Documente Academic

Documente Profesional

Documente Cultură

SD 3

Încărcat de

api-3750765Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SD 3

Încărcat de

api-3750765Drepturi de autor:

Formate disponibile

Design of externally pressurised

gas-!ubricated porous journal

bear=ngs

B. C. Majumdar*

Design charts for the evaluation of the performance characteristics of externally

oressurized, porous gas bearings under static loading are Dresented for a wide

range of parameters for direct use in practice. The theoretical results are

obtained from a rigorous analysis by simultaneous solution of the continuity

equation (derived from Darcy's law) and the modified Reynolds' equation

satisfying the boundary conditions of sealed end bearings. The effect of the

feeding parameter on static behaviour is discussed. Finally, a design procedure

of one such bearing is described.

Nomenclature bearings, when supported on rubber 'O' rings, could be

rotated up to a speed of nearly 4200 Hz with a shaft dia-

C radial clearance meter of about 6 ram. The most complete theoretical analy-

D diameter of journal sis, using the perturbation method and considering only

e eccentricity radial gas flow in the porous wall, is due to Sneck and Yen 3.

G,G mass rate of flow and flow parameter Later, Mori et al 4,s, gave an incompressible solution assum-

H thickness of porous bushing ing an equivalent clearance model. Mori et al 6 in another

k x, ky, k z permeability coefficients of bushing material in paper indicated a theoretical method for the solution for a

circumferential, axial, and radial directions porous bearings as a boundary value problem. Although

respectively this work 6 considered three dimensional flow in the porous

L bearing length media, it failed to give sufficient information for the design

P pressure (absolute) in the bearing clearance of a journal bearing.

p' pressure (absolute) in the porous media

Pa atmospheric pressure (absolute) The limitations of the work of Sneck and Yen 3 are that the

Ps , -fis supply pressure (absolute), Ps = Ps/Pa results are applicable only to a lightly loaded bearing and

R journal radius are only valid for a thin porous wall. On the other hand,

gas constant Mori e t al 4,s used incompressible flow theory as a basis of

S,S stiffness and stiffness parameter their solution. Hence the results are only true for low gas

T absolute temperature supply pressures. The present work considers the problem

W,W load capacity and load parameter for conditions between these two extremes.

X, y, Z coordinates

7? absolute viscosity of gas Theoretical considerations

6 eccentricity ratio, e = e/C (dimensionless) For an externally pressurized journal bearing with sealed

0 angular coordinate, 0 = x / R ends as shown in Fig 1, gas is fed at constant pressure from

A feeding parameter A = 12kzR2/C3H (dimension- behind the porous bushing throughout the length of the

less) bearing. The flow of gas takes place in the axial, circum-

ferential and radial directions within the bush and then

Note: A dimensionless quantity has a bar on the top. exhausts through the bearing clearance to the atmosphere.

Assuming the flow of gas through the porous media is

characterized by Darcy's law and no slip occurs at the

porous surface, the flow equations in the porous wall and in

A porous material can be used as a bearing surface, with the the bearing clearance are respectively6:

porousity of the material controlling the gas supply by

serving as a restrictor between the supply manifold and the ~2p'2 c32p,2 ~2p,2

bearing. More even distribution of gas is possible compared

with a discrete hole-admission bearing 1. Moreover, a bearing

~x ~xx2-+ky -0~- +k z ~zY = 0 (I)

with a porous surface has an inherent damping capability. and

Hence a porous bearing may be preferred to a conventional

hole-admission bearing in many industrial applications.

Probably the first experimental work on gas porous bearings O h3 ~)p2t + h3 (2)

is that of Montgomery and Sterry 2 who showed that these ~x -~x] -~y2 = 12 k z ~ 3z ]z=H

* Department of Mechanical Engineering, Indian Institute of With the following substitutions: 0 = x / R , ~ = y/(L/2),

Technology, Kharagpur, India z = z/H, h = h/C (= 1 + e cos 0),P- ' = (p'/pa) 2 and ff = (p/pa) 2,

TRIBOLOGY international April 1976 71

x,8 ~ L The static stiffness of this type of bearing is given by:

dW

S= - (9)

de

and in dimensionless lbrm is:

dW

Porous beorin 9

de

#%0

Fig 1 A gas-lubricated porous journal bearing where

SC

equations (1) and (2) for the case of uniform permeability S-= (10)

coefficients (ie k x = ky = kz) will be respectively: LD(Ps - Pa)

02p' 02p' 02p' Hence the slope of W versus e at any particular value of e

---- + (D/L) 2

002 ~y2-

+ (R/H) 2

T~-

=0 (3) gives the stiffness. However, a simplified formula in terms of

calculated W for small values ofe (e ~< 0.5) can be computed

using a linear perturbation theory with respect to e.

and

In these cases the stiffness

02]6 3 3P dh 32P A (OP']

--- + + (D/L) 2 - (4) dW W

002 h 30 dO 3y 2 h 3 ~32-]z=l S- - (ll)

de Ce

where where

12 kzR 2 LD(p, pa)~

A- S=

-

(12)

C3H Ce

As pressure p is given by pressure p' in tile porous media at

Therefore, the stiffness at any radial clearance C can be cal-

the bearing surface, which is the boundary between the

culated from the dimensionless load W using equation (7).

