Documente Academic

Documente Profesional

Documente Cultură

Dual Band Patch S & L

Încărcat de

Paulo FernandesDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dual Band Patch S & L

Încărcat de

Paulo FernandesDrepturi de autor:

Formate disponibile

Dual Band Patch S & L

9.10.2004 9:36 Uhr

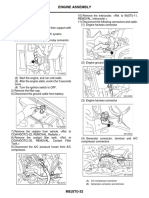

Making a Dual Band S & L Patch I have been working on dual band patches for 1269 MHz and 2401 MHz too, as there is considerable interest in using the 1269 MHz uplink frequency into AO-40. Also shown to the right of my two S & L patches is my good old S & U dual feed.

The first version was made by placing an S band circular patch and reflector and an L band patch & reflector side by side on a plate. This worked OK, but resulted in 8" of separation between the patch centers, and about 10 degrees of pointing difference on my 10' dish. This version was built so readers can use their G3RUH, etc. S band patch along with a 1269 MHz patch. Too much much separation resulted in very poor performance. The next try took just the two patch plates and put them on a common reflector plate. This reduced the center to center spacing to 4" or 5 degrees on the 10' dish. While this might be OK on a long focal length dish, it is marginally acceptable on a short focal length TVRO dish. The larger reflector impacts the dimensions of both the S and the L patches, and requires modifying the single patch dimensions slightly. Another major concern is desensing by the close proximity in spacing and frequency of the L patch to the S patch. The AIDC 3731 showed no desensing with full power (3 1/2 watts at the L patch), but a UEK3000 downconverter would desense with as little as 1/5 watt at the L band patch. By placing a 4" high shield between the two patches, the UEK-3000 desensing by the nearby L band patch was cured, but this high shield distorted the dish illumination. Axial Circular Dual Band (S & L) patch feed I wanted to make a dual band S & L patch feed that would have both patches on an axial line with no bearing offset problem. After a bit of experimentation, I did it. I was concerned that the 2401 MHz patch's reflector is sometimes bigger than the 1269 MHz patch so I made the 2401 MHz reflector smaller than usual. I was also concerned about minimizing desensing possibilities so I did not try to use the 1269 MHz patch as the 2401 MHz reflector. It worked! The picture at the left shows the dual band circular S & L patch attached to the front of a 7 1/2' TVRO dish in place of the former C Band feed. The dual band patch uses 4 disks. And a few tricks. It may get somewhat confusing, but try to follow the logic. Here is how you can build one (or more) in a few hours for about $20 in parts. Start by cutting out the 4 disks. Except for the the 2401 MHz patch (the smallest disk, in the front) which is 1/32" (1/16" would be easier to tap) brass for solderability, the disks are made from 1/16" aluminum. Cut the rearmost 1269 MHz reflector to 6 5/8" diameter. Cut the 1269 MHz patch in front of the 1269 MHz reflector to 4 3/8" in diameter. The 2401 MHz reflector is next at 3 1/2" in diameter, and finally cut the 2401 MHz patch out of a piece of brass to 2 3/8" in diameter. I use K & S brass from a local hardware or hobby store rack. You could use a soup can lid but it's tough to tap.

