Documente Academic

Documente Profesional

Documente Cultură

Vectrex Trouble Shooting Guide

Încărcat de

MaraakateDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Vectrex Trouble Shooting Guide

Încărcat de

MaraakateDrepturi de autor:

Formate disponibile

.

I

-

-,

GENERAL CONSUMER ELECTRONICS, INC

VECTREX TROUBLE-SHOOTING GUIDE

- . -.' , .........

The folowing trouble-shooting guide assumes a general

understanding of T.V. electronics and digital techniques. As

with all Consumer repair, a complete explanation of the problem

can prove invaluable in determining the problem.

Timely repairs can be accomplished with a "GCE" maintenance Test

Cartridge (latest Revision) , Vectrex Service Manual and this

Trouble-Shooting Guide.

All repairs will require the removal of the rear cover! CAUTION,

the retaining screws are fine-threaded metric (#.7) and are,

subject to easy cross-threading when replaced.

Most repairs will be PCBA replacement at first, but with a little

experience, component level repairs can be made. Replacing

components will require expert soldering techniques to insure

correct operation.

I

-

REQUIRED TOOLS

AND

TEST EQUIPMENT

\

1. Test Cartridge (Latest Revision)

2. Maintenance Manual (VECTREX )

3. Start-up Parts Kit (VECTREX )

4. Temperature Controlled Solder Station

5. General Hand Tools

6. Oscilloscope (2 CHAN.)

7. DVM/DMM

8. High Voltage Probe Meter

9. General T.V. Adjustment Tools

T EST CAR T RID G E

PRO C E D U R E

'-l.;'_.'"

.-

TEST CARTRIDGE DESCRIPTIONS

TEST #1

Description: GCE Title Page

(Fig. 1)

1. Insure the following events happen upon

Power-up of unit with Test Cartridge in

place.

A. VECTREX Announcement:

B.

1. Border lines parallel with

each other & sides of tube.

2. Printing complete and straight

or with only slight slant.

Introductory Tune:

1. Sounds are clear.

TEST #2

Description: Cartridges Title Page

(F ig. 2)

1. After 10 seconds, +/-5%, second title

page will be displayed automatically.

Also, any time you hit re-set with

unit on and Test Cartridge in place,

Test title page will be displayed.

,

, ,

I

.,

- --,

1,------,_

- I I 1

I I I 1

I I I I

I I I I

II II

I I I I

I I GeE I 1

I I ENTERTAINING I I

I I NEW I I

I L _ .-. _ __ .J I

L ________ ,

FIGURE -1

o

TEST ftfV. 4

@ GeE 19a1

FIGURE 2 -

I

I

-.

I

I

TEST #3

Description: Linearity Pattern

(Fig. 3)

1. After 5 seconds, this display will

appear automatically.

2. The pattern is used to check the

following:

A.

B.

C.

D.

Picture Geometrical Distortion

Vertical Size

Horizontal Size

Centering

3. Press Button #4 to move to the next test.

Do not depress Button #3 or the control-

ler test (#13) will be displayed and

Button #1 and #3 or #4 must be depressed

simultaneously to exit.

TEST #4

Description: DAC Offset Adjustment

(F ig. 4)

1. This test is used in conjunction with a

DVM or scope to set the DAC offset pot '

R302. See test procedure in later sec-

tion of this manual.

2.

3.

This test will display the statement,

"ADJUST DAC OFF- SET", for a short time

each 6 seconds. The adjustment R302

must only be done when these words are

off the screen.

To move to another test when display is

"on", hit contoller Button #3 or Button

#4 to move to Test #3 or Test #5 respec-

tively. Reset maybe hit at anytime to

return to title page.

4. Button #4 must be depressed to advance

to the next test and Button #3 to return _

to the previous test.

Anytime Test #13, the Hand Controller

Test is d,isplayed, But to!!. #1 and either,

But ton #3 or. # 4 mus t be depressed to

exit that Test.

l-HORIZ. SIZE

LOCATION LINE

2-VERT. SIZE

LOCATION LINE

-..

r

.....

2

2

FIGURE 3

-

..J

A D ~ U " T DAC OF,..5IT

fIGURE 4

I

1

TEST #5

Description: Integrator Offset

(Fig. 5)

1. All lines must meet and be continuous.

2.

NOTE: Please use bottom display for

checking.

