Documente Academic

Documente Profesional

Documente Cultură

Cylinder Head Removal and Installation Guide

Încărcat de

Mohamad ZuhailiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cylinder Head Removal and Installation Guide

Încărcat de

Mohamad ZuhailiDrepturi de autor:

Formate disponibile

CYLINDER HEAD ASSEMBLY

MECHANICAL

19.Cylinder Head Assembly

A: REMOVAL

1) Remove the V-belt. <Ref. to ME(STi)-41, REMOVAL, V-belt.> 2) Remove the crankshaft pulley. <Ref. to ME(STi)44, REMOVAL, Crankshaft Pulley.> 3) Remove the timing belt cover. <Ref. to ME(STi)45, REMOVAL, Timing Belt Cover.> 4) Remove the timing belt assembly. <Ref. to ME(STi)-46, REMOVAL, Timing Belt Assembly.> 5) Remove the camshaft sprocket. <Ref. to ME(STi)-54, REMOVAL, Camshaft Sprocket.> 6) Remove the intake manifold. <Ref. to FU(STi)14, REMOVAL, Intake Manifold.> 7) Remove the bolt which installs the A/C compressor bracket on cylinder head. 8) Remove the camshaft. <Ref. to ME(STi)-57, REMOVAL, Camshaft.> 9) Remove the cylinder head bolts in alphabetical sequence shown in the figure. Leave bolts (A) and (D) engaged by three or four threads to prevent the cylinder head from falling.

(D) (F) (A)

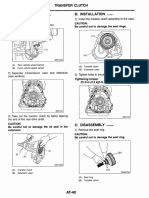

B: INSTALLATION

1) Install the cylinder head and gaskets on cylinder block. NOTE: Use new cylinder head gaskets. Be careful not to scratch the mating surface of cylinder head and cylinder block. 2) Tighten the cylinder head bolts. (1) Apply a coat of engine oil to the washers and bolt threads. (2) Tighten all bolts to 29 Nm (3.0 kgf-m, 22 ftlb) in alphabetical sequence. (3) Tighten all bolts to 69 Nm (7.0 kgf-m, 51 ftlb) in alphabetical sequence again. (4) Back off all bolts by 180 first; back them off by 180 again in reverse order of installation. (5) Tighten all bolts to 49 Nm (5.0 kgf-m, 36 ftlb) in alphabetical sequence. (6) Tighten all bolts 80 to 90 in alphabetical sequence. (7) Tighten all bolts by 40 to 45 in alphabetical sequence again. NOTE: Do not tighten the bolts by more than 45. (8) Further tighten all bolts (A) and (B) by 40 to 45. NOTE: Ensure that the total re-tightening angle in the previous two steps do not exceed 90.

(B)

(E)

(C) ME-00122 (C) (A) (F)

10) While tapping the cylinder head with a plastic hammer, separate it from cylinder block. Remove the bolts (A) and (D) to remove cylinder head.

(E) (D) (F) (A) ME-00123 (B) (D)

(B)

(E)

(C) ME-00122

11) Remove the cylinder head gasket. NOTE: Do not scratch the mating surface of cylinder head and cylinder block. 12) Similarly, remove the cylinder head (RH).

3) Install the camshaft. <Ref. to ME(STi)-58, INSTALLATION, Camshaft.> 4) Install the A/C compressor bracket on cylinder head. 5) Install the intake manifold. <Ref. to FU(STi)-16, INSTALLATION, Intake Manifold.> 6) Install the camshaft sprocket. <Ref. to ME(STi)54, INSTALLATION, Camshaft Sprocket.> 7) Install the timing belt assembly. <Ref. to ME(STi)-48, INSTALLATION, Timing Belt Assembly.> 8) Install the timing belt cover. <Ref. to ME(STi)-45, INSTALLATION, Timing Belt Cover.>

ME(STi)-63

CYLINDER HEAD ASSEMBLY

MECHANICAL

9) Install the crankshaft pulley. <Ref. to ME(STi)44, INSTALLATION, Crankshaft Pulley.> 10) Install the V-belt. <Ref. to ME(STi)-41, INSTALLATION, V-belt.>

