Documente Academic

Documente Profesional

Documente Cultură

D&H Colonie Shop

Încărcat de

staustell92Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

D&H Colonie Shop

Încărcat de

staustell92Drepturi de autor:

Formate disponibile

------------------------------------~=~----=~---

8 THE CALL BOARD

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S.

January 1991

The Delaware & Hudson's Colonie Shops

By Tim Truscott and Dick Barrett

Between the turn of the century and the beginning of the Great Depression in 1929, the railroad industry in the northeastern United States was at its zenith. Many of the Class I railroads, such as the Delaware & Hudson, were amassing great wealth from the huge amount of traffic that they were carrying. After all, railroads were the fastest and most efficient way to carry people and goods at that time. The nation's highway system, which came to be an alternative to the railroads, had not yet developed. The railroads were also the chief conveyer of the nation's primary energy source, coal. The railroad industry's wealth allowed it to meet the demand for new facilities, the demand for which was brought about by the changing railroad technology of larger locomotives and other equipment and by the increase in the numbers of pieces of equipment needed for railroad operations. On the Delaware & Hudson, this change in railroad technology and the increase in business and the wealth derived from that business resulted in a number of major modernization projects in its physical plant: The Oneonta roundhouse, the largest in the world at the time, was built in 1906. A 40-stall roundhouse-in Carbondale and a 10-stall enginehouse and engine terminal in Binghamton were opened in 1911. In 1911 a 37 -mile grade-reduction project was undertaken between Ninevah Junction and Oneonta. The D&H Building, the headquarters for the railroad in downtown Albany which was unmatched for its size and architectural beauty, was built in 1914-15. The compensated grade line, extending along the south side of the valley between Schenevus and Richmondville Summit above East Worcester, was completed in 1921 and facilitated the movement of northbound traffic up the south side of Richmondville Hill. In 1911 and 1912, when it was in its peek period of expansion and modernization, the Delaware & Hudson Railroad constructed a new mechanical facility and freight yard in the Town of Colonie adjacent to Watervliet, New York, approximately five miles north of Albany. The new Colonie facility, constructed at a cost of approximately $2 million dollars, was the largest railroad mechanical facility in New York State at the time and was said to be equal to any in the eastern United States. Colonie replaced the railroad's locomotive terminal and repair shop at Green Island, just a couple of miles further north from the Colonie site, as well as its coach yard facilities in Albany. In fact, Colonie also replaced older facilities for heavy mechanical work at Carbondale and Oneonta, which were inadequate for the size of locomotives and volume of work required at the time. The basic design philosophy for Colonie was to utilize the good functional design features of the leading shops around the country rather than to seek an architectural effect. Two of the chief design criteria were to provide good ventilation and as much light as possible. While the largest of the Delaware & Hudson's locomotives were working on the southern end the railroad at this time, the Colonie facilities were designed with the possibility in mind that these large locomotives might be used on the northern end of the line in the future. Unlike the New York Central's West Albany Shop complex, which evolved through a series of stages of construction and redevelopment beginning in the 1850s, the Delaware & Hudson's Colonie mechanical plant was constructed as an entirely new facility where there were no previous railroad structures. The Colonie project was under the immediate supervision of Mr. V. Z. Caracristi, Consulting Engineer of the Delaware & Hudson. Its size and modem design were

An aerial view from the south of the Delaware & Hudson's Colonie Shop complex. Note the roundhouse and smoke stack of the power house at the center of the photo, as well as the locomotive shop at the right (the large building above the locomotive shop is the Watervliet Arsenal). To the left of the roundhouse is car shop, planing mill and truck shop. The mainline extends diagonally to left of center. Partially concealed by the smoke from the roundhouse are the coal trestle and ash pits. The date of the photo is unknown. (Collection of the authors)

