Documente Academic

Documente Profesional

Documente Cultură

Billets - 321 - 321H-6R35

Încărcat de

rahul kumar singhDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Billets - 321 - 321H-6R35

Încărcat de

rahul kumar singhDrepturi de autor:

Formate disponibile

Billets Sandvik 321/321H-6R35

Current Issue at: 09/03/2011 05:40:37 AM. Supersedes all previous editions General description

Sandvik 6R35 is an austenitic, titanium-stabilised stainless chromium-nickel steel. It is suitable for wet-corrosive service but also has good mechanical strength at high temperatures.

Chemical composition (nominal) %

C 0.05

Si 0.4

Mn 1.3

P max 0.030

S max 0.015

Cr 17.5

Ni 10.5

Mo -

Others Ti>5x(C+N)

Standards

Sandvik Grade: 321/321H-6R35 ASTM: 321 UNS: s32100 EN: 1.4541 W Nr.: 1.4541 DIN: X 6 CrNiTi 18 10 SS: 2337 AFNOR: Z6CNT18-10 BS: 321S31

Product standards EN 10088-3 ASTM A-314 Suitable for production of flanges etc. acc. to ASTM A-182

Certificates Status according to EN 10 204 3.1

Forms of supply

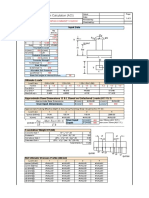

Sizes and tolerances Round-cornered square, as well as round billets, are produced in a wide range of sizes according to the following tables. Larger sizes offered on request. Surface conditions Square billets Unground, spot ground or fully ground condition. Round billets Peel turned or black condition. Square billets Size Tolerance mm mm 80 +/-2 100, 114, 126, 140, 150 +/-3 160, 180, 195, 200 +/-4 >200 - 350 +/-5 Sizes and tolerances apply to the rolled/forged condition. Peel turned round billets Size mm 75 - 200 (5 mm interval) >200 - 450

Length m 4 - 6.3 4 - 6.3 4 - 6.3 3 - 5.3

Tolerance mm +/-1 +/-3

Length m max 10 3-8

Unground round billets Size mm 77 - 112 (5 mm interval) 124, 134 127, 147, 157 142, 152, 163 168, 178, 188 183, 193

Tolerance mm +/-2 +/-2 +/-2 +/-2 +/-2 +/-2

Length m max 10 max 10 max 10 max 10 max 10 max 10

Other products Hollow bar Welding wire Covered electrodes

Mechanical properties

Testing is performed on separately solution annealed and quenched test piece. The following figures apply to material in the solution annealed and quenched condition. At 20C (68F) Metric units Proof strength a) Rp1.0 a) Rp0.2 MPa MPa min min 210 245 Imperial units Proof strength a) Rp1.0 a) Rp0.2 ksi ksi min min 30.5 35.5

Tensile strength Rm MPa 515-700

Elong. b) A % min 40

Contr. Z % min 50

HB

max 215

Tensile strength Rm ksi

Elong. b) A % min 40

Contr. Z % min 50

HB

75-101.5

max 215

1 MPa = 1 N/mm

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength respectively. b) Based on L0 = 5.65 S0 where L0 is the original gauge length and S0 the original cross-section area.

Impact strength Due to its austenitic microstructure, Sandvik 6R35 has very good impact strength both at room temperature and at cryogenic temperatures. o o

Tests on bar have demonstrated that the steel fulfils the requirements (60 J (44 ft-lb) at -196 according to the European standards prEN13445-2(UFPV-2) and EN 10272.

C (-320

F))

At high temperatures Metric units Temperature Proof strength C Rp.02 MPa min. 100 175 200 155 300 135 400 125 500 119 Imperial units Temperature F

Rp1.0 MPa min. 205 185 167 156 149

Tensile strength Rm MPa min. 440 390 375 375 360

Proof strength Rp.02 ksi min.

Rp1.0 ksi min.

Tensile strength Rm ksi min.

200 400 600 800 1000

25.4 22.5 19.6 18.1 17.2

29.7 26.8 24.2 22.5 21.6

63.8 56.6 54.4 54.4 52.2

Further information

Our data sheets and in-depth technical information about our grades and products are available on the Sandvik Materials Technology web-site www.smt.sandvik.com. The following printed matter can be ordered via the web or from the nearest Sandvik office.

S-028 S-030 S-0301 S-110 S-236

Metallurgy and long products division Semi-finished products Billets for forging Stainless pipe-tube-hollow bar, seamless standard programme Stainless welding products

Disclaimer

------------------------------------------------------------------------------------------------------------------------------Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice.

This data sheet is only valid for Sandvik material. Other material, covering the same international specifications, does not necessarily comply with the mechanical and corrosion properties presented in this datasheet.

A document from the Sandvik Materials Technology web-site.