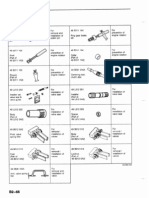

C: DISASSEMBLY

1) Remove the valve lifters. 2) Compress the valve spring and remove the valve spring retainer key. Remove each valve and valve spring. ST1 498267600 CYLINDER HEAD TABLE ST2 499718000 VALVE SPRING REMOVER NOTE: Keep the removed parts in order for re-installing in their original positions. Mark each valve to prevent confusion. Use extreme care not to damage the lips of the intake valve oil seals and exhaust valve oil seals.

ST2

ST1

ME-00124

ME(STi)-64

CYLINDER HEAD ASSEMBLY

MECHANICAL

D: ASSEMBLY

(1) (3)

(11)

(4)

(5)

(6)

(7)

(8)

(9)

(2)

(11)

(4)

(5)

(6)

(7)

(8)

(9)

(12) (4) (10) (6) (12) (4) (10) (6) (7) (8) (9) (7) (8) (9)

ME-00795

(1) (2) (3) (4)

Exhaust valve Intake valve Cylinder head Valve spring seat

(5) (6) (7) (8)

Intake valve oil seal Valve spring Retainer Retainer key

(9) (10) (11) (12)

Valve lifter Exhaust valve oil seal Intake valve guide Exhaust valve guide

ME(STi)-65

CYLINDER HEAD ASSEMBLY

MECHANICAL

1) Installation of valve spring and valve: (1) Coat the stem of each valve with engine oil and insert the valve into valve guide. NOTE: When inserting the valve into valve guide, use special care not to damage the oil seal lip. (2) Set the cylinder head on ST1. (3) Install the valve spring and retainer using ST2. ST1 498267600 CYLINDER HEAD TABLE ST2 499718000 VALVE SPRING REMOVER NOTE: Be sure to install the valve springs with their closecoiled end facing the seat on cylinder head.

NOTE: Uneven torque for the cylinder head nuts can cause warping. When reassembling, pay special attention to the torque so as to tighten evenly.

(A)

(B) ME-00126

2. VALVE SEAT

ST2

Inspect the intake and exhaust valve seats, and then correct the contact surfaces with valve seat cutter if they are defective or when valve guides are replaced. Valve seat width: W Intake Standard 1.0 mm (0.039 in) Limit 1.7 mm (0.067 in) Exhaust Standard 1.5 mm (0.059 in) Limit 2.2 mm (0.087 in)

ST1

ME-00124

(4) Compress the valve spring, and then fit the valve spring retainer key. (5) After installing, tap the valve spring retainers lightly with wooden hammer for better seating. 2) Apply oil to the surface of the valve lifter. 3) Install the valve lifter.

E: INSPECTION

1. CYLINDER HEAD

1) Make sure that no crack or other damage exists. In addition to visual inspection, inspect the important areas by means of red check. 2) Measure the warping of the cylinder head surface that mates with crankcase by using a straight edge (A) and thickness gauge (B). If the warping exceeds 0.05 mm (0.0020 in), regrind the surface with a surface grinder. Warping limit: 0.05 mm (0.0020 in) Grinding limit: 0.3 mm (0.012 in) Standard height of cylinder head: 127.5 mm (5.02 in)

ME-00127

3. VALVE GUIDE

1) Check the clearance between valve guide and stem. The clearance can be checked by measuring the outside diameter of valve stem and the inside diameter of valve guide with outside and inside micrometers respectively. Clearance between the valve guide and valve stem:

