Documente Academic

Documente Profesional

Documente Cultură

Pages

Încărcat de

Rahul SatraDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pages

Încărcat de

Rahul SatraDrepturi de autor:

Formate disponibile

Taking India By Storm

ABOUT US

IWL INDIA LIMITED.

INTRODUCTION:

IWL India Limited was incorporated in 1988 as a Joint Sector Company with Tamil Nadu Industrial Development Corporation Limited (TIDCO) as Co-Promoters. The Company was set up to manufacture revolutionary waterproofing membranes and anti corrosive tapes for civil structures and piping requirements. The Company pioneered the manufacture and usage of these products in India.

IWL presently manufactures more than 25 million square feet of such water barriers per annum. With an ISO 9001:2008 certification to boot, IWLs products are approved by all major consultants, clients and contractors including Military Engineering Services, Nuclear Power Corporation of India, Engineers India Limited, National Thermal Power Corporation, Larsen & Toubro, etc. IWL has a distinction of executing several major waterproofing and anti-corrosion projects such as Delhi Metro underground tunnels, Nuclear Power Complex at Kudangulam at Tamil Nadu, Nuclear Power Complex at Kaiga, Dabhol Power Project at Maharashtra, etc. IWL markets its products throughout the country with a dedicated

marketing team, who are located at all major towns and cities of India.

The manufacture of Polymeric waterproofing membranes and anti corrosive tapes requires complete facilities for handling and processing of Bitumen. IWL in collaboration with European experts set up a completely automated facility at Red Hills near Chennai for the above purposes. The manufacturing facility of IWL is spread over 40,000 square feet of built up area located within 6 acres of industrial land. The facility is completely automated and digitally controlled and monitored.

With the above facility in place and since all Bitumen handling facilities were available, IWL also diversified into manufacture of other bituminous products such as Bitumen emulsions, Crumb Rubber Modified Bitumen (CRMB) and Polymer Modified Bitumen (PMB).

IWL INDIA LTD

Page 1

Taking India By Storm

With the above facility in place and since all Bitumen handling facilities were available, IWL also diversified into manufacture of other bituminous products such as Bitumen emulsions, Crumb Rubber Modified Bitumen (CRMB) and Polymer Modified Bitumen (PMB).

IWL maintains a highly experienced Application Department with Application Engineers who are trained in the application of all its products. These application Engineers are available at moments notice to any Customer anywhere in the country for advice regarding the usage of IWLs products or for any troubleshooting that may be required.

Over the years, IWL has successfully combined research and development, with State of art machinery, modern technology, on line net based sales and management systems and under countermined attitude towards quality catered to the needs of its valued clients and the needs of the civil construction, highway engineering and pipeline industries.

CUSTOMER SUPPORT

IWL has Marketing and Support Presence in every State of India. Our all India team of Marketing and Application Engineers are on call 24/7.

NATIONAL DELIVERY MODEL

IWLs internet based order processing system allows for instant transmission of customers requirements to the factory. We offer instant deliver of ordered products and services.

IWL INDIA LTD

Page 2

Taking India By Storm

OUR VISION

To Become The Best Provider Company of Polymeric Waterproofing Membranes, Road Emulsion & Bitumen based pipe Coating Tapes For Development of Indian and Global Infrastructure.

OUR MISSION

Passionately Committed To Total Quality and Value added Products And Up Holding The Highest Ethical Standards And Believing In Creating New Benchmark In The Global and Indian Industry.

IWL INDIA LTD

Page 3

Taking India By Storm

OUR PRODUCTS

IWL manufactures over 40 different products that fall into the 9 product groups described below. This allows IWL the flexibility of offering the perfect product for the application. IWLs well trained team of Marketing and Application Engineers are trained to make recommendations after site inspection.

Product Groups

IWls products fall into following broad groups:

Polymeric Waterproofing Membranes. Oxidated Waterproofing Membranes. Coal tar based pipe Coating Tapes. Bitumen based pipe Coating Tapes. Primer & Adhesives. Liquid Waterproofing Membranes. Construction Chemicals. Road Emulsion.

