Documente Academic

Documente Profesional

Documente Cultură

33kv Capacitor Bank Specs

Încărcat de

sanresDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

33kv Capacitor Bank Specs

Încărcat de

sanresDrepturi de autor:

Formate disponibile

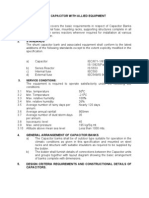

UNITED ARAB EMIRATES FEDERAL ELECTRICITY AND WATER AUTHORITY

33 kV, 20 MVAR CAPACITOR BANK

CONTENT LIST

1.0 2.0 3. 0 4.0 5.0 6.0 7.0 8.0 9.0 9.1 9.2 10.0

Service Conditions Type and rating Construction Protection Discharge device Inrush current Markings Safety features Tests Type tests Routine tests Standards

33KV CAPACITOR BANK (Page 2 of 13)

1.0

SERVICE CONDITIONS The capacitors shall be suitable for the severe atmospheric conditions specified in Volume - II, section 2-1.1 The capacitors shall be designed for the system voltage level and short circuit levels specified in Volume - II, section 2- 1.2 The capacitors shall withstand at least the following over voltage conditions: 110% of normal system voltage for 12 hours in every 24 hours. 115% of the normal system voltage for 30 minutes in every 24 hours. 120% of the normal system voltage for 5 minutes 130% of the normal system voltage for 1 minute Capacitor units shall be suitable for continuous operation at an r.m.s. current of 1.30 times the current that occurs at rated voltage and rated frequency.

2.0

TYPE AND RATING The rating of the bank shall be fixed and standardized to 20 MVAr at 33 kV. The capacitor banks shall be of open terminal type and shall be suitable for outdoor installation.

3.0

CONSTRUCTION The capacitors shall be generally capacitors shall be of PCB free type. in accordance with IEC 871. The

The capacitor units are to be built into galvanized steel racks/aluminium racks and supported wherever necessary by porcelain insulators. The capacitors shall be free from ionization and corona discharges. The capacitors bank shall have provision for termination of 33 kV, single core, XLPE cables. 4.0 PROTECTION Each capacitor unit shall be protected by an internally mounted fuse. The double star connected capacitors will be protected by a relay, which detects unbalance/residual current in the capacitor banks, through a current transformer connected between the two star neutrals. The rating of the Neutral CT will be 10 -5 /1 Amps. The exact parameters for the same will be furnished during detailed design stage. The number of switching operations of the capacitor bank shall be restricted to 10 switching operations per hour. Suitable timers and contacts shall be utilized in the opening and closing circuits to achieve the above.

33KV CAPACITOR BANK (Page 3 of 13)

5.0

DISCHARGE DEVICE Adequate arrangement is to be provided for the discharge of capacitors. The discharge time from 130% of the nominal voltage to 75V shall be less than 10 minutes for capacitors and capacitor banks. The discharge device shall be mounted internally, in the capacitor unit. There should be no switch fuse or any other isolating device between the capacitor unit and the discharge device. One three-phase bank shall have two discharge reactors connected between phases.

6.0

INRUSH CURRENT To prevent the inrush current on energisation of capacitors, in rush current limiting reactors shall be provided on each phase.

7.0

MARKINGS Markings on the capacitors and on the banks shall be as per IEC 871.

8.0

SAFETY FEATURES Safety features shall be an important criterion for the evaluation of capacitor manufacturers. Fault developed in a single capacitor unit shall not affect other equipment. Neither over pressure, nor fire damages outside the faulty unit shall occur. Detailed design of the above shall be within the scope of manufacturer and shall be subject to approval of FEWA and will be implemented by installation contractor. The access control door to the capacitor bank room shall be mechanically and electrically interlocked such that the gate can be opened only after the capacitor bank is switched off and the discharging of the capacitor has been successfully completed. The doors, fittings, accessories shall be from reputed manufactures and the building contractor shall incorporate the facilities as specified above. In addition to the earthing facility in the 33kV capacitor feeder panel, a visible earth switch will be provided near the capacitor bank and the safe operation of the same will be ensured by suitable interlocks.

