Documente Academic

Documente Profesional

Documente Cultură

Section Mill

Încărcat de

Arth SumagueDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Section Mill

Încărcat de

Arth SumagueDrepturi de autor:

Formate disponibile

SECTION MILL Specifications Section Rolling Mill Plants Basic design & layout Consultancy Fully automatic / manual

{as customer desired} Rolling angle, channel, I / H beam, flat, round square etc High production Light / medium / heavy structure Cutting, cooling & handling equipment Straightening arrangement

PLATE MILL Specifications Carbon Steel Plate thickness: 6mm-120mm Width:1400-4100mm Length:6000-28000mm

HOT STRIP MILL Specifications hot strip mill 1.Voltage:DC12V/24V 2.LED Qty:600pcs 5050led 3.Factory direct sale 4.CE,ROHS,FCC Name: 3528/5050 hot strip mill 1.1210(3528) Waterproof silicone tube and epoxy filled flexible LED strip, 600 LEDs/m 2.Product: 1210(3528) Waterproof silicone tube and epoxy filled flexible LED strip, 120 LEDs/m 3.Model:HY-FX-082X 4.Dimension: L5000mm*W11mm*H4.5mm 5.LED quantity: 600 SMDs/pcs, 120 1210 SMDs/m 6.Thickness of PCB: 0.20mm 7.Working voltage: DC 12V(24V) 8.Power dissipation: 9.6W, every 3 LEDs can be cut(12V), and every 6 LEDs can be cut(24V) 9.Working current: 3A/reel 10.Viewing angle: 120 degree 11.Packing: 5m/reel

12.Color: red, yellow, blue, green, white and warmwhite are available 13.Color of PCB: white, brown, black are available. LED Strip detail specifition : Model: HY-5050FX120-060X LED Number: 600 SMDs/pcs Power Consumption: 9.6W Input Voltage: 12V/24V Len Angle: 120 IP Grade: IP68 Lifespan: 50,000hours Working Temp: 20-40C Storage Temp: -40-80 Certifition: CE,ROHS,FCC Color: red, yellow, blue, green, white and warmwhite are available Suitable for hotel,meeting room, show room,shop,telephone booth ApplicationEnvironment: etc

Wire ROD MILL

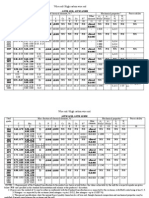

The continuous wire rod rolling mill of the Morgan type was built in 1973, and in 1997 and 2000 it was extensively reconstructed and modernized. Originally four-strand continuous wire rod mill was rebuilt to present two-strand mill of increased production capacity, wider product range and higher quality of the manufactured wire rod. The production process is controlled by an automated computer system. The cast billets and the billets from the reversing mill, after their heating in a new walking-beam furnace, are rolled on the preparatory, roughing and intermediate trains. Next, the rolled material is fed via a controlled loop into the CL double stand with overhung rolls and then to the 10-stand block from which the wire rod runs out at a speed up to 105 m/s. Heat treatment of a wire rod is carried out on each strand in four sections of water cooling. Next phase of heat treatment is performed in an unfold loop on the chain conveyer where air cooling is applied. Then, a coil of wire rod of the weight about 2 t is collected in a reception chamber, from which it is transported by a hook conveyer to the

presses where coils are pressed and prepared for shipment by means of railway or road transport. The mill produces wire rod of the diameter 5.520 mm. Characteristics of the continuous wire rod mill Preparatory train Roughing and intermediate trains Rolls diameter 2-stand block Rolls diameter Finishing block Rolls diameter Rolling speed Capacity SPECIFICATION 4 stands of H-V type 14 stands of H type 540, 440 and 380 mm type H, V 203 mm Finishing block 10-stand of H, V type 200 and 160 mm 105 m/s 825 kt/year

Steel wire mill rod Location: After rough rolling 7; Role: the cutting head, tail broken off and the accident; Type: crank-type; Work system: start-stop-work system - cut head and tail; Continuous duty - incidents broken off; Maximum cutting section: 65 65mm2; Maximum shear force: 60T; Cutting temperature: more or equal 850 C; Cutting head length :50-800mm; Broken-off length: 800mm; Cut accuracy: 20mm; Blade material: 3Cr2W8V; Effective blade width: 240mm; Crank radius: 125mm; Rotation center distance: 870mm; Main Motor: Type: ZFQZ-355-092 Power: 293KW Voltage: 660V Working rpm: 600r/min Cooling: Fan