Allowable Offset other than bottom dis-

plays can be 1/2 of a line offset.

Refer below.

GOOD UNACCEPTABLE

TEST #6

Description: Check Sum

1.

(Test Cartridge Rev. 4)

(F ig. 6)

During performance of forming checksum,

display #1 is near center of tube and is

flashing. Display #2 comes later (5

sec.) and stays. To do another check-

sum, select an adjacent test then im-

mediately return to test #6.

Please note the Checksum B796 is the

Domestic Checksum. It will appear for

the International Executive I or for the

International Executive II in newer pro-

duction.

r

,.

,

INTEGRATOR OFFSET

FIGURE 5

- .......

FOAMING CHECK"UH

(DISPLAY 1) ~ .

CHE'CKSU" I: 8'196

(DISPLAY 2)

FIGURE 6

I

1

TEST #7

Description: Deflection Protect

(Fig. 7)

1. When selected the words "Deflection Pro-

tect" will appear then the screen will

be blank for 6 seconds, the display will

start at half sizeand grow to full

size. Insure pattern #2 does not start

as a dot and grow; it should start at

1/2 full-size. NOTE: Intensity adjust-

ment will effect display. Please refer

to Test #9.

TEST #8

Description: Sound Test

(Fig. 8)

1. Words "CHANNEL A" will appear on bottom

of the screen, at the same time a tone

going from low to high, smoothly and

continuously will be audible.

2.

3.

4.

Words, "CHANNEL B" wi 11 appear in the

middle of the screen and the same

audible tone will be heard.

"CHANNEL C" will be displayed at the top

of the display with the same tone as in

#1 and #2.

Words will next appear in the center of

the display "NOISE ALL CHANNELS". There

will be sound like static or "gun shot"

for a short duration, then the screen

will go blank for a few seconds. Two

other sounds will be heard, which are

CPU generated. This test runs over and

over without Operator intervention.

FIGURE 7

,

c

CWANN

NO .... ALL. CHAHNn.

CHANNI'L A

- .

FIGURE 8

-

I

TEST #9

Description: Intensi ty Adjust

(F ig 9)

1. The word .. INTENSITY" wi 11 appear with 1 7

equally spaced lines running horizon-

tally across the screen. The 2nd, 3rd,

and 4th line from the top should not be

seen, but the 5th line, just on top of

the word, "INTENSITY" must be visable.

Adjust brightness if necessary to meet

the requirements above.

TEST #10

Description: Focus Test

(F ig. 10)

1. The line packets in the center of the

screen should be sharp with a well de-

fined space between each line. Four (4)

corner line packets should exhibit

minimum unfocus.

TEST #11

Description: Distortion Test One

(Fig. 11)

1. A boarder of triangles will appear on

the screen with the work "DISTORTION"

in the center. Check that all triangles

are symmetrical in appearance.

INTENSITV

-------

FIGURE 9

FIGURE 10

FIGURE 11

<

TEST #12

Description: Distortion Test Two

(Fig. 12)

1. The words "DISTORTION 2" will be dis-

played in the center of 16 progres-

sively larger rectangles traced around

it.

The spacing of each side must be the

same for each succeeding rectangle

and the overall pattern must be sym-

metrical.

TEST #13

Description: Key panel Test

(Fig. 13) I

1. NOTE: When you have entered this last

Test Pattern, you must hit "Reset" to

change test, or hold down #1 key

button and hit #3 key button to move

back to Test #12 or #4 key button to

jump to Test #3.

2. After testing controller in plug #1,

KEY 1

*

0

the right controller port, move to **

~

plug #2, the left controller port and

retest controller.

3. Press Buttons 1 thru 4 consecutively:

The

symbol must appear as each button

pushed in the appropriate square.

r

~ s

e;11 I

FIGURE 12

KEY 2 KEY 3

0 0

0 0

*Left Controller

**Right Controller

0

0

0

0

00 DO

0

0

0

0

FIGURE 13

KEY 4

0

0

00

I

,

,

,

t

I

I'

I

r

,

1

,

,

i

,

I

I

I

t

J

-,

-,

,

,

-

-,

-,

, -

J

-,

4. Displace the joystick 90 degrees to the

right slowly. The symbol as above must

appear first in the box closest to the

center, then disappear and the outer box

must indicate the symbol. There will be

a line that extends from the center of

the diagram in the direction the joy-

stick is pushed. Check all four (4)

directions and check that the appro-

priate box lights up.