9.0 9.1

TESTS TYPE TESTS Type test reports for following tests performed on Capacitor unit as per lEC 871, where applicable, shall be submitted. (a) (b) Thermal stability test Capacitor loss tangent (tan delta) measurement at elevated temperature

33KV CAPACITOR BANK (Page 4 of 13)

(c) (d) (e)

A.C. voltage test between terminals and container Lightning impulse voltage test between terminals and container Short-circuit discharge test

The identical design of the same rated capacitors shall be type tested as per relevant IEC standards at an independent internationally reputed test laboratory and the test reports shall be enclosed along with offer. In case such test reports are not available, the type test shall be performed at an independent internationally reputed test laboratory in presence of FEWA Engineer with in the quoted price and tenderer shall bear all the cost for type testing including cost of witness inspection by Authoritys Engineer. 9.2 ROUTINE TESTS Routine tests shall be carried out in accordance with IEC 871 on all capacitors and these shall include the following tests, but not necessarily be limited to them: (a) (b) (c) (d) (e) (f) (g) Capacitance measurement Measurement of tangent of the loss angle (tan ) of the capacitor Voltage test between terminals A.C. voltage test between terminals and container Test of internal discharge device Sealing test Discharge test on internal fuses

Routine tests shall be performed in all units in presence of FEWA Engineer, however, the cost of airfare, accommodation, visa etc. will be borne by FEWA and the cost of same shall not be included in the quoted price. 10.0 STANDARDS IEC-871 Shunt capacitors for A.C. power systems having rated voltages above 1000V.

33KV CAPACITOR BANK (Page 5 of 13)

APPENDIX 1 CORROSION PROTECTION Cleaning, Painting and Finishing It is to be borne in mind that the atmosphere at the site is highly corrosive. Therefore special attention should be given for the protection of all ironwork. The methods proposed and the means adopted for the rust proofing should be fully described in the tender. The following would indicate in general the minimum requirement, which the tenderer should take into account while submitting his own proposal. a. Cleaning

All surfaces shall be thoroughly cleaned and freed from rust, scale, grease, dirt and other foreign matter. Sharp points, weld spatters, flux or other imperfection shall be removed. The interior of all tanks and other oil filled chambers shall be cleaned of all scale and rust by sandblasting or other approved methods. b. Painting

Immediately after cleaning, a primary coat of red lead or other approved primer shall be applied. After the application of the first primary coat all rough surfaces shall be rubbed down and filed and a second coat of red or other approved primer applied. This shall be followed for outdoor equipment by the application of two coats of approved epoxy paint of colour RAL-7032 (finish coat paint thickness shall be more than 80 microns). For indoor equipment, after the application of the two primary coats, two coats of high-class paint shall be applied. The final coat shall a glossy finish of colour RAL7032 (finish coat paint thickness shall be more than 80 microns). The interior of all tanks and other oil filled chambers, after necessary preparation and cleaning as described in a above, shall be painted with an oil resisting varnish or enamel. All paint and/or enamel shall be applied by the brush or sprayer. Dipping shall be permitted. A first class blemish free pleasing finish shall be obtained. Sufficient paint shall be provided for all necessary touching up on site after erection. Damage to paint work incurred during transport up to delivery to stores/site shall be made good by thoroughly cleaning the damaged portion and applying the full number that had been applied before the damage was caused. A matching finish shall be obtained satisfaction of the Authority. c. Plating

Parts which are normally plated in hard chromium finish.

33KV CAPACITOR BANK (Page 6 of 13)

d.

