Documente Academic

Documente Profesional

Documente Cultură

Structural Trunnion

Încărcat de

ecsalomDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Structural Trunnion

Încărcat de

ecsalomDrepturi de autor:

Formate disponibile

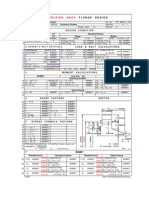

LOCAL STRESS CALCULATION BY KELLOGG METHOD Pipe Dia., D Pipe Nominal Thick, Tn Corrosion Allow., Ca Design Press.

, Dp Cold Allowable, Sc Hot Allowable, Sh Reinforcing Pad thk,Tp = = = = = = = 168 10.97 3 6.67 137 137 10.97 mm mm mm N/mm N/mm N/mm mm

Project: SHDS - OSBL Facilities Calculation No.: APPROXIMATE Date: 21-Aug-11 Line Number : 6"-BFW-525257-DG3y

Node No.:

344

Computing for the corroded thickness, t = 0.875Tn - Ca + 0.875Tp t = 0.875(10.97) - 3 + 0.875(10.97) = 16.2 mm b h tf tw L = = = = = 100 127 10 10 500 mm mm mm mm mm

(with -12.5% mill tolerance)

Axial, Fa (N) Cirumferential, Fc (N) Longitudinal, Fl (N)

Sustained 2100 50 5100

Thermal 20 170 100

Ll

= h - tf + 2b b 2 h 2 =

= (127) - (10) + 2(100) 100 2 127 2 = 50 mm

317

mm

Cy =

Cx =

= b(h-tf) 2 =

63.5 mm (127 - 10) 12 mm 100(127 - 10) 2

Ixx =

(h-tf) 12 b 6 =

817918

mm

Iyy =

(100) 6

166667

Computing for the loads to determine the localized bending stresses at the edge of trunnion. Sustained Thermal fL = longitunidal lineal load (N/mm) = Fl L Cx / Ixx = 197.97 3.88 fC = cirumferential lineal load (N/mm) = Fc L Cy / Iyy = 7.50 25.50 fA = radial lineal load (N/mm) = Fa / Ll = 6.62 0.06 fR = resultant lineal load in the long. & circum. direction = sqrt(fL + fC) = 198.11 25.79 resultant check, fL 3fC or fC 2fL 1 1 = DON'T USE fR DON'T USE fR f1 f2 = load producing max. stress in longitudinal direction (N/mm) = load producing max. stress in circum. direction (N/mm) = = = = fL + 1.5fA 207.91 1.5(fC + fA) 21.19 fL + 1.5fA 3.98 fC + 1.5fA 25.59

Computing for the local stresses Total Longitudinal Stress,SL 1.17 f1 (Rt)0.5 SBL = t Total Circumferential Stress,SC 1.17 f2 (Rt)0.5 SBC = t

DpR 2t

N mm

51.47

17.93

DpR t

N mm

= = =

38.04 1.5 Sh 205.5

38.77 1.25Sc+0.25Sh 205.5

Allowable stress (SHALL not exceed 206 N/mm) (N/mm)

LOCAL STRESS CALCULATION BY KELLOGG METHOD Evaluation Ratio

Project: SHDS - OSBL Facilities Calculation No.: APPROXIMATE Date: 21-Aug-11 Line Number : 6"-BFW-525257-DG3y

Node No.:

344

OK 0.25

OK 0.19

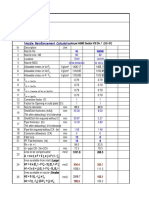

Computing the stresses at the edge of pad

= D Sin 60 = 145.5 = h + 100 = 227

Ixxp

Iyyp

Llp

= = = = = = = = =

(y/6) + (xy/4) (227/6) + ((145.5)(227)/4) 3823881 mm (x/6) + (yx/4) (145.5/6) + ((227)(145.5)/4) 1714790 mm 2(x + y) 2(145.5 + 227) 745 mm Sustained 75.69 1.06 2.82 75.70

DON'T USE fR

fL fC fA fR

= = = = =

longitunidal lineal load (N/mm) =( Fl L y) / ( 2 Ixxp) cirumferential lineal load (N/mm) =( Fc L x) / (2 Iyyp) radial lineal load (N/mm) = Fa / Llp resultant lineal load in the long. & circum. direction sqrt(fL + fC) resultant check, fL 3fC or fC 2fL 1 1

