Documente Academic

Documente Profesional

Documente Cultură

LAB SHEET For Pelton Wheel 21 Sept 2011

Încărcat de

Mohd FazliTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LAB SHEET For Pelton Wheel 21 Sept 2011

Încărcat de

Mohd FazliDrepturi de autor:

Formate disponibile

UNIVERSITI PERTAHANAN MALAYSIA KEM SUNGAI BESI LAB 3 - PELTON WHEEL TURBINE

DIMENSIONS AND WEIGHTS Nett:- 580 x 230 x 500 mm, 9.0 Kg. Gross:- 0.078m, 12 Kg.

Objectives

To investigate typical performance characteristics of Pelton Wheel (Impulse Turbine)

Apparatus

Pelton Wheel Turbine Hydraulic Bench by Cussons Technology Ltd. Model P6240, digital tachometer, pressure gage and volume flow rate measurement apparatus.

Background

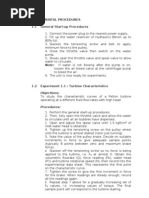

Pelton Wheel Turbine is the only impulse water turbine now in common use named in honour of Sir L.A. Pelton (1829- 1908) of California, USA. It is a tangential flow impulse turbine. The water strikes the buckets along the tangent of the runner. The energy available at the inlet of the turbine is only kinetic energy. The pressure at the inlet and outlet of the turbine is atmospheric. This turbine is used for high heads. The present set-up consists of a runner which buckets are mounted on it. The design is typical industrial practice with a horizontal shaft, single horizontal jets produced by a single nozzle fitted with a needle or spear regulator, and a wheel fitted with multiple (16) elliptical ridged buckets at a mean diameter of 100 mm. The nozzle is positioned in the same plane as the wheel and arranged so that the jet of water impinges tangentially on to the buckets. The desired maximum deflection of the jet (180) cannot be achieved without the fluid leaving one bucket striking the following one, and so in practice the deflection is limited to approximately 155 (i.e. see Fig. 1, 180 - 25). The wheel mounted on the shaft which fitted with a 60mm diameter friction dynamometer (Prony brake) as illustrated in Fig. 2, so that the efficiency of the turbine can be calculated. A fabric brake band which used as a brake lining is tensioned by a weight hanger and masses with the fixed end being secured via a spring balance to the support frame.

WAWM 2010

Pressure gauge is fitted at the inlet of the turbine to measure the total supply head to the turbine. The circular window of the turbine casing is provided with a transparent acrylic sheet for observation of flow on to the buckets. The bottom of the casing is open to allow the water leaving the buckets to drain away.

Expected Results

Compute and plot; 1. 2. 3. Turbine efficiency against unit speed (Nu) for all three flow rates on one graph. Unit power (Pu) against unit speed ( Nu) on one graph Iso-efficiency curves on graph Pu against Nu.

Discussion

Discuss about your result and graphs What is the best opening at nozzle for the best efficiency? Can you get it or not? If cannot, explain why. The results as what you expected OR not, explain in detail.

Conclusion

Conclude your result and finding.

WAWM 2010

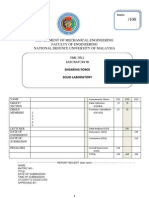

LAB 3 - PELTON WHEEL DATA AND RESULT

Mean wheel diameter = Brake wheel diameter = Inlet Pressure = 0.1 0.06 _____ m m Pascal

POSITION 1 : FULLY OPEN, 2/3 OPEN and 1/3 OPEN

Flow rate, Q = Input Power, Pin =

Speed N (r.p.m)

Spring Balance reading (gram)

Torque T (Nm)

Input Power Po (Watt)

Efficiency %

m3/s Watt Unit Power Pu

Unit Speed Nu

POSITION 2 : 2/3 OPEN

Flow rate, Q = Input Power, Pin =

Speed N (r.p.m)

Spring Balance reading (gram)

Torque T (Nm)

Input Power Po (Watt)

Efficiency %

m3/s Watt Unit Power Pu

Unit Speed Nu

POSITION 3 : 1/3 OPEN

Flow rate, Q = Input Power, Pin =

Speed N (r.p.m)

Spring Balance reading (gram)

Torque T (Nm)

Input Power Po (Watt)

