Documente Academic

Documente Profesional

Documente Cultură

Coal Companies in India

Încărcat de

Vishal KhandekarDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Coal Companies in India

Încărcat de

Vishal KhandekarDrepturi de autor:

Formate disponibile

EASTERN COALFIELDS LTD

HISTORY Raniganj Coalfield, which falls under E.C.L. is the birth place of coal mining in the Country. In 1774, first mining operation in the Country was started in this Coalfield by Sumner & Heatly. In 1820, first Coal Company M/s. Alexander & Company was established. In 1835, first Indian Enterprise i.e. M/s. Carr & Tagore Company was formed. In 1843, the first joint stock Coal Company i.e. M/s. Bengal Coal Company was formed. Since then, underground coal mining operation had been continuing in Raniganj Coalfields by numerous small owners. Raniganj Coalfield remained the principal producer of coal in India in 19th Century and considerable period of the 20th Century. Birth Place of Coal Mining in the Country NATIONALISATION AND AFTER In 1973, all Non-Coking Coal Mines were nationalized and brought under Eastern Division of Coal Mines Authority Limited. In 1975 Eastern Coalfields Limited, a Subsidiary of Coal India Limited (C.I.L) was formed and inherited all the private sector coal mines of Raniganj Coalfields ECL Headquarter at SANCTORIA GEOGRAPHIC LOCATION & AREA ECLs total command area is 1620 Sq.Kms. It is situated in two States West Bengal and Jharkhand. Area of Raniganj Coalfield is 1530 Sq. Kms spreading over Burdwan, Birbhum, Bankura and Purulia Districts in West Bengal and Dhanbad District in Jharkhand. Saherjuri Coalfield in Deoghar District of Jharkhand is having an area of 10 Sq.Kms is being worked as SP Mines Area under ECL. Hura Coalfields in Godda District of Jharkhand is also under ECL having an area of 80 Sq.Kms. ECLs largest opencast mine Rajmahal is being operated here. Heart of Raniganj Coalfield is however, in Burdwan District bounded by Ajoy River in North and Damodar River in South. Kasta Coalfields is located on the North of Ajoy while Mejia and Parbelia are on South of Damodar River. In Dhanbad Distgrict, Mugma field lies on the west of Barakar River.Formation of coal seems has occurred mainly in two sequence at ECL Raniganj measures & Barakar measures. Raniganj measures covers the entire coalfield of Raniganj Pandaveswar, Kajora, Jhanjra Bankola, Kenda, Sonepur, Kunustoria, Satgram, Sripur, Sodepur & Partly at Salanpur Areas. Barakar measures covers two areas Salanpur & Mugma Areas, SP Mines & Rajmahal Areas are mainly related to Barakar measure & Talchair series).

MINES & MANPOWER

At present ECL has 105 no. of operating mines out of which 88 are underground mines, 17 are opencast mines. The existing manpower in Eastern Coalfields Limited as on 1.4.2010 is 85617, out of which female employees are 7750 (9.05%).

Underground Coal Mine COAL RESERVE As on 1.4.2008, the total coal reserve in ECL command area upto 600 metre depth is 40.648 Billion tone out of which 23.572 billion tone is in the State of West Bengal and 17.126 Billion tone is in the State of Jharkhand. Total proved reserve in the state of West Bengal is 11.423 billion tonne and 4.103 billion tone is in the State of Jharkhand. BEST QUALITY NON-COKING COAL The Raniganj measures coal has special characteristics containing the best type of non-coking coal reserves in the country with average ash percentage of less than 20%. The main features of this coal are high volatile content, long flame, quick ignition and high heat value. All the heat intensive industries like glass, ceramics, fertilizers, refractories, forging etc use Raniganj coal. Other Industries also prefer Raniganj coal. The major portion of export coal from the country is contributed from Raniganj coalfield. Raniganj coal which is the most important by way of its higher quality, low ash content and its requirement under MOEF stipulations, is most suited to Power Utilities for replacing the import quantity. Due to its unique characteristics Raniganj coal has high demand in the market throughout the Country. Barakar measures coals are low moisture, high fixed carbon, low sulphur & are suitable for modern power houses & other small scale industries. ECL has earned highest gain over notified price (Rs. 188 crore) from e-auction during the year 2008-09, but the gain over notified price in 2009-10 was only 91.60. New chapter opened through MoU with DVC, WBPDCL,NTPC & other power utilities where coal will be supplied at mutually agreed price considering the cost of production & imported price of coal to recover the loss of u/g mines at Raniganj field producing higher grades for making them sustainable. E.C.L. produces best quality non-coking coal

OUR ACHIEVEMENTS The total coal production of ECL at the time of nationalization was around 21 million tonnes, of which over 19 million tonnes was from underground mines and the rest from manual quarries. Immediately after nationalization, efforts were made to improve production level with addition of inputs by way of both shortterm and long term investment resulting into increase in production. However, owing to suspension of operation of number of mines/ units on the ground of exhaustion of coal reserves in working seams, on safety ground as well as being uneconomic and problem of land acquisition for depillaring with caving as well as gradual reduction of loader strength production from underground mines could not be sustained and got reduced considerably and ultimately attained at a level of 8.395 million tonnes in 08-09. However, the declining trend of underground production has been arrested from 07-08 with a marginal growth in 08-09. In order to sustain and augment the underground production a road map has been formulated envisaging mechanization of manual mines by way of introduction of SDL/LHD in loading operation covering more mines wherever practically feasible. As on 31.3.2010 company is deploying 152 nos. of SDL and 24 nos. of LHD. In 2009-10, 40 nos. standard height SDLs had been received and commissioned. During 2010-11 procurement action has been taken for 21 nos. of standard height SDLs, 5 nos. low height SDLs and 26 nos. of LHDs. Apart from this, for augmentation of underground production three mines have been identified for introduction of Mass production technology by way of deployment Continuous Miner with shuttle Car on risk/gain sharing basis. At the first instance Continuous Miners Package was introduced at Jhanjra Project in collaboration with M/s. Joy Mining Machinery Limited on risk/gain sharing basis in Sept. 2007 and is running successfully at present. For deployment of another Continuous Miner at Sarpi UG mine of Bankola Area agreement with M/s. Joy Mining Machinery Limited has been done on 6.4.2009. Part of the consignment i.e. Shuttle Car Load Centre and Quad Bolter have arrived at site in the last week of April 2010 and have been assembled at Jhanjra workshop. The main equipment i.e. the Continuous Miner and Feeder Breaker have also reached Kolkata port on 26.5.2010. Arrangements are being done for their inland transport to the site.