IWL INDIA LTD

Page 4

Taking India By Storm

APP Modified Polymeric Waterproofing Membrane

Hyperplas Polyester Hyperplas Aluminium Hyperplas Mineral Hyperplas Fiberglass Hyperplas Standard Cold stick Primer Reflux (Aluminum Paint)

Liquibit Bitumen Emulsion

Liquibit Rapid Setting Liquibit Slow Setting Liquibit Medium Setting

PYPKOTE

IWL INDIA LTD

Page 5

Taking India By Storm

SOME OF OUR VALUED CLIENTS

IWL INDIA LTD

Page 6

Taking India By Storm

PRODUCT DETAILS

We, M/s IWL India Ltd, proudly introduce HYPERPLAS a revolutionary polymeric waterproofing membrane. Hyperplas is a perfabricated readymade waterproofing system, which can be easily applied over existing and new strucutures to achieve 100% barrier against water moisture.

Hyperplas has a centre core of a 90 micron plastic film (HMHDPE) which is protected on both side by a polymeric asphalt mix. This is again protected by another plastic film on the top and botton.

IWL has been supplying waterproofing membranes MULTIPLAS and HYPERPLAS brand products to various MES zones all over india for atleast 7 to 8 years now. IWL has never faced any quality problem so far in this 7 to 8 years in these MES zones where these products are uesd.

We would like to describe in detail the range of products we manufaature and its essential importance for different applications.

IWL manufactures Hyperplas waterproofing membrance in Five categories.

Hyperplas Polyester Hyperplas Aluminium Hyperplas Mineral Hyperplas Fiberglass Hyperplas Standard

IWL INDIA LTD

Page 7

Taking India By Storm

FIVE LAYER APP MODIFIED POLYMERIC WATERPROOFING MEMBRANE

The Speciality of Hyperplas waterproofing range is it consists of a 90 mincron think High Molecular High Density Polyethylene Film as the Centre Core. All the above five range of products compulsorily has this 90 micron Plastic Centre Core. It is this plastic centre core which acts as a main barrier for waterproofing. Plasic by virture of its inert and non decaying nature does not allow even air (or) water moisture to pass through it.

The Centre core plastic is protected on both side with Polymeric Asphaltic Mix which as a High Penetration, High Resistance and Softening point. These three plies i.e. plastic centre core and two layers of polymeric asphalt constitutes in all the five grades of Hyperplas.

IWL INDIA LTD

Page 8

Taking India By Storm

HYPERPLAS POLYESTER

It contains a centre core of 100 micron thick plastic along with two layers of polymeric asphaltic mix. It also contains a layer of non woven 160 GMS polyester along with a layer of polymeric asphaltic mix. The polyester yields puncture resistant property and yield better tensile strength.

It is recommended in areas such as basement waterproofing, swimming pools where major loads always acts over the membrance.

HYPERPLAS ALUMINIUM

It comprises of the plastic centre core along with two layers of polymeric asphalt. It is finished on the top with an Embossed Aluminium foil. This membrane is self finished and does not require any mechanical protection after applicatio. This membrane is normally used in inaccessible areas like Slope Roofs. It also yield good amount of insulation property due to reflection of sunlight by the exposed aluminium foil.

HYPERPLAS MINERAL

It consist of centre core of a non woven Polyester mat of minimum 160 gms/sqm. The centre core is protected on both side with polymeric asphaltic mix. Which has high penetration, high resistance and high softening point. The membrane is finished with mineral slates on the top and a layer of HMHDPE at the bottom. The resultant membrane has adequate elongation to absorb all structural movements. With hight tensile strength, the membrane is still extremely flexible and pliable to adapt to contours.

IWL INDIA LTD

Page 9

Taking India By Storm

HYPERPLAS FIBERGLASS

It Consist of the plastic centre core along with two layers Of polymeic asphalt. In additon to that, it comprises of a core of Fiberglass which yields nore tensile strength to the membrane and another layer of Polymeric asphalt. Membrane having higher tensile strength and with fiberglass Reinforcements are recommended to be used in place where Structural movement is less and load factor over waterproofing membrane is high. Area recommended are Roof Garden, car Park Decks etc.

HYPERPLAS STANDARD :

It comprises of the plastic centre core along with two layers of Polymeric asphalt. It is further terminated with a layer of HMHDPE on top and bottom of the membrane. It is specifically used in places where the elongation due to structural Movement is large especially on large span Roof . However it is not recommended to be used in areas where structural load is to be applied over the waterproofing membrane.

The effectiveness of HYPERPLAS membrane primarily relies on a centre core plastic, which acts as the system. Plastic by virtue is 100% air tight and watertight. Plastic is nonbiodegradable and non decaying. Plastic does not age with time. It is this property of HYPERPLAS membrane that makes it to stand apart from other waterproofing systems available in the Market. HYPERPLAS Standard has to be covered with a mechanical toping such as cement mortar, Tiles, etc. HYPERPLAS Aluminium comes with an embossed Alumninium foil on the top which can be directly exposed to sunlight. The Aluminium yields an insulation property additionally. HYPERPLAS Fiberglass and Polyester are 7 ply systems having additional reinforcement of Fiberglass or Polyester for heavy duty application .