Galvanizing

Materials to be galvanized shall be of full dimensions shown or specified, and all punching, cutting, drilling, screw tapping and the removal of burrs is to be completed before the galvanizing process commences. Galvanizing shall be done by the hot dip process with spelter not less than 98% of which must be pure zinc. No alternative process may be used without the approval of the Authority. No components may be galvanized which are likely to come into subsequent contact with oil. Bolts shall be completely galvanized including the threads. The zinc coating shall be uniform, clean, smooth and as free from spangle as possible. In the case of component parts, galvanizing shall be in accordance with BS 729 and the minimum zinc coating shall be 915 gmlm2 (127 micron). Galvanized wire for general purpose shall comply with the requirement of BS 183, galvanized wire for cable armouring shall comply with BS 1442. the weight of zinc coating on wires shall be according to BS 443. Nuts and bolts shall be galvanized to comply with requirements of BS 729. galvanized parts shall be protected from injury to the zinc coating due to differential aeration and abrasion during periods of transit, storage and erection. Damaged areas of the coating shall be brushed up with an approved metallic zinc rich priming paint complying with BS 4652.

33KV CAPACITOR BANK (Page 7 of 13)

APPENDIX 2 SMALL WIRING All control panel wiring, secondary control wiring in circuit breakers, motor starters, control gear and the like shall be carried out in a neat and systematic manner with cable supports clear of the panels and other surfaces at all points to obtain free circulation of air. In all cases, the sequence of the wiring terminals shall be such that the junction between multicore cables and the terminals is effected without crossover. Claw washers or crimped connectors of approved type shall be used to terminate all small wiring. Insulators bushes shall be provided where necessary to prevent the chafing of wiring. All panel wiring shall conform to the requirements of IEC 228 and BS 6231. The conductors shall have a minimum cross section equivalent to 50/0.25mm (2.5 mm2) or 7/0.67mm (2.5mm). Wire colours shall be as follows: Colour of wire Red Circuit Particulars Red-phase connections in current and voltage transformer circuits only Yellow-phase connections in current and voltage transformer circuits only Blue-phase connections in current and voltage transformer circuits only Connections to earth A.C. neutral connections, earthed or unearthed, connected to the secondary circuits of current and voltage transformer. A.C. connections other than those above, and connections in a.c/d.c. circuits Connections in d.c. circuits

Yellow

Blue

Green-Yellow Black

Grey

Wiring diagrams shall indicate wire colours. All diagrams shall be drawn as viewed from the back of the panel and shall state the highest number in any group. All wires shall be fitted with numbered ferrules of approved type at each termination. The same ferrule number should not be used on wires forming connections not directly in series or parallel in the same panel. At points of interconnection between wiring, where a change of numbering cannot be avoided, double ferrules shall be provided. Such points shall be clearly indicated on the wiring diagram. The ferrules on all wiring directly connected to circuit breaker trip coils, tripping switches etc. shall be of a colour, preferably red, different from that of the remainder and marked trip.

33KV CAPACITOR BANK (Page 8 of 13)

No wires may be teed or jointed between terminal points. Electrical wiring and instruments shall be so located that leakage of oil or water cannot affect them. Bus wiring between control panels, etc. shall be fully insulated and be completely segregated from the main panel wiring. All metallic cases of instruments, switches, relays etc. mounted on control panels or in cubicles steel or otherwise, shall be connected by means of bare copper conductors of not less than 2.5 mm2 section to the nearest earth bar. All wiring when made up completely is to be capable of withstanding a minimum HV test of 2000 Volt RMS for one minute applied between each core and earth.

33KV CAPACITOR BANK (Page 9 of 13)

Sl.No.

Description

Unit

Value

1. 2. 3. 4. 5. 6. 7.

Manufacturer & Country of origin Type Voltage Rating Rated frequency Capacitance of single capacitor unit Rated current per phase unit/bank Output of capacitor unit/bank at rated voltage Continuous over voltage withstand Dielectric material Impregnant material Maximum permissible voltage Maximum permissible current Residual Voltage Capacitor losses at 400 C per unit Tangent of the loss angle of capacitor Capacitance tolerance for capacitor units Rated capacitance per phase per unit Permanent raise/drop of system voltage by switching on / off Fault level at 400 C Variation of capacitance with temperature Risk of case bursting to be guaranteed % V A V KW MFD A KVAr

8. 9. 10. 11. 12. 13. 14. 15. 16.

17. 18.

F+ 5% %

19. 20.

MVA Curve

21.

Yes/No.

33KV CAPACITOR BANK (Page 10 of 13)

Sl.No.