For introduction of 2nd set of Continuous miner at Jhanjra, project report has been approved by ECL Board and approved by CIL Board in Feb 2009. Global tender has been floated. Techno-commercial Part has been opened and a technical committee was formed by competent authority for evaluation of technical eligibility. Technical committee has submitted its report on 19.4.2010. Commercial evaluation by Tender Committee is under progress. In addition to this, High Power PSLW set is also proposed to be introduced at R-VI seam of Jhanjra for mechanized production from Longwall operation. Global Tender has been floated. A technical committee was formed by competent authority to evaluate technical eligibility. Technical committee meeting has been held on 20.5.2010 and report is still awaited.

Power Plant-Core Sector Principal Consumer Rajmahal Opencast Project ACCEPTING THE CHALLENGE In order to meet the growing demand of coal of the consumers, Eastern Coalfields Limited intends to increase coal production from both Opencast and Underground Mines from the existing coal production of 30.067 Million tonne in 2009-10 to an optimum level of 34.00 million tone in 2011-12. Target of coal production in 2010-11 is 33.00 million tonne and OB removal target is 55.00 million cu.m. Company achieved a profit of Rs. 333.40 crore during 2009-10. In addition to mechanization of manual mines by way of introduction of SDL/LHD, Continuous Miner is going to be introduced at Sarpi underground project very soon. Introduction of 2nd Continuous Miner and PSLW (2nd phase) at Jhanjra project are also under process. Ten number of new reorganized Underground Projects have been taken up for implementation during X Plan period and seven number of underground projects have proposed to be taken up in XI Plan period to replace and augment the existing underground production. Out of 10 UG Projects identified in the X Plan period, production from 3 projects are contributing and rest of the Projects are in different stages of implementation. A Dragline machine in Opencast project Increase in Open Cast Production: (1) Global Tender floated twice for Rajmahal Expansion from 10.5 million tonnes to 17 million tonnes, could not be finalised. Hence, tender was cancelled. Revised project report has been approved by Ministry of Coal in Sept. 2009 with a capital investment of Rs. 153.82 crore under partial outsourcing option. Project Report has been approved by MOC in Sept. 2009. Pre-NIT meeting based

on draft tender document was held in Dec. 2009. Final NIT has been prepared and awaiting approval of ECL Board. Simlong Open Cast Mine, where operation had been suspended during 2002, has been restarted for extraction of remaining 0.9 million tonne of coal and to facilitate starting of neighbouring Chuperbhita Open Cast Project

(2) Coal India Ltd. will consider the Project Report of Chuperbhita for 4 MTY and Hurra C for 3 MTY after obtaining forest clearance. Company is pursuing the matter for obtaining forest clearance expeditiously. Efforts are being made to operate Chuperbhita OC and Hura-C OC Projects in the non-forest area. Tendering for opening up a patch in non-forest area in respect of Hura-C OC is in progress.

(3) ECL Board has approved Project Report of Sonepur Bazari combined OC of 8 MTY with an investment of Rs. 495.09 crore in January2008. The revised project report for Sonepur Bazari combined OC is under preparation at CMPDIL, RI-I, Asansol. However, to augment the production of Sonepur Bazari, an outsourced OC patch with a surface miner has started with production of 1 MTY.

(4) For Expansion of Chitra Project to 2.5 million tonnes, Coal India Board has accorded its approval to the Project Report with capital investment of Rs. 112.69 crore during August2007. Estimate for outsourcing of OB removal is under scrutiny.

(5) ECL in totality surveyed off 173 equipment against which 122 have been procured, ordered for 15 nos. and tendered for 34 nos.

Outsourcing of patches: During 2009-10, company produced 4.336 million tone of coal from outsourcing OC patches. As on date, company is operating 8 outsourcing patches. More number of patches have been identified & proposed to be worked in future like Narainkuri, Bonbahal, Deep mining zone of Rajmahal, Samla, Madhaipur etc.

BHARAT COKING COAL LTD

ABOUT BCCL Bharat Coking Coal Limited (BCCL) is a Public Sector Undertaking engaged in mining of coal and allied activities. It occupies an important place in as much as it produces bulk of the coking coal mined in the country. BCCL meets almost 50% of the total prime coking coal requirement of the integrated steel sector. BCCL was incorporated in January, 1972 to operate coking coal mines (214 Nos) operating in the Jharia & Raniganj Coalfields, taken over by the Govt. of India on 16th Oct,1971 to ensure planned development of the scarce coking coal resources in the country. Currently, the Company operates 81 coal mines which include 40 underground, 18 opencast & 23 mixed mines as on 01.04.2010. The Company also runs 6 coking coal washeries, 2 non-coking coal washeries. The mines are grouped into 13 areas for administrative convenience. The total manpower as on 1.4.05 was 92,268 and as on 01.03.2010 is 72,222.