Remove the hand control cord from right

port and move it to the left port. Re-

peat the above test.

NOTE: If the left joystick is not plug-

ged in, one of the inner boxes will

light because of the lMEG pull-up re-

sistor internal to the VECTREX. No

boxes should light on either port for

which a controller is plugged into when

the joystick is at rest.

'SYMPTON TOOLS/EC. NEEDED

,

Unit wi 11

up.

not Power YOM

Philips Scredriver

GCE

TROUBLESHOOTING GUIDE

VECTREX SYSTEM

NOTE: VECTREX Orientation is from

the Rear Left to Right.

TEST PROCEDURE

- Measure resistance at A/C plug (set YOM to OHMS scale IX)

should read 10 to 21 OHM +/- 5%.

- CAUTION: AC Switch SW301 is located on secondary side

side of nOl.

- Remove rear cover - REF. Pg. 11, Service Manual HP3000.

P'ROBABLE CAUSE

T101 PRIMARY

open or shorted.

- Check Fuse F101. F101 Open.

- Check SW301 - Turn unit onside (CAUTION: Damage can be SW301 open or shorted

done) and make a continuity check of the A/C switch.

- - - - - - - - - - - - - - - - - ~ - - - - - - - - - - - - - - - - ~ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ~ - - - - - - - - - - - - - - -

No Vector YOM

Intermitten Vector DMM/DVM

Intensity bad Scope

Shop Tools

Test Cartridge

" I I I I I I I I I I I I I I I I I , , , , , ,

- Select Test #3.

- Check for +/- 5 VDC and -13 VDC at connector J204

Left to Right -5, GND, +5, -13.

- Measure AC input voltage to power supply PCB.

- EP105 (center tap) to EP106 = 8.6 VAC.

- EP105 (center tap) to EP104 - 8.6 VAC.

- CAUTION: When replacing Power Supply wires, insure you

check continuity on both sides of P/$ PCB.

- Check that there are no shorts between the +9 and -9

power supply to GND. (T503 (IN) - T401 (IN) ).

- Remove T401 or T503_ and check that t h e ~ e are no shorts

to GND.

- Check for short between heat sink (on Power Board) and

IC401 heat sink.

I I I I

0101 - 0104

IC 101, 102

IC 207

T101

Fl01

Q502

IC 401

T502

I I I I I I '_1_

" I I I I

. SYMPTON

No Vector

Intermitten Vector

Intensity bad

TOOLS/EC. NEEDED

VOM

DMM/DVM

Scope

Shop Tools

Test Cartridge

I I I I I I I I I I I I

- ... '

GCE

TROUBLESHOOTING GUIDE

NOTE: VECTREX Orientation is from

the Rear Left to Right.

VECTREX SYSTEM

TEST PROCEDURE

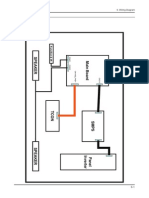

- C h e c k S i g n a 1 Wa v e form (X, Y, & Z a x i s- See A tt a c h. 1)

(Red Blue Yellow)

at J402 on Logic PCB. Refer to Page 15, WAVE FORMS

"A".

Also check these same signals at EP401-404 (Y,Y,)

and EP506 on Power PCB same Waveforms as above.

Connect scope: EXT. SYNC to PIN 9 of lC302, set

scope CHAN. A to .2 volts/Div. and Time/Div. to Ims.

- Select TEST #4.

plROBABLE CAUSE

IC303

IC302

IC301

IC401

IC501

- Check Signal Waveform at PIN 7 and PIN 8 of IC401 (no DC

level is carried) Refer to Page 15, WAVEFORMS "B". IC 401

Set Scope: Same as above except Volts/DIV. = .02

Time/DIV - 2 ms.

NOTE: Waveform is seen only when "DAC OFFSET" is

displayed.

- Check supply voltage at CRT PCB PINS 2 (+40), 3 (+.3 mv), No Z axis is applied.

5 (-29 to +3 brightness control) and 6 (+135).

(A 11 + / - 10%)

- Check Z Axis Waveform at PIN 2 of CRT socket (EP505)

Page 15.

- Connect Scope: Ext.-SYNC. to PIN 9 of lC303.

- SET Scope: Volts/Div. = 2 and Time/Div. - Ims.