IWL INDIA LTD

Page 10

Taking India By Storm

FEATURES OF HYPERPLAS

HYPERPLAS is very easy to apply on both New and Old Construction. HYPERPLAS comes with a warranty of 10 Years. HYPERPLAS can be use in accessible areas as well as in accessible areas. HYPERPLAS is highly cost effective. HYPERPLAS has a track record of more than 10 million Sq.M in India applied and performing. HYPERPLAS can be terminated over vertical and it withstands all elongation and contraction. It is 100% waterproof. HYPERPLAS water absorption property is less than 0.5% which is very negligible and hence no cause of leakage. HYPERPLAS thickness and weight is minimal and hence no additional load adds on the roof slab. HYPERPLAS does not age or decay with time. The membrane withstands Hoop Stress and does not crack due to Thermal Variations.

IWL INDIA LTD

Page 11

Taking India By Storm

APPLICATION GUIDE

APPLICATION PROCEDURE FOR LAYING OF WATERPROOFING MEMBRANE (TERRACE)

The surface to be treated for waterproofing shall be free from dust, sharp projection and moisture. The surface shall be clean and free from mortar/concrete droppings. The cleaned surface is then coated with Cold stick Primer @ 250 gms/sqm. The Primer coated surface is allowed to dry for minimum 8 hours in good dry weather condition or 24 hrs if the climate is not favorable. Membrane is unrolled over the coated primer surface with 10cm overlap. The bottom layer of the membrane heated on the entire surface by flame using LPC torch and also overlaps are then thermofussed by flame. The laid Membrane is uniformly pressed to the full width of the membrane without any air gaps. The overlaps are then thermo fussed and sealed by flame using LPG torch. Special care is taken at singularities such as drains, and all around pipe fixed in the floor and wall. Groove cutting 25mm X25mm at 300mm height in parapet wall Required to terminate the membrane in vertical areas, if the vertical/Parapet wall is not fully covered with Membrane. Membrane is required to be topped with suitable topping such as Cement screed with Chicken Wire Mesh or ties on accessible roofs. For vertical portion of the parapet wall, we recommend cement plastering with Chicken Wire Mesh.

APPLICATION PROCEDURE FOR LAYING OF WATERPROOFING MEMBRANE USING HOT BLOWN BITUMEN

The surface to be treated for waterproofing shall be free from dust, sharp projection and moisture. The surface shall be clean and free from mortar/concrete droppings. The clean surface is then coated with Water Based Emulsion Primer. Before Application Water Based Emulsion Primer is mixed with water 1:1 ratio. The coverage of mix is 200gms/sqm. The Primer coated surface is allowed to dry for minimum 8 hours in good dry weather condition or 24 hrs if the climate is not favorable. Membrane is unrolled over the coat of hot Blown Bitumen 85/25 or 90/15 at the rate of 1.2kg/sqm with 10cms overlaps. The laid Membrane is uniformly pressed to the full width of the membrane without any air gaps. The overlaps are then thermo fussed and sealed by flame using LPG torch.

IWL INDIA LTD

Page 12

Taking India By Storm

Special care is taken at singularities such as drains, and all around pipe fixed in the floor and wall. Groove cutting 25mm X25mm at 300mm height in parapet wall Required to terminate the membrane in vertical areas, if the vertical/Parapet wall is not fully covered with Membrane. Membrane is required to be topped with suitable topping such as Cement screed with Chicken Wire Mesh or ties on accessible roofs. For vertical portion of the parapet wall, we recommend cement plastering with Chicken Wire Mesh.

APPLICATION PROCEDUTE FOR LAYING OF WATERPROOFING MEMBRANE (BASEMENT)

The surface to be treated for waterproofing shall be free from dust, sharp projection and moisture. The surface shall be clean and free from mortar/concrete droppings. The cleaned surface is then coated with Cold stick Primer @ 250 gms/sqm. The Primer coated surface is allowed to dry for minimum 8 hours in good dry weather condition or 24 hrs if the climate is not favorable. Membrane is unrolled over the coated primer surface with 10cm overlap. The bottom layer of the membrane heated on the entire surface by flame using LPC torch and also overlaps are then thermo fussed by flame. The laid Membrane is uniformly pressed to the full width of the membrane without any air gaps. The overlaps are then thermo fussed and sealed by flame using LPG torch. Over the laid membrane in the floor and vertical area/retaining wall to be protected with 25mm thick Thermocole/Hyperboard/Chicken Wire Mesh Plastering. Laid membrane in the vertical area with protection layer is to be immediately supported by either back-filling with earth (preferably within 2 days) or membrane directly protected with Single Layer Brick wall to avoid falling of membrane due to Self Weight. Groove cutting 25mm X25mm at 300mm height in parapet wall Required to terminate the membrane in vertical areas, if the vertical/Parapet wall is not fully covered with Membrane.