Efficiency %

m3/s Watt Unit Power Pu

Unit Speed Nu

WAWM 2010

S-ar putea să vă placă și

- Application Engineering: Reda Esp System ComponentsDocument4 paginiApplication Engineering: Reda Esp System Componentselsayed amerÎncă nu există evaluări

- Impact of A Jet Lab ReportDocument3 paginiImpact of A Jet Lab ReportSaiful IslamÎncă nu există evaluări

- Basics of Hydrogen TechnologyDocument28 paginiBasics of Hydrogen TechnologyAkshay Gattu100% (2)

- V Notch PracticalDocument13 paginiV Notch PracticalAnushaBheenuck0% (2)

- Nilesh Y. Jadhav Auth. Green and Smart Buildings Advanced Technology OptionsDocument188 paginiNilesh Y. Jadhav Auth. Green and Smart Buildings Advanced Technology OptionsNicolasan21100% (1)

- Impact of A Water JetDocument5 paginiImpact of A Water JetAnirban SardarÎncă nu există evaluări

- EXP 5 - Study of Hydraulic Jump in A Rectangular ChannelDocument9 paginiEXP 5 - Study of Hydraulic Jump in A Rectangular Channelsiva ramÎncă nu există evaluări

- Shading PrinciplesDocument5 paginiShading PrinciplesNisa Ann100% (1)

- Measure Flow in Open ChannelsDocument5 paginiMeasure Flow in Open ChannelsKheshav Jhundoo100% (2)

- Energy Losses in Pipes: Experiment # 4Document4 paginiEnergy Losses in Pipes: Experiment # 4محمد جوادÎncă nu există evaluări

- Bulletin 2 - Heat Recovery From Hot Water System of Tyre Curing SystemDocument2 paginiBulletin 2 - Heat Recovery From Hot Water System of Tyre Curing SystemSivaram KrishnamoorthyÎncă nu există evaluări

- Offshore Wind Farm ProjectDocument39 paginiOffshore Wind Farm ProjectAlireza Aleali89% (9)

- Mka-03 Pelton and Francis TurbinesDocument11 paginiMka-03 Pelton and Francis TurbineshasshosÎncă nu există evaluări

- Lab 1Document15 paginiLab 1Mohd FazliÎncă nu există evaluări

- Experiment 3 Reaction TurbineDocument20 paginiExperiment 3 Reaction TurbineAnonymous T7vjZG4ot100% (1)

- Lab 4-Friction Losses and Minor LossesDocument7 paginiLab 4-Friction Losses and Minor LossesJJ Sean CruzÎncă nu există evaluări

- BROAD CRESTED WEIR LABORATORY EXPERIMENTDocument12 paginiBROAD CRESTED WEIR LABORATORY EXPERIMENTSyafiq Roslan75% (4)

- Pelton Turbine LabDocument12 paginiPelton Turbine LablufimanÎncă nu există evaluări

- Specific Energy Hydraulic Jumps WeirsDocument23 paginiSpecific Energy Hydraulic Jumps WeirsHaris jugnooÎncă nu există evaluări

- Review of Existing Hydro and PSH ModelsDocument102 paginiReview of Existing Hydro and PSH ModelsgausscanaveaÎncă nu există evaluări

- Material LaboratoryDocument14 paginiMaterial LaboratoryAnonymous tLXKwTÎncă nu există evaluări

- ICIS PetrochemicalsPosterDocument1 paginăICIS PetrochemicalsPosterKinoiÎncă nu există evaluări

- Manning's Roughness Coefficient (N)Document11 paginiManning's Roughness Coefficient (N)Khurram MumtazÎncă nu există evaluări

- Inductance in AC Circuits ExplainedDocument24 paginiInductance in AC Circuits ExplainedAbdur RahmanÎncă nu există evaluări

- SS350 Series Air StartersDocument8 paginiSS350 Series Air StartersRICARDO MAMANI GARCIAÎncă nu există evaluări

- LED Street Light Catalogue 2016Document12 paginiLED Street Light Catalogue 2016Sudalai MuthuÎncă nu există evaluări

- Lab7-Phelton Turbine Experiment-UpdatedDocument7 paginiLab7-Phelton Turbine Experiment-Updatedtomtoms92Încă nu există evaluări

- Pelton Wheel TurbineDocument8 paginiPelton Wheel TurbineSiew LynÎncă nu există evaluări

