Documente Academic

Documente Profesional

Documente Cultură

BCM

Încărcat de

Shweta BhagwaniDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BCM

Încărcat de

Shweta BhagwaniDrepturi de autor:

Formate disponibile

Soil- Components Of Soil Or Phases Of Soil

Minerals soils consist of 4 major components: Mineral materials, OM, water and air in various proportions. Approximately 50% of the total volume of the surface horizon of many soils is made up of inorganic Materials (mineral matter) and OM (5%) and the remaining volume is per space between the soil particles. Water and air occupy these pore spaces in various proportions. The proportion of air and water varies from one season to another. At optimum moisture for plant growth, the 50% of pore space possessed is divided roughly in half 25% of water space and 25% or air. The soil may be described as the three phase system: Soil solid, Liquid and gaseous phase.

1. Solid phase: Soil material less than 2 mm size constitutes the soil sample. It is broadly composed of inorganic and organic constitutes. Soils having more than 20% of org. constitutes are arbitrarily designated organic soils. Where inorganic constituents dominate, they are called mineral soils. The majority of the soils of India are mineral soils. It accounts for nearly 50% of the total volume and 95% without of the solid phase is made up of inorganic or mineral matter. The remaining 5% weight comprises of OM which is mainly derived from dead parts of the vegetation an animals.In inorganic constituents consist of silicates, certain preparation of carbonates, soluble salts, an free oxides of iron, aluminium and silicon. The humus and humus like fractions of the solid phase constitute the soil organic matter. Soil is the habitat for enormous number of living organisms like roots of higher plants (Soil Macro flora), bacteria, fungi, actinomycetes and algae (Soil Micro flora). A gram of fertile soil contains billions of these micro-organisms. The live weight of the micro-organisms may be about 4000 kg/ha may constitute about 0.01 to 0.4% of the total soil mass. Soil also consists of protozoa and nematodes (Soil Micro Fauna).

2. Liquid phase: About 50% of the bulk volume of the soil body is generally occupied by voids or soil pores which may be completely or partially filled with water. A considerable part of the rain which falls on soil is absorbed by the soil and stored in it to be returned to the atmosphere by direct evaporation or by transpiration through plants. The soil acts as the reservoir for supplying water to plants for their growth. The soil water keeps salts in solution which act as plant nutrients. Thus, the liquid phase is an aqueous solution of salts, when water drains from soil pores are filled with air.

3. Gaseous phase: The air filled pores constitutes the gaseous phase of soil system and dependent on that of the liquid phase. The N and O2 contents of soil air are almost the atmospheric air but the concentration of CO2 is much higher (8 10 times more) which may be toxic to plant roots. This phase supplies O2and thereby prevents CO2 toxicity.

The 3 phases of the soil system have definite roles to play. The solid phase provides mechanical support for and nutrients to the plants. The liquid phase supplies water and along with it dissolved nutrients to plant roots. The gaseous phase satisfies the acration (O2) need of plants. Foundation Type and Construction System

The three basic types of foundations full basement, crawl space, and slab-on--gradeare shown in Figure 1-5. Of course, actual houses may include combinations of these types. Information on a fourth type of foundationthe shallow or half-bermed basementcan be found in the Building Foundation Design Handbook (Labs et al. 1988).

There are several construction systems from which to choose for each foundation type. The most common systems, cast-in--place concrete and concrete block foundation walls, can be used for all four basic foundation types. Other systems include pressure-preservative-treated wood foundations, precast concrete foundation walls, masonry or concrete piers, cast-in--place concrete sandwich panels, and various masonry systems. A slab-on-grade construction with an integral concrete grade beam at the slab edge is common in climates with a shallow frost depth. In colder climates, deeper cast-in-place concrete walls and concrete block walls are more common, although a shallower footing can sometimes be used depending on soil type, groundwater conditions, and insulation placement.

Figure 1-5: Basic Foundation Types

Most of the foundation types and construction systems described above can be designed to meet necessary structural, thermal, radon, termite and moisture or water control requirements. Factors affecting the choice of foundation type and construction system include site conditions, overall building design, the climate, and local market preferences as well as construction costs. These factors are discussed below.