IWL INDIA LTD

Page 13

Taking India By Storm

DIAGRAMMATIC PROCESS

IWL INDIA LTD

Page 14

Taking India By Storm

User Guide

IWL INDIA LTD

Page 15

Taking India By Storm

IWL INDIA LTD

Page 16

Taking India By Storm

IWL INDIA LTD

Page 17

Taking India By Storm

IWL INDIA LTD

Page 18

Taking India By Storm MAJOR PROJECTS WHERE HYPERPLAS HAS BEEN USED Delhi Metro Railway Corporation IMCC MC 1 B Underground Waterproofing Military Engineering services. Kerala State P.W.D. Larsen & Toubro Limited. Tamilnadu Housing Board. Tamilnadu Electricity Board. Punjab Police Housing Corporation Ltd. National Airport Authority. Indian Institute of Technology, Powai, Mumbai Bharat Heavy Electricals Limited. Life Insurance Corporation Ltd. Indian Oil Corporation Limited. Hindustan Steel Works Construction Limited. Aeronautical Development Agency. Central Public Works Department. M. N. Dastur & Company Ltd. United India Insurance Co Ltd. Titan Watches Ltd. National Buildings Construction Corporation Ltd. Punjab State container & Warehousing Corporation Ltd. Lok Global & National Construction Ltd.

IWL INDIA LTD

Page 19

Taking India By Storm

MAJOR CLIENTS:

Military Engineering Services Central Public Works Department. Indian Railways Larson & Toubro Limited. IVRCL. HCC. UDHE India. HPCL. BPCL. INDIAN OIL. PETRON. Afcons Infrastructure. Simplex Infrastructure. GMR PROJECTS PVT LTD.

IWL INDIA LTD

Page 20

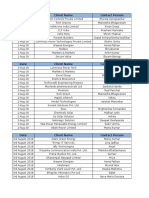

Taking India By Storm MAJOR & IMPORTANT WATERPROOFING ORDERS

PROJECT

Delhi Metro Railway Larsen & Toubro (Various Guj. Govt. School) Southern Railway Pit line Southern Railway MRTPS Audco India Ltd. MA Chidambaram Cricket Stadium (Chennai) Anna International Airport (Chennai) Ashok Leyland Factory Hotel Rohini International Delhi Metro Railway Station Shastri Park/ ISBT Station IIT New Delhi New Delhi Municipal Corp. Palika Bazar Roof Garden Punjab State Container & Warehousing Crop. Ltd. Gharda Chemical Ltd. The Paper Products Ltd. Glaxo Mumbai Lok Global & National Construction Ltd. Mumbai. Vendanta Aluminium GDC Suraj Infrastructure (MES Pune & Ahmednagar Zone) Mukund Enterprises (Nashik & Ahmednagar) K. S. Chadda (Air force, Pune) Spanish Waterproofing (Chatrapati Shivaji Terminus) CST Railway Stn. Mumbai National Waterproofing (Dabol Power Project) Prestigious Hyderabad Palace like Falak Nama & other IIT, Mumbai

PRODUCT

Hyperplas Polyester 4 MM Hyperplas Polyester 3MM Hyperplas Std. 3Kg/M2 Hyperplas Polyester 4Kg/M2 Hyperplas Polyester 4Kg/M2 Plasfal 3 Kg/M2 Hyperplas Standard 3 Kg/M2 Hyperplas Polyester 4 Kg/M2 Hyperplas Polyester 4 Kg/M2 Hyperplas Standard 3 MM Hyperplas Aluminium Hyperplas Polyester 4 Kg/M2 Multiplas Standard 3 Kg Hyperplas Polyester 4 Kg/M2 Hyperplas Hiper Hyperplas Aluminium Hyperplas Polyester 4 Kg/M2 Hyperplas Standard 4 MM Hyperplas Mineral 3 MM

QTY.