COLD ROLLING TANDEM MILL

Specifications 1.500 6-hi 4 tandem cold rolling mill 2.For common carbon steel 3.In:Thk:2.5mm Width:400mm 4.Out:Thk:0.45 Width:400 400 6-Hi 4 Tandem cold rolling mill Reversible Rolling Machine Technical Parameter A. Rolling Conditions 1. Material: Common Carbon Steel, etc. 2. Material Spec.: Thickness 2.5mm Width: 400mm Max. roller weight: 7000kg 3. Finished Product Spec.: 0.45mm Width: 400mm Roller Inter Diameter: 510mm Max. roller weight: 10000kg 4. Rolling force: p750T 5. Max. Rolling speed: v180m/min 6. Rolling tension: T80KN B. Equipment Components 1. Main frame Spec.: 155/620750 4-roller reversible getting-down mill. 2. Transmission method: Back-up roller transmission 3. Press device: a. Press motor: Model Power 22KW2, Grade 6 Simultaneous or separate action of press-down and lifting b. High-speed worm gear case: WS250 I=45 Central distance A=250mm

c. Lowspeed worm gear case: Double enveloping worm gear and endless screw Central distance A=48 0mm, Mn=16mm, I=50 d. Pressing screw: S22010, Pressing speed: 0.05mm/s e. The pressing cabinet adopts casting steel parts. 4. Frame: a. 2 closed housing window, vertical section 320450, ZG35 b. Integral processing, manual leveling-off. c. Tension frame (C-shape frame) squeezing roller 5. Roller system part: a. Working roller diameterroller width: 155750mm.Material 9Gr2Mo, Bearing: FC Bearing b. Backup roller diameterroller width: 620730mm.Material 9Gr2Mo, Bearing: FCD72104450 Bearin g c. Bearing lubricating mode: Dry oil lubricating d. Back-up roller balancing device: Hydraulic balancing e. Roller change mode: Hydraulic control WELDED PIPE MILL Specifications WF32A steel tube welding machine. 1>Pipe diameter: 13~50mm. 2>Pipe thickness: 0.6~1.8mm. 3>Welding speed: 20~90m/m.

WF32A steel tube welding machine. Main technical parameters and details: 1>Pipe diameter: 13~50mm. 2>Pipe thickness: 0.6~1.8mm. 3>Welding speed: 20~90m/m. 4>Welding method: high frequency welding. Main components of the welding machine:

1>Uncoiler. 2>Accumulator. 3>Shearing and butt welding machine. 4>Forming unit. 5>Welding unit. 6>Sizing unit. 7>Computer controlled flying cutting saw. 8>Run-out table. Power output of major motor: 1>Main motor: 75KW. 2>High frequency unit: 100KW

SEAMLESS PIPE MILL Specifications 1seamless pipe mill 2Size:10-508mm*2-50mm 3A53/A106/API 5L Gr.B 4 hot rolled,cold drawn process seamless pipe mill 1> seamless steel pipe Size: OD 1/8 inch --14 inch, wall thickness 2mm --60mm. 2> ERW steel pipe Size: OD89mm to 820mm, wall thickness: 4mm to 30mm 3> Spiral double-side submerged-Arc Welded steel pipe, Size : OD 219mm to 2000mm , wall thickness : 5mm to 25.4mm 4> centrifugal casting pipe, size OD 203mm-770mm,thickness 30mm-120mm. length 1-7 meters 5> hot rolled thick walled seamless steel pipe:OD102mm to 770mm,wall thickness:15mm to 100mm 6> precision cold drawn seamless steel pipe: OD20mm to 203mm,wall thickness:2mm to 30mm the material are A53B,A106B,ST37,ST45,ST52,10#, 20#, 35#, 45# 40Cr, 16Mn, 20Cr,40Cr,35CrMo,42CrMo,12Cr MoV,10CrMo910, 12Cr1MoV, 15CrMo etc.

S-ar putea să vă placă și

- Copper & Aluminium Rod Continuous CastingDocument5 paginiCopper & Aluminium Rod Continuous CastingYonathan JonathanÎncă nu există evaluări

- PVC PipesDocument35 paginiPVC Pipespratikgarg03Încă nu există evaluări

- Catalogue of Thread Rolling MachineDocument14 paginiCatalogue of Thread Rolling MachinelusakeÎncă nu există evaluări

- Experimental and Computational Investigation of The Roll Forming ProcessDocument148 paginiExperimental and Computational Investigation of The Roll Forming Processakhilesh120Încă nu există evaluări

- JRF-C&Z 70 - 300Document16 paginiJRF-C&Z 70 - 300Ravi ChandranÎncă nu există evaluări

- 5 - Double Layer Roll Forming MachineDocument6 pagini5 - Double Layer Roll Forming MachineJHON SEGURA GONZALEZÎncă nu există evaluări

