Documente Academic

Documente Profesional

Documente Cultură

Agriculture Sugarcane

Încărcat de

Gunasridharan LakshmananDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Agriculture Sugarcane

Încărcat de

Gunasridharan LakshmananDrepturi de autor:

Formate disponibile

Agriculture :: Sugarcane

http://agritech.tnau.ac.in/postharvest/pht_sugarcrop.html

Crop Production Crop Protection Crop Improvement Sustainable Agriculture Organic Farming Indigenous Farming

Agriculture :: Sugarcane

Special Technologies

SRI-System of Rice Intensification Precision Farming GAP | GLP | GMP

Weather Soil Water Constituents of sugarcane and sugarcane juice Seed The sugarcane contains not only sucrose but also numerous other dissolved substances, as well as cellulose or Farm Enterprises woody fibre. The percentage of sugar (polarization) in the cane varies from 8 to 16 per cent and depends to a Nutrition great extent on the variety of cane, its maturity, the condition of the soil, the climate and agricultural practices Post Harvest Technology Bio Technology followed. Bio-Fuels

Govt. Schemes & Services IAMWARM Development Blocks Banking & Credit Crop Insurance KVK ATMA NGOs & SHGs Kisan Call Centre MDG-2015

Dynamic Market Info TNAU-DEMIC HRD Television Programs Farm Radio Programs News Paper Information Farm Magazines Water Level (Dams)

TNAU Community e-Radio

Minimum Support Price The constituents of the ripe cane vary widely in different countries and regions but fall generally within the Input Source following limits: Export & Import Patents

Sl.No Constituents Level, % Ripe cane Cane Juice 1 2 3 Water Sucrose Reducing sugars (Dextrose, Levullose) Organic matter other than sugar Inorganic compounds Nitrogenous bodies Ash Fibre 69 to 75 8 to 16 0.5 to 2.0 75 to 88 10 to 21 0.3 to 3.0

Environment & Pollution Disaster Management ICT Initiatives Important Links

0.5 to 1.0 0.5 to 1.0

Total solids 12 -23 0 brix

5 6 7 8

0.2 to 0.6 0.5 to 1.0 0.3 to 0.8 10.0 to 16.0

0.2 to 0.6 0.5 to 1.0

Other organic compounds include proteins, organic acids, pentosans and pectins (gums), colouring matters and wax. Organic acids present in the cane juice are glycollic acid, malic acid, succinic acid and a small quantity offanoic acid, butyric acid and aconitic acid. These vary from 0.5 to 1.0 per cent of cane by weight.

The inorganic compounds are made up of phosphates, chlorides, sulphates, nitrates and silicates, sodium, potassium, calcium, magnesium, aluminium and iron chiefly. These are present to the extent of 0.2 to 0.6 per cent. The 'Nitrogenous bodies' are albuminoids, amides, amino acids, ammonia and xanthine bases. These are present to the extent of 0.5 to 1-0 per cent. Fibre is the insoluble substance in cane. Dry fibre contains about 18 per cent lignin, 15 per cent water soluble substances, 45 per cent cellulose and the remainder hemicellulose. The colouring matters viz. (i) Chlorophyll, (ii) Anthocyanin, (iii) Saccharetin and (iv)Tannins are present in sugarcane juice. VALUE ADDITION BOTTLING OF SUGARCANE JUICE FOR BEVERAGE Fresh sugarcane juice obtained from mature cane is sweet and tasty. It is not only a thirst quenching drink but also nutritious due to the presence of several minerals like phosphorus, calcium, magnesium, vitamins, amino acids etc., and has medicinal properties also particularly for the cure of jaundice. Cane juice mixed with the extracts of lemon, ginger, chillies etc., adds to the taste, helps in better digestion and improved bowel movement. But due to its seasonal availability and fast deterioration by microbial decomposition, the possibility of its use as fresh juice is very much limited. In order to make the availability of cane juice at all times as a soft drink prepared under hygienic conditions, a simple method of bottling the cane juice has been developed.

1 of 3

05/02/2011 08:21

Agriculture :: Sugarcane

http://agritech.tnau.ac.in/postharvest/pht_sugarcrop.html

Choosing a good variety The sugarcane variety for juice should give high in juice extraction and have high sugar content. The internodes should be long without splits. The rind should be preferably light coloured and the cane should have less fibre and pith. Some of the varieties which are ideally suited for bottling of juice are CoC 671, Co 62175, Co 7717, Co 86032 and Co94012. Harvesting the cane for juice extraction The canes should be harvested when they are at peak maturity ie, when the sucrose content is maximum and the non-sugars are at maximum. After harvesting, the top few immature internodes should be removed as they contribute to bad taste due to high amount of salts and other undesirable organic substances. The canes should be cleaned free of roots at the nodes and adhering soil particles. It is preferable to remove the rind portion of the cane by suitable means as the pigments present in the rind contribute to dark colour and unpleasant taste to the juice. The canes should be crushed in clean power operated crusher (preferably with stainless steel rollers) and juice collected after filtration through muslin cloth into a clean sterilized stainless steel vessel. One medium sized lemon and 2-3g of ginger can be added for every 3kg of cane while the canes are crushed. FLOW CHART FOR PREPARATION OF SUGARCANE JUICE *

