Documente Academic

Documente Profesional

Documente Cultură

PTC Korea

Încărcat de

A Rahim A Bakar0 evaluări0% au considerat acest document util (0 voturi)

61 vizualizări11 paginiDrepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

61 vizualizări11 paginiPTC Korea

Încărcat de

A Rahim A BakarDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 11

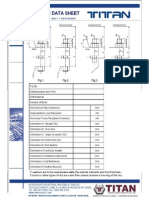

DISC FLEXIBLE COUPLING

PTC PT couplings CoHO

'" ':

;

r

DISC FLE)(BLE COUPLING

1. !:i (Characteristic)

gI71 [LH.OlI

04, gi.:Jl

Et7:l101

L

H Nt5AI !::!

gi o::! 4-@:J

?lHf5fJl 9.le{

ti e!j2.1 [,

o

4. =iCf

.2.7:t2.1 61 $fj 7 ==I 71 rlH .Oll A Oll

it 'Btljl 4- cL .sc: Et 7:11 OJI 2.1"5" C1

E 61t5 01

.:ie{.

. '2.]11PI

$fj5::IA,IOl oPil

gI.:::i] ==171 rlH.OJI 0IEj

7i10l1.s:.

D

7 . [1i-01

A,.s:. 7t:;<5tCr.

,oPf %OIf5fe{.

t

8. NJlAI

JIi-E'5:.1[1 /11

;Uq.

1 No lubrication

Np moving parts in PTC Disc-flex coupling

herfore lubrication is not necessary,

2.Maintenance free

All metal construction and no wearing parts need

no maintenance.

3.Simple design, light wieght and high torque.

Two hubs. one center member. one disc pack

and several bolts form the basic coupling PTC

Disc-flex couplings are available in wide range of

size to meet variable operation conditions.

4.PTC Disc-Flex couplings are designed to

allow axial. angular and parallel and parallel

misaignment.

5.No backlash and high torsional stiffness.

PTC Disc-Flex couplings allow no backlash and

high torsional stiffness.

6.High performance

High temperature do not affect the all metal

construction.

7,Easy to mount and dismount.

PTC Disc-Flex couplings have small number of

parts and simple constructions which allow quick

and easy mounting and dismounting work.

8.Safety measure.

When a severe over load may damage the

couplings, the transmitting rotation will be

continued through bolts.

36 PTe PTC PT couplings Co.lm

2. (Misalignment)

t! misalignment)

t!:z.t(angurar misalignment)

-J(----l-'

-'1-____ -=-_)

t

t!:z.t 1 (angular & parallel misalignment)

O:jel Sl'i:jOJI .2.loH '3J

:?le[.

7t 71CHEt

?,!-AI -q.

i'12.l '3J ElZ{, Lj-EtLHDi

01

3.

The shafts may be misaligned by various causes. :u:h as

heat Vibration and worm bearing etc.

When the initial alignment is not correct and heavy stress is

imposed on the coupling life time is shontened.

Any or aii of the misalignments shown in the above

illustrations are present in ali connected drives.

1

1. Flange: SM45C

2. Disc pack : STS304

3. Spacer : SM45C

4. Bolt : SM45C-H

5. Lock Nut : SS41

6. Over Load Bush

7. Washer

PIC PT couplings CoHO

PTr37

Structure

POWER TRANSMISSION COUPLINGS I

q A 3.-I!!j.2.1 ~ f

(kinds of disc-pack)

s

s

e

- Part Numbers

1. Flange : SM45C

2. Disc pack : STS304

3. Spacer : SM45C

4. Bolt : SM45C-H

5. Lock Nut: SS41

6. Over Load Bush

7. Washer

43

!

IPT COUPLINGS

Ail7HQI

01 '

O.!X:..2.}:,:Li! iA-O-LI- NC"7l

L...;;-,..l1 ------, Tre> 12 t=I-r IL- o-,-vi -,E::i0rLrf '5

At--'E!Cr.

Characteristic '

1. Single DISC-FLEX coupling

Single DISC-FLEX coupling is used where shafts are

supported by three bearings.

The coupling allow large radial load, angular and axial

misalignment.

[ Af%30'll tij]oj.g

L-________ _____(S_e_l_f-_A_lig_n_in_g_B_e_a_ri_n_g) __

2. Double DISC-FLEX coupling

In case both shafts are supported by two bearings double

DISC-FLEX coupling must be used.

The coupling allow angUlar, axial and parallel misalignment.

The bearings should be placed reasonably.

;:11

...-- ...--

;:i

h

1 I

"L .....I

..

r

.......,. .......,.

'--" '-"

3. Floating shaft DISC=FLEX coupling

Floating shaft DISC-FLEX couplings are used to connect

two equipment remotely aligned.