http://www.ultimatecharger.com/Dish_Feed_SL.html

Seite 1 von 4

Dual Band Patch S & L

9.10.2004 9:36 Uhr

Center Hole in all four Disks Drill a 3/16" hole in the center of the 4 disks which will be used for axial alignment of the disks when a 10-24 bolt, 1 3/4" long, is passed through the disks. Make a mark anywhere on the brass disk that is 11/16" out from the center hole. This will be the point of attachment of the 2401 MHz coaxial connector and the centering hole for the larger holes in the bigger aluminum disks. Temporarily bolt the four disks together tightly with the brass disk on top. Now drill a hole through the mark on the brass disk and the 3 aligned aluminum disks below the brass disk. Remove the 10-24 bolt and mark one side of each disk as "UP". 2401 MHz Patch Plate Put a mark on the brass disk 1/2" clockwise from the 1/8" feed hole, also 11/16" out from the center hole. Drill a 1/8" hole in the brass 2401 MHz patch at this point. Then tap this hole with a 6-32 tap held perfectly perpendicular to the surface of the 2401 MHz patch. Screw in a 1/2" long 6-32 flat head bolt from the "down side". Put a 1/4" wide hex nut on the "UP" side of the bolt, with about 1/8" extending downwards. Finger tighten the nut to avoid stripping the threads in the brass disk. This screw will be used to tune for best received circularity and strongest received signal (hopefully the same point). Set the brass disk aside for now. 2401 MHz Reflector Now the 2401 MHz reflector is drilled out to attach a type N male long chassis connector. I have 2 male sizes in my connector collection. The shorter 3/4" version is not long enough to directly attach a downconverter. Drill out the off center 1/8" hole previously drilled to 3/8" exactly centering the drill on the 1/8" hole. Some chassis connectors have a bottom taper that may require as much as a 1/2" hole for center pin clearance. This type N male chassis connector is attached from the "DOWN" side with four 4-40 flathead 1/4" long bolts inserted from the "UP" side. Holding the connector centered in the 3/8" (1/2") hole with the outer edge of the connector parallel with the outer rim of the 2401 MHz reflector, mark where the holes will be drilled. Drill four 1/8" holes at the marks. Then turn the 2401 MHz over and counter sink bevel the holes from the "UP" side so the four flathead screws will attach as flush as possible. Now attach the type N Male long chassis connector to the "DOWN" side of the 2401 MHz reflector using the four 440 flathead 1/2" long bolts and 4-40 1/4" nuts. Another disk done. 1269 MHz Patch Plate The 1269 MHz patch plate gets another hole on its "UP" side. Draw a line from center to edge, 90 degrees clockwise to the 1/8" feed hole previously drilled for the 2401 MHz feed hole. Now put a mark on this line 1 5/16" out from this center. This will be the 1269 MHz patch's feedpoint, 90 degrees out of phase with the 2401 MHz patch feedpoint. Bolt the center of the two 1269 MHz disks together with "UP" up, patch on top. Then temporarily lock the two plates' orientation together by putting a short 4-40 bolt through the 1/8" holes drilled in each. Now drill a 5/32" hole at the mark on the line for attaching the 1269 MHz coaxial center pin. Unfasten the two plates and drill a 3/8" hole centered on the 1/8" alignment hole. Dig out your old 1" Greenlee tube hole punch and punch a 1" hole in both the 1269 MHz reflector and 1269 MHz patch plate for the 2401 MHz feed to pass through. Set the 1269 MHz patch plate aside. 1269 MHz Reflector The disk with the most holes will be this 1269 MHz reflector. Orient the disk with "UP" upwards, and the 1" hole to the left. The 5/32" hole drilled in the previous section should be at the top. Place a mark 1" clockwise from this 5/32" hole, also 1 5/16" out from the center. This hole will be used for the circularity