January 1991

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. between buildings and between outdoor locations, as well as into and out of the buildings. A high-speed craneway, with a span of 671/2 ft. and a capacity of 5 tons, ran in an east-west direction on the north side of the car shop all the way to the eastern edge of the property, a distance of 1,162 ft. This craneway tied the entire Colonie facility together. Another craneway with a 100-ft. span and a capacity of 10 tons ran in an north-south direction and separated the locomotive shop from the foundry and stores building. A third crane, 450 ft. long with an 85-ft. span and a 5-ton capacity, served as a yard crane south of the planing mill for the purpose of moving lumber in the stockpile. The locomotive shop, located on the east side of the property, was by far the largest building constructed in the Colonie complex. With a north-south dimension of 510 ft. and and east-west dimension of 387 ft., it housed all units of the locomotive department except the hammer shop and foundry. The building consisted of seven bays across its 387 ft. width, with the center bay (transfer bay) and the two bays adjoining the center bay (erecting bays) on each side being 69 ft. wide, while the side bays were 59 ft. wide and the outside bays were

THE CALL BOARD 9

equal to any other in the east at the time. The Colonie facility was constructed with a north-south orientation on a 160['.....;~ 'acre tract of land, and comprised a general omotive repair shop (including a main shop, foundry and hammer shop), a locomotive repair terminal (including a roundhouse with the necessary facilities for coaling, watering and storing steam locomotives), a large coach yard (in which passenger cars were cleaned and classified), a freight car receiving yard and repair shop, a paint shop, and a stores department. All of the buildings were constructed with their long dimension on a north-south orientation and designed so that they could be expanded in the future, if necessary, without interfering with one another. Of particular interest, the locomotive shop and the car shop were provided with expansion potentials of at least 50 percent, while the roundhouse could be expanded by 11 or 12 stalls (over 30%). Outdoor craneways served the principle buildings within the facility and were situated on either a north-south or east-west axis. Some of these craneways 'Were equipped with more than one crane. The purpose of these cranewa ys was to provide for the efficient movement of materials

An aerial view from the north of the Delaware & Hudson's Colonie Shop complex. At center is the 3D-stall roundhouse with the locomotive shop to the left of it. To the right of the roundhouse is the truck shop, 'planing mill and car shop. The mainline extends diagonally to the right of the roundhouse. The date of the photo is unknown. (Collection of the authors)

30 ft. in width. The outside bays had second story "galleries" (more recently referred to by D&H personnel as "balconies") along the outside walls. Steam locomotives brought into the shop for overhaul entered the building on one of two tracks through doors near the middle of the west side of the building. Engines were de-greased with hot water under pressure on a washing table just outside the building before entering. This arrangement replaced the use of lye vats for de-greasing, which had been the customary method, and was safer and more economical. Unlike most locomotive shops of the period, the Delaware & Hudson's Colonie Shop used a I50-ton capacity Shaw electric crane to position steam engines within the shop, rather than the customary transfer table and pit. This procedure provided an economy of space so that other functions could be performed within the building. The 150-ton, 65-ft. span transfer crane would lift a steam engine and place it in an east-west position over a pit in the center bay (transfer bay) in the north half of the shop, where it was to be stripped. Shop trucks were placed under the engine after it was stripped, and the engine moved either east or west into one of the two erecting bays (one erecting bay on either side of the transfer bay) by means of an electric winch. The erecting bays each had 12 pits, while the transfer bay had a total of seven pits. Two of the pits in the transfer bay were in incoming and outgoing tracks, while the remaining five pits in this bay were situated in alternating tracks of the other ten track positions of this bay. Each of the erecting bays was equipped with a 100-ton capacity Shaw overhead electric crane which had a 65-ft. span. When the engine was stripped in the transfer bay, the parts which required repair were transported from the transfer bay to their respective departments while the remaining parts not needing repair were stored in the transfer bay until they were needed for re-assembly (erecting). Under the east gallery in the south end of the building was a small work smith shop. The south end of the transfer and erecting bays was used as a boiler shop, while a portion of the easterly bay served as a tender shop. Each of the bays in the south end was served by lO-ton Shaw overhead electric cranes. Heavy machine work was performed in the north end and central portion of the two 59-ft. bays, which were served by lO-ton and 30-ton cranes. Light machine work was performed on both the ground floor and the gallery level of the

10 THE CALL BOARD

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S.

, ,

January1991

1

.I- - -1---

1!

~,

--I

!JIJ7' -' -

~I -,f ~ ~

h

;~

.,

~

~I ,

~ ~

~-

~-

. -~- I

T

--

--l.

...

7::!

1~ I

'"\'

~'

i I

=

--~------".------------,

r

'0 <

.>J'

~.

Ayf~

() Ton

~""'~,:;

-~'~

()

~IJ.