- Qoutation of Double Layer Roof Sheet Roll Forming MachineDocument8 paginiQoutation of Double Layer Roof Sheet Roll Forming MachineJHON SEGURA GONZALEZÎncă nu există evaluări

- Techno-Commercial Proposal - Slitting Machine - Rev 01Document9 paginiTechno-Commercial Proposal - Slitting Machine - Rev 01Chandru ChristurajÎncă nu există evaluări

- Proposal HMG-350JM SXKH Die Spotting PressDocument9 paginiProposal HMG-350JM SXKH Die Spotting Press846213Încă nu există evaluări

- 12 MM Capacity 4-Roll Hydraulic Double Pinch Cum Pyramid Type Plate Bending MachineDocument19 pagini12 MM Capacity 4-Roll Hydraulic Double Pinch Cum Pyramid Type Plate Bending MachineImamul HaqueÎncă nu există evaluări

- Bokaro Steel PlantDocument3 paginiBokaro Steel PlantSayan ChatterjeeÎncă nu există evaluări

- Balbir Rolling Mills Project Management 1 AbDocument19 paginiBalbir Rolling Mills Project Management 1 AbPruthvi BaisÎncă nu există evaluări

- Oree Laser Quotation of or-PG 6025 12kw MAX (Three in One) Cynthia 20230105 - 230105 - 225357Document17 paginiOree Laser Quotation of or-PG 6025 12kw MAX (Three in One) Cynthia 20230105 - 230105 - 225357iqbal husseinÎncă nu există evaluări

- High Speed Z Purlin MachineDocument6 paginiHigh Speed Z Purlin MachineChris RishbinÎncă nu există evaluări

- Low Table/table Top Semi Automatic Carton Strapping Machine: Wz-443 GF, Naraina Village, New Delhi - 110028Document2 paginiLow Table/table Top Semi Automatic Carton Strapping Machine: Wz-443 GF, Naraina Village, New Delhi - 110028Shekhar SrivassÎncă nu există evaluări

- Structural Steel Design DetailsDocument7 paginiStructural Steel Design DetailsJanya AssociatesÎncă nu există evaluări

- Quot 1 Aditi Vinod PDFDocument5 paginiQuot 1 Aditi Vinod PDFVasoya Manoj0% (1)

- FENN Division Tcm20-23390Document15 paginiFENN Division Tcm20-23390Juan Fernando Campuzano100% (1)

- ControlPanel MPC210 PriceListDocument4 paginiControlPanel MPC210 PriceListNamQuyÎncă nu există evaluări

- S & S Polymers. Tamil Nadu IndiaDocument10 paginiS & S Polymers. Tamil Nadu IndiaS & S PolymersÎncă nu există evaluări

- Speed Control of Steel Rolling Mill Using Neural Network: January 2006Document6 paginiSpeed Control of Steel Rolling Mill Using Neural Network: January 2006Pranati MishraÎncă nu există evaluări

- Chaitanya IntroductionDocument7 paginiChaitanya Introductionanon_647217551Încă nu există evaluări

- 132 EC - A 10 - VIT - Chennai - Meggger & Multimeter - JE QTNDocument4 pagini132 EC - A 10 - VIT - Chennai - Meggger & Multimeter - JE QTNDr. Chandan SharmaÎncă nu există evaluări

- Light and Medium Merchant MillDocument35 paginiLight and Medium Merchant MillPeram Bharath Kumar Reddy100% (1)

- CCL 108sg PBXDocument13 paginiCCL 108sg PBXpratipÎncă nu există evaluări

- Q1089 - Offer For Supply of Screw ConveyorDocument2 paginiQ1089 - Offer For Supply of Screw ConveyorashokÎncă nu există evaluări

- Hot Rolled SlittingDocument4 paginiHot Rolled SlittingVikas SinghÎncă nu există evaluări

- TMT BarsDocument26 paginiTMT BarsPardeep KushwahaÎncă nu există evaluări

- Comments - MSEL 25072017 Rod Mill RequirementDocument14 paginiComments - MSEL 25072017 Rod Mill RequirementHarshGuptaÎncă nu există evaluări

- No.:13Name:QNF450 Horizontal Packaging MachineDocument2 paginiNo.:13Name:QNF450 Horizontal Packaging MachineAmin Ali AminÎncă nu există evaluări

- Tech Spec. of EOT CraneDocument7 paginiTech Spec. of EOT CraneSuresh MuttaÎncă nu există evaluări