Description

Unit

Value

22. 23.

Fire proof design Maximum temperature rise at continuous full load Overload Weight of capacitor bank Insulation level of capacitor unit :Units with full insulation to container Units with containers insulated from earth Insulation across phase of the capacitor bank Insulation across phase to phase of the capacitor bank Lightning impulse withstand voltage Power frequency withstand voltage Creepage distance (enclosed insulators) Creepage distance (outdoor) Container Material Thickness Painting Painting system Thickness

Yes/No.

0

24. 25. 26. a) b)

% Kg

c)

d)

e) f) g)

kV kV mm/kV

h) 27. a) b) 28. a) b)

mm/kV

mm

micron

33KV CAPACITOR BANK (Page 11 of 13)

Sl.No.

Description

Unit

Value

29. a) b) c) d) e) f) g) 30. a) b) c) d) e) f) g) h) i) j) k)

Discharge Device Type of discharge device Discharge time per bank Nominal voltage Maximum voltage Lightning impulse withstand voltage Power frequency withstand voltage Manufacturer Current Limiting Reactor Damping reactance Nominal voltage Maximum voltage Insulation level Nominal current rating Continuous over current Thermal short circuit rating Dynamic short circuit rating Total phase losses Type Manufacturer Mh kV kV kV kA % kA kA W/kVAr Sec kV kV kV rms kV peak

33KV CAPACITOR BANK (Page 12 of 13)

Sl.No.

Description

Unit

Value

31. a) b) c) d) e) f)

Neutral CT Ratio Class Burden & Vk Rct at 75 Magnetizing current I mag Manufacturer Ohms mA

Signature Designation Name of Tenderer Date

: : ; :

_________________________ _________________________ _________________________ _________________________

33KV CAPACITOR BANK (Page 13 of 13)

S-ar putea să vă placă și

- VCB PanelsDocument17 paginiVCB PanelsSenthil Prasadh100% (1)

- Package SubstationDocument9 paginiPackage SubstationuddinnadeemÎncă nu există evaluări

- 20 Mvar Capacitor BankDocument9 pagini20 Mvar Capacitor BankTejaswi ShuklaÎncă nu există evaluări

- Off Load Tap Changer - Part 1Document20 paginiOff Load Tap Changer - Part 1Moncoz Aye100% (3)

- 12 220 KV 4400pF CVTDocument13 pagini12 220 KV 4400pF CVTAshwin SevariaÎncă nu există evaluări

- 33kv Capacitor With Allied EquipmentDocument9 pagini33kv Capacitor With Allied EquipmentsbpathiÎncă nu există evaluări

- 11kv SWGR SpecsDocument87 pagini11kv SWGR SpecsMekonnen Shewarega100% (1)

- REC Spec.Document128 paginiREC Spec.Sanjay RoutÎncă nu există evaluări

- Vol2-4.8 11 KV SwitchgearDocument7 paginiVol2-4.8 11 KV SwitchgearNazakat HussainÎncă nu există evaluări

- Medium Voltage Capacitor Bank SpecificationsDocument4 paginiMedium Voltage Capacitor Bank SpecificationsAlexander WijesooriyaÎncă nu există evaluări

- 132 33kv SubstationDocument44 pagini132 33kv SubstationRatnesh KumarÎncă nu există evaluări

- Electrical Online CalculationsDocument5 paginiElectrical Online Calculationsdarsh2001patelÎncă nu există evaluări

- Voltage Drop Calculation of 11kV H.V. Motor at Starting: ST STDocument2 paginiVoltage Drop Calculation of 11kV H.V. Motor at Starting: ST STdpkfatnani05Încă nu există evaluări

- 33kv GIS SpecificationDocument37 pagini33kv GIS SpecificationSudharsan SD67% (3)

- Vol-2B Tech Spec.220kV XLPE Cable MedhaDocument43 paginiVol-2B Tech Spec.220kV XLPE Cable MedhaamolÎncă nu există evaluări

- Auxiliary Transformer DatasheetDocument3 paginiAuxiliary Transformer DatasheetRigoberto UrrutiaÎncă nu există evaluări