ME(STi)-66

CYLINDER HEAD ASSEMBLY

MECHANICAL

Standard Intake 0.030 0.057 mm (0.0012 0.0022 in) Exhaust 0.040 0.067 mm (0.0016 0.0026 in) Limit 0.15 mm (0.0059 in) 2) If the clearance between valve guide and stem exceeds the limit, replace the valve guide or valve itself whichever shows greater amount of wear. See the following procedure for valve guide replacement. Valve guide inner diameter: 6.000 6.012 mm (0.2362 0.2367 in) Valve stem outer diameters: Intake 5.955 5.970 mm (0.2344 0.2350 in) Exhaust 5.945 5.960 mm (0.2341 0.2346 in) (1) Place the cylinder head on ST1 with the combustion chamber upward so that valve guides enter the holes in ST1. (2) Insert the ST2 into valve guide and press it down to remove the valve guide. ST1 498267600 CYLINDER HEAD TABLE ST2 499767200 VALVE GUIDE REMOVER

ST2

(4) Before installing a new valve guide, make sure that neither scratches nor damages exist on the inside surface of the valve guide holes in cylinder head. (5) Put a new valve guide, coated with sufficient oil, in cylinder, and insert ST1 into valve guide. Press in until the valve guide upper end is flush with the upper surface of ST2. ST1 499767200 VALVE GUIDE REMOVER ST2 18251AA020 VALVE GUIDE ADJUSTER

ST1 ST2

ME-00130

(6) Check the valve guide protrusion. Valve guide protrusion: L 15.8 16.2 mm (0.622 0.638 in) (7) Ream the inside of valve guide with ST. Gently rotate the reamer clockwise while pressing it lightly into the valve guide, and return it also rotating clockwise. After reaming, clean the valve guide to remove chips. ST 499767400 VALVE GUIDE REAMER NOTE: Apply engine oil to the reamer when reaming. If the inner surface of the valve guide is torn, the edge of the reamer should be slightly ground with an oil stone. If the inner surface of the valve guide becomes lustrous and the reamer does not chip, use a new reamer or remedy the reamer. (8) Recheck the contact condition between valve and valve seat after replacing the valve guide.

ST1 ME-00128

(3) Turn the cylinder head upside down and place ST as shown in the figure. ST 18251AA020 VALVE GUIDE ADJUSTER

ST

ME-00757

ME(STi)-67

CYLINDER HEAD ASSEMBLY

MECHANICAL

4. INTAKE AND EXHAUST VALVE

1) Inspect the flange and stem of valve, and replace if damaged, worn, or deformed, or if H is less than the specified limit. H: Intake (A) Standard 1.2 mm (0.047 in) Limit 0.8 mm (0.031 in) Exhaust (B) Standard 1.5 mm (0.059 in) Limit 0.8 mm (0.031 in) Valve overall length: Intake (A) 104.4 mm (4.110 in) Exhaust (B) 104.65 mm (4.120 in)

Free length Set Tension/spring height Lift Squareness

Valve spring 47.32 mm (1.863 in) 205 235 N (20.9 24.0 kgf, 46.1 52.8 lb) /36.0 mm (1.417 in) 426 490 N (43.4 50.0 kgf, 95.8 110 lb) /26.45 mm (1.041 in) 2.5, 2.1 mm (0.083 in)

ME-00132

6. INTAKE AND EXHAUST VALVE OIL SEAL

(A)

Replace the oil seal with a new one, if the lip is damaged or spring out of place, or when the surfaces of intake valve and valve seat are reconditioned or intake valve guide is replaced. 1) Place the cylinder head on ST1. 2) Press in the oil seal to the specified dimension indicated in the figure by using ST2. ST1 498267600 CYLINDER HEAD TABLE ST2 498857100 VALVE OIL SEAL GUIDE NOTE: Apply engine oil to oil seal before press-fit. Differentiate between the intake valve oil seal and exhaust valve oil seal by noting their difference in color. Color of rubber part: Intake [Black] Exhaust [Brown]

ME-00758

(B)

2) Put a small amount of grinding compound on the seat surface and lap the valve and seat surface. Install a new intake valve oil seal after lapping.

Color of spring part: Intake [White] Exhaust [White]

5. VALVE SPRINGS

1) Check the valve springs for damage, free length, and tension. Replace the valve spring if it is not within specifications presented in the table. 2) To measure the squareness of valve spring, stand the spring on a surface plate and measure its deflection at the top using a try square.