Procedure for bottling the juice a) Materials required 1. 2. 3. 4. 5. 6. Glass bottles of 300ml capacity Stainless steel vessels of 30-40 lit capacity Cane crusher Gas/electrical heaters Sterilizer/hot water tank Bottle corking machine

b) Juice treatment The filtered clear juice taken in a stainless steel vessel is heated to 60-70 0C and the juice is maintained at that temperature for about 15 minutes. Due to this, impurities in the juice start coagulating. A part of the coagulated material that floats on the top of the juice is scooped out with the help of a ladle or strainer. Another part of precipitated material starts settling at the bottom of the vessel. After 15 minutes, the clear supernatant juice is decanted through a muslin cloth. While the juice is still at bearable warmth, sodium meta-bi-sulphite is added as a preservative @ 1g per 8 lit of juice and stirred well. When the juice is till warm, it is transferred to hot water sterilized bottles and sealed with sterilized corks with a help of a corking machine. Chilling before consumption improves the taste. Storage period The juice bottled as above was found to keep well at room temperature without much deterioration for at least 6-8 weeks and the taste was also not affected. Storing bottles under refrigerated condition will prolong the life for a further period of 3-4 weeks. Precautions to be taken 1. The cane material should be clean and the crusher, bottles, vessels, etc., should be completely sterilized to prevent deterioration of juice by microbial decomposition. 2. The juice should not be heated above 80 0C and should not be heated beyond 15 minutes at that temperature. 3. Bottling of juice should be done before the juice is completely cooled to room temperature.

2 of 3

05/02/2011 08:21

Agriculture :: Sugarcane

http://agritech.tnau.ac.in/postharvest/pht_sugarcrop.html

Economics The initial investment for bottling 500 nos. of juice bottles daily is approximately Rs.5000/ to Rs.6000/. The cost of 300 ml quality of juice will work out to be Rs. 3-4/ approximately. Technology Available *- Post Harvest Technology Centre, TNAU, Coimbatore. Source

http://www.artuproar.com/uploads/skins/previews_m/dsci0043.jpg

http://d3.biggestmenu.com/00/00/33/cb5608f4ede062a8_m.jpg

| Home | About Us | Success Stories | Farmers Association | | Gallery | Message Board | TNAU Publications | FAQs | Queries | Downloads | Site Map | Disclaimer | Contact | All Rights Reserved. TNAU-2008.

3 of 3

05/02/2011 08:21

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Agrometeorology Wind and Plant GrowthDocument3 paginiAgrometeorology Wind and Plant GrowthGunasridharan LakshmananÎncă nu există evaluări

- Agrometeorology Solar Radiation and Plant GrowthDocument1 paginăAgrometeorology Solar Radiation and Plant GrowthGunasridharan LakshmananÎncă nu există evaluări

- Agrometeorology Temperature and Plant GrowthDocument3 paginiAgrometeorology Temperature and Plant GrowthGunasridharan Lakshmanan100% (1)

- Crop Insect Pest - Cash Crops - Pest of SugarcaneDocument7 paginiCrop Insect Pest - Cash Crops - Pest of SugarcaneGunasridharan LakshmananÎncă nu există evaluări

- Agrometeorology - Micro Climate and Plant GrowthDocument2 paginiAgrometeorology - Micro Climate and Plant GrowthGunasridharan LakshmananÎncă nu există evaluări

- Agriculture - Mineral Nutrition - Introduction 4Document2 paginiAgriculture - Mineral Nutrition - Introduction 4Gunasridharan LakshmananÎncă nu există evaluări

- Agriculture - Mineral Nutrition - IntroductionDocument2 paginiAgriculture - Mineral Nutrition - IntroductionGunasridharan LakshmananÎncă nu există evaluări

- Agriculture - Home3Document1 paginăAgriculture - Home3Gunasridharan LakshmananÎncă nu există evaluări

- Agrometeorology - Crop PlanningDocument2 paginiAgrometeorology - Crop PlanningGunasridharan LakshmananÎncă nu există evaluări

- Agriculture Home11Document1 paginăAgriculture Home11Gunasridharan LakshmananÎncă nu există evaluări

- Agriculture Home8Document1 paginăAgriculture Home8Gunasridharan LakshmananÎncă nu există evaluări

- Agriculture Home7Document1 paginăAgriculture Home7Gunasridharan LakshmananÎncă nu există evaluări

- Agriculture - Home5Document1 paginăAgriculture - Home5Gunasridharan LakshmananÎncă nu există evaluări

- Agriculture - Home4Document1 paginăAgriculture - Home4Gunasridharan LakshmananÎncă nu există evaluări

- Agriculture - Home2Document1 paginăAgriculture - Home2Gunasridharan LakshmananÎncă nu există evaluări