.(1~

[r_

(f-

It>'>

Q1~ (~ IC~

u-

er_ ~~

I

L..J r:

-..;1

I

I

1

T

l'

~ ~

I/>

:l"

"

if

4---",,=,-,=-,

----t

I

I

0 "D

. ;; ~ ~ .

C

II>

.. .

a

:l"

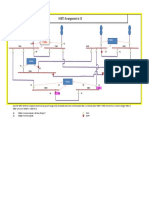

An enlarged schematic of the Colonie locomotive shop showing the transfer bay at center with the erecting bays on either side. Adjacent to the erecti ng bays were the machine shops, with galleries over the outermost bays. (Collection of the authors)

ou ide bay, with the ground floor handling the rods, pistons, valves and associated parts, while the galleries contained the manufa turing tool room, brass room, electric room, paint shop, cab shop, tin shop, et .Overhead cranes in the 59-ft. machine bay erved the galleries by means of platforms projecting 9 ft. from the galleries at intervals. The foundry measured 91 ft. by 180 ft. and was located west of the main locomotive shop. The foundry building was connected with the main shop by means of industrial tracks. The main bay of the foundry building, which was 60 ft. wide,

J:

..

c:: Co

0

"

r

Ii R ~~ ~

71n"

I

~~

.. "

I,

I

.. " ~

~

i> ~ '?-

vr-

\j

<

m' ~

~ ~i~;~~

it

~~

~ ~ ~ I:!l

A schematic of the Delaware & Hudson's Colonie Shop complex as it was builtin 1911-1912.Note the 30-stall roundhouse at center and locomotive shop to the right. To the left of center (west) and below the roundhouse is the truck shop, planing mill and car shop. Also note the loop track at lower right, as well as the coal trestl and ash pits above (north of) the roundhouse. (Collection of the authors)

January 1991

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S. walls with two rows of steel columns equally spaced between the inner and outer walls. A clerestory 30 feet from the inner circle allowed light and permitted ventilation through two windows and a louver above each stall. The hinged wooden doors on the inner circle opening into the turntable area did not have windows. Asbestos smoke jacks 20 feet from the outer wall conveyed each locomotive's smoke through the roundhouse roof. The roundhouse was designed so that it could be expanded on the northwest quadrant at a future date. A "rest house", attached to the roundhouse on its north side and measuring 38 by 52 feet, contained a restaurant, sleeping room, rest room, wash and locker room for use by trainmen. It also contained the offices of the roundhouse foreman and engine dispatcher, as well as the switchboard for the telephone system of the entire shop complex. North of the roundhouse were located coal pockets for fueling steam locomotives, while further north four concrete ash pits each 160 feet long were arranged in pairs with a depressed ash track between the two pits of each pair. Between the two pairs of ash pits were the tracks for coal pockets with one for the loaded cars and one for the empties. Cars were hauled up the coal trestle by means of a FairbanksMorse electric hoist and emptied into pockets with a capacity of 600 tons. The pockets had air operated automatic gravity measuring chutes of two- and four-ton capacity. Sand storage, as well as sand drying and handling equipment, was 10-

THE CALL BOARD

11

included a 10-ton overhead crane which served the cast iron and cast steel moulding floors. The iron foundry had a capacity of 20-tons per day and the steel foundry'S r--~ apacity was 2 tons per hour. A second bay consisted of a ground floor and secondfloor gallery, with the gallery including the charging floors and brass foundry. The ground floor beneath the gallery included the core ovens, tumblers and other functions. Washrooms, together with the blowers, were located on a mezzanine floor between the ground floor and the gallery. The gallery was served by an elevator from the ground floor, as well as by the lO-ton foundry crane and a general storage crane by means of overhanging platforms. The gallery of the foundry was also served from the exterior by means of the lO-ton, 100-ft. span craneway which separated the foundry building from the main shop. North of the foundry was a two-story building 53 ft. by 82 ft. which served as a pattern shop. The hammer shop, located south of the main shop, measured 68 ft. by 158 ft. and was utilized for heavy forging work. A standard gauge track passed through the building's entire length and into the main shop for the handling of heavy material. The 30-stall roundhouse was 379 feet in iameter with a 20-foot extension on the uter circle over five bays, with this extension housing the equipment necessary for light repairs. A 90-foot turntable served the roundhouse, as did the facilities for coaling, watering and storing, along with oil supply, water supply and ash pits. The roundhouse was 90 feet between its inner and outer

