Documente Academic

Documente Profesional

Documente Cultură

Autoclaved Aerated Concrete (AAC) We Put Concrete Into Shape

Încărcat de

eduardoaffreDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Autoclaved Aerated Concrete (AAC) We Put Concrete Into Shape

Încărcat de

eduardoaffreDrepturi de autor:

Formate disponibile

We put concrete into shape

HESS Group - Successful for more than 5 decades

HESS AAC Systems B.V. (previously Stork Bouwtechniek) possesses specific knowhow on the building of machines and plants for the autoclaved aerated concrete and sand-lime brick industry. About thirty years ago HESS AAC became active on the AAC market, concentrating mainly on manufacturing, installing and maintaining the production machinery for the world market leaders in AAC. During this relationship HESS built several production lines for key customers in Europe. Today HESS is known worldwide for its excellent craftsmanship, engineering know-how and high quality of the products and services it supplies. The machinery is robust and equipped with first class components, at a very competitive price level.

Autoclaved Aerated Concrete (AAC)

HESS

G R O U P

HESS AAC Systems B.V. P.O. Box 321, 7550 AH Hengelo (Ov.), The Netherlands Phone: Fax: E-Mail: Internet: + 31 (0)74 240 70 00 + 31 (0)74 240 70 86 info@hess-aac.com www.hess-aac.com

HESS

AAC SYSTEMS

Autoclaved Aerated Concrete (AAC)

HESS

AAC SYSTEMS

The Autoclaved Aerated Concrete (AAC) material was developed in 1924 in Sweden. It has become one of the most used building materials in Europe and is rapidly growing in many other countries around the world. Autoclaved Aerated Concrete, also known as Aircrete, is a lightweight, load-bearing, high-insulating, durable building product, which is produced in a wide range of sizes and strengths. AAC offers incredible opportunities to increase building quality and at the same time reduce costs at the construction site. AAC is produced out of a mix of quartz sand and/or pulverised fly ash (PFA), lime, cement, gypsum/anhydrite, water and aluminium and is hardened by steam-curing in autoclaves. As a result of its excellent properties, AAC is used in many building constructions, for example in residential homes, commercial and industrial buildings, schools, hospitals, hotels and many other applications.

Autoclaved aerated concrete is actually hydrated calcium silicate. The calcium is obtained from quick lime, hydrated lime and cement. The gypsum is used as a katalyst and for optimizing the properties of AAC. The silica is obtained from silica sand, fly ash (PFA), crushed silica rock and/or stone. It is possible to obtain silica as a by-product from other processes, e.g. foundry sand or burgee from glass grinding, provided the levels of alkalis or other impurities, are not too high.

Advantages of AAC

large variety of sizes: AAC can be produced in a large variety of sizes, from standard blocks to large reinforced panels; excellent thermal insulation: AAC has a very low thermal conductivity and therefore a very high thermal energy efficiency is achieved. This results in savings on heating and cooling costs; extremely lightweight: AAC weighs approximately 50% less than other comparable building products; high compressive strength: AAC is a solid product, therefore making it highly load bearing. The entire surface area is used in structural calculations; high dimensional accuracy: As a result of its dimensional accuracy, AAC is extremely easy to install, as no thick set mortar is required; great acoustic insulation: The porous structure of AAC provides a high acoustic insulation; high fire resistance: AAC has an extremely high fire rating of at least 4 hours and more; termite resistance: AAC can not be damaged by termites or insects; high workability: As a result of the excellent size/weight ratio, constructing with AAC is very rapid. Even though AAC is a solid building material, it can be cut, sawn, drilled, nailed and milled like wood, making it an extremely workable product.

Autoclaved Aerated Concrete (AAC)

HESS

AAC SYSTEMS

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. ball mill for milling sand slurry tanks silos for lime, cement and gypsum dosing and mixing casting position for reinforcement insertion rising/pre-curing position for extraction of reinforcement holding pins tilting the cake with tilting crane mould oiling vertical cut and profiling 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. horizontal cut cross cut and handgrip milling back-tilting of the cake onto a cooking frame bed waste removal stacking and buffering of green cakes autoclaving buffering and destacking of hardened cakes unloading from cooking frames separating packaging of final product

17

19 21 20 14 16

18

15 13 12 The HESS philosophy is to provide our customers with a pro-duction system designed as a solution for the specific needs of the market in terms of capacity and product range. The HESS Keen-Crete systems can offer this high degree of flexibility in plant design, based on know-how and experience in both tilt-cake and flat-cake systems. Performance is guaranteed through the use of proven standard machine modules and components. Following plant concepts are generally available: KBT-S version: capacity range from 450 - 900 m per day KBT version: capacity range from 900 - 1550 m per day 11 9 5 6 1 2 7 10 4

Autoclaved Aerated Concrete (AAC)

HESS

AAC SYSTEMS

Raw material preparation

A ball mill finely wet-grinds the quartz sand with water to a sand slurry, which is then mixed with lime, cement, gypsum and aluminium powder/paste.

Casting and rising/pre-curing

The mix is poured into moulds. In the rising area the cake pre-cures for ca. 2 3 hours and is then ready for cutting.