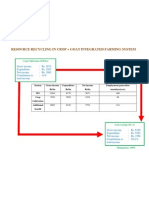

- Agri Major Areas Ifs Ressourceflow RainfedDocument1 paginăAgri Major Areas Ifs Ressourceflow RainfedGunasridharan LakshmananÎncă nu există evaluări

- Agriculture - HomeDocument1 paginăAgriculture - HomeGunasridharan LakshmananÎncă nu există evaluări

- Sugarcane TechnicalDocument5 paginiSugarcane TechnicalGunasridharan LakshmananÎncă nu există evaluări

- Sugarcane Trash ManagementDocument42 paginiSugarcane Trash ManagementGunasridharan Lakshmanan100% (1)

- Cane Production ManualDocument193 paginiCane Production ManualGunasridharan LakshmananÎncă nu există evaluări

- Sugarcane Budchips For Seed MultiplicationDocument4 paginiSugarcane Budchips For Seed MultiplicationGunasridharan LakshmananÎncă nu există evaluări

- Cane Production ManualDocument192 paginiCane Production ManualGunasridharan LakshmananÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Sonic Drive-In Operations ManualDocument65 paginiSonic Drive-In Operations Manualdenby_mÎncă nu există evaluări

- Diet Plan For 1800 Calorie DietDocument7 paginiDiet Plan For 1800 Calorie DietAchyut TodiÎncă nu există evaluări

- Class 30Document155 paginiClass 30Oaves MominÎncă nu există evaluări

- Past Simple Interactive Worksheet: Esl / Efl ResourcesDocument2 paginiPast Simple Interactive Worksheet: Esl / Efl ResourcesJuliana Giacobelli100% (2)

- Labour Saving DevicesDocument26 paginiLabour Saving DevicesAkash Niwal100% (4)

- Can Mushrooms Really Save The World?Document26 paginiCan Mushrooms Really Save The World?ArabellaÎncă nu există evaluări

- Best Keto Diet PlanDocument4 paginiBest Keto Diet PlanOkoyeocha Moses Michael0% (1)

- Price List 2014 r2Document112 paginiPrice List 2014 r2SuppDaddyÎncă nu există evaluări

- Syazila Market List Ala CarteDocument2 paginiSyazila Market List Ala CarteSyazilla AzallanÎncă nu există evaluări

- Aquarius PDFDocument8 paginiAquarius PDFJoannaAllen0% (1)

- Hika MakaDocument20 paginiHika MakaJanÎncă nu există evaluări

- Food PreservationDocument18 paginiFood PreservationNeca Borromeo100% (1)

- Indian CuisineDocument13 paginiIndian Cuisinejsphcesar6415Încă nu există evaluări

- Silage MakingDocument16 paginiSilage MakingGanpat Lal SharmaÎncă nu există evaluări

- Business Proposal 1 4 PPDocument32 paginiBusiness Proposal 1 4 PPKatrin Ellaine Dimla71% (14)

- Active and Passive VoiceDocument14 paginiActive and Passive Voicekitty killer100% (1)

- The Principles of Pulp Washing - PdfaDocument9 paginiThe Principles of Pulp Washing - Pdfashabi049Încă nu există evaluări

- Irmas Sandwich ShopDocument14 paginiIrmas Sandwich ShopDavid Dtm100% (1)

- Calories in Indian Food - Indian Food Calories - Calorie Chart of Indian FoodDocument2 paginiCalories in Indian Food - Indian Food Calories - Calorie Chart of Indian Foodvenkateshbabu2004Încă nu există evaluări

- Insights 5 U4 Test StandardDocument6 paginiInsights 5 U4 Test StandardCaba ArturoÎncă nu există evaluări

- Latihan UN 9 SMPDocument3 paginiLatihan UN 9 SMPazizahÎncă nu există evaluări

- Office Catering BrochureDocument9 paginiOffice Catering BrochureG'Day ChefÎncă nu există evaluări

- Baking T Ools and & Equipment, Its Use and Care: Bakery ScienceDocument45 paginiBaking T Ools and & Equipment, Its Use and Care: Bakery ScienceMarilou AllegoÎncă nu există evaluări

- Tortillas From WSMexicanDocument1 paginăTortillas From WSMexicannezbeÎncă nu există evaluări

- BycotDocument16 paginiBycotMuhammad idreesÎncă nu există evaluări

- Revision - Basic GrammarDocument4 paginiRevision - Basic GrammarTuisyen Dewan Hj AliÎncă nu există evaluări

- First Periodical Test in Science and HealthDocument23 paginiFirst Periodical Test in Science and HealthLea EstarezÎncă nu există evaluări

- Career Module in TLE HE 9 Q3 Week 3 4Document10 paginiCareer Module in TLE HE 9 Q3 Week 3 4Merajoy BautistaÎncă nu există evaluări

- New KolaDocument12 paginiNew KolaORIRE Ekohimi PROGRESSÎncă nu există evaluări

- Advertising EffectivenessDocument75 paginiAdvertising Effectivenesskomalg0840% (5)