- Technical Specification For Rollling Mill-20200922Document15 paginiTechnical Specification For Rollling Mill-20200922Nilton Bruno Salazar MartinezÎncă nu există evaluări

- XTR 0107 Rev1Document6 paginiXTR 0107 Rev1anand shekhawatÎncă nu există evaluări

- 5Kw Grid-Tied Hybrid PV System: Item No. Description Qty UnitDocument4 pagini5Kw Grid-Tied Hybrid PV System: Item No. Description Qty UnitJess BergoniaÎncă nu există evaluări

- JSW, Steel Works Bellary: Presented byDocument26 paginiJSW, Steel Works Bellary: Presented byRakesh Karan Singh100% (1)

- Cleaning of Steel and Removal of Rust PDFDocument10 paginiCleaning of Steel and Removal of Rust PDFDawooz SaDam OnexoxÎncă nu există evaluări

- MS 2002 Cold Rolling Mill Speed OptimizationDocument7 paginiMS 2002 Cold Rolling Mill Speed Optimizationsurajit7guptaÎncă nu există evaluări

- Quot 15138801Document2 paginiQuot 15138801Anandha PadmanabhanÎncă nu există evaluări

- Hydraulic Bending PlateDocument10 paginiHydraulic Bending PlateDimas SamidÎncă nu există evaluări

- Rolling 1Document142 paginiRolling 1atul bartyÎncă nu există evaluări

- Ramsey Conveyor Protection SwitchesDocument6 paginiRamsey Conveyor Protection SwitchesArif AmirÎncă nu există evaluări

- CVSRM PresentationDocument102 paginiCVSRM Presentationrazen_inÎncă nu există evaluări

- A New Method For Roll Pass Design Optimi PDFDocument12 paginiA New Method For Roll Pass Design Optimi PDFFarooq Ameer Jordan WalaÎncă nu există evaluări

- High Carbon Wire RodDocument9 paginiHigh Carbon Wire Rodninganray6316100% (1)

- D2.03 15 Bar and Merchant Bar Mills enDocument36 paginiD2.03 15 Bar and Merchant Bar Mills enLymeParkÎncă nu există evaluări

- Bhushan Traioning Report 786Document53 paginiBhushan Traioning Report 786Deepak Giri50% (2)

- Gen - Assembly Dwg-Energy ChainDocument2 paginiGen - Assembly Dwg-Energy ChainJohn Renzel Rivera IIIÎncă nu există evaluări

- Prasanth LeeDocument46 paginiPrasanth LeePRASANTHÎncă nu există evaluări

- Turret Bearing Deflection MonitoringDocument1 paginăTurret Bearing Deflection MonitoringVinay RajputÎncă nu există evaluări

- 28 Casting Processes 3 Continuous Casting of Steel - Solidification.20101112.4cdda08c2c28b1.24761975Document20 pagini28 Casting Processes 3 Continuous Casting of Steel - Solidification.20101112.4cdda08c2c28b1.24761975Syed HasniÎncă nu există evaluări

- Withdrawal Speed Bott Withdrawal Speed Mould Oscillator Speed RDB Speed 986.7151956324Document6 paginiWithdrawal Speed Bott Withdrawal Speed Mould Oscillator Speed RDB Speed 986.7151956324Deepak Sharma100% (2)

- TURKEY. TECHNICAL REPORT. PLANNING OF ROLLING MILL PLANTS AND ROLL PASS DESIGN TECHNOLOGY (14800.en) PDFDocument88 paginiTURKEY. TECHNICAL REPORT. PLANNING OF ROLLING MILL PLANTS AND ROLL PASS DESIGN TECHNOLOGY (14800.en) PDFKalyan HalderÎncă nu există evaluări

- Annex 1 CCM ProcessDocument16 paginiAnnex 1 CCM ProcessehsanÎncă nu există evaluări

- Eesar Steel ReportDocument34 paginiEesar Steel ReportchinmaiÎncă nu există evaluări

- Slitting Machine Manufacturer in NoidaDocument13 paginiSlitting Machine Manufacturer in NoidaNIRMAL OVERSEAS LIMITEDÎncă nu există evaluări

- Continuous casting The Ultimate Step-By-Step GuideDe la EverandContinuous casting The Ultimate Step-By-Step GuideÎncă nu există evaluări

- 2139 12021 1 PB PDFDocument9 pagini2139 12021 1 PB PDFSantosh Kumar PandeyÎncă nu există evaluări

- Rolling ExampleDocument3 paginiRolling ExampledevtorÎncă nu există evaluări

- Slit Rolling TechnologyDocument6 paginiSlit Rolling Technologyeng_ahmedkassemÎncă nu există evaluări