- Introduction Impact JetDocument4 paginiIntroduction Impact JetIniaan SaminathanÎncă nu există evaluări

- Impact of JetDocument5 paginiImpact of Jetميسرة33% (3)

- Pelton Turbine CharacteristicsDocument10 paginiPelton Turbine CharacteristicsViknesh MjÎncă nu există evaluări

- Pelton TurbineDocument4 paginiPelton TurbineHenDricky Magosi100% (1)

- Centre of Hidrostatic PressureDocument16 paginiCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Orifice Jet Flow Experiment GuideDocument3 paginiOrifice Jet Flow Experiment GuideshaneshaneshaneshaneÎncă nu există evaluări

- CEWB21 Exp 4 Full ReportDocument9 paginiCEWB21 Exp 4 Full ReportNur FarehaÎncă nu există evaluări

- Flow in Open ChannelDocument24 paginiFlow in Open ChannelSue IlaÎncă nu există evaluări

- 5 Calibration of Triangular NotchDocument8 pagini5 Calibration of Triangular Notchkanavan monÎncă nu există evaluări

- Free VortexDocument3 paginiFree VortexVrushiket Patil67% (3)

- Impact of JetDocument7 paginiImpact of JetHeng Xiu KohÎncă nu există evaluări

- Venturi meter experiment proceduresDocument2 paginiVenturi meter experiment proceduresAnonymous mRBbdopMKf100% (1)

- Lab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels.Document4 paginiLab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels.Muhamad IzzanÎncă nu există evaluări

- Lab 2 Mini FLow ChannelDocument16 paginiLab 2 Mini FLow ChannelIr Fik TÎncă nu există evaluări

- CE 2020 - Fluid Mechanics LaboratoryDocument67 paginiCE 2020 - Fluid Mechanics LaboratoryMd.Tarequl IslamÎncă nu există evaluări

- Pelton Turbine Experiment ResultDocument2 paginiPelton Turbine Experiment ResultShea Cheng KuangÎncă nu există evaluări

- Theory VenturiDocument7 paginiTheory VenturiMahendranath RamakrishnanÎncă nu există evaluări

- Venturi MeterDocument15 paginiVenturi MeterFatimah BadruddinÎncă nu există evaluări

- Bernoulli's TheoremDocument5 paginiBernoulli's TheoremVrushiket PatilÎncă nu există evaluări

- Swinburne University of Technology: School of Engineering (Sarawak Campus)Document19 paginiSwinburne University of Technology: School of Engineering (Sarawak Campus)Mahfuzah MustaphaÎncă nu există evaluări

- Fluid Mechanics Lab 3.1Document13 paginiFluid Mechanics Lab 3.1mahmoudÎncă nu există evaluări

- Table of Content DocDocument17 paginiTable of Content DocjjÎncă nu există evaluări

- CavitationDocument3 paginiCavitationTara JenkinsÎncă nu există evaluări

- StrutsDocument7 paginiStrutsBatrisyialya RusliÎncă nu există evaluări

- Discharge Through An Orifice: ME419 Fluid Mechanics LabDocument13 paginiDischarge Through An Orifice: ME419 Fluid Mechanics LabMansor MajbriÎncă nu există evaluări

- Francis ReportDocument24 paginiFrancis Reportantukara100% (3)

- Lab Report 2Document16 paginiLab Report 2Limmy Yingran0% (1)

- Calibrating a Venturi MeterDocument10 paginiCalibrating a Venturi MeterAgyeman EmmanuelÎncă nu există evaluări

- eXPERIMENT NO 06 FMDocument9 paginieXPERIMENT NO 06 FMAsim Bajwa100% (1)

- Centre of Pressure Level 1Document12 paginiCentre of Pressure Level 1Mohd Azeem RizalÎncă nu există evaluări

- Flow Rate Measurement Using Venturi, Orifice & RotameterDocument13 paginiFlow Rate Measurement Using Venturi, Orifice & RotameterxxxxxÎncă nu există evaluări

- Jet ReactionDocument4 paginiJet ReactionSelva RajÎncă nu există evaluări

- Bernoullis Equation Lab ReportDocument12 paginiBernoullis Equation Lab ReportgeduyoxÎncă nu există evaluări

- V NotchDocument2 paginiV NotchUstaziyatul AlamÎncă nu există evaluări

- Exp No # 7 Impact of Jet On VanesDocument4 paginiExp No # 7 Impact of Jet On VanesBadari Narayan P50% (2)