Performance

PRODUCTION

(Figs in Million Tonnes) 197 198 199 200 200 200 200 200 200 200 200 2009 Compan Type 4 - 4 - 4 - 1 - 2 - 3 - 4 - 5 - 6 - 7 - 8 - - 10 y 75 85 95 02 03 04 05 06 07 08 09 U/G BCCL 15.6 13.3 11.4 7.59 7.29 6.74 6.38 5.47 4.90 4.46 4.13 3.9 4 4 9 17.2 17.6 16.8 15.9 15.9 17.8 19.3 20.7 21.3 23.61 6 6 6 4 4 4 0 5 8

OC 2.10 8.50

TOT 17.7 21.8 28.7 25.2 24.1 22.6 22.3 23.3 24.2 25.2 25.5 27.5 AL 4 4 5 5 5 8 2 1 1 1 1 1

Coal Reserve

COAL RESERVES IN INDIA : (As on 1st April, 2009) (in billion tonnes) Total Reserve Coking Non-Coking Total

Areas KUSUNDA, P. B. AREA, KUSTORE, BASTACOLLA, E. JHARIA, W. JHARIA, BARORA, BLOCK II, GOVIINDPUR, KATRAS, SIJUA, LODNA, C. V. AREA

Proved Reserve 17.5 88.3 105.8

Indicated Reserve 13.8 109.7 123.5

Inferred Reserve 2.1 35.8 37.9

33.4 233.8 267.2

CENTRAL COALFIELDS LTD

Central Coalfields Limited The Historical March Central Coalfields Limited is a Category-I Mini-Ratna Company since October 2007. During 2009-10, coal production of the company reached its highest-ever figure of 47.08 million tones, with net worth amounting to Rs. 2644 crore against a paid-up capital of Rs. 940 crore. Formed on 1st November 1975, CCL (formerly National Coal Development Corporation Ltd) was one of the five subsidiaries of Coal India Ltd. which was the first holding company for coal in the country (CIL now has 8 subsidiaries). Presently CCL has Number of Mines 58 Operative Mines (21 Underground & 37 Opencast mines) 7 Washeries 4 Coaking Coal Washeries (Kathara, Rajrappa, Kedla & Sawang) - throughput capacity of 9.35 MTPA 3 Non-Coking Coal Washeries (Piparwar, Kargali & Gidi) - throughput capacity of 11.72 MTPA

Washeries

1 Central Workshop (ISO 9001) at Barkakana Repair/Worksh 5 Regional Repair/Workshops (3 w/s are ops ISO 9001) at Jarandih, Tapin North, Dakra, Giridih & Bhurkunda

Operating Coalfields

6 Coalfields (East Bokaro, West Bokaro, North Karanpura, South Karanpura, Ramgarh & Giridih)

Geological Coal Reserves in CCL Command Area up to 300m & above depth (As on 01.04.2009) Reserve Depth 0-300 m Depth 300-1200 m Total (BT)

Prov Indica Inferr Tota Prov Indica Inferr Tota ed ted ed l ed ted ed l (BT) (BT) (BT) (BT) (BT) (BT) (BT) (BT) Coking Coal 6.459 3.942 Non-Coking 10.61 3.490 Coal 2 Total 0.048 1.090 10.4 0.967 5.093 49 15.1 0.576 3.481 91 1.613 2.115 7.67 18.183 3 6.17 21.364 2

17.0 25.6 1.54 13.8 7.432 1.138 8.574 3.728 39.550 41 41 3 45 65% 35%

CCL Reserve at Depth 01200 m Prove d (BT) Indica Inferr Total ted ed (BT) (BT) (BT) 4.866 39.55

Coal Reserve CCL % in Total India Reserve 15%

Total India (BT) 267.210

18.614 16.00

NORTHERN COALFIELDS LTD

About NCL Northern Coalfields Limited was formed in April 1986 as a subsidiary company of Coal India Limited. Its headquarter is located at Singrauli, Distt. Sidhi (M.P.). Singrauli is connected by road with Varanasi (220 Km.) a holy city on the banks of river Ganga, and Rewa (206 Km.) the state of white tigers and Sidhi (100 Km.) district headquarter town of Madhya Pradesh. The nearest railway station is Singrauli located on the Katni-Chopan branch line running parallel to the northern boundary of the Coalfield. The nearest railway station for reaching directly to Delhi and Kolkata is Renukoot that is located on the Garh waChopan rail-line. Nearest (private) airstrip is at Muirpur (60 Km.). The area of Singrauli Coalfields is about 2202 Sq.Km. The coalfield can be divided into two basins, viz. Moher sub-basin (312 Sq.Km.) and Singrauli Main basin (1890 Sq.Km.). Major part of the Moher sub-basin lies in the Sidhi district of Madhya Pradesh and a small part lies in the Sonebhadra district of Uttar Pradesh. Singrauli main basin lies in the western part of the coalfield and is largely unexplored. The present coal mining activities and future blocks are concentrated in Moher sub-basin. The exploration carried out by GSI/NCDC/CMPDI has proved abundant resource of power grade coal in the area. This in conjunction with easy water resource from Govind Ballabh Pant Sagar makes this region an ideal location for high capacity pithead power plants. The coal supplies from NCL has made it possible to produce about 10515 MW of electricity from pithead power plants of National

Thermal Power Corporation (NTPC), Uttar Pradesh Rajya Vidyut Utpadan Nigam Ltd (UPRVUNL) and Renupower division of M/s. Hindalco Industries. The region is now called the "power capital of India". The ultimate capacity of power generation of these power plants is 13295 MW and NCL is fully prepared to meet the increased demand of coal for the purpose. In addition, NCL is also supplying coal to power plants of Rajasthan Rajya Vidyut Utpadan Nigam Ltd, Delhi Vidyut Board (DVB) and Hariyana State Electricity Board. NCL produces coal through mechanised opencast mines but its commitments towards environmental protection is total. It is one of very few companies engaged in mining activities, which has got ISO 14001 Certification for its environmental systems. NCL, through its community development programmes, has significantly contributed towards improvement and development of the area. It is helping local tribal, non-tribal and project-affected persons in overall improvement of quality of their life through self-employments schemes, imparting education and providing health care. Production During 2008-09, coal production was 63.65 Mill Tes. In 2009-10, the target for coal production is fixed at 66.50 Mill. Tes. . NCL has excellent record of capacity utilization , which is around 80.06 % in 2008-09. The productivity in terms of OMS (out put per man shift) of NCL during 2008-09 was 14.57 Tonnes, which has been the highest in CIL and during successive years , it is increasing . It is planned to remove 242.00 Mill Cum of overburden during 2009-10, out of which 140.50 Mill. Cum. will be removed departmentally and rest 101.50 Mill. Cum. is out sourced under Emergency Coal Production Plan.