, , , , , ,

Intermittent or poor

contact of CRT socket

P501.

Q503

Q505

Open Cable

IC303

IC302

I I I I I I

" I I

'SYMPTON

No sound,

Abnormal sound on

CHAN. A, B or C

& CPU.

Weak sound, distor-

ted sound, or

noisey sound.

I I I I I I I I I I I I I I I

TOOLS/EQ. NEEDED

VOM, Scope

Test Cartridge

I I I I I I I I

GCE

TROUBLESHOOTING GUIDE

VECTREX SYSTEM

NOTE: VECTREX Orientation is from

the Rear Left to Right.

"

TEST PROCEDURE

SELECT TEST #8

- Check for signal on IC 208 PINS 1, 4, and 5.

NOTE: Chan. A = PIN 5, Chan. B = PIN 4 and

Chan. C = PIN 1.

- Set Scope: VOLTS/Div. - .5V Time/Div. = 5 ms.

- Check continuity between J302 on Logic PCB & J302 on

Power PCB.

NOTE: Black audio cable can not

loss of audio will occur.

make continuity check you

inside connectors.

be inverted end for end,

Also insure, when you

do not bend contacts

- Check signal Waveform at PIN 8 of IC103 and PIN 1 of

J103 (Speaker Cable), both should be the same.

NOTE: The Waveforms will be different for each sound.

- Set Scope: Volts/Div. = .02; Time/Div. = 5 ms.

- When checking volume control, place scope probe on

PIN EP108 and turn volume control up to see same Wave-

forms as above, also check wave forms at J103 'PIN 1.

NOTE: Check that audio cables are routed away from

yoke and all IC areas when possible.

-

I I I I

P'ROBABLE CAUSE

IC 208

IC 302

IC 207

R341 - R346

C-224

Volume Control

Speaker

Cable

'SYMPTON TOOLS/EC. NEEDED

Ripple in Picture YOM

Shaking or Flashing DMM/DVM

Scope

Picture distortion

Pincushioning,

Barreling and

keystoning.

Abnormal sound &

pi cture whil e

tapping.

Test Cartridge

Shop tools

Test Cartridge

Shop tools

Meter

" I I I I , , , , , ,

GCE

TROUBLESHOOTING GUIDE

VECTREX SYSTEM

NOTE: VECTREX Orientation is from

the Rear Left to Right.

TEST PROCEDURE

SELECT TEST #3

- Check ripple on + and - 9VDC and 5 VDC power supplies

at T503 (IN), should be less than .05V.

- Set Scope: Volts/DIY. = .01 Time/DIV. 5 ms (AC)

- Check AC voltage between GND and EP104 and EP106.

EP104 = 8.5 VAC +/- 10%

EP106 = 8.5 VAC +/- 10%

- Set Scope: Volts/DIY. 1 Time/DIV. 5 ms

Internal SYNC.

- Check Waveform at PIN 7 of T502, Refer to Page 15 of

manual.

- Check ripple Waveform at G1 (PIN 5) CRT. PCB.

(Maximum 400 mv).

- Check output Waveform at PIN 10 and PIN 5 of IC401 -

These waveforms should be the same.

- Set Scope: Volts/DIV. = .05 Time = Sync external

SELECT TEST #1

- Loosen yoke clamp, push yoke tight against CRT bell.

-

Orient yoke to correct axis; tighten clamp. If dis-

tortion is still not acceptable, inspect yoke magnets.

- Do visual inspection of unit taking careful note of all

connectors, IC sockets and areas previously repaired.

I I I I I I I

plROBABLE CAUSE

D101 - D104

C111 & C110

T101

C514, C515

IC401

Yoke magnets missing

Bad yoke winding

" I I

SYMPTON

Picture off-center

Vertical size

incorrect

Poor lettering

Di s play, i. e. ,

Tilt & size

Picutre size

changed and

unstable when

input voltage

is normal

I I I I I

TOOLS/EC. NEEDED

Shop tools

Scope

Shop tool s--

Scope

DMM/DVM

VOM

Test Cartridge

Scope

DMM/DVM

Test Cartridge

. .

I I I I I

GCE

TROUBLESHOOTING GUIDE

VECTREX SYSTEM

TEST PROCEDURE

NOTE: VECTREX Orientation is from

the Rear Left to Right.

plROBABLE CAUSE

-

SELECT TEST #3 Adjustments incorrect

- Refer to Page 12 of manual - ilLogic Board

- Refer to Page 15 of manual - "Power Board

SELECT TEST # 4

.