Site Conditions

The topography, water table location, presence of radon, soil type, and depth of bedrock can all affect the choice of a foundation type. Any foundation type can be used on a flat site; however, a sloping site often necessitates the use of a walkout basement or crawl space. On steeper slopes, a walkout basement combines a basement foundation wall on the uphill side, a slab-on--grade foundation on the downhill side, and partially bermed foundation walls on the remaining two sides.

A water table depth within 8 feet of the surface will likely make a basement foundation undesirable. Lowering the water table with drainage and pumping usually cannot be justified, and waterproofing may not be feasible or may be too costly. A water table near the surface generally restricts the design to a slab-on-grade or crawl space foundation.

The presence of expansive clay soils on a site requires special techniques to avoid foundation movement and significant structural damage. Often, buildings placed on sites with expansive clay require pile foundations extending down to stable soil strata or bedrock. Similarly, sites with bedrock near the surface require special foundation techniques. Expensive bedrock excavation is not required to reach frost depth nor is it economically justifiable to create basement space. In these unusual conditions of expansive clay soils or bedrock near the surface, special variations of the typical foundation types may be appropriate.

Overall Building Design

The foundation type and construction system are chosen in part because of appearance factors. Although it is not usually a major aesthetic element, the foundation at the base of a building can be raised above the ground plane, so the foundation wall materials can affect the overall appearance. A building with a slab-on-grade foundation has little visible foundation; however, the foundation wall of a crawl space or basement can vary considerably from almost no exposure to full exposure above grade.

Climate

The preference of foundation type varies with climatic region, although examples of most types can generally be found in any given region. One of the principal factors behind foundation preference is the impact of frost depth on foundation design. The impact of frost depth basically arises from the need to place foundations at greater depths in colder climates. For example, a footing in Minnesota must be at least 42 inches below the surface, while in states along the Gulf Coast footings need not extend below

the surface at all in order to avoid structural damage from frost heave. Because a foundation wall extending to a substantial depth is required in northern climates, the incremental cost of creating basement space is much less, since it is necessary to build approximately half the basement wall anyway. In a southern climate the incremental first cost of creating a basement is greater when compared with a slab-on--grade with no significant required footing depth.

This historic perception that foundations must extend below the natural frost depth is not entirely accurate. Buildings with very shallow foundations can be used in cold climates if they are insulated properly.

Local Market Preferences and Construction Costs

The foundation type and construction system are also chosen based on cost and market factors that vary regionally or even locally. Virtually any foundation type and construction system can be built in any location in the United States. The relative costs, however, are likely to differ. These costs reflect local material and labor costs as well as the availability of certain materials and the preferences of local contractors. For example, in certain regions there are many contractors specializing in cast-in-place concrete foundation walls. Because they have the concrete forms and the required experience with this system and because bidding is very competitive, this system may be more cost-effective compared with other alternatives. In other regions, the availability of concrete blocks is greater and there are many contractors specializing in masonry foundation walls. In these areas, a cast-in--place concrete system may be less competitive economically because fewer contractors are available.More subjective factors that influence a designer's choice of foundation type and construction system are the expectations and preferences of individual clients and thehome-buying public. These market influences are based not only on cost but also on the area's tradition. If people in a certain region expect basements, then builders generally provide them. Of course, analyzing the cost-effectiveness of providing a basement requires a somewhat subjective judgment concerning the value of basement space. These more subjective market factors and regional preferences tend to increase the availability of materials and contractors for the preferred systems, which in turn makes these systems more cost-effective choices. A deep foundation is a type of foundation distinguished from shallow foundations by the depth they are embedded into the ground. There are many reasons a geotechnical engineer would recommend a deep foundation over a shallow foundation, but some of the common reasons are very large design loads, a poor soil at shallow depth, or site constraints (like property lines). There are different terms used to describe different types of deep foundations including the pile (which is analogous to a pole), the pier (which is analogous to a column), drilled shafts, and caissons. Piles are generally driven into the ground in situ; other deep foundations are typically put in place using excavation and drilling. The naming