http://www.ultimatecharger.com/Dish_Feed_SL.html Seite 2 von 4

Dual Band Patch S & L

9.10.2004 9:36 Uhr

adjusting bolt. Drill a 3/16" hole at this mark. Now draw a line across the top of the disk, starting at the 5/ 32" feed hole continuing through the center hole to the opposite edge. 2" out from the center, place a mark on this line for the frequency adjusting screw. Drill a 3/16" hole at this mark too. Tap out both 3/16" holes with a 1/4-20 tap, keeping the tap perpendicular to the surface of the plate. Drill out the 5/32" hole to 3/8" for the type N female chassis connector, making sure you keep the 3/8" (1/ 2") hole centered to the 5/32" hole. Then, while holding this female chassis connector centered in the hole and the edges parallel with the rim of the disk, mark the four holes that are used to attach the connector. Drill the four holes with a 1/8" drill. From the "UP" side counter sink bevel the 4 holes so that four 4-40 flathead 1/2" long bolts will lie flush. The final holes in the 1269 MHz reflector plate are used to attach this dual patch to a dish using the original mounting arms used with a Chaparral C Band feed. The Chaparral feed was attached to the arms from a four 1/4-20 bolts in a 4 1/8" square pattern. The exact pattern is not particularly important, but I like things squared off, so after making a 4 1/8" square pattern, I hold this pattern on the 1269 MHz reflector plate so that the sides of the square are parallel/perpendicular to an axial line drawn between the two feed holes in the plate, and centered. Then I place a mark at each corner and drill a 1/4" hole at the four marks for mounting bolts. Put on four 1/4-20 hex head bolts from the "UP" side and fasten with a nut on the "DOWN" side, along with an additional nut and wingnut on each bolt for precise focusing. Attach the type N female chassis connector to the "DOWN" side of the 1269 MHz reflector plate using four 4-40 flathead 1/2" long bolts and 4-40 1/4" nuts. From the "UP" side of the 1269 MHz reflector plate screw in a 1" long 1/4-20 flathead bolt into each of the two 1/4-20 tapped holes from the "UP" side. Leave extended about a 3/8" high and place a 1/4-20 nut on the "DOWN" side of each bolt to lock it in place after calibration. Finger tighten only, to avoid stripping the threads in the plate. Assembling the Dual Band S & L Patch In reverse order, or "bottom up" sequence, place a 1 3/4" long 10-24 bolt through the center hole in the 1269 MHz reflector plate from the "DOWN" side. Fasten with a 10-24 hex nut and firmly tighten. Now put another 10-24 nut on the the 10-24 bolt and adjust so that a 1/2" space between the plates will result. The center conductor of the type N female chassis connector has to extended. I cut the head off a 3/4" long brass 6-32 bolt and sharpen the cut off end on a grinder so that the end result is about 5/8" long. I tin this sharpened end the center conductor of the type N female chassis connector. Holding the sharpened end on the center conductor, I solder the two together, making sure this center conductor extension is standing up straight, perpendicular to the surface of the 1269 MHz reflector. Place the 1269 MHz patch plate on the center mounting bolt and align the patch plate so the 1" holes match and the feed screw goes through the 5/32" feed hole in the patch plate. When appropriate adjustments are made if needed, remove the patch plate, put a 1/4" wide 6-32 hex nut on the screw so the patch plate will be spaced 1/2" from the reflector, put back the patch plate and add another 10-24 nut and 6-32 nut to hold firmly in place. Make sure the patch plate is spaced 1/2" from the reflector all around and the connector extending screw is not being pulled up, potentially breaking the solder joint. Put another 10-24 nut on the center screw, placed so another 1/2" of plate to plate separation occurs, and place the 2401 MHz reflector on the center hole, with the type N male long chassis connector extending through the center of the 1" holes in the 1269 MHz reflector and 1269 MHz patch plate. Now put another 10-24 nut over this center screw to lock the orientation perfectly centered. Put a 10-24 nut on the top of the last nut, snug it up and verify that you have 1/4" spacing. If your nuts are not exactly 1/8" thick like mine, then use washers to achieve 1/4" spacing between the 2401 MHz reflector and the 2401 MHz patch plate. Align the 1/8" hole in the 2401 MHz patch plate with the center conductor