- Battery Sizing CalculationsDocument28 paginiBattery Sizing CalculationsSaravana ElectricÎncă nu există evaluări

- Short Circuit Current Calculation (Base KVA Method) - Electrical Notes & ArticlesDocument17 paginiShort Circuit Current Calculation (Base KVA Method) - Electrical Notes & ArticlesAnonymous mNQq7ojÎncă nu există evaluări

- 33KV C&R Panel Spec With SCADA OC & Numerical Differential RelayDocument27 pagini33KV C&R Panel Spec With SCADA OC & Numerical Differential RelayMohanathan VCÎncă nu există evaluări

- Form 3A Form 3B Form 3B Type 1Document2 paginiForm 3A Form 3B Form 3B Type 1syed hassanÎncă nu există evaluări

- Cable Schedule For Shahzada Bagh Bay Extension WorkDocument8 paginiCable Schedule For Shahzada Bagh Bay Extension WorkAnkur SangwanÎncă nu există evaluări

- S.C Calculations: Short Circuit StudyDocument17 paginiS.C Calculations: Short Circuit StudyAhmedRaafatÎncă nu există evaluări

- Msetcl 400 220kv Gis SpecDocument51 paginiMsetcl 400 220kv Gis SpecPrashanth Chandrashekar0% (1)

- Capacitor BankDocument12 paginiCapacitor BankMostafa Azab0% (1)

- High Voltage Components PresentationsDocument28 paginiHigh Voltage Components Presentationschristian fruto100% (1)

- Technical Specification of Kiosk Type 33 / 0.4 KV Sub - Station 250, 400, 630, 1000 kVADocument15 paginiTechnical Specification of Kiosk Type 33 / 0.4 KV Sub - Station 250, 400, 630, 1000 kVAAhmed Ja100% (1)

- Transformer Impedance OptimizationDocument2 paginiTransformer Impedance OptimizationDundi Kumar Bevara100% (1)

- Guide For The Design and Production of LV Power Factor Correction CubiclesDocument76 paginiGuide For The Design and Production of LV Power Factor Correction CubiclesGunadevan Chandrasekaran100% (1)

- NGR SizingDocument14 paginiNGR SizingSibolis Naburju0% (1)

- HT Capacitor Sizing-MotorDocument7 paginiHT Capacitor Sizing-MotorSamarjit Narayan Chowdhury100% (1)

- 4000A Bus DuctDocument9 pagini4000A Bus DuctRan Vijaysingh100% (1)

- (A) Transformer Specification SheetDocument2 pagini(A) Transformer Specification SheetPranay KharbeÎncă nu există evaluări

- Boq 132 - 33kv GssDocument14 paginiBoq 132 - 33kv GssMathur DineshÎncă nu există evaluări

- 400kV Layout GujaratDocument1 pagină400kV Layout GujaratHeather CarterÎncă nu există evaluări

- Surge Arresters: Subject Document Revision No. Sheet No. Equipment Specification Surge Arresters 1 1Document5 paginiSurge Arresters: Subject Document Revision No. Sheet No. Equipment Specification Surge Arresters 1 1PRAKASH SÎncă nu există evaluări

- Spec HT CapacitorDocument35 paginiSpec HT CapacitorJAY PARIKH100% (1)

- Battery Sizing SS 06Document6 paginiBattery Sizing SS 06aanouar77Încă nu există evaluări

- Ni-CD Battery Charger SpecificationDocument18 paginiNi-CD Battery Charger SpecificationAdrianne DouglasÎncă nu există evaluări

- Electrical Thumb Rules-Illumination - (Part-16) - Electrical Notes & ArticlesDocument14 paginiElectrical Thumb Rules-Illumination - (Part-16) - Electrical Notes & ArticlesElectrical Radical100% (1)

- Technical Specification: Odisha Power Transmission Corporation LimitedDocument55 paginiTechnical Specification: Odisha Power Transmission Corporation LimitedPritam SinghÎncă nu există evaluări