conventions may vary between engineering disciplines and firms. Deep foundations can be made out of timber, steel, reinforced concrete and prestressed concrete. Pile foundation systems Foundations relying on driven piles often have groups of piles connected by a pile cap (a large concrete block into which the heads of the piles are embedded) to distribute loads which are larger than one pile can bear. Pile caps and isolated piles are typically connected with grade beams to tie the foundation elements together; lighter structural elements bear on the grade beams while heavier elements bear directly on the pile cap Driven or displacement piles They are usually pre-formed before being driven, jacked, screwed or hammered into ground. This category consists of driven piles of steel or precast concrete and piles formed by driving tubes or shells which are fitted with a driving shoe. The tubes or shells which are filled with concrete after driving. Also included in this category are piles formed by placing concrete as the driven piles are withdrawn.

Bored or Replacement piles They require a hole to be first bored into which the pile is then formed usually of reinforced concrete. The shaft (bore) may be eased or uncased depending upon type of soil.

Classification of Piles according to Materials Timber piles Timber piles are made of-tree trunks driven with small end as a point Maximum length: 35 m; optimum length: 9 - 20m Max load for usual conditions: 450 kN; optimum load range = 80 - 240 kN

Disadvantages of using timber piles: Difficult to splice, vulnerable to damage in hard driving, vulnerable to decay unless treated with preservatives (If timber is below permanent Water table it will apparently last forever), if subjected to alternate wetting & drying, the useful life will be short, partly embedded piles or piles above Water table are susceptible to damage from wood borers and other insects unless treated.

Advantages: Comparatively low initial cost, permanently submerged piles are resistant to decay, easy to handle, best suited for friction piles in granular material.

Steel piles Maximum length practically unlimited, optimum length: 12-50m Load for usual conditions = maximum allowable stress x cross-sectional area The members are usually rolled HP shapes/pipe piles. Wide flange beams & I beams proportioned to withstand the hard driving stress to which the pile may be subjected. In HP pile the flange thickness = web thickness, piles are either welded or seamless steel pipes, which may be driven either open ended or closed end. Closed end piles are usually filled with concrete after driving. Open end piles may be filled but this is not often necessary., dm Advantages of steel piles: Easy to splice, high capacity, small displacement, able to penetrate through light obstructions, best suited for end bearing on rock, reduce allowable capacity for corrosive locations or provide corrosion protection.

Disadvantages: Vulnerable to corrosion. HP section may be damaged/deflected by major obstruction

Concrete Piles Concrete piles may be precast, prestressed, cast in place, or of composite construction Precast concrete piles may be made using ordinary reinforcement or they may be prestressed. Precast piles using ordinary reinforcement are designed to resist bending stresses during picking up & transport to the site & bending moments from lateral loads and to provide sufficient resistance to vertical loads and any tension forces developed during driving.

Prestressed piles are formed by tensioning high strength steel prestress cables, and casting the concrete about the cable. When the concrete hardens, the prestress cables are cut, with the tension force in the cables now producing compressive stress in the concrete pile. It is common to higher-strength concrete (35 to 55 MPa) in prestressed piles because of the large initial compressive stresses from prestressing. Prestressing the piles, tend to counteract any tension stresses during either handling or driving. Max length: 10 - 15 m for precast, 20 - 30 m for prestressed Optimum length 10 - 12 m for precast. 18 - 25m prestressed Loads for usual conditions 900 for precast. 8500 kN for prestressed Optimum load range: 350 - 3500 kN Advantages: High load capacities, corrosion resistance can be attained, hard driving possible Cylinder piles in particular are suited for bending resistance. Cast in place concrete piles are formed by drilling a hole in the ground & filling it with concrete. The hole may be drilled or formed by driving a shell or casing into the ground. Disadvantages: Concrete piles are considered permanent, however certain soils (usually organic) contain materials that may form acids that can damage the concrete. Salt water may also adversely react with the concrete unless special precautions are taken when the mix proportions are designed. Additionally, concrete piles used for marine structures may undergo abrasion from wave action and floating debris in the water. Difficult to handle unless prestressed, high initial cost, considerable displacement, prestressed piles are difficult to splice. Alternate freezing thawing can cause concrete damage in any exposed situation. Composite piles In general, a composite pile is made up of two or more sections of different materials or different pile types. The upper portion could be eased cast-in-place concrete combined with a lower portion of timber, steel H or concrete filled steel pipe pile. These piles have limited application and arc employed under special conditions Timber As the name implies, timber piles are made of wood.