Cutting

The cake in cut by high precision cutting machines. Cutting is done by pneumatically tensioned cutting wires. the pre-cutter and vertical cutter cut the block length and panel width. In this station the profiling (tongue and groove) can be cut into the cake with profiling knives; the horizontal cutter cuts the block and panel thickness; the cross cutter cuts the block height and the panel length. Optionally hand-grips can be milled into the cake in the green stage.

Tilting

The tilting crane tilts the mould by 90. The crane unlocks the mould and removes the mould body, so that the cake remains on one mould side/platform for cutting. This tilting system has proven to be the safest method for tilting the cake into the vertical cutting position, as the cake is tilted onto the same side that it rose on.

Autoclaved Aerated Concrete (AAC)

Back-tilting and bed removal

In most tilt cake systems the cake is autoclaved in the vertical position. The HESS KBT-S and KBT systems have combined the advantages of the tilt-cake and flat-cake system. After the cutting is completed, the cake is tilted back by 90 onto a cooking frame. In the HESS system no part of the mould or platform used for cutting go into the autoclaves. After the cake has been tilted back into the horizontal orientation, the bottom/bed waste will be removed before autoclaving. Autoclaving the cake on the cooking frames allows efficient autoclave loading and most importantly, will prevent most of the sticking of the layers, which is a typical disadvantage for the traditional tilt-cake systems. HESS SYSTEMS PRODUCE NO PROCESS RELATED WASTE

HESS

AAC SYSTEMS

Unloading and packaging

After the autoclaving is completed the cakes are destacked and the cakes are unloaded from the cooking frames. Depending on product specification and raw material quality, it might be necessary to separate the layers.

Autoclaving

The cakes on the cooking frames get stacked three high and are then fed into the autoclave, where they are cured for 10-12 hours at a temperature of 190C with saturated steam at a pressure of 12 bar.

The finished products are packed according to the market requirements. Usually this is on wooden pallets and covered in foil.

Autoclaved Aerated Concrete (AAC)

Development Design Fabrication

HESS machinery is designed on modern 3-D CAD systems. In the production only materials and components of the highest standards are used. Continuous in-house control ensures this high quality standard. Machine components are made out of certified steel types and manufactured with the help of CNC controlled welding-, milling- and drilling machinery. This results in machinery and systems with accurate dimensions and a high quality standard.

HESS

AAC SYSTEMS

HESS can offer you a financially and technically attractive solution to upgrade your existing Hebel-type cutting machine.

In order to increase the quality of the product as well as the reliability of the plant, without investing in a complete new cutting machine, the modification of the Hebel technology based cutting machine is possible. new cutting table with moving bridges new set of needles with rectangular design replacement of the cross cutting shafts vertical wire tensioning system top crust removal system horizontal cutting system for lintel cutting counter pusher with pusher package bottom and top profiling system new control system new hydraulic system Highlights short installation time proven technology the existing logistics and production do not require major changes due to these modifications

Even after the installation and commissioning of your plant, HESS customers benefit from the first-class know how of our engineers. Experienced and trained service engineers can assist in resolving problems by access to the machinery via remote diagnosis. Also regular service inspections on site can be offered to ensure that the productivity and product quality remain at a constantly high level. Storage facilities worldwide with original spare and wearing parts guarantee availability and ensure continuous production of your systems.

S-ar putea să vă placă și

- Safol 23 E-7-90Document3 paginiSafol 23 E-7-90eduardoaffreÎncă nu există evaluări

- Lutensol XL Types: Technical InformationDocument8 paginiLutensol XL Types: Technical InformationeduardoaffreÎncă nu există evaluări

- Industrial and Institutional Care ClariantDocument21 paginiIndustrial and Institutional Care Clariantdaniel_12Încă nu există evaluări

- Brochure - Printing - ScreenPrinting - ACHITEX MINERVADocument12 paginiBrochure - Printing - ScreenPrinting - ACHITEX MINERVAeduardoaffreÎncă nu există evaluări

- Eulan PresentationDocument13 paginiEulan PresentationeduardoaffreÎncă nu există evaluări

- StepanFormulation149 Liquid Soap PDFDocument2 paginiStepanFormulation149 Liquid Soap PDFeduardoaffreÎncă nu există evaluări

- Catalytic Bleaching of Cotton - Thesis - Topalovic PDFDocument195 paginiCatalytic Bleaching of Cotton - Thesis - Topalovic PDFeduardoaffre100% (1)

- Fatty Alcohol Ethoxylates by CAS #Document1 paginăFatty Alcohol Ethoxylates by CAS #eduardoaffre100% (1)

- Base Fluids and Additives For Fire Resistand Hydraulic FluidsDocument8 paginiBase Fluids and Additives For Fire Resistand Hydraulic FluidseduardoaffreÎncă nu există evaluări

- Modern Aspect of Emulsion Science-Cap1 BinksDocument55 paginiModern Aspect of Emulsion Science-Cap1 BinkseduardoaffreÎncă nu există evaluări