ST2

ME-00133

ME(STi)-68

CYLINDER HEAD ASSEMBLY

MECHANICAL

7. VALVE LIFTER

1) Visually check the valve lifter. 2) Measure the outer diameter of valve lifter. Outer diameter: 34.959 34.975 mm (1.3763 1.3770 in)

1) If the valve is damaged, remove the valve and neutralize it by immersing it in water, and dispose of it in the same way that general steel materials are disposed of. The disposal method is described in the following. (1) Wearing rubber gloves, remove the damaged valve from the cylinder head. (2) Prepare a large receptacle (bucket or other container) in a well ventilated location, and fill the receptacle with water (at least 10 liters). (3) Immerse the damaged valve in the receptacle. CAUTION: A severe reaction may occur, so stand at least 2 3 m from the receptacle. Because the reaction will produce hydrogen gas, moreover, keep the receptacle away from sparks or flames. (4) Once the reaction is completed (about 4 5 hours have elapsed), carefully remove the valve using large pincers so that the reaction liquid does not contact your skin, and dispose of it with other parts that are being disposed of. (5) The reaction liquid is a strong alkaline solution, so it must be disposed of in accordance with local regulations. CAUTION: Make sure the reaction liquid does not contact your skin. If contact with skin occurs, immediately wash the affected area with large quantities of water.

ME-00134

3) Measure the inner diameter of valve lifter mating part on cylinder head. Inner diameter: 34.994 35.016 mm (1.3777 1.3786 in)

ME-00135

NOTE: If difference between outer diameter of valve lifter and inner diameter of valve lifter mating part is over the limit, replace the cylinder head. Standard: 0.019 0.057 mm (0.0007 0.0022 in) Limit: 0.100 mm (0.0039 in)

ME-00755

F: DISPOSAL

CAUTION: Metallic sodium is enclosed in the exhaust valve. Metallic sodium is extremely alkaline and may produce severe chemical reactions. Full consideration must therefore be given to the following points when handling or disposing of the valve. Since metallic sodium may cause blindness if contacted with the eyes, burns if contacted with the skin, and fire, do not deliberately take the valve apart.

ME(STi)-69

S-ar putea să vă placă și

- MSA5T0122A27579Document8 paginiMSA5T0122A27579miguelÎncă nu există evaluări

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocument8 pagini2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozÎncă nu există evaluări

- Procedimietos CulataDocument15 paginiProcedimietos CulataSERVICIO TECNICO AUTOMOTRIZ TONATOÎncă nu există evaluări

- Replace Timing Belt AssemblyDocument8 paginiReplace Timing Belt AssemblySteve FosterÎncă nu există evaluări

- 007008Document22 pagini007008susanta_kumarÎncă nu există evaluări

- Injector Installation 107 EngineDocument5 paginiInjector Installation 107 EnginevalterripÎncă nu există evaluări

- Reglaje de ValvulasDocument15 paginiReglaje de ValvulasJuan Antonio Ochoa PadronÎncă nu există evaluări

- Manual Repair Nissan QuestDocument18 paginiManual Repair Nissan QuestALONDRA NATALI GONAZLEZ CANCHEÎncă nu există evaluări

- Adjust Valve Clearance 1ZZ-FE EngineDocument11 paginiAdjust Valve Clearance 1ZZ-FE EngineAlan Dell SnyderÎncă nu există evaluări

- Genesis Coupe Cylinder Head Components and Repair GuideDocument21 paginiGenesis Coupe Cylinder Head Components and Repair GuideCristian.E.B100% (1)

- Yanmar 4tne88 TNE Series PDFDocument15 paginiYanmar 4tne88 TNE Series PDFluna281068Încă nu există evaluări

- MT-TITLEDocument66 paginiMT-TITLERolfs Almonte DiazÎncă nu există evaluări

- Clutch Echo 2002Document17 paginiClutch Echo 2002Tomas DominguezÎncă nu există evaluări

- Front Differential AssemblyDocument8 paginiFront Differential AssemblySethu RamÎncă nu există evaluări