Performance Highlights of the Year 2007-08 The company has concluded year 2007-08 with excellent performance, highlights thereof are mentioned hereunder:NCL has achieved all time high coal production of 59.623 MT during the year 2007-08 with a growth of 14.31% over actual production of 52.158 MT during

the year 2006-07. The over burden removal of 186.25 M. Cu. M. recorded a growth of 33.41% over OBR of 139.598 M. Cu. M. during the year 2006-07. Despatches at 59.016 MT during the year 2007-08 too being highest ever, have registered a growth of 12.16% over the despatches of 52.620 MT during the year 2006-07. Record turnover of Rs. 5455.21 Crores during the year 2007-08 is 17.80% higher than last year's turnover of Rs. 4630.84 Crores. NCL maintained its position as top profit earning subsidiary of Coal India Limited (CIL) with record Profit before Tax (PBT) of Rs. 2763.75 Crores during the year 2007-08 which has recorded an increase of 26.92% over previous year's PBT of 2177.61 Crores. Profit after tax (PAT) too reached a level of Rs. 1771.66 Crores i.e. up by 29.65% over previous year's PAT of Rs. 1366.48 Crores. Total Dividend for the year 2007-08 being 598.29% of paid up equity share capital amounting to Rs. 1063.00 Crores against 307.64% i.e. Rs. 546.59 Crores for the year 2006-07. Earning Per Share (EPS) during the year 2007-08 has gone up to Rs. 9971.49 from Rs. 7691.02 of previous year. Efforts for greening the environment and pollution control continued during the year. During 2007-08, 3.78 lakhs saplings have been planted. The total saplings planted up to 31st March 2008 reached 1.95 Crores. NCL continued to practice workers participation in management, as a result industrial relations remained healthy and harmonious. Employees' welfare, community development and human resource development continued to be as focus areas.

WESTERN COALFIELDS LTD

Western Coalfields Limited (WCL) is one of the eight Subsidiary Companies of Coal India Limited (CIL) which is under administrative control of Ministry of Coal. The Company incorporated under the Companies Act, 1956 has its registered office at Coal Estate, Civil Lines, Nagpur440001. WCL has been conferred "Miniratna" status on 15th March'2007. The Company has contributed about 8.6% of the national coal production during 2009-10. It has mining operation spread over the states of Maharashtra (in Nagpur, Chandrapur & Yeotmal Districts) and Madhya Pradesh (in Betul and Chhindawara Districts). The Company is a major source of supplies of coal to the industries located in Western India in the States of Maharashtra, Madhya Pradesh, Gujrat and also in Southern India in the States of Andhra Pradesh, Tamil Nadu, Karnataka and Kerala. A large numbers of Power Houses under Maharashtra, Madhya Pradesh, Gujrat, Karnataka, Punjab and Uttar Pradesh - Electricity Boards are major consumers of its coal along with cement, steel, chemical, fertilizer, paper and brick Industries in these states.

COAL RESERVES The Command Area of WCL has reserves of 13247.00 Million Tonnes of coal, out of total coal reserves of 276810* Million Tonnes in India (as on 01.04.2010). The distribution is delineated below: (Million Tonnes) State Maharashtra Madhya Pradesh Total WCL: ALL INDIA Coking -666 666 33413 Non- Coking Total 10308 2273 12581 243397 5.12 10308 2939 13247 276810* 4.78

WCL reserves as % of 1.99 All India

Trend of Annual Coal Production During Last Years (Figures in Million Tonnes) YEAR 2002-03 2003-04 2004-05 2005-06 2006-07 2008-09 2009-10 OC MINES TARGET 27.050 27.750 28.500 32.100 32.100 32.750 34.850 ACTUAL 28.427 30.016 31.761 33.166 33.297 34.585 36114 UG MINES TARGET 9.950 9.500 9.500 9.800 9.900 10.300 10.150 ACTUAL 9.388 9.510 9.649 10.038 9.915 10.115 9.621 TOTAL TARGET 37.000 37.250 38.000 41.900 42.000 43.050 45.000 ACTUAL 37.815 39.526 41.410 43.204 43.212 44.700 45.735

SOUTH EASTERN COALFIELS LTD

South Eastern Coalfields Limited is the largest coal producing company in the country. It is one of the eight subsidiaries of Coal India Limited (A Govt. of India Undertaking) under the Ministry of Coal . The company was adjudged the best PSU in the country for 97-98 and was awarded Jawaharlal Nehru Memorial National Award for pollution control and energy conservation in the year 2003, Excellence award in 2004 ,2006 and 2008,National safety award from Hon'ble President of India in 2004,2005 and 2006. SECL has been awarded " Mini Ratna" Status by Govt of India in 2007 . In year 2009-10,total coal production by SECL was 108.01 million tonnes from open cast and underground mines which is highest among all subsidiaries of Coal India Ltd and among all coal producing companies in India.In the year 2009-10 out of total coal production of 431.27 million tonnes produced by Coal India Ltd., total coal production by SECL was 108.01 million tonnes SECL has been making profits since its inception. The coal deposits of SECL occur in five districts i.e. Bilaspur,Korba, Raigarh ,Surguja &Korea in Chhattisgarh and three districts Shahdol,Umaria,Anuppur district in Madhya Pradesh. This occurs in the great Son Mahanadi master basin.

SECL has 92 Mines.Total UG Mines are 70 and Total OC mines are 21.There is 1 mixed mine. There are 42 UG Mines ,13 OC Mines , 1 Mixed Mines in Chhattisgarh and 28 UG Mines , 8 OC Mines in Madhya Pradesh. These mines are divided into 13 Administrative areas 1.Johilla area 5.Chirimiri area 9.Korba area area . 2.Sohagpur area 3.Jamuna & kotma area 7.Bisrampur area 4.Hasdeo area 8.Bhatgaon Area

6.Baikunthpur area

10.Gevra area

11.Kusmunda area

12.Raigarh area 13.Dipka

The corporate office is at Bilaspur (C.G.). As on 31/03/2007 SECL has geological coal reserve of 44.838 billion tonnes. As on 31/03/2007 SECL has mining right over 956.41 sq.km and all rights over 259.85 sq km. SECL has four major coalfields with following geological reserves. Reserve potential of SECL as per GSI as on 31/03/2007.