-

," - . .

~ - ' l x i DAC 0 l\djusblent'-

. ,

- Do intergrator OFF - SET adjustment

page 15 of manual.

- SELECT TEST #5

SELECT TEST #3

- Check voltage at PIN 5 and PIN 8 of IC501

PIN 5 = 5VDC +/- 5%

PIN 8 = 3VDC +/- 5%

Adjustments".

Adjustments".

(Refer to

- Check waveform at PIN 7 of T502 and base of Q502,

these should be the same.

- Disconnect C504, check waveform at PIN 3 of IC501,

adjust R 525 and R 526 to conform to display on wave-

forms section (Refer to Waveforms, C) Page 15.

- Set Scope: Volts/DIV. = 1 Time/DIV. = .1 ms

internal.

, , , , , ,

IC305

IC303

IC301

IC401

Q301

IC305

IC303

IC301

R 333

R 335

C501, C517

IC501

R 505

T 501

R 527

T 502

, , ,

SYMPTON

Slanting of

announcement

and sub-title

display.

Picture dis-

tortion - long

and short of

picture.

TOOLS/EQ. NEEDED

Shop tools

Test Cartridge

Scope

DMM DVM

/

Test Cartridge

I I I I I I I I I I I I I I I I I I I I I I

GeE

TROUBLESHOOTING GUIDE

VECTREX SYSTEM

NOTE: VECTREX Orientation is from

the Rear Left to Right.

TEST PROCEDURE

SELECT TEST #1

- Display of Title Paqe

tilted, replace IC302. 1S

' .

- Printinq

-

inside Title Page is slanted, replace IC301.

.

SELECT TEST #3

Check Si nal waveform at J301 g

X Y (, )

I

\Compare these to Signal

r2spectively (return to

at R413 and R406 on

signal).

/

. ,.

Power PCB

P'ROBABLE CAUSE

IC302

IC301

Q 301

I

\ IC401

Mounting method of

IC401.

I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I , , ......

ATTACHMENT 1

VECTREX

ft

WAVEFORMS

x Y

X

=

A

Y

=

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Z

=

IC 401

~

..

PIN 7

B

~

PIN 8

IC 501

n'OJJ$

PIN 3

I I

I

C

~ 5 0 P S

~

J301

D

I I

f I:::C

PCB

1

X(R) Y(BL) Z(Y)

S-ar putea să vă placă și

- 79 Mattel Intellivision-ManualDocument14 pagini79 Mattel Intellivision-Manualluiz9fnandesÎncă nu există evaluări

- AQ12FANDocument9 paginiAQ12FANhdave32Încă nu există evaluări

- Atari Flashback 8 Instruction ManualDocument13 paginiAtari Flashback 8 Instruction ManualBill Loguidice0% (1)

- Atari Portable AP3228 IM Standard 20170619Document10 paginiAtari Portable AP3228 IM Standard 20170619Pat BergeÎncă nu există evaluări

- MODEL 5872: 5150 Rosecrans Avenue Hawthorne. California 90250Document27 paginiMODEL 5872: 5150 Rosecrans Avenue Hawthorne. California 90250JAIME ALBERTO MARTINEZ DIAZÎncă nu există evaluări

- Vectrex Service ManualDocument35 paginiVectrex Service Manualnegrelli-rnÎncă nu există evaluări

- Intellivision Service Manual, Model 2609 PDFDocument68 paginiIntellivision Service Manual, Model 2609 PDFChipytoÎncă nu există evaluări

- SEGA SATURN Instruction ManualDocument30 paginiSEGA SATURN Instruction ManualBlaze123xÎncă nu există evaluări

- NiGHTS - Journey of Dreams - WiiDocument12 paginiNiGHTS - Journey of Dreams - Wiimoloko68Încă nu există evaluări

- Mega-CD - Wikipedia, The Free EncyclopediaDocument8 paginiMega-CD - Wikipedia, The Free EncyclopediaHesreh SulpÎncă nu există evaluări

- Intellivision Black Whale Reverse Engineering Report 20180423b PDFDocument101 paginiIntellivision Black Whale Reverse Engineering Report 20180423b PDFzawarskiÎncă nu există evaluări