- 2rz - Valve Clearance InspectionDocument5 pagini2rz - Valve Clearance Inspectionberdeaberdea100% (1)

- Toyota Matrix Timing Chain Removal and Installation GuideDocument16 paginiToyota Matrix Timing Chain Removal and Installation GuideGesco EscobarÎncă nu există evaluări

- Ac Compressor ServicingDocument25 paginiAc Compressor Servicingsonny1234100% (1)

- Cylinder Head 3sfeDocument27 paginiCylinder Head 3sfePham Huy83% (18)

- Detroit 8.2 v8Document25 paginiDetroit 8.2 v8Jose Juan Davila100% (3)

- A32 MTDocument47 paginiA32 MTLevin Tan HtÎncă nu există evaluări

- Manutencao Caixa Direcao Hilux PDFDocument12 paginiManutencao Caixa Direcao Hilux PDFseverinocvÎncă nu există evaluări

- Cam Shaft Removal and InstallationDocument9 paginiCam Shaft Removal and InstallationAlexander Dominguez0% (1)

- Engine Assembly Tools and Torque SpecificationsDocument13 paginiEngine Assembly Tools and Torque SpecificationsJacob SilverstielkÎncă nu există evaluări

- Accent Cylinder Head AssemblyDocument30 paginiAccent Cylinder Head Assemblyflash_24014910Încă nu există evaluări

- Timing Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalDocument7 paginiTiming Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalPablo FernandezÎncă nu există evaluări

- Cylinder HeadDocument2 paginiCylinder Headsteven_hoyt8914Încă nu există evaluări

- TRANSFER CLUTCH REMOVAL AND INSTALLATIONDocument6 paginiTRANSFER CLUTCH REMOVAL AND INSTALLATIONorangewedge32Încă nu există evaluări

- 1kd FTV OverhaulDocument37 pagini1kd FTV OverhaulJehuty8897% (34)

- Remo TBDocument5 paginiRemo TBTyler MacÎncă nu există evaluări

- Timing Chain Oil SealDocument2 paginiTiming Chain Oil SealEduardo Segundo Gonzalez MuñozÎncă nu există evaluări

- 4d94e Shop ManualDocument25 pagini4d94e Shop Manualyeudys100% (4)

- Motor 3054#2Document71 paginiMotor 3054#2mateo apolinar95% (19)

- Timing Belt Replacement Guide for 5S−FE EngineDocument14 paginiTiming Belt Replacement Guide for 5S−FE EnginechasquareÎncă nu există evaluări

- REAR AXLE (Single Tyre)Document4 paginiREAR AXLE (Single Tyre)MochamadIsmail Ninjutsu FromhellÎncă nu există evaluări

- Toyota Highlander Timing Chain Replacement GuideDocument14 paginiToyota Highlander Timing Chain Replacement GuideOscar jhonyffer Pereda RiscoÎncă nu există evaluări

- Motor ProboxDocument12 paginiMotor ProboxrufuruÎncă nu există evaluări

- 10 - Timing Chain - InstallationDocument7 pagini10 - Timing Chain - Installation08088338Încă nu există evaluări

- 1HD-T 2Document37 pagini1HD-T 2HERMAWAN100% (2)

- Remove & Install Bucket CylinderDocument8 paginiRemove & Install Bucket CylinderchanlinÎncă nu există evaluări

- Propeller ShaftDocument13 paginiPropeller Shaftmika DataÎncă nu există evaluări

- Medidas e Torques (C15 C18)Document50 paginiMedidas e Torques (C15 C18)caiocunhaconquista100% (1)

- Oilpump4afe PDFDocument7 paginiOilpump4afe PDFhanzhio elÎncă nu există evaluări

- Desmontaje de Culata-800240Document35 paginiDesmontaje de Culata-800240Juan Esteban Arango ArangoÎncă nu există evaluări

- Hyundai Santa Fé 2.7L 2008 - Cabeçote - Remoção Recolocação PDFDocument31 paginiHyundai Santa Fé 2.7L 2008 - Cabeçote - Remoção Recolocação PDFLeonardo Limberger0% (1)