Major Coalfields

Coal Mining Area (Sq.KM) 530.0 5345.0 520.0 260.0 6655.0

Geological Reserves (Mil Tonnes) 10115.21 15613.98 19106.04 1616.79 46452.02

Depth (metres) 0-600 0-1200 0-1200 0-600 0-1200

Korba Central India Mand-Raigarh Ramkola-Tatapani SECL

PRODUCTION AND PRODUCTIVITY A Mini Ratna Company - South Eastern Coalfields Limited has made a record in the year 2009-10 in Production and set an all time highest record in Overall Performance in respect of off-take/despatches, production, wagon loading, quality improvements and optimization of overall consumers satisfaction in terms of meeting their coal requirement.Total Production in the year 2009-10 was 108.01 Million Tonnes against the target of 106 Million Tonnes which is 6.78 % more than in the year 2008-09. SECL has also set a historical all time high record of despatch by despatching 105.87 Million Tonnes to its various Consumers during the year 2009-10. This is an all time high record by any subsidiary of Coal India Limited .

PRODUCTION AND PRODUCTIVITY FROM 1998 - 2010

Production (mill. Tonnes) year 98-99 99-00 00-01 01-02 02-03 03-04 04-05 05-06 06-07 07-08 08-09 09-10

Productivity (Output/manshift) UG Overall

OC UG Tota OC l 41. 16. 57.5 9.24 56 00 6 42. 16. 58.7 9.36 75 01 0 44. 15. 60.3 9.96 57 76 3

0.92 2.64 0.93 2.70 0.93 2.83

48. 15. 64.1 10.03 0.97 3.0 21 91 2 50. 16. 66.6 10.70 1.01 3.21 44 16 0 54. 16. 71.0 11.25 1.05 3.49 65 36 1 61. 16. 78.5 12.27 1.11 3.95 97 58 5 66. 16. 83.0 12.76 1.12 4.17 50 52 2 72. 16. 88.5 13.27 1.14 4.51 30 20 0 77. 16. 93.7 14.30 1.19 4.83 05 74 9 83. 17. 101. 15.76 1.26 5.26 58 57 15 90. 17. 108. 18.89 1.33 5.96 18 83 01

MAHANADI COALFIELDS LTD

Mahanadi Coalfields Ltd (MCL), a subsidiary of COAL INDIA LTD (CIL), is a Mini Ratna Public Ltd. Co. doing business in COAL mining in the State of ORISSA. Its activities are located in two coalfields, namely, IB Valley Coalfields & Talcher Coalfields. The company is committed to produce 137 Mte non-coking coal in the XI Plan and 180 Mte in the XIITH PLAN period. MCL is also committed to supply washed coal to its valued consumers. The company intends to establish suitable infrastructures in terms of coal washeries for washing of non-coking coal (Ash % range 38 ~ 48). Initially it is proposed to construct three washeries in two Coalfields washing capacity being 10 Mty each. The washery will be built on (BOM) concept that means the washery will be constructed on the finance made available by CIL or its subsidiary as in the case of turn key execution and the plant has to be operated & maintained by the BOM operator for 10 years with a provision of reviewing by the owner at the end of 10 (Ten) years for each term of 05 (Five) years thereafter on the basis of same terms and conditions for which the BOM operator will get suitable remunerative washery charges. MCL invites EOI from reputed leaders in this field to participate for establishment of COAL washeries in IB & Talcher Coalfields in MCL command area in terms of an offer which essentially shall include general terms, scope and limitations.

Mahanadi Coalfields Limited (MCL) a subsidiary of Coal India Limited (CIL) was formed on 3rd April 1992. It has two coalfields, Talcher & IB Valley in Orissa. Talcher Coalfield area is approximately 25 KMs from District Headquarter, Angul.

Talcher Coalfield (Geological Reserve 35.78 B.T. As on 1.1.2002) Talcher Coalfield was first discovered at Gopalprasad in the 1837. Lateron GSI surveyed and mapped in 1855. M/S East India Prospecting Syndicate in Talcher Town in 1920 Handidhua Colliary was opened by M/s Villiers Ltd in 1921. NCDC opened mines at South Belanda, Nandira & Jagannath in the year 1960,1962 and 1972 respectively. After formation of CIL all mines were in CCL then in SECL before formation of MCL in 1992. Production of coal raised from 0.91 M.T. in 1972-73 to 33.10 M.T. in 2001-02.

Talcher Coalfield Map The coalfields at Talcher consist of 5 Coalfields : 1. Talcher Area 2. Jagannath Area 3. Kalinga Area 4. Lingraj Area 5. Hingula Area

NORTH EASTERN COALFIELDS

North Eastern Coalfields is a unit of Coal India (CIL) operating in states of Assam, Meghalaya, Nagaland and Arunachal Pradesh. North Eastern Region consists of seven states; only Assam, Meghalaya, Arnachal Pradesh and Nagaland are endowed with moderate coal reserves. Though the coal occurrences are reported from four states of North Eastern Region, the actual coal exploitation activity is confined to states of Assam (Margherita Area) and Meghalaya (Simsong U/G) only. NEC coal is of Tertiary age (Eocene to Oligocene= 40-55 million years) younger compare to deposits found in the Bihar, Jharkhand belt, attain low maturity of sub-bituminous coal rank with high calorific heat value ranging between 6500-7500 k.cal/kg.(Grade = A) Although North Eastern Coalfields contains meagre quantity of mineable coal reserves, is one of the countrys best coalfields having good quality coal characterized by very low ash content, high sulphur, high volatile matter and high caking index. Hence has got high demand for coal liquefaction plant and as blendable coal in steel industry. In the year 1870 coal mining development activity was initiated by Dr.John Berry White, Civil Surgeon and Mr.George Turner, Mining Engineer in Assam.The first colliery Ledo Underground mine was opened in the year 1882 by M/s.Assam Railways & Trading Company Ltd. in the North Eastern Region . Subsequently, more collieries were opened to meet the demand of coal from this region. In the beginning of 19th Century the coal production was 30% of the total countrys output, which now stands nearly at 0.37% only (1.05MT) against total 360.94 MT of Coal India. Out of total 257 BT Indian coal reserves , only 0.94 BT occur in the North Eastern Region which constitutes 0.37% share of Indian coal reserves (up to 1200 m. depth and as on 01.01.2007). After nationalization, the mining operations were confined to Makum and Dilli-Jeypore Coalfields of Margherita Area in Assam. At present there are five working mines 3(Three) underground and 2(Two) opencast mines. In 1995, Namchik mine was surrendered to State Govt. Arunachal Pradesh for want of Forest Clearance.The activity of exploratory mining at Simsong in Meghalaya was suspended. Since 1999, due to problems in mining activity and insurgency.

