- Welding Repair ProcedureDocument4 paginiWelding Repair ProcedureRiky SumantriÎncă nu există evaluări

- What Are ASTM GradesDocument4 paginiWhat Are ASTM Gradesmohan babuÎncă nu există evaluări

- Aws Module 10Document25 paginiAws Module 10rex valenciaÎncă nu există evaluări

- Poster Welding P VoxXa PDFDocument1 paginăPoster Welding P VoxXa PDFAd Man GeTigÎncă nu există evaluări

- WPS - 017Document12 paginiWPS - 017MAT-LIONÎncă nu există evaluări

- Duplex Stainless Steel - Part 2 - TWIDocument6 paginiDuplex Stainless Steel - Part 2 - TWItuanÎncă nu există evaluări

- Welding Procedure For BOXNR Wagon (WPS)Document8 paginiWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- Explanation of Weld SymbolsDocument2 paginiExplanation of Weld SymbolspmjoshirÎncă nu există evaluări

- Bs Tech: Electrodes Issue and Return RegisterDocument1 paginăBs Tech: Electrodes Issue and Return RegisterRhannie GarciaÎncă nu există evaluări

- Table of Content: SR. TitleDocument2 paginiTable of Content: SR. TitlePratik KarekarÎncă nu există evaluări

- Lot Inspection Report For LPG New CylindersDocument3 paginiLot Inspection Report For LPG New CylindersJagannath MajhiÎncă nu există evaluări

- Welder's Master ListDocument8 paginiWelder's Master ListAnonymous rYZyQQot55Încă nu există evaluări

- Essential and Non-Essential Variables For WPS - PQRDocument4 paginiEssential and Non-Essential Variables For WPS - PQRNatarajan MurugesanÎncă nu există evaluări

- QA-R-04 - Visual Inspection ReportDocument1 paginăQA-R-04 - Visual Inspection ReportvinothÎncă nu există evaluări

- Avesta 3D ElectrodesDocument2 paginiAvesta 3D ElectrodesOndrej PelešÎncă nu există evaluări

- Welding Technology Steelconstr - EngDocument32 paginiWelding Technology Steelconstr - EngLukman Tarigan SumatraÎncă nu există evaluări

- Esab DublexDocument8 paginiEsab DublexSuphi YükselÎncă nu există evaluări

- Avesta 2D3D4DDocument12 paginiAvesta 2D3D4DKamal ShahÎncă nu există evaluări

- The Australian Welding Guide 2012Document220 paginiThe Australian Welding Guide 2012maxxandÎncă nu există evaluări

- L1 26159 en SOUDOTAPE 310MM 7SD9A01C 3204822 ENDocument1 paginăL1 26159 en SOUDOTAPE 310MM 7SD9A01C 3204822 ENkamals55Încă nu există evaluări

- Brochure Sugar IndustryDocument2 paginiBrochure Sugar Industrykamals55Încă nu există evaluări

- Product Catalog: In-Depth Know-HowDocument174 paginiProduct Catalog: In-Depth Know-HowbrayanÎncă nu există evaluări

- Bohler Fox S EV 50-1Document1 paginăBohler Fox S EV 50-1kamals55Încă nu există evaluări

- Bohler Fox N CM 2 KBDocument1 paginăBohler Fox N CM 2 KBkamals55Încă nu există evaluări

- Brochure Sugar IndustryDocument2 paginiBrochure Sugar Industrykamals55Încă nu există evaluări

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 paginăL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55Încă nu există evaluări

- TQM BookDocument257 paginiTQM Bookimran27pk84% (19)

- UTP For Chemical IndustryDocument12 paginiUTP For Chemical Industrykamals55Încă nu există evaluări

- Lect 1 1610799804379Document42 paginiLect 1 1610799804379kamals55Încă nu există evaluări

- POV Total Quality Management An Early Adopter of The ISO Process Approach 1634453099052Document8 paginiPOV Total Quality Management An Early Adopter of The ISO Process Approach 1634453099052kamals55Încă nu există evaluări

- L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENDocument1 paginăL1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENkamals55Încă nu există evaluări

- Bw140e - Welding in Tool MakingDocument24 paginiBw140e - Welding in Tool MakingAlvaro A. Kalle GonzalesÎncă nu există evaluări

- Boehler ElectrodesDocument506 paginiBoehler ElectrodesThomas Mitchell100% (1)

- UTP For OffshoreDocument16 paginiUTP For Offshorekamals55Încă nu există evaluări

- Manual For Surface Treatment of Stainless Steels: Lasting ConnectionsDocument40 paginiManual For Surface Treatment of Stainless Steels: Lasting ConnectionsAsgard Sanchez100% (1)

- Böhler Welding Produktkatalog EN 2019 1Document671 paginiBöhler Welding Produktkatalog EN 2019 1Bouzaida Maher100% (1)

- Process Analysis 202021 R1Document39 paginiProcess Analysis 202021 R1kamals55Încă nu există evaluări

- Cement Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler MetalsDocument2 paginiCement Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler Metalskamals55Încă nu există evaluări

- Böhler Welding Produktkatalog EN 2019 1Document671 paginiBöhler Welding Produktkatalog EN 2019 1Bouzaida Maher100% (1)

- Strips and Fluxes For Electroslag and Submerged Arc Welding: Tailor-Made Protectivity™Document38 paginiStrips and Fluxes For Electroslag and Submerged Arc Welding: Tailor-Made Protectivity™kamals55Încă nu există evaluări