http://www.ultimatecharger.com/Dish_Feed_SL.html

Seite 3 von 4

Dual Band Patch S & L

9.10.2004 9:36 Uhr

underneath. Add a final 10-24 nut to the center bolt to lock the 2401 MHz patch plate to the assembly. You can use a small wire to bridge a gap if if you center conductor is short, but I usually just form a solder bridge between the center conductor and the 2401 MHz 1/8" feed hole. K5MAN has made the following mechanical drawings in *.pdf format for those confused by my verbal description. S band patch. L band patch. S & L side view Attach this S & L dual band patch in place of the C Band Chaparral feed horn. Connect 1269 MHz coax to the type N female connector, and put a downconverter on the type N male long connector. An AIDC 3731 is shown in the picture at the right. Attach a coax line with a type F male connector to the down converter. Calibration I find that if I have exactly followed the dimensions and set the three tuning bolts as will be detailed, the patch will work very close to perfect without further adjustment. Loosen the 6-32 locknut on the 2401 MHz patch plate and turn the front screw so that it is spaced .020" or the thickness of 3 "bingo" postcards above the reflector. Loosen the 1/4-20 locknut on the frequency tuning bolt furthest from the 1269 MHz type N connector. Turn the 1/4-20 flathead bolt so that it is as far from the 1269 MHz patch plate as possible. Loosen the 1/4-20 locknut on the circularity tuning bolt next to the 1269 MHz type N connector, and turn the bolt so that it is just touching the back of the 1269 MHz patch. Note the position of the slots on this flathead bolt and turn the bolt back exactly one turn (.050") or 7 "Bingo" postcards separation. These setting will be very close, but you can use the frequency tuning 1/4-20 bolt furthest from the 1269 MHz type N connector to trim the 1269 MHz patch to exact frequency. I achieved an almost perfect match when this frequency tuning bolt was 3 turns back (.150") from touching the rear of the 1269 MHz patch. Does it work? I used this patch for the first time on a 7 1/2' dish. The AO-40 beacon came in just over S9 +15, and was exactly 20 over S9 on my 10' dish. Although the squint was rather high for L band operation at 30 degrees, the return voice signal strength was about 3 db or so higher than an occasional Leila bleeping nearby. And I was only running about 3 watts at the time on L1. Sources for the type N connectors Some people have e-mailed me telling me that they were unable to located some of the type N connectors and adapters used on these multi-band circular patch feed systems. I got the type N male chassis connector, long, from Radioshack.com, but they went out of business last Summer, and I have been unable to find any more. I now use the short standard version which works fine. Pasternack (949) 261-1920 has these connectors (PE4131) for $8 each as well as the double male (PE 9007) and the double female (PE 9006) also at $8 each. Their type N female chassis connector (PE4013) is $5 each. Hangar 19 in Texas may also have these connectors and adapters at more reasonable prices (around $3 to $4 each). Avoid the cheap plastic insulated type N connectors. They melt when soldered, and sometimes result in a patch impossible to tune for low SWR.

http://www.ultimatecharger.com/Dish_Feed_SL.html

Seite 4 von 4

S-ar putea să vă placă și

- Dual Core Balun Construction ProjectDocument7 paginiDual Core Balun Construction ProjectCarlos MerelloÎncă nu există evaluări

- Vifa 2-Way Loudspeaker SystemDocument6 paginiVifa 2-Way Loudspeaker SystemKaka ItedÎncă nu există evaluări

- Pacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsDocument6 paginiPacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsedosviracÎncă nu există evaluări

- Travel AntennaDocument5 paginiTravel Antennanw2sÎncă nu există evaluări

- Build A Four Transistor Metal DetectorDocument19 paginiBuild A Four Transistor Metal Detectorkamelferes100% (1)

- Antenna HandoutDocument8 paginiAntenna HandoutPhil BoxxÎncă nu există evaluări

- GPS Helical Antenna DesignDocument6 paginiGPS Helical Antenna DesignGuadalajara Jalisco100% (1)

- Antennas 40M3FS-125Document15 paginiAntennas 40M3FS-1257c3c conteststationÎncă nu există evaluări

- Fractal Magic DIY HDTV Antenna PDFDocument56 paginiFractal Magic DIY HDTV Antenna PDFDarin ArmsteadÎncă nu există evaluări