= = = = = = = = =

Thermal 1.48 3.61 0.03 3.90

DON'T USE fR

f1 f2

= load producing max. stress in longitudinal direction (N/mm) = load producing max. stress in circum. direction (N/mm)

fL + 1.5fA 79.92 1.5(fC + fA) 5.82

fL + 1.5fA 1.52 fC + 1.5fA 3.65

Total Longitudinal Stress,SL 1.17 f1 (R)0.5 SBL = (Tn-Ca)1.5 Total Circumferential Stress,SC 1.17 f1 (R)0.5 SBC = (Tn-Ca)1.5

DpR

2(Tn-Ca)

N mm

92.98

43.39

DpR

2(Tn-Ca)

N mm

= = = =

88.52 2.0 Sh 206 OK

87.15 1.25Sc+0.25Sh 205.5 OK

Allowable stress (SHALL not exceed 206 N/mm) (N/mm) Evaluation

2(OPE) 3(SUS)

194 -5071 2019 33 -5080 2032 161 9 -13

S-ar putea să vă placă și

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 paginiASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Saddle Dimension CalculationDocument2 paginiSaddle Dimension Calculationrinabiswas50% (2)

- Asme Viii D Table 2aDocument16 paginiAsme Viii D Table 2aJohakim974100% (1)

- Trunnion Calculation SheetDocument3 paginiTrunnion Calculation Sheetsudhisnair67% (3)

- Trunnion Calc r6Document4 paginiTrunnion Calc r6Chirag Shah50% (2)

- Design of Flanges - Full-Face Gasket 2010Document29 paginiDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Trunion Load CalculationDocument6 paginiTrunion Load CalculationUmer AziqÎncă nu există evaluări

- Ring Flange CalculationDocument3 paginiRing Flange CalculationLuizÎncă nu există evaluări

- Weldstrength Calc ProgDocument10 paginiWeldstrength Calc ProgSajal KulshresthaÎncă nu există evaluări

- Dummy Leg JacobsDocument1 paginăDummy Leg Jacobsananyo_sengupta0% (1)

- Trunnion CalculationDocument8 paginiTrunnion CalculationPrashant ChauhanÎncă nu există evaluări

- Saddle Calc PD5500Document6 paginiSaddle Calc PD5500Vamsi SÎncă nu există evaluări

- Flange CalculationsDocument3 paginiFlange CalculationssanjaysyÎncă nu există evaluări

- ASME B31.3 Area ReplacementDocument2 paginiASME B31.3 Area ReplacementJahsbuck100% (1)

- Sif B31.3Document10 paginiSif B31.3Rob Gillespie100% (1)

- 16147-Shoe With Gusset No RepadDocument5 pagini16147-Shoe With Gusset No RepadRamesh Krishnan100% (1)

- DummyDocument1 paginăDummythopa_nath100% (2)

- Master Trunnion CalcDocument4 paginiMaster Trunnion CalcgenergiaÎncă nu există evaluări

- Modification Thickness of A FlangeDocument3 paginiModification Thickness of A FlangePeter PerezÎncă nu există evaluări

- Operating Case Trunnion Calculation Sheet: Input DataDocument1 paginăOperating Case Trunnion Calculation Sheet: Input DataJagadish JasÎncă nu există evaluări

- Flange CalculationsDocument5 paginiFlange CalculationsswapnavattemÎncă nu există evaluări

- Design of Flanges - Loose Hub Type 2010Document58 paginiDesign of Flanges - Loose Hub Type 2010bakellyÎncă nu există evaluări

- Trunnion Calculation SheetDocument2 paginiTrunnion Calculation SheetIshu Vohra0% (1)

- Ancor Flanges Asme ViiiDocument3 paginiAncor Flanges Asme ViiiAnjani PrabhakarÎncă nu există evaluări

- Sif B31 3Document10 paginiSif B31 3Sergio SmithÎncă nu există evaluări

- Nozzle Neck CalculationDocument4 paginiNozzle Neck CalculationAkshat JainÎncă nu există evaluări

- Design of Flanges - Optional Type 2010Document59 paginiDesign of Flanges - Optional Type 2010bakellyÎncă nu există evaluări