S-ar putea să vă placă și

- Indian Pregnancy Diet Plan For Women - Max HospitalDocument3 paginiIndian Pregnancy Diet Plan For Women - Max Hospitalrahul kumar singhÎncă nu există evaluări

- Software Testing Interview QuestionsDocument214 paginiSoftware Testing Interview Questionsapi-3860576100% (5)

- Adobe Illustrator 10Document431 paginiAdobe Illustrator 10Sasi100% (4)

- Sample Bhel FormDocument4 paginiSample Bhel Formrahul kumar singhÎncă nu există evaluări

- Interview Questions Software TestingDocument40 paginiInterview Questions Software TestingAbdulrahemanÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Construction of the Seikan Undersea Tunnel--Overcoming Difficult SectionsDocument7 paginiConstruction of the Seikan Undersea Tunnel--Overcoming Difficult SectionsAbdelali SolÎncă nu există evaluări

- Tensionmembers With Staggered HolesDocument10 paginiTensionmembers With Staggered HolesJomarie AlcanoÎncă nu există evaluări

- Sikaceram - 288 MyDocument4 paginiSikaceram - 288 MyKenji TanÎncă nu există evaluări

- Sapi Pompa Utama HT - en - 50hzDocument12 paginiSapi Pompa Utama HT - en - 50hzHilary JawaÎncă nu există evaluări

- Iron Wafer Type Check Valve: Kitz Cast Iron ValvesDocument1 paginăIron Wafer Type Check Valve: Kitz Cast Iron ValvesAndy SetyawanÎncă nu există evaluări

- Jeddah First Industrial City: Mezzanine Floor LayoutDocument1 paginăJeddah First Industrial City: Mezzanine Floor LayoutSafety dimentionsÎncă nu există evaluări

- LunaCel VBX H13 FilterDocument1 paginăLunaCel VBX H13 FilterKurkuma PlusÎncă nu există evaluări

- Seattle Design-WSCC AdditionDocument77 paginiSeattle Design-WSCC Additionbranax2000Încă nu există evaluări

- A Reinforced Soil Mix Wall Cofferdam Supported by High Capacity Removable Soil AnchorsDocument9 paginiA Reinforced Soil Mix Wall Cofferdam Supported by High Capacity Removable Soil AnchorsHüseyin EkiciÎncă nu există evaluări

- Behaviour of Recycled Aggregate Concrete at Elevated TemperaturesDocument12 paginiBehaviour of Recycled Aggregate Concrete at Elevated Temperaturestaramalik07Încă nu există evaluări

- Steel Design 5 May 2022Document3 paginiSteel Design 5 May 2022tous les joursÎncă nu există evaluări

- NirmanaDocument1 paginăNirmanaAdinarayana RaoÎncă nu există evaluări

- RC pier reinforcement input sheetDocument423 paginiRC pier reinforcement input sheetAbhishekKumarÎncă nu există evaluări

- COMPANY Container Site OfficeDocument1 paginăCOMPANY Container Site OfficeGrenda SatriaÎncă nu există evaluări

- Materials, Properties, and Processes in MetallurgyDocument3 paginiMaterials, Properties, and Processes in MetallurgyMicko AllanigueÎncă nu există evaluări

- Microstructures, Mechanical Properties, and Fracture Behaviors of Metal-Injection Molded 17-4PH Stainless SteelDocument7 paginiMicrostructures, Mechanical Properties, and Fracture Behaviors of Metal-Injection Molded 17-4PH Stainless SteelCJPATAGAN100% (1)

- Piping QuizDocument3 paginiPiping QuizAnji Reddy DÎncă nu există evaluări

- Isolated Foundation Calculation (ACI) : Input DataDocument7 paginiIsolated Foundation Calculation (ACI) : Input DataAlma M. LaraÎncă nu există evaluări

- BoqDocument5 paginiBoqDilon FernandoÎncă nu există evaluări

- Alberdingk - Peelable Coatings PDFDocument14 paginiAlberdingk - Peelable Coatings PDFMauro Di FraiaÎncă nu există evaluări

- Diagrama Hidraulico Jumbo0 SandvikDocument20 paginiDiagrama Hidraulico Jumbo0 SandvikwladimirÎncă nu există evaluări

- Heritage Infraspace Private LimitedDocument10 paginiHeritage Infraspace Private LimitedGagan GoswamiÎncă nu există evaluări

- Multistoreyed Building 5Document11 paginiMultistoreyed Building 5V.m. RajanÎncă nu există evaluări

- Role of Columns in Construction.....Document21 paginiRole of Columns in Construction.....Muhammad Hamza100% (1)

- Standard Specification For Hot Dip GalvanizingDocument6 paginiStandard Specification For Hot Dip GalvanizingKrunal PanchalÎncă nu există evaluări

- Vastu Mantra - Powerful Mantras To Remove Vastu Dosha PDFDocument1 paginăVastu Mantra - Powerful Mantras To Remove Vastu Dosha PDFPuvvada RaambaabuÎncă nu există evaluări

- Aquatic Complex NET Case Study SummaryDocument11 paginiAquatic Complex NET Case Study SummaryAjay KumarÎncă nu există evaluări

- LG SERVICE MANUALDocument35 paginiLG SERVICE MANUALfurqansÎncă nu există evaluări

- Cable Shedule With Voltage Drop CalculationsDocument1 paginăCable Shedule With Voltage Drop CalculationsJason SecretÎncă nu există evaluări

- Building LawsDocument32 paginiBuilding LawsJayvee Latosa DividinaÎncă nu există evaluări