cated with a 100,000 gallon water supply at the south end of the coal pockets so that locomotives could take sand and water simultaneously. All ingoing and outgoing tracks converged into three main tracks before entering the roundhouse. The locomotive terminal also included an oil house with dimensions of 34 ft. by 60 ft. and a capacity of over 45,000 gallons. The oil house served the entire facility through underground pipes. The coach yard with over two miles of track was outfitted with underground pipe tunnels conveying air, hot and cold water, steam, filtered drinking water, gas and a vacuum cleaning system. A stores and office building 20 ft. by 96 ft. served the coach yard, along with an ice house 22 ft. by III ft. just north of the car department office building. A complete loop in the south end of the property facilitated the turning of locomotives, cars or complete trains. The car department consisted of a car repair shop, a planing mill, a truck shop, repair tracks and a "bad order" storage yard. The car repair shop, located on the west side of the complex of buildings, was 104 ft. by 268 ft. and was divided into two bays, each bay being served by a 15-ton overhead electric crane. Two tracks, together with an industrial track, served each bay. The building was constructed in such a way that another bay with two tracks and a crane could be added on the west side of the building. The car department included additional facilities. A small machine and blacksmith

Section 01 Machine and Erecting

Shop, Watervliet,

N. Y.

A section through the Delaware & Hudson's Colonie locomotive shop as it was built in 1911-1912. Note the transfer bay at the center, with an erecting bay on either side. The machine shops were located adjacent to the erecting bays. (Collection of the authors)

12 THE CALL BOARD

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S.

January 1991

..J.. EUVATIO/i

ELEVAT.'ON

Section Through

Roundhouse, Watervliet

Shops.

A section through the Delaware & Hudson's Colonie roundhouse as it was built in 1911-1912. Note the smoke jack over the engine's stack. To the left is shown an elevation of the doors and clerestory facing the turntable. To the right is shown an elevation of the outside of the building with its large windows. (Collection of the authors)

shop southwest of the car repair shop, measuring 22 ft. by 88 ft., was available for performance of light work. The planing mill building measured 68 ft. by 180 ft. and had a track extending through its entire length. Lumber was stored to the south of the planing mill in an area served by a 5-ton crane. North of the planing mill, on the opposite side of the craneway, was the truck shop. In the north end of the facility was the "bad order" car receiving yard with a capacity of more than 300 cars. The stores department building was constructed at a central location relative to the main locomotive shop and the roundhouse. A 100-ft. craneway ran along the east side of the building, separating this building from the main shop. The stores department, occupying three-stories plus basement and measuring 62 ft. by 162 ft., was designed to serve as the mechanical storehouse for the entire northern division and as stationary storehouse for the whole railroad. A portion of the second story was divided into offices for the superintendent of shops and his staff, as well as an apprentice instruction room. (At that time, the D&H had a complete system of instruction for apprentices consisting of an elementary course in arithmetic, drawing and other courses which were compulsory.) An electric elevator with 3,000 lbs. capacity moved materials within the building, while the overhead crane on the lOO-ft. craneway running between the store~-~ building and the main shop was available 1<-, _ mo e materials on platforms on the east and south side of the building. Loading platforms surrounded the building, with tracks running parallel to and in close proximity to all of these. An industrial track connected the main shop with the stores building. The power house, which was located just south of the roundhouse, was an Lshaped building 156 ft. by 121 ft. with a boiler room 41 ft. wide and an engine and pump room 80 ft. wide. While the principal electric power source for Colonie was the Delaware & Hudson's Mechanicville steam power station, built principally for the company's electric lines, a 350 kilowatt DC reciprocating steam generating set was included in the Colonie power house. The electric power from Mechanicville was delivered as 40-cycle, 11,OOO-voltAC current and transformed into 240-volt AC. A motor-generator set also converted AC power to 240 volts DC for operating some of the machinery such as the overhead cranes. There was also a steam powered air compressor with a capacity of 2,000 cu. ft per min., as well as an electric motor driv air compressor of 2,000 cfm capacity. Heat for the Colonie facility was sup-

II

The newall-welded boiler and frame of D&H Class E-6a 2-8-0 No. 1219 being reassembled in one of the erecting bays of the locomotive shop at Colonie in May of 1937. The 1219 was built by the American Locomotive Company in Schenectady in 1918. (Col-Iection of the authors)

January 1991

NEWSLETTER

OF THE MOHAWK & HUDSON CHAPTER, N.R.H.S.

