Documente Academic

Documente Profesional

Documente Cultură

11the Heating Treatment Manual of P91 After Welding

Încărcat de

Akshay SinghTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

11the Heating Treatment Manual of P91 After Welding

Încărcat de

Akshay SinghDrepturi de autor:

Formate disponibile

RPSCL

ROSA POWER SUPPLY COMPANY LIMITED LUCKNOW, UTTAR PRADESH

2 x 300 MW - Stage - I Rosa Thermal Power Project Rosa, Shahjahanpur (U.P.)

DOCUMENT TITLE

The heating treatment manual of P91 after welding

DOCUMENT NO:

28/X-TEPC-HJZ011-2008

UEEPL

Utility Energytech and Engineers Pvt. Ltd. Ground Floor, H-146/147 Sector-63 Noida 201 307 Uttar Pradesh DEVELOPMENT CONSULTANTS PRIVATE LIMITED CONSULTING ENGINEERS 24B, PARK STREET, KOLKATA - 700 016, INDIA TPSC (INDIA) PRIVATE LIMITED A-1 Module, D-Quadrant, 2nd Floor Cyber Towers, Hi-Tec City, Hyderabad-81 Shanghai Electric Group Co. Ltd. No. 8 , Xingyi Road. Shanghai

China - 200336 Tianjin Electric Power Construction Company The 26th floor, Harbor Centre ,No. 240 Zhangzizhong Road, Heping district, Tianjin P.R.China p.c:300041

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

DOCUMENT CONTROL SHEET

PROJECT

: 2300 MW ROSA THERMAL POWER PROJECT

CLIENT

: ROSA POWER SUPPLY COMPANY LIMITED

DOCUMENT TITLE : THE HEATING TREAMENT MANUAL OF P91 AFTER WELDING DOCUMENT NO. : 28/X-TEPC-HJZ011-2008 REV. NO. :

ENDORSEMENTS

Rev No

Date

DescriptionInitials Sgn. Prepared by

Initials

Sgn.

Initials

Sgn.

Initials Sgn. Issue Authorization

Reviewed by

Approved by

CONTENTS

DOCUMENT NO. : 28/X-TEPC-HJZ011-2008 Page 1 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

1.Work preparation:................................................................................................................2 1.1 Drawings and equipment instruction:...............................................................................2 1.2 main T & P and inspection instruments:...........................................................................3 1.3 the construction conditions...............................................................................................3 1.4 safety proceeding .............................................................................................................3 2. working procedure and methods.........................................................................................4 2.1 Construction art flow............................................................................................................4 3. Appendix...............................................................................................................................12

1.Work preparation: 1.1 Drawings and equipment instruction:

1.1.1 Drawing instruction Drawing for main steam pipe 1.1.2 Equipment instruction and work quantity: main steam pipe ID368.3*41.275, ID273.05*30, ID368.3*47.04, HP bypass steam pipe241.3*27, material is SA335-P91.

DOCUMENT NO. : 28/X-TEPC-HJZ011-2008 Page 2 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

1.2 main T & P and inspection instruments:

1.2.1 Main T & P and inspection instruments SN. Description Model Num. Remarks

1 2 3 4 5 6

Heating treatment temperature control carbine Crawler heater Line type heater Infrared thermometer Leebs hardness tester Thermocouple

DLWK-12-360

2 PCS 60 SETS

Acceptance Acceptance Acceptance Acceptance Acceptance Acceptance

30m TI120EL HT-2000A K type

10 pieces 1 block 1 block 6 pieces

1.3 the construction conditions

1.3.1 the power shall be arranged and ensured that during heating treatment, the power could not be cut off. 1.3.2 The operator shall have the certification.

1.4 safety proceeding

1.4.1 On the heating treatment area, the protection and alarm board shall be hanged. 1.4.2 There shall have two men on duty during electrical heating. Before remove the heating device, ensure the power has been cut off. After the heating treatment, check the site, leaving without the fire hidden danger. 1.4.3 Helmet and safety belt shall be worn correctly during working. 1.4.4 The scaffolds shall be fastened with adequate light.

DOCUMENT NO. :

28/X-TEPC-HJZ011-2008

Page 3 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

2. working procedure and methods 2.1 Construction art flow

Operator shall have the certification Receive the commission from construction team

28/X-TEPC-HJZ011-2008

DOCUMENT NO. :

Page 4 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

Check whether there has the work condition Bind up the heater

Pre-heating

Heating treatment after welding

Hardness checking

Report

Data hand over welding

DOCUMENT NO. :

28/X-TEPC-HJZ011-2008

Page 5 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

Heating treatment construction methods

SN. Description Note Content and methods Checking index 1 Operator shall have the certification Receive the commission from construction team Check whether the conditions have been prepared Bind up the heater Heating operator shall have the certification as per the IBR requirements. The written commission shall be given to heating technician, and shall be signature by heating technician. The heating technician shall confirm the working conditions after receiving the commission, the technician shall contract the construction team immediately if the working conditions could not be met the requirements. The welding joint on the commission list shall be bound up, the cover area shall be met the heating requirements during using crawler heater and