COAL RESERVE OF NER(AS ON 01.01.2007) (Figs. in MT) STATES DEPTH (MTRS.) ASSAM 0 300 300 600 0 600 ARUNACHAL 0 300 31.23 40.11 18.89 90.23 9.55 171.00 143.59 314.59 16.98 9.85 26.83 32.82 1.19 34.01 220.80 154.63 375.43 PROVED INDICATED INFERRED TOTAL % AGE 39.73

PRADESH MEGHALAYA NAGALAND TOTAL 0 300 0 300 0 600 117.83 3.43 467.08 40.89 1.35 109.18 300.71 15.16 368.77 459.43 19.94 945.03 48.62 2.11 100.0 0

SINGARENI COLLIERIES COMPANY LTD

SCCL is a joint undertaking of Government of Andhra Pradesh and the Government of India. The equity capital is shared in the ratio of roughly 51:49 between Government of Andhra Pradesh and the Central Government respectively. The headquarters of the company is at Kothagudem in Andhra Pradesh SCCL produces about 10% of the countrys coal production and 76% of its production is despatched to the coal based thermal power plants in Maharashtra, Andhra Pradesh and Karnataka. The remaining part of SCCLs coal production is supplied to the cement companies and other industries. In order to provide long-term financial stability in SCCL for investment in new coal projects and for increasing its production efficiently, the financial restructuring of the company has been done in June, 1999.

NEYVELI LIGNITE CORPORATION LIMITED

LIGNITE DEPOSIT IN NEYVELI: Lignite is the younger offspring of the coal family. It is a fossil fuel belonging to the Miocene age (25 million years). Popularly known as Brown Coal, lignite is tan brown in colour, light to handle and brittle in nature. This fuel is born from vegetable matter having undergone bio-chemical decay to the stage of peat (rotten wood) and then metamorphosed to lignite under the pressure of the soil above through floods, movements of the earths crust and dehydration when the pressure of the lignite, particularly the horizontal thrust is further increased, lignite is made more dense, less volumetric and becomes coal as such. The lignite mined at Neyveli varies in colour from brown to dark brown and has a non-bonded granular structure. Microscopic studies of this sections prepared from bulk samples of lignite indicate that the fuel is composed of a wide variety of plant ingradients, mainly of coniferous nature. Quality of Lignite: Lignite contains 65-70% of carbon, 20-25% of oxygen, about 5% of hydrogen and small amounts of nitrogen and sulphur. The average calorific value of lignite is

2400 K.cal/Kg. It cannot be compared favourably with the high calorific value of pure coal. Yet lignite has an advantage of being free burning (non coking), of having low ash and of giving rapid and complete combustion. Since the volatile matter is usually high, lignite burns readily. Air dried lignite is quite suitable for direct burning. For high capacity boilers lignite can be burnt in the pulverized form

Detail s

U ni t

20092010 Tar get Act ual

20082009 Tar get Act ual

20072008 Tar get Act ual

20062007 Tar get Act ual

20052006 Tar get Act ual

Overbu rden

La kh Cu bi c M et re La kh To nn e( LT ) Mi lli on Un it (M U)

152 6.0 0

159 4.2 5

13 99. 00

14 63. 44

13 12. 00

13 58. 26

11 95. 00

12 80. 70

11 95. 00

11 96. 59

Lignite

217 .50

223 .38

21 1.4 0

21 3.0 7

20 0.5 0

21 5.8 6

20 4.0 0

21 0.1 4

20 4.0 0

20 4.3 5

Power Genera tion (Gross)

166 00. 00

176 57. 94

16 29 0

15 76 0

15 71 0

17 46 0

15 71 0

16 24 0

15 28 0

16 74 0

S-ar putea să vă placă și

- Coal India ReportDocument317 paginiCoal India Reportnick1425Încă nu există evaluări

- Mineral Mining IndustryDocument9 paginiMineral Mining Industrypankaj455Încă nu există evaluări

- DCI Yearbook 2011Document256 paginiDCI Yearbook 2011Bugaev100% (3)

- Oil and Gas in MyanmarDocument3 paginiOil and Gas in MyanmarKunwadi ChantaraparnÎncă nu există evaluări

- Coal Mines in India-2014Document3 paginiCoal Mines in India-2014iData InsightsÎncă nu există evaluări

- Alderon Iron OreDocument528 paginiAlderon Iron Oreblackscrib100% (1)

- Vietnam CementDocument35 paginiVietnam CementPhạm ChúcÎncă nu există evaluări

- Alufer - Bauxite Factsheet PDFDocument2 paginiAlufer - Bauxite Factsheet PDFRaraÎncă nu există evaluări

- The Growing Cement Industry of The UAEDocument7 paginiThe Growing Cement Industry of The UAESadam Lodhi100% (1)

- Coal Handling OperationalDocument12 paginiCoal Handling Operationalmugiraharjo7Încă nu există evaluări

- Iron Ore Mines in IndiaDocument11 paginiIron Ore Mines in IndiaRaviraj SuryawanshiÎncă nu există evaluări