- 220 KV Switchyard EquipmentsDocument3 pagini220 KV Switchyard EquipmentsRaj Kumar Prajapati100% (1)

- Tech. Specification For HT Power CableDocument21 paginiTech. Specification For HT Power CablePramod B.WankhadeÎncă nu există evaluări

- 50/75/100 MVA, 220/132 KV & 50/75/100 MVA, 22/33 KV Outdoor SubstationDocument16 pagini50/75/100 MVA, 220/132 KV & 50/75/100 MVA, 22/33 KV Outdoor Substationdeepthik27Încă nu există evaluări

- Fault Current CalculationDocument3 paginiFault Current CalculationfarhanajnÎncă nu există evaluări

- UPS SpecificationDocument15 paginiUPS Specificationpreetam100% (1)

- Cable Sizing Rev.3Document13 paginiCable Sizing Rev.3nadeem UddinÎncă nu există evaluări

- 32 PDFDocument49 pagini32 PDFharmlesdragonÎncă nu există evaluări

- 12.es-10 Capcitor BankDocument5 pagini12.es-10 Capcitor BankDEADMANÎncă nu există evaluări

- LV Capacitor Sizing:: Thus APFC Capacitor Bank Size Selected As 925 KVARDocument10 paginiLV Capacitor Sizing:: Thus APFC Capacitor Bank Size Selected As 925 KVARSonu DesaiÎncă nu există evaluări

- VCB 5678 CatalogueDocument20 paginiVCB 5678 CataloguemuraliÎncă nu există evaluări

- Technical Specification FOR 66kV, 132kV & 220 KV XLPE Insulated Single Core Power CableDocument13 paginiTechnical Specification FOR 66kV, 132kV & 220 KV XLPE Insulated Single Core Power CableGokul VenugopalÎncă nu există evaluări

- Section 26 24 13-LV Power Distribution Boards PDFDocument15 paginiSection 26 24 13-LV Power Distribution Boards PDFmasoodaeÎncă nu există evaluări

- Drop Voltage Calculation For MotorsDocument8 paginiDrop Voltage Calculation For MotorsSESA43142Încă nu există evaluări

- 20 Mvar Capacitor BankDocument9 pagini20 Mvar Capacitor BankFarah Diba Pos-PosÎncă nu există evaluări

- BuswayDocument5 paginiBuswayuddinnadeemÎncă nu există evaluări

- 16320Document9 pagini16320uddinnadeemÎncă nu există evaluări

- Specifications For Re Installation of Elc SysDocument19 paginiSpecifications For Re Installation of Elc SysFauzi Akbar SetikoÎncă nu există evaluări

- Power Energy - Tender SpecsDocument6 paginiPower Energy - Tender SpecsAbdul-Madid Ciudad GuimbaÎncă nu există evaluări

- 630 KVA Distribution TransformerDocument4 pagini630 KVA Distribution TransformerusmanaliÎncă nu există evaluări

- Fdocuments - in Karnataka Power Transmission Ae Nhkpdfkarnataka Power Transmission CorporationDocument12 paginiFdocuments - in Karnataka Power Transmission Ae Nhkpdfkarnataka Power Transmission CorporationsanresÎncă nu există evaluări

- ES3045 Series New Digital High Voltage Insulation Tester SpecificationDocument25 paginiES3045 Series New Digital High Voltage Insulation Tester Specificationsanres0% (1)

- SL No 12 Point2point1Document12 paginiSL No 12 Point2point1sanresÎncă nu există evaluări

- Companies Act 1956 Notes PDFDocument73 paginiCompanies Act 1956 Notes PDFsanresÎncă nu există evaluări

- Fall Arrest Spec PDFDocument6 paginiFall Arrest Spec PDFAnonymous I8nZsDqlmhÎncă nu există evaluări

- IMPA Marine Stores GuideDocument10 paginiIMPA Marine Stores GuideAbdul Anis50% (2)

- Material Stud Anhor Masonry For Hilti - 3 PDFDocument23 paginiMaterial Stud Anhor Masonry For Hilti - 3 PDFAndy MdlÎncă nu există evaluări