Historically, timber has been a plentiful, locally-available resource in many areas. Today, timber piles are still more affordable than concrete or steel. Compared to other types of piles (steel or concrete), and depending on the source/type of timber, timber piles may not be suitable for heavier loads. A main consideration regarding timber piles is that they should be protected from rotting above groundwater level. Timber will last for a long time below the groundwater level. For timber to rot, two elements are needed: water and oxygen. Below the groundwater level, oxygen is lacking even though there is ample water. Hence, timber tends to last for a long time below groundwater level. It has been reported that some timber piles used during 16th century in Venice still survive since they were below groundwater level. Timber that is to be used above the water table can be protected from decay and insects by numerous forms of wood preservation using pressure treatment (ACQ, CCA, creosote, etc.). Splicing timber piles is still quite common and is the easiest of all the piling materials to splice. The normal method for splicing is by driving the leader pile first, driving a steel tube (normally 60100 cm long, with an internal diameter no smaller than the minimum toe diameter) half its length onto the end of the leader pile. The follower pile is then simply slotted into the other end of the tube and driving continues. The steel tube is simply there to ensure that the two pieces follow each other during driving. If uplift capacity is required, the splice can incorporate bolts, coach screws, spikes or the like to give it the necessary capacity. [edit]Steel Pipe piles are a type of steel driven pile foundation and are a good candidate for battered piles. Pipe piles can be driven either open end or closed end. When driven open end, soil is allowed to enter the bottom of the pipe or tube. If an empty pipe is required, a jet of water or an auger can be used to remove the soil inside following driving. Closed end pipe piles are constructed by covering the bottom of the pile with a steel plate or cast steel shoe. In some cases, pipe piles are filled with concrete to provide additional moment capacity or corrosion resistance. In the United Kingdom, this is generally not done in order to reduce the cost. In these cases corrosion protection is provided by allowing for a sacrificial thickness of steel or by adopting a higher grade of steel. If a concrete filled pipe pile is corroded, most of the load carrying capacity of the pile will remain intact due to the concrete, while it will be lost in an empty pipe pile. The structural capacity of pipe piles is primarily calculated based on steel strength and concrete strength (if filled). An allowance is made for corrosion depending on the site conditions and local building codes. Steel pipe piles can either be new steel manufactured specifically for the piling industry or reclaimed steel tubular casing previously used for other purposes such as oil and gas exploration. H-Piles are structural beams that are driven in the ground for deep foundation application. They can be easily cut off or joined by welding or mechanical drive-fit splicers. If the pile is driven into a soil with low pH value, then there is a risk of corrosion, coal-tar epoxy or cathodic protection can be applied to slow or eliminate the corrosion process. It is common to allow for an amount of corrosion in design by simply

over dimensioning the cross-sectional area of the steel pile. In this way the corrosion process can be prolonged up to 50 years. [edit]Prestressed concrete piles Concrete piles are typically made with steel reinforcing and prestressing tendons to obtain the tensile strength required, to survive handling and driving, and to provide sufficient bending resistance. Long piles can be difficult to handle and transport. Pile joints can be used to join two or more short piles to form one long pile. Pile joints can be used with both precast and prestressed concrete piles. [edit]Composite piles Composite pile is a pile made of steel and concrete members that are fastened together, end to end, to form a single pile. It is a combination of different materials or different shaped materials such as pipe and H-beams or steel and concrete. [edit]

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Siemens MV Gas Insulated Switch GearDocument14 paginiSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VÎncă nu există evaluări

- Theories of Motivation and Child Moral DevelopmentDocument5 paginiTheories of Motivation and Child Moral DevelopmentPamela mirandaÎncă nu există evaluări

- Immune System Quiz ResultsDocument6 paginiImmune System Quiz ResultsShafeeq ZamanÎncă nu există evaluări