- Atari 2600 VCS Domestic Field Service ManualDocument156 paginiAtari 2600 VCS Domestic Field Service Manualkingbela100% (1)

- GBA Programming Manual v1.22Document172 paginiGBA Programming Manual v1.22proxymo1Încă nu există evaluări

- Assingments On LatchingDocument4 paginiAssingments On LatchingsalonyÎncă nu există evaluări

- 984-0110FS Full Size - R020212Document17 pagini984-0110FS Full Size - R020212Anonymous zSpR5jUdÎncă nu există evaluări

- Nintendo of America Inc. P.O. Box 957, Redmond, WA 98073-0957 U.S.ADocument18 paginiNintendo of America Inc. P.O. Box 957, Redmond, WA 98073-0957 U.S.AsuperwakkaÎncă nu există evaluări

- ELEGOO L298 Arduino TutorialDocument11 paginiELEGOO L298 Arduino TutorialAhmadiAnouarÎncă nu există evaluări

- 06 Ly7146bDocument9 pagini06 Ly7146bm.omeracarÎncă nu există evaluări

- "Sound Innovation, On Call": EMS5 Call Director Easy Set-Up InstructionsDocument19 pagini"Sound Innovation, On Call": EMS5 Call Director Easy Set-Up Instructionswayne mcmurrayÎncă nu există evaluări

- Owner'S Manual Owner'S Manual Owner'S Manual Owner'S Manual Owner'S ManualDocument106 paginiOwner'S Manual Owner'S Manual Owner'S Manual Owner'S Manual Owner'S ManualRodolfoÎncă nu există evaluări

- Sega Genesis Ultimate Portable User ManualDocument20 paginiSega Genesis Ultimate Portable User ManualSharif Shahadat100% (2)

- Swline User ManualDocument32 paginiSwline User ManualUmer FarooqÎncă nu există evaluări

- FR-BU Instruction ManualDocument20 paginiFR-BU Instruction ManualcoronaqcÎncă nu există evaluări

- Manuel Minivator 2000Document46 paginiManuel Minivator 2000TUPET81100% (1)

- 4-Reg. y Montaje - BUSDocument16 pagini4-Reg. y Montaje - BUSvÎncă nu există evaluări

- Atari 5200 VCS Adapter Modification PDFDocument5 paginiAtari 5200 VCS Adapter Modification PDFOscar Arthur KoepkeÎncă nu există evaluări

- DIY Quick Reference Guide - 3300Document5 paginiDIY Quick Reference Guide - 3300allbsforakÎncă nu există evaluări

- 078-0183-01B Intro To LonWorks Rev 2Document98 pagini078-0183-01B Intro To LonWorks Rev 2bradalbiÎncă nu există evaluări

- Design Guide VPLDocument28 paginiDesign Guide VPLKHA120096 StudentÎncă nu există evaluări

- 7.2 Safety Brake - Q 409 710: 1 Description and Mode of OperationDocument7 pagini7.2 Safety Brake - Q 409 710: 1 Description and Mode of OperationDobra Alexandru RomeoÎncă nu există evaluări

- BSG001A RulebookDocument32 paginiBSG001A RulebookDavid HuntÎncă nu există evaluări

- ECD-2010 UM RevAocrDocument66 paginiECD-2010 UM RevAocrsÎncă nu există evaluări

- ETSD Emergency Traction Slowdown Installation and Operation InstructionsDocument1 paginăETSD Emergency Traction Slowdown Installation and Operation InstructionsfreddyjoertyÎncă nu există evaluări

- Genesis User Manual PDFDocument451 paginiGenesis User Manual PDFPolkadots3Încă nu există evaluări

- Dynamic Braking Resistor Chopper CircuitDocument5 paginiDynamic Braking Resistor Chopper CircuitAri SutejoÎncă nu există evaluări

- Apple 2 Computer Information - Document 532 - Schematic 050-0051-DDocument5 paginiApple 2 Computer Information - Document 532 - Schematic 050-0051-DGabriel GarciaÎncă nu există evaluări

- AP47 TechnicalHB RulesDocument30 paginiAP47 TechnicalHB RulesMichael DaoÎncă nu există evaluări

- ETSD Emergency TRaction Slowdown Test ProcedureDocument5 paginiETSD Emergency TRaction Slowdown Test ProcedurefreddyjoertyÎncă nu există evaluări