THE CALL BOARD

13

'{

plied by six large boilers in the power house which burned birds-eye coal under forced drafts provided by two 8 ft. fans. A !oncrete smoke stack was 210 ft. high and ft. in diameter. All of the buildings with the exception of the stores building, the roundhouse and the truck shop, were heated by indirect radiation, i.e. the heating coils and motor driven fans were located in the clerestory bays of the buildings and ductwork conveyed the hot air down to the floor levels. The roundhouse, truck shop and stores building were all heated by direct radiation. The Delaware & Hudson's Colonie facility was the result ofD&H President L. F. Loree's desire to have the most modem facility possible. Loree, a civil engineer by training, was said to have played a direct role in planning the new facility, which was undoubtedly "state-of-the-art" for the time.

References

"Watervliet Terminal, Delaware & Hudson Co.," in Railway Engineering and Maintenance of Way, December 1912. "Construction Features of the Watervliet Shops of the Delaware & Hudson Company," in Cassiers Magazine: An Engineering Monthly, May 1912.

Delaware & Hudson Class E-5 2-8-0 No. 1056 in the Colonie roundhouse on May 22, 1917. Note the smoke jacks in the upper right of the photograph, as well as the pits between the tracks. The Colonie roundhouse had 30 stalls and was built with a 90-ft. turntable. (Collection of the authors)

The heavy machine shop bay on west side of the D&H Colonie locomotive shop in about 1925. (D&H Collection, New York State Library)

..

Delaware & Hudson Class E-5 2-8-0 No. 1056 sitting on the track leading into the locomotive shop at Colonie on May 21,1917, with the foundry building in the background. The 1056 was built by the American Locomotive Company in Schenectady in 1912.

S-ar putea să vă placă și

- Stuff Happens: The Far from Humdrum Life of a PhotojournalistDe la EverandStuff Happens: The Far from Humdrum Life of a PhotojournalistÎncă nu există evaluări

- Boil 'Em Cabbage Down UkeDocument1 paginăBoil 'Em Cabbage Down UkeLiathGlasÎncă nu există evaluări

- Ukulele Coldplay - Viva La VidaDocument3 paginiUkulele Coldplay - Viva La VidaJohnnyÎncă nu există evaluări

- Johannes Jacobus Adrianus Van Dijk: To The Memory ofDocument5 paginiJohannes Jacobus Adrianus Van Dijk: To The Memory ofaminÎncă nu există evaluări

- Italian Landscape GroupDocument20 paginiItalian Landscape GroupVaibhav Ananda KadamÎncă nu există evaluări

- Tropical Hawai'in DayDocument4 paginiTropical Hawai'in DaygaryÎncă nu există evaluări

- Agro Forestry Guides For Pacific IslandsDocument50 paginiAgro Forestry Guides For Pacific IslandsJulio Ugarte GuerraÎncă nu există evaluări

- Shack Mountain Final ReportDocument145 paginiShack Mountain Final Reportnmustard7203Încă nu există evaluări

- D&H Colonie Shop Conversion For ChallengersDocument2 paginiD&H Colonie Shop Conversion For Challengersstaustell92Încă nu există evaluări

- Castleton Cut-Off of The New York CentralDocument2 paginiCastleton Cut-Off of The New York Centralstaustell92100% (1)

- DL&W Scranton Yard and ShopsDocument3 paginiDL&W Scranton Yard and Shopsstaustell92100% (1)

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. Meadows Division and Harrison Transfer Yard. Paper No. 1153De la EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. Meadows Division and Harrison Transfer Yard. Paper No. 1153Încă nu există evaluări

- West Albany's Last Steam Locomotive The 5270Document4 paginiWest Albany's Last Steam Locomotive The 5270staustell92Încă nu există evaluări

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The Cross-Town Tunnels. Paper No. 1158De la EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The Cross-Town Tunnels. Paper No. 1158Încă nu există evaluări

- The D&H BuildingDocument5 paginiThe D&H Buildingstaustell92Încă nu există evaluări