- RAV Engine ManualDocument24 paginiRAV Engine ManualIsaac Okorie zakuÎncă nu există evaluări

- 4-Speed Transmission ManualDocument9 pagini4-Speed Transmission ManualashkansoheylÎncă nu există evaluări

- EECD0001Document36 paginiEECD0001Sergey Gusev100% (3)

- Cr250 Engine Service ManualDocument21 paginiCr250 Engine Service ManualGary Cline100% (1)

- Zx200 5g Engine ManualDocument36 paginiZx200 5g Engine Manualeviton luisÎncă nu există evaluări

- 018 - Rocker ArmDocument5 pagini018 - Rocker Armmax_simonsÎncă nu există evaluări

- Overhaul 4 & 5 SpeedDocument22 paginiOverhaul 4 & 5 SpeedJeff PascoeÎncă nu există evaluări

- Toyota Prius Timing Chain Service GuideDocument13 paginiToyota Prius Timing Chain Service Guidefernando ortizÎncă nu există evaluări

- Volvo Penta Workshop Manual Part BDocument60 paginiVolvo Penta Workshop Manual Part BMišo Vučko100% (1)

- E Mopi TS005 eDocument8 paginiE Mopi TS005 emikestifflerÎncă nu există evaluări

- SECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyDocument35 paginiSECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyHassan Vela VenegasÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Checklist Method of Statement Ref: Midr No. Midr/Sfsb/Bobe/Ins-001Document1 paginăChecklist Method of Statement Ref: Midr No. Midr/Sfsb/Bobe/Ins-001Mohamad ZuhailiÎncă nu există evaluări

- Ball Valve InspectionDocument1 paginăBall Valve InspectionMohamad ZuhailiÎncă nu există evaluări

- Thank YouDocument1 paginăThank YouMohamad ZuhailiÎncă nu există evaluări

- Thanks ScribdDocument1 paginăThanks ScribdMohamad ZuhailiÎncă nu există evaluări

- Leakage Acceptance Rates Comparison Metal & Soft SEATED VALVES ISO 5208/API 598/API 6D/MSS SP-61/FCI 70-2Document5 paginiLeakage Acceptance Rates Comparison Metal & Soft SEATED VALVES ISO 5208/API 598/API 6D/MSS SP-61/FCI 70-2nirbhay111Încă nu există evaluări

- AmatureDocument1 paginăAmatureMohamad ZuhailiÎncă nu există evaluări

- BallValve PDFDocument116 paginiBallValve PDFMohamad ZuhailiÎncă nu există evaluări

- NORSOK Standard-Compact Flanged ConnectionsDocument93 paginiNORSOK Standard-Compact Flanged Connectionsകന്നിമേൽ ആശിഷ് നായർÎncă nu există evaluări

- BallValve PDFDocument116 paginiBallValve PDFMohamad ZuhailiÎncă nu există evaluări

- Questions: AnswerDocument5 paginiQuestions: AnswerMuhammad El-FahamÎncă nu există evaluări

- Sinorix™: A6V10867394 - en - c2 Building Technologies 2017-06-06 Control Products and SystemsDocument4 paginiSinorix™: A6V10867394 - en - c2 Building Technologies 2017-06-06 Control Products and SystemsEngineering TFIÎncă nu există evaluări

- Positioning Strain Gages To Monitor Bending, Axial, Shear, and Torsional LoadsDocument2 paginiPositioning Strain Gages To Monitor Bending, Axial, Shear, and Torsional LoadsPrakash VasudevanÎncă nu există evaluări

- Module-3: Kinematics: ExercisesDocument1 paginăModule-3: Kinematics: ExercisesHamza SiddiquiÎncă nu există evaluări

- Instrukcja Obslugi Subaru Legacy 2004 (ENG)Document33 paginiInstrukcja Obslugi Subaru Legacy 2004 (ENG)malypebikÎncă nu există evaluări