- Sharp Crested WeirDocument7 paginiSharp Crested WeirMohamad Zahir Razak100% (1)

- Report 3a Pelton Turbine - HydraulicDocument13 paginiReport 3a Pelton Turbine - HydraulicAin SherinÎncă nu există evaluări

- Mka 03 (B) Francis TurbineDocument5 paginiMka 03 (B) Francis TurbineHawaiiChongÎncă nu există evaluări

- OpenChannel Flow Lab ReportDocument8 paginiOpenChannel Flow Lab ReportNur SalwaniÎncă nu există evaluări

- Report Buckling of StructsDocument7 paginiReport Buckling of StructsAnonymous 59kjvq4OLBÎncă nu există evaluări

- Venturimeter ExperimentDocument9 paginiVenturimeter ExperimentcoutohahaÎncă nu există evaluări

- Hydraulic Jump Lab ExperimentDocument6 paginiHydraulic Jump Lab ExperimentCarlos J. SantacruzÎncă nu există evaluări

- LAB SHEET For Pelton WheelDocument3 paginiLAB SHEET For Pelton WheelA41XOÎncă nu există evaluări

- Lab Test Set Up of Pelton Wheel and TestDocument7 paginiLab Test Set Up of Pelton Wheel and TestHimansu GoswamiÎncă nu există evaluări

- Lect Week 2 (Sem 2 1011..2012)Document41 paginiLect Week 2 (Sem 2 1011..2012)Mohd FazliÎncă nu există evaluări

- Lect Week 2 (Sem 2 1011..2012)Document41 paginiLect Week 2 (Sem 2 1011..2012)Mohd FazliÎncă nu există evaluări

- Pen Gen Alan Kepada Sistem Instrumentasi Latest (Sem 2 2011.2012)Document47 paginiPen Gen Alan Kepada Sistem Instrumentasi Latest (Sem 2 2011.2012)Mohd Fazli100% (1)

- Dynamic Deformation in Mre Driven by Magnetic Field, Gy Zhou, 2003Document9 paginiDynamic Deformation in Mre Driven by Magnetic Field, Gy Zhou, 2003Mohd FazliÎncă nu există evaluări

- Lab 4Document8 paginiLab 4Mohd FazliÎncă nu există evaluări

- Time Response Control SystemDocument19 paginiTime Response Control SystemMohd FazliÎncă nu există evaluări

- Rise TimeDocument1 paginăRise TimeMohd FazliÎncă nu există evaluări

- Lab 4Document8 paginiLab 4Mohd FazliÎncă nu există evaluări

- Block Diagram ManipulationDocument13 paginiBlock Diagram ManipulationMohd FazliÎncă nu există evaluări

- Pen Gen Alan Kepada Sistem Instrumentasi Latest (Sem 2 2011.2012)Document47 paginiPen Gen Alan Kepada Sistem Instrumentasi Latest (Sem 2 2011.2012)Mohd Fazli100% (1)

- Step Response of A First and Second Order SystemDocument28 paginiStep Response of A First and Second Order SystemMohd FazliÎncă nu există evaluări

- Lab 2Document3 paginiLab 2Mohd FazliÎncă nu există evaluări

- Lab 3 Sheet Refrigeration Unit - 25 Sep 11Document2 paginiLab 3 Sheet Refrigeration Unit - 25 Sep 11Mohd FazliÎncă nu există evaluări

- Lab 3 Sheet Refrigeration Unit - 25 Sep 11Document2 paginiLab 3 Sheet Refrigeration Unit - 25 Sep 11Mohd FazliÎncă nu există evaluări

- Lab 3 Sheet Air Compressor Unit - 25 Sep 11Document3 paginiLab 3 Sheet Air Compressor Unit - 25 Sep 11Mohd FazliÎncă nu există evaluări

- Notes on Oscilloscopes in 40 CharactersDocument28 paginiNotes on Oscilloscopes in 40 Charactersywakade100% (2)

- Mathematical ModellingDocument36 paginiMathematical ModellingMohd Fazli100% (2)

- Lab III V Notch CoverDocument2 paginiLab III V Notch CoverMohd FazliÎncă nu există evaluări