- Legacies of the Industrial Revolution: Steam Engine and Transportation - History Book for Kids | Children's HistoryDe la EverandLegacies of the Industrial Revolution: Steam Engine and Transportation - History Book for Kids | Children's HistoryÎncă nu există evaluări

- Classic American Locomotives: The 1909 Classic on Steam Locomotive TechnologyDe la EverandClassic American Locomotives: The 1909 Classic on Steam Locomotive TechnologyÎncă nu există evaluări

- Another Century of Narrow Gauge Steam II UpdateDocument4 paginiAnother Century of Narrow Gauge Steam II UpdateLinda SmithÎncă nu există evaluări

- White CityDocument7 paginiWhite CityMuhammadMazidÎncă nu există evaluări

- Illustrated Catalogue of Locomotives; Baldwin Locomotive WorksDe la EverandIllustrated Catalogue of Locomotives; Baldwin Locomotive WorksÎncă nu există evaluări

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. Paper No. 1150De la EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. Paper No. 1150Încă nu există evaluări

- Rolling StockDocument27 paginiRolling StockJizelle HascoÎncă nu există evaluări

- Engineering Vol 72 1901-08-02Document35 paginiEngineering Vol 72 1901-08-02ian_newÎncă nu există evaluări

- Asquith Railway Station GroupDocument6 paginiAsquith Railway Station GroupMonika ScholzÎncă nu există evaluări

- User Research 268 SurveyDocument3 paginiUser Research 268 SurveyjohnnyrpprÎncă nu există evaluări

- The Four Remaining Water Balance Lifts in The UK: David A. CooperDocument12 paginiThe Four Remaining Water Balance Lifts in The UK: David A. CooperfreddyjoertyÎncă nu există evaluări

- Transactions: Paper No. 1158Document36 paginiTransactions: Paper No. 1158Gutenberg.orgÎncă nu există evaluări

- Romance of the Rails: Why the Passenger Trains We Love Are Not the Transportation We NeedDe la EverandRomance of the Rails: Why the Passenger Trains We Love Are Not the Transportation We NeedÎncă nu există evaluări

- Elevator NotesDocument33 paginiElevator NotesLakshmi NarayananÎncă nu există evaluări

- The Railroad Builders: A Chronicle of the Welding of the StatesDe la EverandThe Railroad Builders: A Chronicle of the Welding of the StatesÎncă nu există evaluări

- Appalachian Railroad Modeling - Article - ABCs of Coal LoadersDocument3 paginiAppalachian Railroad Modeling - Article - ABCs of Coal LoadersbuchkasperÎncă nu există evaluări

- Transactions: Paper No. 1153Document18 paginiTransactions: Paper No. 1153Gutenberg.orgÎncă nu există evaluări

- Baldwinlocomotiv 00 BaldrichDocument146 paginiBaldwinlocomotiv 00 BaldrichMark GrayÎncă nu există evaluări

- South Yarra Cable Tram Engine House and Tram ShedDocument18 paginiSouth Yarra Cable Tram Engine House and Tram ShedGary VinesÎncă nu există evaluări

- Rail Haul: History in AmericaDocument9 paginiRail Haul: History in AmericaCharles PetersonÎncă nu există evaluări

- Hydraulic Power NetworkDocument10 paginiHydraulic Power NetworkTreeSix SolutionsÎncă nu există evaluări

- Three Axis Pneumatic-624Document16 paginiThree Axis Pneumatic-624swapnilÎncă nu există evaluări

- Revisiting the Long Island Rail Road: 1925-1975De la EverandRevisiting the Long Island Rail Road: 1925-1975Evaluare: 2 din 5 stele2/5 (1)

- Rhems ReportDocument9 paginiRhems ReportAngelo John R. JavinezÎncă nu există evaluări

- Silingofer Arm FailureDocument51 paginiSilingofer Arm FailurekrunalÎncă nu există evaluări

- Locomotives For Heavy Industry-C. Wordsworth-1955Document64 paginiLocomotives For Heavy Industry-C. Wordsworth-1955Goldburg GoldburgÎncă nu există evaluări

- DL&W Scranton Yard and ShopsDocument3 paginiDL&W Scranton Yard and Shopsstaustell92100% (1)