- Steelworks Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler MetalsDocument2 paginiSteelworks Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler Metalskamals55Încă nu există evaluări

- UTP Raiilways BrochureDocument8 paginiUTP Raiilways Brochurekamals55Încă nu există evaluări

- Railways Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler MetalsDocument2 paginiRailways Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler Metalskamals55Încă nu există evaluări

- Facility Location & Layout (F)Document15 paginiFacility Location & Layout (F)kamals55Încă nu există evaluări

- Facility Location & Layout (F)Document15 paginiFacility Location & Layout (F)kamals55Încă nu există evaluări

- Process AnalysisDocument26 paginiProcess AnalysisMridula HariÎncă nu există evaluări

- Reference Cement HolcimDocument11 paginiReference Cement Holcimkamals55Încă nu există evaluări

- Facility LayoutDocument63 paginiFacility LayoutBharti KumariÎncă nu există evaluări

- Tubes and Pipes Potable Water SanitationDocument3 paginiTubes and Pipes Potable Water Sanitationkamals55Încă nu există evaluări

- Gib BracingDocument36 paginiGib BracingStefan Reuther100% (1)

- Sika MonoSeal 101 H EngDocument3 paginiSika MonoSeal 101 H Engjpantazis1975Încă nu există evaluări

- E 90 48Document4 paginiE 90 48Agus Qupink Luph AriaÎncă nu există evaluări

- Manual For Mini Project 1 (Slump Test)Document2 paginiManual For Mini Project 1 (Slump Test)Nor Azizah Mohd AliÎncă nu există evaluări

- HILTI Direct Fastening Technical Guide - Ed 18Document212 paginiHILTI Direct Fastening Technical Guide - Ed 18rodriguez.gaytanÎncă nu există evaluări

- Astm C 270 - 03Document14 paginiAstm C 270 - 03EliKax!Încă nu există evaluări

- Silica fume/CHAPTER 1Document45 paginiSilica fume/CHAPTER 1mohanÎncă nu există evaluări

- FULLTEXT01Document73 paginiFULLTEXT01hengkiirawan2008Încă nu există evaluări

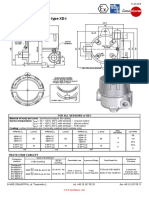

- Data Sheet - IECExDocument3 paginiData Sheet - IECExAndreas PalalanganÎncă nu există evaluări

- BOQ For Block WorkDocument16 paginiBOQ For Block Workbaboonijj100% (1)

- Technical Data Handbook of TK CorporationDocument172 paginiTechnical Data Handbook of TK CorporationGerard Adrian Bautista AnonuevoÎncă nu există evaluări

- Set 8-3 PDFDocument56 paginiSet 8-3 PDFAek JayÎncă nu există evaluări

- Asme Section Ii C Sfa-5.7Document10 paginiAsme Section Ii C Sfa-5.7Oscar Fernando Loaiza DiazÎncă nu există evaluări

- Local Stress CheckDocument7 paginiLocal Stress Checkprabhakaran.cÎncă nu există evaluări

- Timber: Heavy Duty Wood Screw & Rafter/Truss To Top Plate ConnectionDocument3 paginiTimber: Heavy Duty Wood Screw & Rafter/Truss To Top Plate ConnectionDan McGeeÎncă nu există evaluări

- Topic 3 - Concrete and MasonryDocument60 paginiTopic 3 - Concrete and MasonryYoseph BirruÎncă nu există evaluări

- Atc - Cur12Document1 paginăAtc - Cur12mahmoudÎncă nu există evaluări

- Module 4 - QuantityDocument12 paginiModule 4 - QuantityKimberly Wealth Meonada MagnayeÎncă nu există evaluări

- Floor Decking Sheets: Design ConsiderationsDocument2 paginiFloor Decking Sheets: Design ConsiderationsVikas MouryaÎncă nu există evaluări

- Zwaluw High Tack enDocument2 paginiZwaluw High Tack enRichard DÎncă nu există evaluări

- Strip Weld OverlayDocument24 paginiStrip Weld OverlaymayataÎncă nu există evaluări

- Sae Ams-Qq-A-250-4a-2010Document8 paginiSae Ams-Qq-A-250-4a-2010vinicius_bacellar100% (2)

- Lime & TimberDocument16 paginiLime & TimberRiya JaiswalÎncă nu există evaluări

- FPE Review 2 18th OctDocument18 paginiFPE Review 2 18th OctPrateek SachanÎncă nu există evaluări

- Iso 9227Document13 paginiIso 9227Raj Kumar100% (6)

- Logbook CEBDocument36 paginiLogbook CEBAnonymous ICo9rpfVt0Încă nu există evaluări

- Sikadur - 32 Normal: 2-Part Structural Epoxy Bonding AgentDocument4 paginiSikadur - 32 Normal: 2-Part Structural Epoxy Bonding AgentFarhanSyarifÎncă nu există evaluări

- Analysis of Full Depth Precast Concrete Bridge Deck PanelsDocument12 paginiAnalysis of Full Depth Precast Concrete Bridge Deck PanelsMedi EyobÎncă nu există evaluări

- CCANZ - Cracking (IB 73) PDFDocument8 paginiCCANZ - Cracking (IB 73) PDF4493464Încă nu există evaluări

- DPL DripPanElbowDocument1 paginăDPL DripPanElbowPartha Sarathi SadhukhanÎncă nu există evaluări