- Life Overseas 7 ThesisDocument20 paginiLife Overseas 7 ThesisRene Jr MalangÎncă nu există evaluări

- 57882d4608ae21394a0c7b00 PDFDocument574 pagini57882d4608ae21394a0c7b00 PDFtualaÎncă nu există evaluări

- Slaked Lime MSDS Safety SummaryDocument7 paginiSlaked Lime MSDS Safety SummaryFurqan SiddiquiÎncă nu există evaluări

- AYUSHMAN BHARAT Operationalizing Health and Wellness CentresDocument34 paginiAYUSHMAN BHARAT Operationalizing Health and Wellness CentresDr. Sachendra Raj100% (1)

- Speaking Coursebook C1.1Document80 paginiSpeaking Coursebook C1.1Yến VõÎncă nu există evaluări

- Rockwool 159: 2.2 Insulation ProductsDocument1 paginăRockwool 159: 2.2 Insulation ProductsZouhair AIT-OMARÎncă nu există evaluări

- Roadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostDocument4 paginiRoadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostJanel Castillo Balbiran33% (3)

- Female Reproductive System Histology IDocument5 paginiFemale Reproductive System Histology ISolomon Seth SallforsÎncă nu există evaluări

- HR Policy For Hotel IndustriesDocument5 paginiHR Policy For Hotel IndustriesHR Forum India78% (9)

- g21 Gluta MsdsDocument3 paginig21 Gluta Msdsiza100% (1)

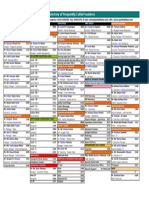

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocument1 paginăDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoÎncă nu există evaluări

- EcR - 1 Leading and Lagging IndicatorsDocument10 paginiEcR - 1 Leading and Lagging IndicatorsMiloš ĐukićÎncă nu există evaluări

- Soal UTS Bahasa Inggris SMP Semester Genap Tahun Ajaran 2020Document5 paginiSoal UTS Bahasa Inggris SMP Semester Genap Tahun Ajaran 2020awan MustofaÎncă nu există evaluări

- Strauss Dental Catalog 2013Document74 paginiStrauss Dental Catalog 2013d3xt3rokÎncă nu există evaluări

- Operating Instructions: Katflow 100Document52 paginiOperating Instructions: Katflow 100Nithin KannanÎncă nu există evaluări

- Pulsar2 User Manual - ENDocument83 paginiPulsar2 User Manual - ENJanette SouzaÎncă nu există evaluări

- Case Report on Right Knee FuruncleDocument47 paginiCase Report on Right Knee Furuncle馮宥忻Încă nu există evaluări

- M-LVDT: Microminiature Displacement SensorDocument2 paginiM-LVDT: Microminiature Displacement Sensormahdi mohammadiÎncă nu există evaluări

- Construction and Operation 1. Air Conditioning Control PanelDocument18 paginiConstruction and Operation 1. Air Conditioning Control PanelRoma KuzmychÎncă nu există evaluări

- Growth Developt Pearl MilletDocument17 paginiGrowth Developt Pearl MilletdarmaÎncă nu există evaluări

- December - Cost of Goods Sold (Journal)Document14 paginiDecember - Cost of Goods Sold (Journal)kuro hanabusaÎncă nu există evaluări

- LAST CARGOES AND CLEANINGDocument1 paginăLAST CARGOES AND CLEANINGAung Htet KyawÎncă nu există evaluări

- Tutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)Document3 paginiTutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)NOR SYAZLIANA ROS AZAHARÎncă nu există evaluări

- CERADocument10 paginiCERAKeren Margarette AlcantaraÎncă nu există evaluări

- Wastewater Treatment Plant Design PDFDocument68 paginiWastewater Treatment Plant Design PDFmostafa1alaahobaÎncă nu există evaluări

- Rreinforcement Pad Leak Test ProcedureDocument5 paginiRreinforcement Pad Leak Test ProcedureAmin Thabet100% (2)

- MR23002 D Part Submission Warrant PSWDocument1 paginăMR23002 D Part Submission Warrant PSWRafik FafikÎncă nu există evaluări