- Contactors and Relay PartsDocument42 paginiContactors and Relay Partswayne mcmurrayÎncă nu există evaluări

- Personal Computer Embedded Type Servo System Controller: - MR-EM340GFDocument670 paginiPersonal Computer Embedded Type Servo System Controller: - MR-EM340GFAbdÎncă nu există evaluări

- Almega Manual 1Document63 paginiAlmega Manual 1Tecwyn WebsterÎncă nu există evaluări

- Buck Rogers (Gottlieb) (1980) Manual PDFDocument23 paginiBuck Rogers (Gottlieb) (1980) Manual PDFCarlos André Guizzo0% (1)

- General-Controller-Manual-VVVFDocument47 paginiGeneral-Controller-Manual-VVVFBeltran HéctorÎncă nu există evaluări

- Gyrators To Replace PSU ChokesDocument3 paginiGyrators To Replace PSU Chokeschuongdv100% (2)

- Sega Mega CD DatabaseDocument21 paginiSega Mega CD DatabaseAnonymous wFFQEvGRlMÎncă nu există evaluări

- Wiring DiagramDocument6 paginiWiring DiagramZoran ProkicÎncă nu există evaluări

- 100 - 1. Lift Controller ManualDocument41 pagini100 - 1. Lift Controller ManualDjordje GavrilovicÎncă nu există evaluări

- 3773b - en - SM-POS - Quick Start Commissioning GuideDocument24 pagini3773b - en - SM-POS - Quick Start Commissioning GuideBruno RochaÎncă nu există evaluări

- Binder 1Document36 paginiBinder 1BobbyÎncă nu există evaluări

- G..26160B.tension Carriage.508.512Document3 paginiG..26160B.tension Carriage.508.512Jean ChungÎncă nu există evaluări

- Portable Elevator Tool 7100 1120 302 A0Document33 paginiPortable Elevator Tool 7100 1120 302 A0Mhamad ArabiÎncă nu există evaluări

- Danbury Flight School Cessna 172SP G1000 ChecklistDocument13 paginiDanbury Flight School Cessna 172SP G1000 ChecklistGeorge SandovalÎncă nu există evaluări

- Baldor - Spindle Drive Instructions, 7500 WD Tuning v11-4Document7 paginiBaldor - Spindle Drive Instructions, 7500 WD Tuning v11-4Asif JamilÎncă nu există evaluări

- FPGA-Based Video GamesDocument3 paginiFPGA-Based Video Gameswahyan100% (1)

- U2Document4 paginiU2TouficFereidÎncă nu există evaluări

- Kss 240Document2 paginiKss 240dr_best_001Încă nu există evaluări

- Subassembl V Service Manual: Ntellivision"Document21 paginiSubassembl V Service Manual: Ntellivision"ChipytoÎncă nu există evaluări

- Carrier Primeline Troubleshooting Note 3Document4 paginiCarrier Primeline Troubleshooting Note 3Paul CraciuneanuÎncă nu există evaluări

- KORG KROSS Service ManualDocument28 paginiKORG KROSS Service ManualCarlosÎncă nu există evaluări

- Service Manual Europa BDocument68 paginiService Manual Europa BMarco Orlandi69% (16)

- Maz18 Maz38 ManualDocument5 paginiMaz18 Maz38 Manualheritage336Încă nu există evaluări

- V 112Document4 paginiV 112simon_someone217Încă nu există evaluări

- Akpark: Cover Sheet - ElectricalDocument10 paginiAkpark: Cover Sheet - ElectricalEngr M.Arshad KhalidÎncă nu există evaluări

- AC 43.13-1B Section 5 Penetrant InspectionDocument8 paginiAC 43.13-1B Section 5 Penetrant Inspection320338100% (1)

- ADPDocument165 paginiADPmohhizbarÎncă nu există evaluări

- TGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular PositionDocument10 paginiTGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular Positionvinodk335Încă nu există evaluări

- Kata LogDocument48 paginiKata LogsofiakeramikÎncă nu există evaluări

- LinuxDocument206 paginiLinuxDinesh BhawnaniÎncă nu există evaluări

- ASAP MethodologyDocument14 paginiASAP MethodologyTiffany HughesÎncă nu există evaluări

- Erpi Admin 11123510Document416 paginiErpi Admin 11123510prakash9565Încă nu există evaluări