- Gasket Dimension (ASME B16.5 & B16.47)Document4 paginiGasket Dimension (ASME B16.5 & B16.47)amaÎncă nu există evaluări

- Pipe Is Under Clamping ForceDocument7 paginiPipe Is Under Clamping Forcejosediaz141Încă nu există evaluări

- Flange Loading CheckDocument48 paginiFlange Loading CheckrefuzerÎncă nu există evaluări

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocument3 paginiASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyÎncă nu există evaluări

- Stress Sample Calculation On Base EllDocument1 paginăStress Sample Calculation On Base EllLionel TorradoÎncă nu există evaluări

- Nozzle Reinforcement Calculation Excel SheetDocument3 paginiNozzle Reinforcement Calculation Excel Sheetramesh punjabiÎncă nu există evaluări

- Saddle AnalysisDocument17 paginiSaddle AnalysisPEJU0007Încă nu există evaluări

- Design of Flanges - Welded-On Integral Type 2010Document59 paginiDesign of Flanges - Welded-On Integral Type 2010bakellyÎncă nu există evaluări

- Calculation LugDocument20 paginiCalculation LugKartika ZuhraÎncă nu există evaluări

- ASME B31.8 Riser CalcDocument12 paginiASME B31.8 Riser CalcSalz EngineeringÎncă nu există evaluări

- Reinforcement Pad DesignDocument3 paginiReinforcement Pad DesignAkshat JainÎncă nu există evaluări

- Reinforcement CalculationDocument2 paginiReinforcement CalculationVekaymech100% (9)

- Bolted Flange Thickness CalculationDocument6 paginiBolted Flange Thickness Calculationshazan0% (1)

- New - Reinforcement of NozzleDocument31 paginiNew - Reinforcement of NozzleNithin ZsÎncă nu există evaluări

- Blind Flange DesignDocument1 paginăBlind Flange DesignSachin5586Încă nu există evaluări

- Branch Reinforcement Per Asme B31.4 PipelineDocument1 paginăBranch Reinforcement Per Asme B31.4 PipelinegateauxboyÎncă nu există evaluări

- Nozzle Reinf Calc (Rough)Document12 paginiNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Annexure - Bolt Torque CalculationDocument4 paginiAnnexure - Bolt Torque CalculationDarshan PanchalÎncă nu există evaluări

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 pagină2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanÎncă nu există evaluări

- Blind Calculation - RoarkDocument10 paginiBlind Calculation - Roarkrustamriyadi100% (2)

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocument4 paginiDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastav50% (2)

- ASME B31.3 Wall Thickness CalculationDocument27 paginiASME B31.3 Wall Thickness CalculationJesus Magallanes SÎncă nu există evaluări

- Vortex Shedding Load On PipingDocument1 paginăVortex Shedding Load On Pipingananyo_sengupta100% (1)

- Crane Load-Chemical Storage ShelterDocument44 paginiCrane Load-Chemical Storage ShelterAndreas HendiÎncă nu există evaluări

- Pad Footing Analysis and Design (Bs8110-1:1997) : Project Job NoDocument6 paginiPad Footing Analysis and Design (Bs8110-1:1997) : Project Job Nocheligp1981Încă nu există evaluări

- Exit Area CalculationDocument6 paginiExit Area CalculationSATISH PAWAR100% (1)

- Trunnion Calculation SheetDocument3 paginiTrunnion Calculation SheetRafael SequeiraÎncă nu există evaluări

- Design of Column9 Footing1 (Exterior Corner) Design ParametersDocument6 paginiDesign of Column9 Footing1 (Exterior Corner) Design ParametersCeline SamonteÎncă nu există evaluări

- Post Tensioned Analysis & DesignDocument9 paginiPost Tensioned Analysis & DesignPn Ekanayaka100% (1)

- Design of MonorailDocument9 paginiDesign of MonorailAnonymous Q8XIGqHyCÎncă nu există evaluări

- Design Z Section PurlinDocument9 paginiDesign Z Section PurlinSudipta HuiÎncă nu există evaluări

- Pad Footing Analysis and Design (Bs8110-1:1997)Document6 paginiPad Footing Analysis and Design (Bs8110-1:1997)ikanyu79Încă nu există evaluări

- Trunnion Calc SHTDocument1 paginăTrunnion Calc SHTAtty Atty100% (1)