1,50,000 M2 60,000 M2 8,700 M2 13,000 M2 15,000 M2 25,000 M2 8,000 M2 4,000 M2 8,000M2 40,000 M2 7,000 M2 7,000 M2 19,500 M2 4,000 M2 3,5000 M2 3,5000 M2 11,000 M2 1,20,000 M2 50,000 M2 30,000 M2 20,000 M2 15,000 M2 20,000 M2 25,000 M2 15,000 M2

Page 21

Hyperplas Mineral 3 MM Hyperplas Polyester 3MM Multiplas Standard 3 Kg

Hyperplas Polyester 3MM Hyperplas Aluminium Hyperplas Aluminium

IWL INDIA LTD

Taking India By Storm

MAJOR & IMPORTANT PROJECTS LIST

PROJECT

L & T Gujarat, Government School Tirupur Exporters Knitwear Industries ITC, Sharanpur Larsen & Toubro, Tirupur Uttar Pradesh Health State Development Co. MES Pune Zone MES Allahabad MES Lucknow Enron Power Project

TYPE OF WORK

Prefab Roof Waterproofing Prefab Roof Waterproofing Prefab Roof Waterproofing Prefab Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Plant Building, Rolls Deck RCC Slop Roofs & Underground Tank Roof Waterproofing Prefab Slabs Roof Waterproofing Roof Waterproofing Roof Waterproofing Prefab Roof Waterproofing Roof Waterproofing Prefab Roof Waterproofing Roof Waterproofing Roof Waterproofing Prefab Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Prefab Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing

QTY.

3,50,000M2 90,00M2 80,000M2 80,000M2 72,000M2 60,000M2 60,000M2 50,000M2 45,000M2 40,000M2 30,000M2 25,000M2 25,000M2 25,000M2 25,000M2 23,000M2 21,000M2 20,000M2 20,000M2 20,000M2 17,000M2 15,000M2 15,000M2 13,110M2 13,000M2 12,864M2 12,500M2 12,500M2 12,250M2 12,000M2 12,000M2

Page 22

T. N. Slum Clearance Board ITC Limited MES Jaipur Zone MES Bareily DRDO, Delhi & Kanpur MA Chidambaram Cricket Stadium MES Delhi Zone Karnataka Breweries & Distilleries Ltd. MES Chandigarh Gupta Construction Nagpur Zilla, Shetkari Sahakari Soot Girni MES Jodhpur Zone Sathya Sai Super Speciality Hospital Audeo India Ltd. Godrej G. E. Wardha Zilla Shetkari Shakari Soot Girni Larsen & Toubro, Tirupur North Madras Thermal Power Project Gupta Construction Shapoorji Pallonji & Co. Punjab Police Housing Corporation Ltd. Sahara Lonavala Project

IWL INDIA LTD

Taking India By Storm

Aeronautical Development Agency Hotel Projects at Samarkhand, Bukhara (Russia) SAIL, Salem Steel Plant Material Testing & Preservation ITC, Filterona STI Granites Nehru Place Hotels Ltd. Delhi Anna International Airport MES Ahmadabad Hotel Rohini International United India Insurance Corporation of India Nuclear Fuel Complex IIT New Delhi DCW Home Products LTD L & T, Pithambur Larsen & Toubro MIDC Watva Gujarat Central Scientific Research Organisation National Bid Const. Rashtriya Chemical & Fertilizers Ltd. MICO Ltd. Store Building. Metro Engineering RVR Projects Usha India Ltd. Friends Construction Ashok Leyland Factory India Precision Bearing Mfrs Ltd. Development Holding Pvt. Ltd. Gupta Construction Tamil Nadu Slum Clearance Board National Airport Authority Sriram Postors Ltd. Vikram Sarabhai Space Centre Tirumala Tirupathi Devasthanam Metro Construction K. J. Somaiya Trust Gea Cooling Tower Alankar Theatre Sher-I-Kashmir, International Conference Centre Brook Bond A L. Sudershen CC Ltd. Air India, Bombay Adcance Research Centre Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Prefab Roof Waterproofing Prefab Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Toilet Pits. 12,000M2 11,500M2 10,000M2 10,000M2 10,000M2 10,000M2 9,000M2 8,000M2 8,000M2 8,000M2 7,500M2 7,450M2 7,000M2 6,700M2 6,500M2 6,500M2 5,800M2 5,500M2 5,158M2 5,000M2 5,000M2 4,700M2 4,620M2 4,200M2 4,100M2 4,000M2 3,990M2 3,990M2 3,140M2 3,000M2 3,000M2 3,000M2 3,000M2 3,000M2 3,000M2 2,690M2 2,500M2 2,500M2 2,216M2 2,200M2 2,120M2 2,000M2 1,700M2