- Sangean ATS-909 / Radio Shack DX-398, Roberts R861: What Is The ATS-909? What Is The DX-398?Document17 paginiSangean ATS-909 / Radio Shack DX-398, Roberts R861: What Is The ATS-909? What Is The DX-398?jeanpaul CAYTANÎncă nu există evaluări

- Wb3ayw Wire Collinear For 2 MetersDocument7 paginiWb3ayw Wire Collinear For 2 MetersEduard Gabi OrdeanÎncă nu există evaluări

- I Kemo CabinetDocument14 paginiI Kemo CabinetSidney RiveraÎncă nu există evaluări

- Firefly PCB Guide 8Document16 paginiFirefly PCB Guide 8Renier Orlando BlancoÎncă nu există evaluări

- TRANSLINE AntennaDesignDocument10 paginiTRANSLINE AntennaDesignmgoldiieeeeÎncă nu există evaluări

- Fractal Magic DIY HDTV AntennaDocument56 paginiFractal Magic DIY HDTV Antennadetroit_me2553100% (3)

- Designing and Constructing A Magnetic Loop Antenna: Presentation To The Richmond Amateur Radio ClubDocument52 paginiDesigning and Constructing A Magnetic Loop Antenna: Presentation To The Richmond Amateur Radio ClubDarko EpliÎncă nu există evaluări

- A $20 HF Mobile Antenna: A Few Hours of Fun With PVC and Wire and You've Got Yourself A Respectable Road Radiator!Document4 paginiA $20 HF Mobile Antenna: A Few Hours of Fun With PVC and Wire and You've Got Yourself A Respectable Road Radiator!Marckos FrancoÎncă nu există evaluări

- Vintage New U47 Build GuideDocument16 paginiVintage New U47 Build Guidepiretto77Încă nu există evaluări

- 2-Meter Vertical Dipole ArrayDocument15 pagini2-Meter Vertical Dipole ArrayJacky SinurayaÎncă nu există evaluări

- 2 Meter Phased Vert AntDocument6 pagini2 Meter Phased Vert AntBenny SÎncă nu există evaluări

- Balun Intro and Construction 1Document6 paginiBalun Intro and Construction 1Robson Batista do nascimentoÎncă nu există evaluări

- 5EL 6m LFA Yagi PDFDocument10 pagini5EL 6m LFA Yagi PDFآكوجويÎncă nu există evaluări

- End Fed 40meter Half Wave AntennaDocument4 paginiEnd Fed 40meter Half Wave AntennaDefaultAnomoly100% (1)

- RX RegenDocument8 paginiRX RegenhgbarieroÎncă nu există evaluări

- Ilovepdf MergedDocument5 paginiIlovepdf Mergedvelin panchevÎncă nu există evaluări

- CollantDocument2 paginiCollantpogee752Încă nu există evaluări

- Metal Detector ReportDocument13 paginiMetal Detector ReportAnonymous ytZsBOVÎncă nu există evaluări

- Endfed6 40Document8 paginiEndfed6 40Leopoldo AlvarezÎncă nu există evaluări

- Pigrig v2Document17 paginiPigrig v2ffwwfÎncă nu există evaluări

- Stacked 2m Array Dipole PDFDocument6 paginiStacked 2m Array Dipole PDFWillowÎncă nu există evaluări

- 2-Meter Vertical Dipole ArrayDocument15 pagini2-Meter Vertical Dipole ArrayRádioWeb SapucaiaÎncă nu există evaluări

- Make A Simple 2.425GHz HelicalDocument12 paginiMake A Simple 2.425GHz Helicalf.lastÎncă nu există evaluări

- MM c414 Build Guide 1.2Document23 paginiMM c414 Build Guide 1.2Pule123Încă nu există evaluări

- Vertical Rev HDocument10 paginiVertical Rev HMiguel OyarzabalÎncă nu există evaluări

- FRB 15 Watt Instruction PacketDocument8 paginiFRB 15 Watt Instruction PacketStephen Dunifer100% (1)