- Fluid and Fluid PropertiesDocument42 paginiFluid and Fluid PropertiesCIPETIPT Tool RoomÎncă nu există evaluări

- Bobcat 843 Service Repair Manual PDFDocument520 paginiBobcat 843 Service Repair Manual PDFservimaquinados plazas sas56% (9)

- Annual scissor lift inspection reportDocument1 paginăAnnual scissor lift inspection reportWisnu WardhanaÎncă nu există evaluări

- Western Cabinet Inner and Outer Forming Line Operation MannualDocument50 paginiWestern Cabinet Inner and Outer Forming Line Operation Mannualvikrant singhÎncă nu există evaluări

- Dead loads and gravity framing designDocument3 paginiDead loads and gravity framing designYURITZI MARTINEZ CUELLARÎncă nu există evaluări

- Strengthening Mechanisms ExplainedDocument74 paginiStrengthening Mechanisms ExplainedRyan TorresÎncă nu există evaluări

- Permanent Magnet DC MotorDocument4 paginiPermanent Magnet DC MotorSourav Kumar100% (1)

- Modeling Cracked Behavior of Shear Walls in ETABSDocument2 paginiModeling Cracked Behavior of Shear Walls in ETABSjadlouis100% (3)

- Repair Stuck Grease Pumps EX2600-7Document7 paginiRepair Stuck Grease Pumps EX2600-7TLK ChannelÎncă nu există evaluări

- Integrated Control of Braking and SteeringDocument10 paginiIntegrated Control of Braking and SteeringakkkkÎncă nu există evaluări

- PC2000-8 Shop ManualDocument1.348 paginiPC2000-8 Shop ManualPeetÎncă nu există evaluări

- Fluid Flow Measurement Techniques and DevicesDocument75 paginiFluid Flow Measurement Techniques and DevicesArah Louise ApostolÎncă nu există evaluări

- Assemble Xootr Scooter in Under 20 MinutesDocument1 paginăAssemble Xootr Scooter in Under 20 MinutesPulkit AggarwalÎncă nu există evaluări

- Relativity QuestionsDocument4 paginiRelativity QuestionsChristoph KirchÎncă nu există evaluări

- An Insight of Compacted Graphite Iron (Cgi) Characteristics and Its Production A ReviewDocument18 paginiAn Insight of Compacted Graphite Iron (Cgi) Characteristics and Its Production A ReviewMiguel BrionesÎncă nu există evaluări

- Rigid Pavement Thesis 3Document12 paginiRigid Pavement Thesis 3san htet aungÎncă nu există evaluări

- Difference Between Spillback and Minimum Circulation Line - Google SearchDocument1 paginăDifference Between Spillback and Minimum Circulation Line - Google SearchGourav KumarÎncă nu există evaluări

- Depressurisation - A Practical GuideDocument20 paginiDepressurisation - A Practical GuideAhmad Firman Masudi100% (2)

- Industrial Project Report (WPS)Document79 paginiIndustrial Project Report (WPS)Khairil Anwar MuhajirÎncă nu există evaluări

- Rav M05 0001Document40 paginiRav M05 0001DanielDeFrancescoÎncă nu există evaluări

- Kurt Pamvouxoglou KDE11 20SS Service - Manual PDFDocument111 paginiKurt Pamvouxoglou KDE11 20SS Service - Manual PDFرحمة هداية اللهÎncă nu există evaluări

- Kirloskar SP 3HH Leaflet (A)Document2 paginiKirloskar SP 3HH Leaflet (A)Imran_firdousiÎncă nu există evaluări

- Seahawk Cement Unit 2300 BHP AC Electric: Available OptionsDocument2 paginiSeahawk Cement Unit 2300 BHP AC Electric: Available Optionsbruce lianÎncă nu există evaluări

- Science 8 q1 w3Document12 paginiScience 8 q1 w3Je-ann AcuÎncă nu există evaluări

- Leser US Order Price Information 2012Document204 paginiLeser US Order Price Information 2012Matheus de AlmeidaÎncă nu există evaluări