IWL INDIA LTD

Page 23

Taking India By Storm

RVR Projects American Embassy Integral Coach Factory Madras MGM Group of Companies PWD, Govt. High School Malbar Regional Co-Op RVR Project Amararaja Computer Building Stainless House Salem R & S Projects Maharashtra State Road Transport United Breweries Ltd. Gupta Construction Mazagon Dock Ltd. St. George Cathedral Other Miscellaneous Projects all over India TOTAL WORK DONE Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Bus Tops Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing Roof Waterproofing

1,600M2 1,500M2 1,500M2 1,500M2 1,350M2 1,365M2 1,300M2 1,200M2 1,050M2 1,000M2 1,000M2 1,000M2 1,000M2 550M2 955M2 3,00,000M2 18,61,068M2

IWL INDIA LTD

Page 24

Taking India By Storm

IWL CREDENTIALS

IWL INDIA LTD

Page 25

S-ar putea să vă placă și

- Behavioral Based Interview Questions With StarDocument5 paginiBehavioral Based Interview Questions With StarShamim Imtiaz67% (3)

- Book of Best PracticesDocument117 paginiBook of Best PracticesMoeen Khan Risaldar100% (2)

- Vinyl Ester Epovia Data SheetDocument32 paginiVinyl Ester Epovia Data SheetAmjad MehmoodÎncă nu există evaluări

- Rubber and Sealants Market SurveyDocument16 paginiRubber and Sealants Market SurveyAnirudh MalpaniÎncă nu există evaluări

- Affluent Clients Special ReportDocument23 paginiAffluent Clients Special ReportMichael ElkinÎncă nu există evaluări

- Developing The Leader Within - Maxwell.ebsDocument12 paginiDeveloping The Leader Within - Maxwell.ebstarek_bouzayaniÎncă nu există evaluări

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe la EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionÎncă nu există evaluări

- Buying A Cafe Checklist TemplateDocument6 paginiBuying A Cafe Checklist TemplateMohammad Abd Alrahim ShaarÎncă nu există evaluări

- Ricwil Catalog 10 Final PDFDocument32 paginiRicwil Catalog 10 Final PDFHermanuadi100% (2)

- K450 Plus Updated PDFDocument138 paginiK450 Plus Updated PDFCongson JeffÎncă nu există evaluări

- SigmaprimeDocument8 paginiSigmaprimeHaresh BhavnaniÎncă nu există evaluări

- J. Swot AnalysisDocument3 paginiJ. Swot AnalysisTaskeen Zafar100% (1)

- Holiday 2011 EmmaDocument788 paginiHoliday 2011 EmmaAlaina Long100% (3)

- Case 1 Managing Hindustan Unilever StrategicallyDocument7 paginiCase 1 Managing Hindustan Unilever StrategicallyYash Agarwal100% (3)

- Alupex Fire Rated Acp PanlesDocument24 paginiAlupex Fire Rated Acp PanlesvirtechÎncă nu există evaluări

- Investor Business Proposal Pitch PresentationDocument60 paginiInvestor Business Proposal Pitch PresentationSlideTeam100% (1)

- Waterproofing SystemsDocument4 paginiWaterproofing SystemsfairmatechemicalÎncă nu există evaluări

- SC3058Document16 paginiSC3058A MahmoodÎncă nu există evaluări

- RubberBond FleeceBack EPDM FAQsDocument30 paginiRubberBond FleeceBack EPDM FAQsRubberBondÎncă nu există evaluări

- POLYFOAM Brochure - Qatar InsulationDocument16 paginiPOLYFOAM Brochure - Qatar InsulationAbdullah Ahmed FarazÎncă nu există evaluări

- Dr. Fixit Polyplus CP Admix - Submittal & Test Certifictes PDFDocument100 paginiDr. Fixit Polyplus CP Admix - Submittal & Test Certifictes PDFVimal Gopalakrishnan100% (1)

- 7 9layerblownfilmlinesDocument6 pagini7 9layerblownfilmlinesductoan32Încă nu există evaluări

- General Waterproofing Brochure 58 1Document21 paginiGeneral Waterproofing Brochure 58 1KAMAL BEHL100% (1)

- Flexitallic Products PDFDocument108 paginiFlexitallic Products PDFNguyễn Xuân NamÎncă nu există evaluări

- How Laminates With Eval™ Evoh Film Improve The Performance of VipsDocument9 paginiHow Laminates With Eval™ Evoh Film Improve The Performance of VipsDam HaÎncă nu există evaluări