- The Iron Puddler My life in the rolling mills and what came of itDe la EverandThe Iron Puddler My life in the rolling mills and what came of itÎncă nu există evaluări

- 5 6176700143207711706Document198 pagini5 6176700143207711706abc defÎncă nu există evaluări

- National Power Training Institute: Admission Notice: 2020-21Document3 paginiNational Power Training Institute: Admission Notice: 2020-21a.jainÎncă nu există evaluări

- Renewsys India Pvt. LTD.: Form Factor - 18 Cells Reference Drawing Numbers: Bom For C06 - 5Wp With Elmex JB Per ModuleDocument31 paginiRenewsys India Pvt. LTD.: Form Factor - 18 Cells Reference Drawing Numbers: Bom For C06 - 5Wp With Elmex JB Per Modulesandeep devabhaktuniÎncă nu există evaluări

- CE 411 Lecture 03 - Moment AreaDocument27 paginiCE 411 Lecture 03 - Moment AreaNophiÎncă nu există evaluări

- Data Flow Diagrams PDFDocument9 paginiData Flow Diagrams PDFYasmine2410Încă nu există evaluări

- Excel CatDocument132 paginiExcel Catjuanf_scribdÎncă nu există evaluări

- Bombas Pentax SADocument48 paginiBombas Pentax SAAgustin CahuanaÎncă nu există evaluări

- MMD 74 XX DR PS 0020 - C03Document1 paginăMMD 74 XX DR PS 0020 - C03bramexÎncă nu există evaluări

- To Dmaic or Not To DmaicDocument1 paginăTo Dmaic or Not To Dmaicritch99Încă nu există evaluări

- RCJ&Y - Jubail Industrial City 2: Phase 3 and 4 Sea Water Cooling StationDocument5 paginiRCJ&Y - Jubail Industrial City 2: Phase 3 and 4 Sea Water Cooling Stationsalman KhanÎncă nu există evaluări

- Black Invention MythsDocument16 paginiBlack Invention MythsjoetylorÎncă nu există evaluări

- SA Flight Instructors Training ProceduresDocument371 paginiSA Flight Instructors Training ProceduresGuilioÎncă nu există evaluări

- Deepwater Horizon Accident Investigation Report Appendices ABFGHDocument37 paginiDeepwater Horizon Accident Investigation Report Appendices ABFGHBren-RÎncă nu există evaluări

- Knowledge Area Quiz-Project Integration ManagementDocument4 paginiKnowledge Area Quiz-Project Integration Managementcrown212Încă nu există evaluări

- 1.1 Control Philosophy CAS-1 NMDCDocument36 pagini1.1 Control Philosophy CAS-1 NMDCkoushik42000Încă nu există evaluări

- AVR Interrupt Programming in Assembly and CDocument38 paginiAVR Interrupt Programming in Assembly and CK142526 AlishanÎncă nu există evaluări

- ARRI SkyPanel - DMX Protocol Specification V4.4Document88 paginiARRI SkyPanel - DMX Protocol Specification V4.4Quan LyÎncă nu există evaluări

- Cyclic Redundancy CheckDocument3 paginiCyclic Redundancy CheckmeerashekarÎncă nu există evaluări

- Paper AeroplaneDocument19 paginiPaper Aeroplanejkb SudhakarÎncă nu există evaluări

- Libeskind Daniel - Felix Nussbaum MuseumDocument6 paginiLibeskind Daniel - Felix Nussbaum MuseumMiroslav MalinovicÎncă nu există evaluări

- Cooling Water BasicsDocument163 paginiCooling Water BasicsEduardo Castillo100% (1)

- GL 314Document2 paginiGL 314Vinayak SinghÎncă nu există evaluări

- Mitsubishi Electric Product OverviewDocument116 paginiMitsubishi Electric Product OverviewPepes HiuuÎncă nu există evaluări

- Avaya Call History InterfaceDocument76 paginiAvaya Call History InterfaceGarrido_Încă nu există evaluări

- Isuzu 4hk1x Sheet HRDocument4 paginiIsuzu 4hk1x Sheet HRMuhammad Haqi Priyono100% (1)

- Notes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsDocument4 paginiNotes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsArif HidayatÎncă nu există evaluări

- Ism Practical FileDocument62 paginiIsm Practical FilePriya AgrawalÎncă nu există evaluări

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 paginăTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliÎncă nu există evaluări

- Internet Intranet ExtranetDocument28 paginiInternet Intranet ExtranetAmeya Patil100% (1)

- Mainframe Vol-II Version 1.2Document246 paginiMainframe Vol-II Version 1.2Nikunj Agarwal100% (1)