In addition to above types other types are available on

customers order.

44

, :

POWER TRANSMISSION COUPLINGS I

"'"'

r-..

r

I

L

'-" '-"

I

Tmax = m)

kw =

HP =

N

=

=

S'F L...:L...: .,...

i l' 'I .A uJIO 71 012 7-'1:A; f;f'i5 7L:At :A;i;tf;f i5:1AI.2 Ai:A;

'" . ..j -I 2. 2. 2. 0 L...:-'- 10' -, t:::1 L...: 0,2 L.: 0

1: ICI,.

*?301 <.ULf

tHJQI

1'iii'EJ ?3Sf. 71

c

..\7r

kl2.1

1;!1 f-!{;!O I

Selection Method of Size

1. Selection method of size

Obtain maximum torque

Tmax Maximum torQue(kg . m)

kw =Transmitting power(kw)

HP =Transmitting power(HP)

N =Working revolution(rpm}

S'F = Recommended Service Factor

2. Selection procedure

CD Determine spacer length and select type.

By using above formula, calculate torque.

@ Select coupling size equal to or larger than the design

torque.

@ Check limiting conditions:

maximum bore

space limitation

end float

maximum speed.

necessity of dynamic balance.

45

IPI COUPLINGS

"' "

Designation

P4 45 s 127

Distance between shaft ends(mm)

1:

-5J-Q71:!(OtC/lJE ife?:)

Type(see below)

S : Single D: Double F: Floating

(Size)

..-

AilO Icr.

*(

46

P4

P4-SD

P4-D

P4-F

P4-FH

P4-FV

3.4""'

650

0

P6 P8

P6-D P8-D (P10) (P12) (R4)

P6-F P8-F (P10-F) (P12-F) (RB)

P6-FH P8-FH (P10-FH) (P12-FH) (RH)

P6-FV P8-FV (P1O-:FV) (P12-FV) (RV)

58""' 382'" 1,379'" 1,669""' MAX'"

13,070 18,150 26,130 31,936

100X 1()3

*The type in ( ) are available on order

I

%1=!lPIOII 3:1:::

OJI :g71*

-'j?AloPil .q.

1.

d)

:I :2:1{!AI7i q

i.I.1:::

i! xil(O)

,;) qAI

360

0

711

POWER TRANSMISSION COUPLINGS

General Instruction for Installation

Correct installation and alignment will assure longer life

and smooth, trouble free service.

Fig. 1

1. Check that shaft, hub bore

and keyway have been

cleaned completely

2. Check Angular misalignment

(fig.1 )

<D Install dial indicator to hub and

rotate the hub to locate point of

minimum. Reading the number

set dial to zero.

Rotate coupling 360C, read

indicator for misalign-ment

value. Driver and driven

rrtlmAI

should be li[led up when dial

indicator comes within

maximum allowable figures.

I) l2':!1=!:::

011::1011

1?3 '*

:')

OI%or04 i.lcH oi%*1 OILH

4. .:r-::;;:!i= q

IllAI

'o'J oPI -9-!5HAi::

I?AIfJO IlH 011 0 I un E

3. Parallel misalignment

(fig.2)

<D Install dial indicator to driving

hub, rotate driven hub and

read indicator number.

Move or shim units so that

parallel misallignment is

brought within the maximum

allowable variations.

4. Refering to diagrams on

page 43 assemble the

coupling.

For longer servece life, recheck the coupling for angular

and parallel misalignment after 12 hours operatiorl and

fasten the bolts/nuts by rated torque.

47

IPI COUPLINGS

P4-00S 'cIi'tJh.3. Disc Flex)

G

F F

B

9.2 4.1 3.2 2.3 25 32 81 57.1 25 7.1 46 16 1.1 0.9

18 8.1 6.3 4.5 56 34,000 35 93 66.4 29 8.4 51 24 1.7 2.2

25 11.3 8.7 6.0 83 30,000 42 . 104 79 34 11 61 30 2.5 80 2.2

43 19.3 16.0 11.0 120 25,000. 50 125 93.2 41 11.2 71 , 27 4.3 224 4.2

79 35.5 27.6 . 20.0 180 22,000 58 143 108.5 ' 48 12.5 84 28 6.9 440 7.3

130 58.5 45.5

. 32.5

270 19,000 74 168 130 57 16,106 i 26 11.3 1080 7.3

94.5 73.4 52.5 380 16,000 83 194 145 64 17 118 30 16.7 2080

15.9

153 119 95 214

'34'

22.7 3520 15.9

225 i 171 125 610 13,000 109 246 202 24 156 26 35.4 7200 22.1

292 227 163 770 11,000 118 276 230 102 26 169 42 52.0 12800 55.3

48

I {h0j4 &-JpOWER TRANSMISSION COUPLINGS

:>; \...