28/X-TEPC-HJZ011-2008

Requirements Quality standard IBR Checking instruments and methods

Results Checking results Acceptance

Witness

Legible Handwriting

The scoffed shall be fastened

The relative specialty T &P

23R

DOCUMENT NO. :

Page 6 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

line type heater. In any heating condition, the heater could not be cross and overlapped. And the material could not touch heating wire. The heater shall be close to the pipe without kink and uneven, the insulation material on heater shall be intact. From the center of welding joints, the heating width shall be not less than 3 times of the thickness of pipe wall and shall the minimum heating width is 60mm. if the outer diameter is more than 219mm or the thickness of pipe wall more than or equal to 20mm, the heating width shall be 3 times more than the thickness of pipe wall and meanwhile, the minimum heating width is 100mm. According to the temperature difference and conduction, it can be divided into two parts, from top to under part, from thin part to thick part with tightness and fastness bound

DOCUMENT NO. : 28/X-TEPC-HJZ011-2008 Page 7 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

Pre-heating

up. For example: for Yconnection, on the straight pipe, the insulation was thin and short, on the leveling pipe, from top to under part, the thickness of the wall was increased. (Thin and thick is comparative) The temperature increasing speed = 25025 wall thickness /h , and also, the temperature shall not be exceeded 300/h. Before welding, the pre-heating temperature is 100 150 before back welding, and the temperature between wall shall less than 300, the preheating temperature is 200 300 while SMAW, and the temperature between wall shall l less than 300, and the heating technician shall monitor in time, if the temperature between wall is more than 300, and welder shall stop welding till the temperature

28/X-TEPC-HJZ011-2008

The heating treatment code for fire power plant DL/T 2002 819-

DOCUMENT NO. :

Page 8 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

down to 200300. During heating, the K type armoured thermo-couple as the temperature control element to monitor the temperature. While temperature reach to the preheating temperature, the infrared thermometer shall be applied to measure the temperature of groove root, if it reaches to the pre-heating temperature, welding started, if not, the thermo insulation shall be adopted till the temperature reaches to the pre-heating temperature. 2pc thermo-couples and vertical pipe type (2G) thermo-couples were arranged at two side of groove. And leveling pipe type (5G) thermo-couple was arranged as per the photo 1. And between thermo-coupler and heater, there shall have

DOCUMENT NO. : 28/X-TEPC-HJZ011-2008 Page 9 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

the heating insulation device.

Heating treatment

Before heating treatment, check the appearance quality of welding joints, and then the welding joints shall be subjected to the heating treatment after acceptance.

After welding, while the temperature become 100200of welding seam, the stabilize the temperature for 1 hour, and then improve the temperature to 750 770 as the speed of 140/h, and then stabilize the temperature for 4 hours, and then low down the temperature to 300 as the speed of 140/h, after this, the welding seam become cold on the nature condition without control. During heating treatment, the thermo-couple is moved to the center of welding seam, and the arrangement method is the same as pre-heating.

28/X-TEPC-HJZ011-2008

R The heating treatment code for fire power plant DL/T 8192002

DOCUMENT NO. :

Page 10 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

Hardness checking

Report

For the heating treatmen tcurve, please refer to appendix 3. The welding seam shall be subjected to the 100% hardness test during heating treatment, after the treatment, the hardness of welding seam shall be not more than HB hardness of original material +100, and less than HB350. If the test result was not confirmed to the requirement, the heating treatment shall be redone. After the hardness accepted, the report shall be issued. Tidy up the heating treatment curve and hardness report etc.

Data handover

R: Record the point (PETRON done) W: witness (PETRON and REL) H: Stop working to inspect (PETRON, REL and SEC)

DOCUMENT NO. : 28/X-TEPC-HJZ011-2008 Page 11 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

3. Appendix

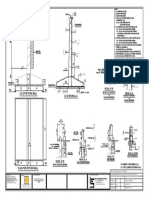

Appendix 1

The binding up method for straight pipe

DOCUMENT NO. :

28/X-TEPC-HJZ011-2008

Page 12 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

3-5

The width is 3-5 times of wall thickness

Rope type heater Crawler type heater Heater center line Seam center line

Appendix 2: The binding up method for T type pipe

DOCUMENT NO. :

28/X-TEPC-HJZ011-2008

Page 13 of 14

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

3-5

The width is 3-5 times of wall thickness

NOTE: A) For A, the heating area shall be 3-5 times than welding seam thickness, and the insulation material shall be covered the whole area. B) For B, the heater 3 shall be used crawler heat, and for the other, any heater can be applied, and the insulation materials shall be covered on the whole welding seam and other place affected by the heater.