- Structured Packings GasDocument20 paginiStructured Packings GasBowo Edhi WibowoÎncă nu există evaluări

- Innobit BrochureDocument14 paginiInnobit Brochurenguyen hoang AnhÎncă nu există evaluări

- QTM FinalDocument7 paginiQTM FinalJacob Sarfraz GillÎncă nu există evaluări

- Ifs Brochure 2009 PDFDocument12 paginiIfs Brochure 2009 PDFA MahmoodÎncă nu există evaluări

- Water Guard Epdm MembraneDocument4 paginiWater Guard Epdm MembranefairmatechemicalÎncă nu există evaluări

- Roof WaterproofingDocument10 paginiRoof WaterproofingNazir MobasharÎncă nu există evaluări

- Modified BitumenDocument2 paginiModified BitumenmicrefeeÎncă nu există evaluări

- Motilal Jhunjhunwala College Vashi: ICLE'sDocument30 paginiMotilal Jhunjhunwala College Vashi: ICLE'sSanket TrueblueÎncă nu există evaluări

- Technical Seal Brochure 1Document13 paginiTechnical Seal Brochure 1Moha MaherÎncă nu există evaluări

- Roofing Solutions IsomatDocument36 paginiRoofing Solutions IsomatBragarin DanÎncă nu există evaluări

- Waterproofing Systems GuideDocument28 paginiWaterproofing Systems GuideAlex Bocica100% (1)

- Poly Urea Coating: Smart & Reliable Chemical SolutionsDocument12 paginiPoly Urea Coating: Smart & Reliable Chemical SolutionsAnkita Baban GavadeÎncă nu există evaluări

- Water Guard MembraneDocument4 paginiWater Guard MembranefairmatechemicalÎncă nu există evaluări

- IPPL BrochureDocument8 paginiIPPL BrochuretoharshaÎncă nu există evaluări

- PerstorpDocument98 paginiPerstorpArif FajarÎncă nu există evaluări

- Abstract: While A Coating Is Typically Measured inDocument8 paginiAbstract: While A Coating Is Typically Measured inagrocel_bhv5591Încă nu există evaluări

- ASSIGNMENT 8 - SOMESH SIDDHARTH - A1988520002 (Incomplete)Document9 paginiASSIGNMENT 8 - SOMESH SIDDHARTH - A1988520002 (Incomplete)Somesh SiddharthÎncă nu există evaluări

- Socotherm BrochureDocument9 paginiSocotherm Brochuremaruc08Încă nu există evaluări

- Underground Works - CivilrockDocument12 paginiUnderground Works - CivilrockAndreea DincaÎncă nu există evaluări

- Catalloy Tpo Resins Brochure Eu1Document12 paginiCatalloy Tpo Resins Brochure Eu1Julio GarcíaÎncă nu există evaluări

- Fairmate Guide For Your HomeDocument8 paginiFairmate Guide For Your HomefairmatechemicalÎncă nu există evaluări

- Baxchem Systems Brochure 20061 PDFDocument6 paginiBaxchem Systems Brochure 20061 PDFA MahmoodÎncă nu există evaluări

- Plastic Extrusion ManufacturerDocument1 paginăPlastic Extrusion ManufacturerSpiratexÎncă nu există evaluări

- Inometa Protek Coatings en LowDocument16 paginiInometa Protek Coatings en LowsakthivelÎncă nu există evaluări

- Atmatec - Fibreglass Products For Drainage Systems PDFDocument44 paginiAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalÎncă nu există evaluări

- Thermiculite: Intense Heat. Extreme Cold. Aggressive ChemicalsDocument8 paginiThermiculite: Intense Heat. Extreme Cold. Aggressive ChemicalsFilipÎncă nu există evaluări

- Hempaxane BrochureDocument12 paginiHempaxane Brochuresorion61Încă nu există evaluări

- PolykenDocument8 paginiPolykenVictor Hugo Bustos BeltranÎncă nu există evaluări

- IPC BrochureDocument8 paginiIPC BrochureIPC VietnamÎncă nu există evaluări

- Thermiculite BrochureDocument8 paginiThermiculite BrochureXuan TruongÎncă nu există evaluări

- Company Activities Mobile HomesDocument6 paginiCompany Activities Mobile HomesEssam Al BakryÎncă nu există evaluări

- The Ultimate Guide To Waterproofing SolutionsDocument9 paginiThe Ultimate Guide To Waterproofing SolutionsNippon Paint Total Coating and Construction SolutionsÎncă nu există evaluări