- Black Magic - SIRIXX SBDocument7 paginiBlack Magic - SIRIXX SBRezoanul HaqueÎncă nu există evaluări

- Personal Care SurfactantsDocument72 paginiPersonal Care Surfactantseduardoaffre100% (1)

- Huntsman Agro Brochure - Final101306Document24 paginiHuntsman Agro Brochure - Final101306eduardoaffre67% (6)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Day 1 Borehole Geophysics WDocument21 paginiDay 1 Borehole Geophysics Waliy2k4uÎncă nu există evaluări

- WBNR La Auto BCM SpanishDocument41 paginiWBNR La Auto BCM SpanishHaragopal KrishnaÎncă nu există evaluări

- Astm A182 f22 Class 3Document3 paginiAstm A182 f22 Class 3VõTạÎncă nu există evaluări

- C# Jumpstart Module 1 IntroDocument31 paginiC# Jumpstart Module 1 IntroAnjana JayasekaraÎncă nu există evaluări

- Connections For Hydraulic Fluid Power and General Use - Hose FittingsDocument22 paginiConnections For Hydraulic Fluid Power and General Use - Hose FittingsОлег СоловьевÎncă nu există evaluări

- B200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10Document4 paginiB200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10George P ReynoldsÎncă nu există evaluări

- Simplex Spray Systems OverviewDocument3 paginiSimplex Spray Systems OverviewHuda LestraÎncă nu există evaluări

- Binary Search of Unsorted ArrayDocument3 paginiBinary Search of Unsorted ArrayGobardhan BaralÎncă nu există evaluări

- Transportation ChecklistDocument1 paginăTransportation ChecklistHolly Smith100% (1)

- Leaflet No.2Document7 paginiLeaflet No.2Sabra A.S.Încă nu există evaluări

- Procedures For Solar Electric (Photovoltaic Abbreviated As PV) System Design and InstallationDocument5 paginiProcedures For Solar Electric (Photovoltaic Abbreviated As PV) System Design and InstallationUmamaheshwarrao VarmaÎncă nu există evaluări

- Current Electricity All DerivationsDocument11 paginiCurrent Electricity All DerivationsRonit VaskarÎncă nu există evaluări

- Stanley 46 InstructionsDocument2 paginiStanley 46 Instructionsj_abendstern4688Încă nu există evaluări

- Operation Guide MSBDocument8 paginiOperation Guide MSBMao RathanithÎncă nu există evaluări

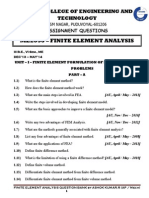

- Assignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Document85 paginiAssignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Ashok Kumar Rajendran100% (9)

- Extra - Exercises Unistall InformixDocument14 paginiExtra - Exercises Unistall InformixМихаи БонцалоÎncă nu există evaluări

- Power Electronics - B. R. Gupta and v. SinghalDocument114 paginiPower Electronics - B. R. Gupta and v. SinghalHarish Kumar M50% (2)

- Excel To C I For Positive in PutDocument23 paginiExcel To C I For Positive in PuthimanshuÎncă nu există evaluări

- Valbart: API 6D & 6A Trunnion Mounted Ball ValvesDocument36 paginiValbart: API 6D & 6A Trunnion Mounted Ball Valvesbabis1980Încă nu există evaluări

- Ee BD ManualDocument37 paginiEe BD Manualsergey62Încă nu există evaluări

- Gen00036-04 Wa600-6 Wheel LoaderDocument98 paginiGen00036-04 Wa600-6 Wheel LoaderJuan Araya BarrazaÎncă nu există evaluări

- Catalogue For AutoDocument22 paginiCatalogue For Autosentimiento azulÎncă nu există evaluări

- Earthquake in TaguigDocument4 paginiEarthquake in TaguigDianca Zyra Rodil-CabanelaÎncă nu există evaluări

- When Good Engineers Deliver Bad FEADocument17 paginiWhen Good Engineers Deliver Bad FEAJarad Wilson100% (1)

- Code Eac NaceDocument2 paginiCode Eac NaceEvan BuwanaÎncă nu există evaluări

- TYBTech Syllabus MechanicalDocument49 paginiTYBTech Syllabus MechanicalswapnillkÎncă nu există evaluări

- A Cylindrical Shadow Eclipse Prediction Model For LEO Satellites With Application To IRS SatellitesDocument14 paginiA Cylindrical Shadow Eclipse Prediction Model For LEO Satellites With Application To IRS SatellitesAsia Pacific Journal of Engineering Science and TechnologyÎncă nu există evaluări

- Language Translation Software Market Industry Size, Share, Growth, Trends, Statistics and Forecast 2014 - 2020Document9 paginiLanguage Translation Software Market Industry Size, Share, Growth, Trends, Statistics and Forecast 2014 - 2020api-289551327Încă nu există evaluări

- MECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Document4 paginiMECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Camila MayorgaÎncă nu există evaluări

- Brige Lauching Cap 1 PDFDocument16 paginiBrige Lauching Cap 1 PDFAnonymous VkzquW39Încă nu există evaluări