- Short-BackFire Antenna DetailsDocument2 paginiShort-BackFire Antenna DetailsAwais2016100% (1)

- End Fed 6 - 40 Meter Multiband HF AntennaDocument6 paginiEnd Fed 6 - 40 Meter Multiband HF AntennalimazulusÎncă nu există evaluări

- E Plus Kit ManualDocument27 paginiE Plus Kit ManualJCMÎncă nu există evaluări

- Kreuger STring Bass K-700 Installation ManualDocument4 paginiKreuger STring Bass K-700 Installation Manualblondeb3Încă nu există evaluări

- Varied 2 Meter Homebrew Antennas-ERC TrainingDocument15 paginiVaried 2 Meter Homebrew Antennas-ERC TrainingIndika WithanageÎncă nu există evaluări

- 15 Watt FET FM Amp Rev 2 Assembly InstructionsDocument7 pagini15 Watt FET FM Amp Rev 2 Assembly InstructionsStephen Dunifer100% (4)

- Bud Die PoleDocument5 paginiBud Die PoleDennis OszuscikÎncă nu există evaluări

- Geet PlansDocument5 paginiGeet PlansbyenterÎncă nu există evaluări

- Manual de Rait KitDocument4 paginiManual de Rait KitFrancisco SanchezÎncă nu există evaluări

- 3 Band Magnetic Loop PDFDocument3 pagini3 Band Magnetic Loop PDFbushconnÎncă nu există evaluări

- Collinear ReportDocument15 paginiCollinear ReportRemonIbrahimÎncă nu există evaluări

- Free Electric Power WindmillDocument3 paginiFree Electric Power WindmillJim100% (4)

- PM 300 v2.2Document4 paginiPM 300 v2.2GabÎncă nu există evaluări

- 10 Watt PLL New Version Assembly InstructionsDocument11 pagini10 Watt PLL New Version Assembly InstructionsStephen Dunifer100% (8)

- Magnetic Loop Antenna - BestDocument12 paginiMagnetic Loop Antenna - BestOth J100% (1)

- A Home Made Helical Antenna For A GPSDocument1 paginăA Home Made Helical Antenna For A GPSbalaban_sorinÎncă nu există evaluări

- M2 Antenna Systems, Inc. Model No: 222-5WL: SpecificationsDocument6 paginiM2 Antenna Systems, Inc. Model No: 222-5WL: SpecificationsAndhi AerosupplyÎncă nu există evaluări

- Receptor de 40mDocument13 paginiReceptor de 40meduardo acostaÎncă nu există evaluări

- Pianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsDe la EverandPianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsEvaluare: 5 din 5 stele5/5 (2)

- T Rec F.20 198811 I!!pdf eDocument7 paginiT Rec F.20 198811 I!!pdf ePaulo FernandesÎncă nu există evaluări

- Sodirasdr: Software-Radio SpecificationDocument15 paginiSodirasdr: Software-Radio SpecificationPaulo FernandesÎncă nu există evaluări

- Thirty YearsDocument30 paginiThirty YearsPaulo FernandesÎncă nu există evaluări

- A 267914Document371 paginiA 267914Paulo FernandesÎncă nu există evaluări

- DVX VHF Digital Voice Transceiver: Moe Wheatley, AE4JYDocument20 paginiDVX VHF Digital Voice Transceiver: Moe Wheatley, AE4JYPaulo FernandesÎncă nu există evaluări

- Tank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDocument4 paginiTank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDanielle JohnsonÎncă nu există evaluări

- Parts Breakdown 259Document4 paginiParts Breakdown 259Luis ParaisoÎncă nu există evaluări

- Man B&WDocument18 paginiMan B&WSatyabrat GaanÎncă nu există evaluări

- Dış Cephe Sistemler ElemanlarıDocument8 paginiDış Cephe Sistemler Elemanlarınedim cılızÎncă nu există evaluări