- S&HR Where Were You?Document2 paginiS&HR Where Were You?staustell92100% (2)

- Commuter Route Alternatives & Sweeney LetterDocument2 paginiCommuter Route Alternatives & Sweeney Letterstaustell92Încă nu există evaluări

- Montreal-New York VHSR Prefeasibility Study 1985Document146 paginiMontreal-New York VHSR Prefeasibility Study 1985EmpireCorridorÎncă nu există evaluări

- The Foibles of Early DieselsDocument1 paginăThe Foibles of Early Dieselsstaustell92Încă nu există evaluări

- D&H World's Fair CarsDocument4 paginiD&H World's Fair Carsstaustell92Încă nu există evaluări

- A Winter InterludeDocument1 paginăA Winter Interludestaustell92Încă nu există evaluări

- Slingerlands D&H StationDocument1 paginăSlingerlands D&H Stationstaustell92Încă nu există evaluări

- The Walschaerts Valve GearDocument2 paginiThe Walschaerts Valve Gearstaustell92Încă nu există evaluări

- United Traction Co. Trolley Last Day of Operation August 31, 1946Document1 paginăUnited Traction Co. Trolley Last Day of Operation August 31, 1946staustell92Încă nu există evaluări

- United Traction Co. Snow SweepersDocument4 paginiUnited Traction Co. Snow Sweepersstaustell92Încă nu există evaluări

- Railroad Historical Articles ListDocument2 paginiRailroad Historical Articles Liststaustell92Încă nu există evaluări

- United Traction Co. Last Trolley Rides August 10, 1946Document2 paginiUnited Traction Co. Last Trolley Rides August 10, 1946staustell92100% (1)

- United Traction Co. 301Document3 paginiUnited Traction Co. 301UnitedTractionCoÎncă nu există evaluări

- Testing The Alco HaulicsDocument3 paginiTesting The Alco Haulicsstaustell92Încă nu există evaluări

- Castleton Cut-Off of The New York CentralDocument2 paginiCastleton Cut-Off of The New York Centralstaustell92100% (1)

- Albany Union Station L&RP No. 12 Jan. - Feb. 1988Document14 paginiAlbany Union Station L&RP No. 12 Jan. - Feb. 1988staustell92100% (1)

- Alco Nothing Serious, You KnowDocument3 paginiAlco Nothing Serious, You Knowstaustell92Încă nu există evaluări

- The New York Central's Schenectady Detour ProjectDocument1 paginăThe New York Central's Schenectady Detour Projectstaustell92Încă nu există evaluări

- D&H Albany MainDocument3 paginiD&H Albany Mainstaustell92Încă nu există evaluări

- West Albany's Last Steam Locomotive The 5270Document4 paginiWest Albany's Last Steam Locomotive The 5270staustell92Încă nu există evaluări

- The D&H BuildingDocument5 paginiThe D&H Buildingstaustell92Încă nu există evaluări

- Selkirk's Last MohawkDocument1 paginăSelkirk's Last Mohawkstaustell92Încă nu există evaluări

- Alco Century 628'sDocument5 paginiAlco Century 628'sstaustell92100% (1)

- The Century Mark A Century Later NYC 999Document3 paginiThe Century Mark A Century Later NYC 999staustell92Încă nu există evaluări

- D&H Colonie Shop Conversion For ChallengersDocument2 paginiD&H Colonie Shop Conversion For Challengersstaustell92Încă nu există evaluări

- Albany Union Station L&RP No. 12 Jan. - Feb. 1988Document14 paginiAlbany Union Station L&RP No. 12 Jan. - Feb. 1988staustell92100% (1)

- The Last of The D&H Commuter TrainsDocument3 paginiThe Last of The D&H Commuter Trainsstaustell92Încă nu există evaluări

- United Traction Co. Snow SweepersDocument4 paginiUnited Traction Co. Snow Sweepersstaustell92Încă nu există evaluări

- Service Station Manual Vespa LX 125 - 150 4t Euro 3Document241 paginiService Station Manual Vespa LX 125 - 150 4t Euro 3Adèle Standard100% (1)

- Fundamentals of Radiologic Physics Course OutlineDocument7 paginiFundamentals of Radiologic Physics Course OutlineJustin Zeus Operio100% (1)