- 03 Vetotouch Europa - Group 170821Document2 pagini03 Vetotouch Europa - Group 170821HalaÎncă nu există evaluări

- MAX32xx, Serial To TTLDocument17 paginiMAX32xx, Serial To TTLDecker JamesÎncă nu există evaluări

- Guidelines For Ceiling Framing WorksDocument3 paginiGuidelines For Ceiling Framing WorksRal GLÎncă nu există evaluări

- 5950 Part 1-1990Document120 pagini5950 Part 1-1990José Miguel100% (1)

- Design and Analysis For Crane HookDocument6 paginiDesign and Analysis For Crane Hookmukeshsonava076314Încă nu există evaluări

- CrcwikiDocument8 paginiCrcwikiPratik MahajanÎncă nu există evaluări

- Removal of SO2 From Low Sulfur Coal Combustion Gases by Limestone ScrubbingDocument12 paginiRemoval of SO2 From Low Sulfur Coal Combustion Gases by Limestone ScrubbingCaballero MarioÎncă nu există evaluări

- Exxon 6101Document2 paginiExxon 6101M. Kürşad ArslanÎncă nu există evaluări

- General Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptDocument3 paginiGeneral Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptNatasha de SilvaÎncă nu există evaluări

- Cama Stryker Sv2-Service ManualDocument117 paginiCama Stryker Sv2-Service ManualjoelpalzaÎncă nu există evaluări

- Instructions VbamDocument2 paginiInstructions VbamAustin Yu LiuÎncă nu există evaluări

- CPP ReportDocument5 paginiCPP ReportSujay Hazra100% (1)

- J Fluids Engineering 2009 Vol 131 N4Document120 paginiJ Fluids Engineering 2009 Vol 131 N4Нильва АлександрÎncă nu există evaluări

- Ce 506 Prestressed Concrete Design: M R M M MDocument2 paginiCe 506 Prestressed Concrete Design: M R M M Mbadr amÎncă nu există evaluări

- Craftsman 82141 User ManualDocument36 paginiCraftsman 82141 User ManualJoe100% (1)

- Enel2ea Tut 5 Rev1Document7 paginiEnel2ea Tut 5 Rev1NOMPUMELELO MTHETHWAÎncă nu există evaluări

- Chapter 3 Waveform Coding Techniques PDFDocument33 paginiChapter 3 Waveform Coding Techniques PDFEunielyn SecretoÎncă nu există evaluări

- UNNPX206R3Document4 paginiUNNPX206R3David OlayaÎncă nu există evaluări

- Computer Graphics - Lesson PlanDocument15 paginiComputer Graphics - Lesson PlansoniadrallÎncă nu există evaluări

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDe la EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialEvaluare: 3.5 din 5 stele3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDe la EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeEvaluare: 4.5 din 5 stele4.5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDe la EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosEvaluare: 5 din 5 stele5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDe la EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceÎncă nu există evaluări

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDe la EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesEvaluare: 5 din 5 stele5/5 (1)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDe la EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonEvaluare: 5 din 5 stele5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4.5 din 5 stele4.5/5 (543)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDe la EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsEvaluare: 3.5 din 5 stele3.5/5 (2)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)De la EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Evaluare: 4.5 din 5 stele4.5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesDe la EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesEvaluare: 5 din 5 stele5/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsDe la EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovÎncă nu există evaluări

- Current Interruption Transients CalculationDe la EverandCurrent Interruption Transients CalculationEvaluare: 4 din 5 stele4/5 (1)

- Practical Electronics for Inventors, Fourth EditionDe la EverandPractical Electronics for Inventors, Fourth EditionEvaluare: 4 din 5 stele4/5 (3)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)De la EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Încă nu există evaluări

- Build Your Own Electric Vehicle, Third EditionDe la EverandBuild Your Own Electric Vehicle, Third EditionEvaluare: 4.5 din 5 stele4.5/5 (3)

- Understanding Automotive Electronics: An Engineering PerspectiveDe la EverandUnderstanding Automotive Electronics: An Engineering PerspectiveEvaluare: 3.5 din 5 stele3.5/5 (16)

- Teach Yourself Electricity and Electronics, 6th EditionDe la EverandTeach Yourself Electricity and Electronics, 6th EditionEvaluare: 3.5 din 5 stele3.5/5 (15)