- CD110R 1Document384 paginiCD110R 1PooÎncă nu există evaluări

- Warp-Drive-Propellers 090-01-21 Manual HPL 3-BladeDocument16 paginiWarp-Drive-Propellers 090-01-21 Manual HPL 3-BladeArtur FrancoÎncă nu există evaluări

- Opel Corsa Aircon InstallationDocument18 paginiOpel Corsa Aircon InstallationMOLL1234100% (1)

- Gestra Pa46 Mpa46 Pa47 Mpa47 Installation..Document32 paginiGestra Pa46 Mpa46 Pa47 Mpa47 Installation..cadhoaÎncă nu există evaluări

- Catalogue VisserieDocument145 paginiCatalogue VisserieMallouli YassineÎncă nu există evaluări

- Delco Remy Service Parts: Model 1990379Document6 paginiDelco Remy Service Parts: Model 1990379Eduardo ColinÎncă nu există evaluări

- Maintenance Handbook On Tap Changer of AC ELectric LocomotiveDocument87 paginiMaintenance Handbook On Tap Changer of AC ELectric LocomotivesanjuuÎncă nu există evaluări

- Doka Automatic Climbing FormworkDocument32 paginiDoka Automatic Climbing FormworkNunyaÎncă nu există evaluări

- Catalogo Accesorios Bradley PDFDocument151 paginiCatalogo Accesorios Bradley PDFSindy Amparo Meza Atencio80% (5)

- Brosura VarifixDocument52 paginiBrosura VarifixDan LimburgÎncă nu există evaluări

- Mesin RumputDocument32 paginiMesin Rumputaep77Încă nu există evaluări

- A-16-008 17MY Conventional Dump Valve InstallationDocument13 paginiA-16-008 17MY Conventional Dump Valve InstallationPhil B.Încă nu există evaluări

- ClutchDocument25 paginiClutchhenry_zambranoÎncă nu există evaluări

- Iso 7412 PDFDocument9 paginiIso 7412 PDFnate anantathatÎncă nu există evaluări

- TYPE 2388: Instruction Manual ForDocument28 paginiTYPE 2388: Instruction Manual ForAntonio LubranoÎncă nu există evaluări

- Hydraulic Bolt Tensioning 10022-1817-C-0002-SC17-00027Document40 paginiHydraulic Bolt Tensioning 10022-1817-C-0002-SC17-00027lemuel bacsaÎncă nu există evaluări

- Manual de Partes 3394RTDocument216 paginiManual de Partes 3394RTfernandoÎncă nu există evaluări

- NutsDocument49 paginiNutsIshant JaiswalÎncă nu există evaluări

- Flender - Gear MotorDocument42 paginiFlender - Gear Motorikuzma_10% (1)

- Engine AssemblyDocument7 paginiEngine AssemblyAmal TharakaÎncă nu există evaluări

- ViGo Cable LifelineDocument48 paginiViGo Cable LifelineAnonymous grOtUtBoo3Încă nu există evaluări

- StepCraft Optimization GuideDocument3 paginiStepCraft Optimization GuideDragos Ioan CosteÎncă nu există evaluări

- Still FM14, 17 y 20 Tipo429 (Ingles 09-1997) PDFDocument207 paginiStill FM14, 17 y 20 Tipo429 (Ingles 09-1997) PDFJuan Carlos Rubio Fresco50% (4)

- Industrial Maintenance Loctite® Wastewater Treatment GuideDocument6 paginiIndustrial Maintenance Loctite® Wastewater Treatment GuideDragoslav DzolicÎncă nu există evaluări

- Operational Instruction: Line Bushing Explosion-Proof and Pressure-SealedDocument5 paginiOperational Instruction: Line Bushing Explosion-Proof and Pressure-SealedIvanÎncă nu există evaluări

- ZF Actuator PDFDocument40 paginiZF Actuator PDFMATIAS100% (3)