- Coal MethodologyDocument22 paginiCoal Methodologyarnoldor5747Încă nu există evaluări

- Refinery Report FINAL 1Document37 paginiRefinery Report FINAL 1pappuÎncă nu există evaluări

- Jhanjra MinesDocument69 paginiJhanjra MinesRathla Naveen100% (1)

- QGPR Apr2014Document76 paginiQGPR Apr2014Anonymous hAiENTeytÎncă nu există evaluări

- ONGC UranDocument10 paginiONGC UranakshaymehraÎncă nu există evaluări

- Coal Outlook ReportDocument51 paginiCoal Outlook ReportSterios SouyoutzoglouÎncă nu există evaluări

- Gas Market Review 2012Document54 paginiGas Market Review 2012gkouretz3855Încă nu există evaluări

- 2019 Global Chemicals Ind Mergers Acquisitions ReportDocument20 pagini2019 Global Chemicals Ind Mergers Acquisitions ReportBmt BmtÎncă nu există evaluări

- Dahej SIR PresentationDocument26 paginiDahej SIR PresentationDeepak ThakkerÎncă nu există evaluări

- Petrosil Base Oil Report - March 15, 2010 - 0Document20 paginiPetrosil Base Oil Report - March 15, 2010 - 0Divik TanwarÎncă nu există evaluări

- Gas DirectoryDocument34 paginiGas DirectoryayshazafarÎncă nu există evaluări

- Manganese projects in South Africa, Guyana and Ivory Coast aim to boost global supplyDocument31 paginiManganese projects in South Africa, Guyana and Ivory Coast aim to boost global supplyleniucvasileÎncă nu există evaluări

- WTO & IranDocument25 paginiWTO & IranAlfredo GuttiÎncă nu există evaluări

- S&P GlobalDocument17 paginiS&P GlobalVamsi Krishna EvkÎncă nu există evaluări

- Project Report ON Proposed Coal Washing Plant AT Korba AreaDocument23 paginiProject Report ON Proposed Coal Washing Plant AT Korba AreaAmitesh Joseph75% (4)

- Turkish Investments Ethiopia Turkish Embassy 2011Document58 paginiTurkish Investments Ethiopia Turkish Embassy 2011Meseret AbrhamÎncă nu există evaluări

- Global Cement IndustryDocument6 paginiGlobal Cement Industrygl101Încă nu există evaluări

- Turkey Business Leads - B2B Company Databases Category No of CompaniesDocument12 paginiTurkey Business Leads - B2B Company Databases Category No of CompaniesSiba PrasadÎncă nu există evaluări

- Guinea Mining GuideDocument32 paginiGuinea Mining GuidePalak LimbachiyaÎncă nu există evaluări

- GCC Power Market Outlook and Renewable Energy SnapshotDocument23 paginiGCC Power Market Outlook and Renewable Energy Snapshotjinalshah1012713Încă nu există evaluări

- Rice Mill Detailed Project Report - 9t Per Hour - For Finance, Subsidy & Project Related Support Contact - 9861458008Document49 paginiRice Mill Detailed Project Report - 9t Per Hour - For Finance, Subsidy & Project Related Support Contact - 9861458008Radha Krishna SahooÎncă nu există evaluări

- Company InformationDocument36 paginiCompany InformationAnaruzzaman SheikhÎncă nu există evaluări

- Scrap Metal Merchants BizHouse - UkDocument2 paginiScrap Metal Merchants BizHouse - UkAlex BekeÎncă nu există evaluări

- Bunker SuppliersDocument17 paginiBunker SuppliersgbhatikarÎncă nu există evaluări

- Ethanol Production from Sugar CaneDocument4 paginiEthanol Production from Sugar CanequixoticepiphanyÎncă nu există evaluări

- Retail Industry Global Report 2010Document36 paginiRetail Industry Global Report 2010Yam NoomÎncă nu există evaluări

- Critical Analysis of Pakistan Cement IndustryDocument42 paginiCritical Analysis of Pakistan Cement Industrytanseer_0493% (15)

- Oil and Gas Company Profile PDFDocument2 paginiOil and Gas Company Profile PDFChandrashekharCSKÎncă nu există evaluări

- Exporter details report for September 2014Document36 paginiExporter details report for September 2014Vivek DomadiaÎncă nu există evaluări

- Coal Vision 2030 stakeholder consultation commentsDocument39 paginiCoal Vision 2030 stakeholder consultation commentsShashank BhardwajÎncă nu există evaluări

- OGDC Annual ReportDocument67 paginiOGDC Annual Reporttanveeraddozai112667% (3)

- Oil and Gas CompaniesDocument4 paginiOil and Gas CompaniesB.r. SridharReddy0% (1)

- North America Merchant Hydrogen Plants Jan2016 MTD+Document3 paginiNorth America Merchant Hydrogen Plants Jan2016 MTD+totpityiÎncă nu există evaluări

- Kenya SugarDocument19 paginiKenya SugarNashon_AsekaÎncă nu există evaluări

- The Strategy of Sinochem Group Oil and Gas ResourceDocument20 paginiThe Strategy of Sinochem Group Oil and Gas ResourceQingming MaÎncă nu există evaluări

- Metals Trade AssociationsDocument20 paginiMetals Trade AssociationschssoÎncă nu există evaluări

- 0QpUa0LN - Vietnam Plastics BriefingDocument10 pagini0QpUa0LN - Vietnam Plastics BriefingMiley Minh HuyenÎncă nu există evaluări

- Arab Fert Association Directory - 2011Document120 paginiArab Fert Association Directory - 2011Gurnam Singh100% (2)

- Dry Cargo DirectoryDocument248 paginiDry Cargo DirectoryJigisha Vasa100% (1)

- 3 - DirutHuluPertamina - Aneko WidiantoDocument32 pagini3 - DirutHuluPertamina - Aneko WidiantoyanipitonoÎncă nu există evaluări

- David HumphreyDocument7 paginiDavid HumphreyMarcoFranchinottiÎncă nu există evaluări