- Cat 307D Main Pump OperationDocument3 paginiCat 307D Main Pump Operationkahandawala100% (1)

- SG Series 41-751NDocument8 paginiSG Series 41-751NRick JordanÎncă nu există evaluări

- Acp 10 - PPT - Q3 - M4Document50 paginiAcp 10 - PPT - Q3 - M4CherryÎncă nu există evaluări

- 2D& 3D-Kate Susannah - Lindsay Sorin and Michelle Maranto-Option 2 - 22.03.23Document11 pagini2D& 3D-Kate Susannah - Lindsay Sorin and Michelle Maranto-Option 2 - 22.03.23Miliausha KarimÎncă nu există evaluări

- Project On Global WarmingDocument22 paginiProject On Global WarmingHilda DsouzaÎncă nu există evaluări

- mayada5977 مهمDocument7 paginimayada5977 مهمAmmar Al-KindyÎncă nu există evaluări

- FILE 51 Use of Grinder or Angle GrinderDocument1 paginăFILE 51 Use of Grinder or Angle GrinderJonathan BobadillaÎncă nu există evaluări

- Hns 36W 4P Se: Product DatasheetDocument4 paginiHns 36W 4P Se: Product Datasheetaban Ibis MedicalÎncă nu există evaluări

- Physics Thermal Chemical Current MCQDocument5 paginiPhysics Thermal Chemical Current MCQAyan GhoshÎncă nu există evaluări

- 31 Getting Your Refrigerator To RDocument19 pagini31 Getting Your Refrigerator To Rraypower2004Încă nu există evaluări

- The Thermodynamic Properties of Platinum: by J. W. ArblasterDocument9 paginiThe Thermodynamic Properties of Platinum: by J. W. ArblasterEmmanuel PlazaÎncă nu există evaluări

- Plumbing - HVAC August 2010Document48 paginiPlumbing - HVAC August 2010aurelian177100% (1)

- Large Field Refrigeration System-USMC Technical ManualDocument228 paginiLarge Field Refrigeration System-USMC Technical ManualbusybusybusyÎncă nu există evaluări

- Basic Preventive Maintenance Check List For ReciprocatingDocument4 paginiBasic Preventive Maintenance Check List For Reciprocatingsubramanyanvenkat6185100% (1)

- A Study of Integrated Choke Characteristic For EMI Filter DesignDocument4 paginiA Study of Integrated Choke Characteristic For EMI Filter DesignDiego GutierrezÎncă nu există evaluări

- Mic Electronics Research ReportDocument17 paginiMic Electronics Research ReportSudipta BoseÎncă nu există evaluări

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document15 paginiInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768jesuz_mtz26Încă nu există evaluări

- Tutorial Presentation LongattDocument119 paginiTutorial Presentation LongattrdelgranadoÎncă nu există evaluări

- P&id LegendDocument1 paginăP&id Legendkamal arabÎncă nu există evaluări

- Space News - Sukhbir GDocument6 paginiSpace News - Sukhbir Gapi-288584327Încă nu există evaluări

- Catalogo Das Bomba Danfoss s90 100.Document240 paginiCatalogo Das Bomba Danfoss s90 100.Agrocampo PeçasÎncă nu există evaluări

- HSBTS Diagram PDFDocument1 paginăHSBTS Diagram PDFMayurÎncă nu există evaluări

- Investigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantDocument5 paginiInvestigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantKR PAÎncă nu există evaluări

- Storage and Dispensing of High Blend Ethanol Fuels Inc E 85 PDFDocument15 paginiStorage and Dispensing of High Blend Ethanol Fuels Inc E 85 PDFMurli RamchandranÎncă nu există evaluări

- 36-Single Phase Specialty MotorsDocument6 pagini36-Single Phase Specialty MotorskfaliÎncă nu există evaluări

- E Series DX Uninterruptible Power System: Product BrochureDocument4 paginiE Series DX Uninterruptible Power System: Product BrochureDania Luna SantanaÎncă nu există evaluări

- Braking Capacity of Railway Wheels - State-Of-The-Art SurveyDocument19 paginiBraking Capacity of Railway Wheels - State-Of-The-Art SurveyManjunath AithalÎncă nu există evaluări

- BHEL - Agitator Specification PDFDocument68 paginiBHEL - Agitator Specification PDFRiyaz100% (1)