- Cavity Wall Insulation ProblemsDocument7 paginiCavity Wall Insulation Problemsfriska_arianiÎncă nu există evaluări

- ASTM A733 Standard Specification For Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesDocument5 paginiASTM A733 Standard Specification For Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesYaser Mohamed AbasÎncă nu există evaluări

- Parmet Catalogue 2017Document36 paginiParmet Catalogue 2017Erki ParikÎncă nu există evaluări

- Technical Seminar For Galvanizers March 2012 Mike Ainsley - Update PDFDocument146 paginiTechnical Seminar For Galvanizers March 2012 Mike Ainsley - Update PDFTalal JameelÎncă nu există evaluări

- Project Report On Galvanised Nut & BoltDocument6 paginiProject Report On Galvanised Nut & BoltEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Influence of Air Knife Wiping On Coating Thickness inDocument9 paginiInfluence of Air Knife Wiping On Coating Thickness inTrilok Chand GuptaÎncă nu există evaluări

- Struct FastCatalogDocument12 paginiStruct FastCatalogGabriel WilliamsonÎncă nu există evaluări

- Standard Scaffolding: Etobicoke Ironworks LimitedDocument4 paginiStandard Scaffolding: Etobicoke Ironworks LimitedkapilÎncă nu există evaluări

- Channel Nut FCN ClixDocument1 paginăChannel Nut FCN ClixArunKumar RajendranÎncă nu există evaluări

- ASTM FFFDocument4 paginiASTM FFFMuhammad NaumanÎncă nu există evaluări

- Viking Water Motor AlarmDocument4 paginiViking Water Motor AlarmLUCASÎncă nu există evaluări

- A Master's Guide To Ship's Piping 2nd EditionDocument42 paginiA Master's Guide To Ship's Piping 2nd Editiondassi99100% (1)

- Workshop Lubrication Truck Mercedes 2Document23 paginiWorkshop Lubrication Truck Mercedes 2Aprizal AzisÎncă nu există evaluări

- Powder Coating TalbertDocument280 paginiPowder Coating Talbertrohith100% (1)

- JSW PresentationDocument18 paginiJSW Presentationrenu.messagesÎncă nu există evaluări

- Fire Hydrants, Valve Assemblies and Parts - EJDocument24 paginiFire Hydrants, Valve Assemblies and Parts - EJironworkÎncă nu există evaluări

- Structural Steel Detailing Practices - Good and BadDocument15 paginiStructural Steel Detailing Practices - Good and Badzeek77Încă nu există evaluări

- Amendment No. 1 Hot-Dip Zinc Coatings On Steel and Cast Iron ProductsDocument2 paginiAmendment No. 1 Hot-Dip Zinc Coatings On Steel and Cast Iron ProductsGMSÎncă nu există evaluări

- Hot Dip Galvanization - FaboryDocument4 paginiHot Dip Galvanization - FaboryBrandon LimÎncă nu există evaluări

- Construction Specification Chain Link FenceDocument2 paginiConstruction Specification Chain Link Fenceyamanta_rajÎncă nu există evaluări

- 11 - 11KV Outdoor Switches - Spec No 36Document40 pagini11 - 11KV Outdoor Switches - Spec No 36diputhe diyaÎncă nu există evaluări

- Sustainable Bridge StructuresDocument331 paginiSustainable Bridge StructureskesharinareshÎncă nu există evaluări

- Katalog BevanandaDocument8 paginiKatalog BevanandakenÎncă nu există evaluări

- NCHRP RPT 675Document116 paginiNCHRP RPT 675RobÎncă nu există evaluări

- Internal Test ReportDocument4 paginiInternal Test ReportAvishek ChowdhuryÎncă nu există evaluări

- ASTM F1554 Anchor RodsDocument2 paginiASTM F1554 Anchor Rodsgiango_09100% (1)

- Division C700 - Miscellaneous Construction: Section C700 - General InformationDocument14 paginiDivision C700 - Miscellaneous Construction: Section C700 - General InformationVictor AmilcarÎncă nu există evaluări