P4-00D llIet:l,6.3. .":.6.(Double Disc Flex)

P4 P4-00D P4 a"(Short) P4-00SD

o F

B

-El zt e angular misalignment

-Elzt(e)= l'

0

=L . tan e

(Parallel misalignment)

L: CI A.3. 0 IE {! 712.1.

88.9 44 39 1.7 41

18 34,000 101.6 2.9 84 47 2.7 79

25 30,000 127.0 7.1 396 53 6.6 136 250

43 25,000 127.0 7.1 386 62 6.6 337 350

79 22,000 127.0 10.8 800 69 10.3 775 300

1680 78 15.6 1628 300 19,000 16:3

'101

16,000 139.7 24.7 3400 89 24.0 3317 350

15,000 152.4 32.5 5600 97 31.5 5428 350

109 48.4 10865 350 13,000 177.8 50.0 11200

20400 11,000 177.8 75.0 134 9 20127 400

Refer to the previous page for dimensions

49

P4-00D Disc Flex)

P4 ft-t(Standard) P4-00D P4 'i!t(Short) P4-00SD

JIPI (I angular misalignment

r

0

=L tan 8

(Parallel mIsalignment)

L:qt:3 i1II;:t

L

/

It

39,000 88.9 1.9 44 39

34,000 10\.6 2.9 84 47

30,000 127.0 7.1 396 53

25,000 127.0 7,1 386 62

22,[Q) 0.8 800 69

19,000 127.0 16.3 1680

16,000 139.7 24.7 3400 89

15,000 152.4 32.5 5600 97

13,000 177.8 50.0 11200 109

11,000 177.8 75.0 20400 134

6.6

6.6

10.3

15.6

24.0

31.5

48.4

9

79

136

337

775

1628

3317

5428

10865

20127

200

250

250

350

300

300

350

350

350

400

Refer to the previous page for dimensions

130

210

340

40 PTE PTC PT couplings Co.LTD

S-ar putea să vă placă și

- Monte Carlo Methods for Dimensionality and Variance ReductionDocument19 paginiMonte Carlo Methods for Dimensionality and Variance ReductionRopan EfendiÎncă nu există evaluări

- Heat E Xchanger Tube Plugs: TP SeriesDocument2 paginiHeat E Xchanger Tube Plugs: TP SeriesA Rahim A BakarÎncă nu există evaluări

- Takaful Malaysia My Gen MedicDocument12 paginiTakaful Malaysia My Gen MedicA Rahim A BakarÎncă nu există evaluări

- Assalammualaikum WBTDocument1 paginăAssalammualaikum WBTA Rahim A BakarÎncă nu există evaluări

- Ten So Ning Data SheetDocument1 paginăTen So Ning Data SheetA Rahim A BakarÎncă nu există evaluări

- BM222 Business Administration Degree StructureDocument3 paginiBM222 Business Administration Degree StructureA Rahim A BakarÎncă nu există evaluări

- Ten So Ning Data SheetDocument1 paginăTen So Ning Data SheetA Rahim A BakarÎncă nu există evaluări

- Borangsps Utm2009 01Document2 paginiBorangsps Utm2009 01A Rahim A BakarÎncă nu există evaluări

- Cover Letter Hari IniDocument1 paginăCover Letter Hari IniA Rahim A BakarÎncă nu există evaluări

- Valve Cci-In-Oil-And-GasDocument8 paginiValve Cci-In-Oil-And-GasA Rahim A BakarÎncă nu există evaluări

- Tafsir Sayyid Qutb Ad-DukhanDocument17 paginiTafsir Sayyid Qutb Ad-DukhanA Rahim A BakarÎncă nu există evaluări

- Tafsir Sayyid Qutb As-SyuraDocument43 paginiTafsir Sayyid Qutb As-SyuraA Rahim A BakarÎncă nu există evaluări

- Rubber Material Selection Guide NBR / Nitrile or Buna N Acrylonitrile ButadieneDocument3 paginiRubber Material Selection Guide NBR / Nitrile or Buna N Acrylonitrile ButadieneA Rahim A BakarÎncă nu există evaluări

- Mixers and Agitators TroubleshootingDocument2 paginiMixers and Agitators TroubleshootingA Rahim A BakarÎncă nu există evaluări

- Mixers and Agitators TroubleshootingDocument2 paginiMixers and Agitators TroubleshootingA Rahim A BakarÎncă nu există evaluări

- Gondola by DOSHDocument3 paginiGondola by DOSHA Rahim A Bakar100% (1)

- Ss 400Document4 paginiSs 400A Rahim A Bakar100% (1)