- A Guide To Elastomer PropertiesDocument5 paginiA Guide To Elastomer PropertiesGunaseelan VÎncă nu există evaluări

- CS Corrosion Protection SystemDocument20 paginiCS Corrosion Protection SystemMichael AlbuquerqueÎncă nu există evaluări

- Introduction Application WiseDocument7 paginiIntroduction Application Wiserajveer raj singh100% (1)

- Regional Waterproofing BrochureDocument6 paginiRegional Waterproofing BrochureVenkata Raju KalidindiÎncă nu există evaluări

- Presentation 2Document63 paginiPresentation 2Karma TsheringÎncă nu există evaluări

- Company-Profile 2Document27 paginiCompany-Profile 2Solar OngridÎncă nu există evaluări

- Internship ReportDocument32 paginiInternship ReportVeeram GokulÎncă nu există evaluări

- Gazechim Brochure Nov 2012 PDFDocument13 paginiGazechim Brochure Nov 2012 PDFByron BrownÎncă nu există evaluări

- KoreanAutoMarket CaseStudy RilsanDocument5 paginiKoreanAutoMarket CaseStudy RilsanProvocateur SamaraÎncă nu există evaluări

- Tanks, Vessels & SilosDocument5 paginiTanks, Vessels & Silosninju1Încă nu există evaluări

- GRP Non Circular Pipe SystemsDocument16 paginiGRP Non Circular Pipe Systemsseby_77Încă nu există evaluări

- TheHub Master BrochureDocument30 paginiTheHub Master BrochureOliver GiamÎncă nu există evaluări

- Brand Wise ReportDocument2 paginiBrand Wise ReportNiTesH GoyalÎncă nu există evaluări

- MCI 11 Purchasing and Vendor Control ProcedureDocument5 paginiMCI 11 Purchasing and Vendor Control ProcedureThương VũÎncă nu există evaluări

- Client Discovery WorksheetDocument6 paginiClient Discovery WorksheetzonenorÎncă nu există evaluări

- 15.963 Management Accounting and Control: Mit OpencoursewareDocument25 pagini15.963 Management Accounting and Control: Mit OpencoursewareNur AuFha KhazNhaÎncă nu există evaluări

- Daily Work Tacker - Sales (August)Document20 paginiDaily Work Tacker - Sales (August)Ameya Potnis50% (2)

- David Aakers FrameworkDocument39 paginiDavid Aakers FrameworkumitiiitÎncă nu există evaluări

- Consumers of Lotus Footwear Company Chap 3 & 4Document37 paginiConsumers of Lotus Footwear Company Chap 3 & 4ginish12Încă nu există evaluări

- V-Care Hair OilDocument12 paginiV-Care Hair OilBoopathi KalaiÎncă nu există evaluări

- Customer Retention Practices of Microfinance BanksDocument7 paginiCustomer Retention Practices of Microfinance BanksIkechukwu AchaÎncă nu există evaluări

- 1 - Introduction To Marketing Communications and IMCDocument29 pagini1 - Introduction To Marketing Communications and IMCArif Khan Joy100% (2)

- Gillette Case Analysis, Islam AzzamDocument6 paginiGillette Case Analysis, Islam AzzamDakshatta RathodÎncă nu există evaluări

- Bata India LimitedDocument29 paginiBata India LimitedRobert GonzalesÎncă nu există evaluări

- 2021 H2 TikTok Ads Rate Card SEADocument27 pagini2021 H2 TikTok Ads Rate Card SEABảo HuỳnhÎncă nu există evaluări

- UnileverDocument2 paginiUnileverAsad UllahÎncă nu există evaluări

- Item RelationshipsDocument6 paginiItem RelationshipsvenkatsssÎncă nu există evaluări

- Principles of MarketingDocument88 paginiPrinciples of MarketingJahidul Karim100% (1)

- Beaumont Enterprise Retail RatesDocument6 paginiBeaumont Enterprise Retail RatesbeaumontenterpriseÎncă nu există evaluări

- Is 210 Complete-2Document8 paginiIs 210 Complete-2karim yassinÎncă nu există evaluări

- Disney Memo Draft 1Document4 paginiDisney Memo Draft 1uygh gÎncă nu există evaluări

- Berceanu Bianca GabrielaDocument20 paginiBerceanu Bianca GabrielaBianca BerceanuÎncă nu există evaluări

- Em Swot AnalysisDocument7 paginiEm Swot AnalysisS YuvashriÎncă nu există evaluări