Appendix 3: heating treatment curve

T/

70 0 6 1 4 h 1 0 / h 5 30 5 1 h =0 m 2m 1 0 /h 5 1 h 10 2 0 -1 0 1 0 / h 5 20 0 0 -3 0 30 0

1 0 / h 5 10 5 0 -1 0 20 0 0 -3 0

DOCUMENT NO. :

28/X-TEPC-HJZ011-2008

R T

Page 14 of 14

t(h ) P9 PH PWT g h 1 & H rap

The heating treatment manual of P91 after welding

2300 MW Rosa Thermal Power Project

T/

760 10 4h 150/ h 350 1h = m 20m 150/ h 1h 100- 120 R T 150/ h 200- 300 300

150/ h 100- 150 200- 300

t ( h) P91 PH PWT graph & H

DOCUMENT NO. :

28/X-TEPC-HJZ011-2008

Page 15 of 14

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Waterproofing Roofs PDFDocument40 paginiWaterproofing Roofs PDFyudhishthir singhÎncă nu există evaluări

- Sun Control and Shading DevicesDocument10 paginiSun Control and Shading DevicesNerinel CoronadoÎncă nu există evaluări

- Admixtures Improve Concrete PropertiesDocument3 paginiAdmixtures Improve Concrete PropertiesAbhiÎncă nu există evaluări

- Composite Construction MethoddDocument13 paginiComposite Construction MethoddEditha BaniquedÎncă nu există evaluări

- Ready Mix Concrete PPT 01Document28 paginiReady Mix Concrete PPT 01Pavan Kumar88% (16)

- Using Hap460 For LeedDocument6 paginiUsing Hap460 For LeedSid KherÎncă nu există evaluări

- Da Manual PDFDocument4 paginiDa Manual PDFJer SowÎncă nu există evaluări

- Fema 154 FormsDocument3 paginiFema 154 FormslesgiuÎncă nu există evaluări

- Room-Integ-TestDocument4 paginiRoom-Integ-TestBinu Sulochanan100% (1)

- Sharkbite Evopex Product Catalog 08 2020Document21 paginiSharkbite Evopex Product Catalog 08 2020Arq Cesar Augusto Mejia GÎncă nu există evaluări

- SS-GPH13H New Unit PG 38Document44 paginiSS-GPH13H New Unit PG 38kbishop7561Încă nu există evaluări

- DIVISION 3 - Assignment Technical SpecificationsDocument3 paginiDIVISION 3 - Assignment Technical SpecificationsPatrisha SantosÎncă nu există evaluări

- Geoplast Skyrail H16 English Technical SheetDocument2 paginiGeoplast Skyrail H16 English Technical SheetThanh TruongÎncă nu există evaluări

- Strong Column-Weak Beam PrincipleDocument1 paginăStrong Column-Weak Beam PrincipleEhsan ShÎncă nu există evaluări

- Evolution of ACI 562 Code Part 9Document5 paginiEvolution of ACI 562 Code Part 9Ziad BorjiÎncă nu există evaluări

- Pre-Mix Selector ChartDocument3 paginiPre-Mix Selector ChartChris Real Real LoyalÎncă nu există evaluări

- Chapter 8 Inderect WasteDocument6 paginiChapter 8 Inderect WastekulotpampuÎncă nu există evaluări

- 2.1.3 Suspending The Indoor Unit: Installation of Indoor Units Tropical Split Type Technical ManualDocument1 pagină2.1.3 Suspending The Indoor Unit: Installation of Indoor Units Tropical Split Type Technical ManualgrwgÎncă nu există evaluări

- Analysis of M15 ConcreteDocument2 paginiAnalysis of M15 ConcreteChau Suktana EnlingÎncă nu există evaluări

- Assignment 1 PDFDocument3 paginiAssignment 1 PDFJunevee AmaranteÎncă nu există evaluări

- Part A: Ground Enbankment: Percentage BoqDocument10 paginiPart A: Ground Enbankment: Percentage BoqNikhilÎncă nu există evaluări

- Structural Report - Type 4 Health PostDocument29 paginiStructural Report - Type 4 Health PostSaurav ShahÎncă nu există evaluări

- Sdron 100Document61 paginiSdron 100lojzemulec5966100% (1)

- Retaining wall reinforcement detailsDocument1 paginăRetaining wall reinforcement detailsSunetra DattaÎncă nu există evaluări

- Genset Pad Plan Genset Pad Section: Client Designer Drawn Reuse of Documents SEB CSCDocument4 paginiGenset Pad Plan Genset Pad Section: Client Designer Drawn Reuse of Documents SEB CSCMark Genesis VelonzaÎncă nu există evaluări

- Flat Slabs: Design of Flat Slabs With and Without Drops by Direct Design Method of IS Code-Design and DrawingDocument23 paginiFlat Slabs: Design of Flat Slabs With and Without Drops by Direct Design Method of IS Code-Design and DrawingSenthil KumarÎncă nu există evaluări

- Standard PVC Conduit and Fittings Colour ChartDocument4 paginiStandard PVC Conduit and Fittings Colour ChartPratikno SajaÎncă nu există evaluări

- Clading (Protecion Mecanica) PDFDocument12 paginiClading (Protecion Mecanica) PDFManuel MarrugoÎncă nu există evaluări

- Project Structure 250L Fuel Day Tank Base Slab DesignDocument6 paginiProject Structure 250L Fuel Day Tank Base Slab DesignKushan Dhanushka NanayakkaraÎncă nu există evaluări

- CE414L Activity1 Group2Document12 paginiCE414L Activity1 Group2MARK RENIELLE BAUTISTAÎncă nu există evaluări