- List Company Registered Bunker Supplier 050712Document7 paginiList Company Registered Bunker Supplier 050712James CapplemanÎncă nu există evaluări

- 150 TPD Mini Cement PlantDocument7 pagini150 TPD Mini Cement PlantDedy Setyo OetomoÎncă nu există evaluări

- Production Companies: Oil and Gas Companies (Yemen)Document0 paginiProduction Companies: Oil and Gas Companies (Yemen)عبدالله عمرÎncă nu există evaluări

- Book CementDocument242 paginiBook Cementproscoke100% (1)

- Review of Technology Requirements of The Coal Preparation Sector in IndiaDocument100 paginiReview of Technology Requirements of The Coal Preparation Sector in IndiaruzmirÎncă nu există evaluări

- MDO-Mining Plan FinalDocument134 paginiMDO-Mining Plan Finalangshuman87Încă nu există evaluări

- Coal India ProfileDocument14 paginiCoal India ProfileMithunÎncă nu există evaluări

- Coal Sector in IndiaDocument8 paginiCoal Sector in IndiaJEFY JEAN AÎncă nu există evaluări

- Updates On Improving Refractory Lining Service LifeDocument11 paginiUpdates On Improving Refractory Lining Service LifeThiruvengadamÎncă nu există evaluări

- YantrohamDocument20 paginiYantrohamAshwin Hulikunte MattadhaÎncă nu există evaluări

- Wheel-Trans Eligibility ApplicationDocument19 paginiWheel-Trans Eligibility ApplicationMARKÎncă nu există evaluări

- Gábor Békés, Gábor Kézdi - Data Analysis For Business, Economics, and Policy-Cambridge University Press (2021)Document742 paginiGábor Békés, Gábor Kézdi - Data Analysis For Business, Economics, and Policy-Cambridge University Press (2021)gatitahanyou100% (2)

- Project Management Process Groups A Case StudyDocument24 paginiProject Management Process Groups A Case Studylim100% (1)

- Boiler Learning ModuleDocument158 paginiBoiler Learning ModuleMallinatha PNÎncă nu există evaluări

- SteelTubeHandbook February2012Document120 paginiSteelTubeHandbook February2012Adisak AumpiemÎncă nu există evaluări

- Tools (Abril2015)Document48 paginiTools (Abril2015)Ricardo LopezÎncă nu există evaluări

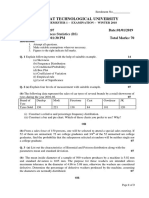

- Gujarat Technological University: Subject Code: Date:01/01/2019 Subject Name: Time: 10:30 AM To 01:30 PM Total Marks: 70Document3 paginiGujarat Technological University: Subject Code: Date:01/01/2019 Subject Name: Time: 10:30 AM To 01:30 PM Total Marks: 70harold_gravity9885Încă nu există evaluări

- Describing Environmental Issues 2021Document2 paginiDescribing Environmental Issues 2021Alisa NovitskayaÎncă nu există evaluări

- Vegetable ProductionDocument329 paginiVegetable Productionpopa_marius_68100% (6)

- Copia de ABB NPCU-01Document4 paginiCopia de ABB NPCU-01Abraham GalvánÎncă nu există evaluări

- IMPLEMENTASI KIA DI LUBUKLINGGAUDocument18 paginiIMPLEMENTASI KIA DI LUBUKLINGGAUecha okta anggrainiÎncă nu există evaluări

- The National ArtistsDocument30 paginiThe National ArtistsJuan Miguel DuranÎncă nu există evaluări

- DIGISOL Wireless Router SettingsDocument2 paginiDIGISOL Wireless Router SettingsAvinash DubeyÎncă nu există evaluări

- Pew CatalogsDocument25 paginiPew CatalogsBon HarperÎncă nu există evaluări

- The Chemistry of ExplosionsDocument7 paginiThe Chemistry of ExplosionsJJ Lim100% (1)

- Education During The Present PeriodDocument2 paginiEducation During The Present PeriodwennieÎncă nu există evaluări

- Composite Action of Octagonal Concrete-Filled Steel Tubular StubDocument9 paginiComposite Action of Octagonal Concrete-Filled Steel Tubular StubvardhangargÎncă nu există evaluări

- Iloilo City Regulation Ordinance 2016-095Document3 paginiIloilo City Regulation Ordinance 2016-095Iloilo City CouncilÎncă nu există evaluări

- World English 3e Level Intro Grammar Activities Unit 4 Lesson CDocument1 paginăWorld English 3e Level Intro Grammar Activities Unit 4 Lesson CFernanda Santos FreitasÎncă nu există evaluări

- Current Regulator DiodeDocument21 paginiCurrent Regulator Diodepayedmiat80% (5)

- Micros 3700Document498 paginiMicros 3700Nikie5100% (2)

- in What Situation Does Alison Believe Facebook Users Might Abandon The Company?Document10 paginiin What Situation Does Alison Believe Facebook Users Might Abandon The Company?Lê TùngÎncă nu există evaluări

- Sistema de LubricacionDocument34 paginiSistema de Lubricacionariel avalosÎncă nu există evaluări

- Unit 4: Cloud Computing Technologies and ApplicationsDocument17 paginiUnit 4: Cloud Computing Technologies and Applicationsronin150101Încă nu există evaluări

- Types of Triangles GCSE WorksheetDocument14 paginiTypes of Triangles GCSE WorksheetSouvik GhoshÎncă nu există evaluări

- Early Orthodontic Treatment Risk Assessment for Primary TeethDocument7 paginiEarly Orthodontic Treatment Risk Assessment for Primary Teethjavi222222Încă nu există evaluări

- Aerospace Engineering Questions Cover Satellite Orbits, Rocket Propulsion, Gas TurbinesDocument4 paginiAerospace Engineering Questions Cover Satellite Orbits, Rocket Propulsion, Gas TurbineskkonthenetÎncă nu există evaluări

- Lab Manual 11 Infrared SpectrosDocument5 paginiLab Manual 11 Infrared SpectrosLuca Selva CampobassoÎncă nu există evaluări