- RCI ReportDocument1 paginăRCI ReportA Rahim A BakarÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 1991 ServiceManual Mitsubishi 3000GT Vol 2Document316 pagini1991 ServiceManual Mitsubishi 3000GT Vol 2NoAccount888100% (1)

- PT316 - Topic 1 - Single Particles in Fluids PDFDocument30 paginiPT316 - Topic 1 - Single Particles in Fluids PDFChemEngGirl89Încă nu există evaluări

- Reshu Tyagi Prof. JaimalaDocument53 paginiReshu Tyagi Prof. JaimalaReshu TyagiÎncă nu există evaluări

- Problems (Solns)Document60 paginiProblems (Solns)reda redaÎncă nu există evaluări

- Contoh SoalanDocument5 paginiContoh SoalanPa ManjaÎncă nu există evaluări

- Scalar Wave Driven Energy ApplicationsDocument15 paginiScalar Wave Driven Energy ApplicationsЗорица ЋирићÎncă nu există evaluări

- Separation ProcessesDocument57 paginiSeparation ProcessesAngelo X0% (1)

- Kinetic Theory of GasesDocument14 paginiKinetic Theory of GasesvaibhavbptÎncă nu există evaluări

- Manual de Engilab PDFDocument144 paginiManual de Engilab PDFRoberto GuzmanÎncă nu există evaluări

- Key Star MDCAT Crash Test # 1Document12 paginiKey Star MDCAT Crash Test # 1Ahmed Saud100% (1)

- Bphet 141 em 2021 22 CP PDFDocument10 paginiBphet 141 em 2021 22 CP PDFPulakith NagarwalÎncă nu există evaluări

- Ethyl Silicate Binders For High Performance CoatingsDocument14 paginiEthyl Silicate Binders For High Performance CoatingsMoustafa Bayoumi100% (1)

- Effects of Lithium Carbonate Additives in High Alumina CastableDocument13 paginiEffects of Lithium Carbonate Additives in High Alumina CastableIan AjaÎncă nu există evaluări

- JAR Part 66 Exam Mod 02Document92 paginiJAR Part 66 Exam Mod 02Shreyas PingeÎncă nu există evaluări

- BeamDocument18 paginiBeamAfia S Hameed100% (1)

- Transformasi Linier-14Document72 paginiTransformasi Linier-14Rizqie Puspita MayasariÎncă nu există evaluări

- Journal of Physics and Chemistry of SolidsDocument6 paginiJournal of Physics and Chemistry of SolidsLUZ YADIRA ZAMORA CANOÎncă nu există evaluări

- Why Does A Stream of Water Deflect in An Electric FieldDocument2 paginiWhy Does A Stream of Water Deflect in An Electric Field1_2_3_4asdfÎncă nu există evaluări

- Particle Like Properties of Electromagnetic Radiation: Yudhiakto PramudyaDocument53 paginiParticle Like Properties of Electromagnetic Radiation: Yudhiakto PramudyaMengharu BiruÎncă nu există evaluări

- An Alternative Treatment For Yukawa-Type Potentials: R R A R VDocument11 paginiAn Alternative Treatment For Yukawa-Type Potentials: R R A R VJose RamirezÎncă nu există evaluări

- Soil MechDocument2 paginiSoil MechtitukuttyÎncă nu există evaluări

- Dynamic Behaviour of Electric Drives: Fundamental Torque EquationsDocument7 paginiDynamic Behaviour of Electric Drives: Fundamental Torque EquationsBerihun Engda80% (5)

- REO-The Rheological Properties of MayonnaiseDocument4 paginiREO-The Rheological Properties of Mayonnaiseghost2011Încă nu există evaluări

- TLWDocument39 paginiTLWCandida DhasonÎncă nu există evaluări

- Well Test Analysis Reveals Reservoir ParametersDocument5 paginiWell Test Analysis Reveals Reservoir ParametersChai CwsÎncă nu există evaluări

- States of matter-i Gas Course OutlineDocument9 paginiStates of matter-i Gas Course OutlineMansoor SarwarÎncă nu există evaluări

- Al-Qalam Academy of Sciences, Muzaffarabad: RT RTDocument4 paginiAl-Qalam Academy of Sciences, Muzaffarabad: RT RTSultan KhanÎncă nu există evaluări

- 37 RelativityDocument39 pagini37 RelativityAdam100% (1)

- Quantum Mechanics Math ReviewDocument5 paginiQuantum Mechanics Math Reviewstrumnalong27Încă nu există evaluări

- Tutorial On Stochastic Differential EquationsDocument27 paginiTutorial On Stochastic Differential EquationsPranav ChandraÎncă nu există evaluări