- Lab 3 Sheet Buckling-21Sep11Document3 paginiLab 3 Sheet Buckling-21Sep11Mohd FazliÎncă nu există evaluări

- Lab 3 Sheet Shearing Force-21Sep11Document4 paginiLab 3 Sheet Shearing Force-21Sep11Mohd FazliÎncă nu există evaluări

- Lab III Centrifugal Pump (I) CoverDocument2 paginiLab III Centrifugal Pump (I) CoverMohd FazliÎncă nu există evaluări

- Function Generator and AWG GuidebookDocument37 paginiFunction Generator and AWG Guidebookpranavd2008Încă nu există evaluări

- Lab 3 Sheet Bending-21Sep11Document4 paginiLab 3 Sheet Bending-21Sep11Mohd FazliÎncă nu există evaluări

- Lab Sheet For V-Notch 21 Sept 2011Document3 paginiLab Sheet For V-Notch 21 Sept 2011Mohd FazliÎncă nu există evaluări

- LAB SHEET For Centrifugal Pump (I)Document2 paginiLAB SHEET For Centrifugal Pump (I)Mohd FazliÎncă nu există evaluări

- Lab III Pelton Wheel CoverDocument2 paginiLab III Pelton Wheel CoverMohd FazliÎncă nu există evaluări

- DC Motor TheoryDocument4 paginiDC Motor TheoryMohd FazliÎncă nu există evaluări

- DC Motor LabDocument1 paginăDC Motor LabMohd FazliÎncă nu există evaluări

- Samsung+C&T E&C+Brochure ENGDocument31 paginiSamsung+C&T E&C+Brochure ENGffyu100% (1)

- Volume Flow in GTDocument64 paginiVolume Flow in GThussain mominÎncă nu există evaluări

- pt6 PaperDocument11 paginipt6 PaperSarvesh KanaujiaÎncă nu există evaluări

- Condenser Graphical AnalysisDocument24 paginiCondenser Graphical Analysissaisrikanths5168Încă nu există evaluări

- Small Hydropower Cost Reference ModelDocument71 paginiSmall Hydropower Cost Reference ModelOne Line ResourcesÎncă nu există evaluări

- Ashok JatrophaDocument20 paginiAshok Jatrophajoe_prince333Încă nu există evaluări

- Step-By-Step Self-Assembled Hybrids That Feature Control Over Energy and Charge TransferDocument7 paginiStep-By-Step Self-Assembled Hybrids That Feature Control Over Energy and Charge TransferLuciano PereiraÎncă nu există evaluări

- AssignmentDocument4 paginiAssignmentIdeal HealthcareÎncă nu există evaluări

- Metodos VerdesDocument18 paginiMetodos VerdesSanchez JorgeÎncă nu există evaluări

- Solar Simulation Standards and QuickSun Measurement SystemDocument34 paginiSolar Simulation Standards and QuickSun Measurement SystemMohamad YazdaniÎncă nu există evaluări

- Solarworld - Magazine 2016 - en - WebDocument18 paginiSolarworld - Magazine 2016 - en - WebSamuel Arévalo GÎncă nu există evaluări

- 100 Homework Ch11Document9 pagini100 Homework Ch11Saad KhalidÎncă nu există evaluări

- EE6009 PERES Unit IIIDocument301 paginiEE6009 PERES Unit IIIrivehappy1996Încă nu există evaluări

- Office of the Chief Engineer solar net metering guidelinesDocument15 paginiOffice of the Chief Engineer solar net metering guidelinesRitesh DhawaleÎncă nu există evaluări

- Direct Driven Fire Water Pump With Angle Gear: Keep Going. Keep SafeDocument8 paginiDirect Driven Fire Water Pump With Angle Gear: Keep Going. Keep Safeandy131078Încă nu există evaluări

- Energy Malaysia Volume 201Document52 paginiEnergy Malaysia Volume 201ridzuwan mohd jaisÎncă nu există evaluări

- University of Manchester Course DescriptionDocument6 paginiUniversity of Manchester Course DescriptionAnonymous xokGtxhÎncă nu există evaluări

- VaranasiSolarCity - 08 Jan 2024Document7 paginiVaranasiSolarCity - 08 Jan 2024abhishrut singhÎncă nu există evaluări

- Gas Steam Specs PDFDocument10 paginiGas Steam Specs PDFhggil3802Încă nu există evaluări