porous media and the bearing clearance, ~ in equation (4)

can be replaced by ~' and as the pressure gradient across the The theoretically predicted results of bearings having LID =

bearing clearance is zero, ~' at ~-= 1 is the film pressure. 0.5, 1.0, and 2.0 for various design parameters are shown in

Equations (3) and (4) are solved by iteration 7 in a finite Figs 2 - 4 . The load capacity in all cases increases with

difference form with a digital computer to determine the increase in the feeding parameter, reaches a maximum and

pressure distribution in the bearing clearance. Thus, with then decreases with further increase in A. Hence an appro-

the pressure distribution known, the load W and the mass priate value of A can be selected for maximum load capa-

rate of flow G at the bearing ends can be calculated from: city. With an increase in the bushing thickness the load falls

considerably and therefore, a one dimensional solution 3

L/2 2n which does not have bush thickness as a parameter is inade-

quate to predict the above behaviour. The flow rate in-

w=-2f f p'RcosOdOdy (s) creases continuously with increases in the feeding parameter

particularly at high values of A. It may also be observed

o o that the flow does not change appreciably with e. In this

connection it may be mentioned that there is no significant

and decrease in flow rate with increase in H. For this reason the

flow is shown only for HID = 0.1 (Figs 2 - 4 ) . From the

2.tr results it appears that the dimensionless load W reaches a

2C 3

G_ (1 +ecosO)3RdO (6) maximum value when LID = 1.0 for most feeding para-

127 ~ T f p, 3p' y=L/2 meters. The absolute value is, of course, higher at higher

0 LID ratios. Thus, an increase in the LID ratio does not result

in a proportional increase in load capacity.

The load and flow in equations (5) and (6) are computed

numerically and expressed in dimensionless form as: Design procedure

W The bearing can be designed either for maximum load or

W= (7) for maximum stiffness. The values of A which yield these

LD(Ps - Pa) criteria are different. Therefore, to fulfil a particular

design criterion the dimensions of the bearing must be

and found separately, the following worked example illustrat-

ing the method.

_ 24 • ~T

G- G (8) A journal bearing is operating at e = 0.2 with the following

c 3% 2 -

specifications.

72 TRIBOLOGY international April 1976

0.8 80

ko /15o

, = o a----///

0.7 70 ,=o 5-~f/

, = 0.8.~,,.//

,~= 0 . 5 - - - - ~

08 ,E=0.27.40

0.6 = , ~=0.2///-~/'" 60

0.5 50 //

o.s • =o.8 ,,// - :5.0

I~ 0.4 _

40 IO /,~-,oo 8

/ • -T2.a__ ~/.d'---, =0 5 ,o

/ f~ ~-- ~,=o.z

03 . .:o5~./ .:o5~..':'$.,3;"-~-,.... \ - 30 o,

~ - - ~ ~.

02 20

C--" - . J "%

1.0 I0

06.5 ,io ,b 5c,0

A 06 ,.'o 6

A

0.8 80 ~0 ,° 0.8-~///50

, =0s--y//

,=0.8~ ,=0.2

07 E = 0.5-~--~ 70

• =0.2 . - ~ 08 40

06 60

05 50

0.6 30

1~04 40 if,.9

Io

0:5 :50 0.4 20

• =o.5 _...~-..

0.2 //" r~,=o.2 /.~/"/ - " - ... "-,,~. -

20

I.O I0 02 10

~ ~ , : 0 . 5 ~'---

i ~-~, =0.2

00.5 I .lO I C) 5, 0

I

.3 IJO I0 2 ,0

b A

0.8 80 IOi ~ 5 0

• =0.8-~

Q7 • = 0.5-~/ 70

0.6 60

o.SF Z" --14o

0.5 50

0.6- . ~ - 30

I~= o 4 ~~ - - o & ~ ~ 40 Io • =0.8 ~ ~ " "=0.8

I~= ~ -,=0.5 Io

• = 0.8

0.5 .'50 ..-.-.~ - - ~ .~..~. --, = 0.2

0.4 "~- 20

02 20 ,E =0.5 "" "'--

0.1 I0

0.2 - ~----~"~/ , _

_----------~ " " ' = 0.2 " " IO

"-----,=0.2 I

oc 5,) 0

L5 I PO I0

c A

Fig2 Load capacity for L / D = 0.5. (a) Ps = 3.0, (b} ~s= °(~3 I}) I() 2~°

c A

6.0, (c) ~ = 8.0*

Fig 3 Load capacity fi~r L / D = ]. O. (a} Ps = 3. O, (b) Ps =

* Figs 2 4: solid line represents w for HID = O.1, the dotted line 6.0, (c) -Ps = 8.0*

w for H/D = 0.2, and the broken line

TRIBOLOGY international April 1976 73

L=5xl0-2m, D=5x 10-2m, H=5x 10-3m T a b l e 1: Stiffness of a bearing having L/D= 1.0, H/D= 0.1,

c = 0.2 and P-s = 6.0

and

A C x 10-6, m S x 106, N/m

k z = 1 x 10 - 1 5 m 2.

2.1 8.88 106.5

Using air as a lubricant and assuming Ps = 6 bar and Pa = 3.0 7.94 113.0

1 bar, and an air temperature of 293 K, design the bearing 6.0 6.30 119.0

for both maximum load and maximum stiffness. 9.0 5.84 114.0

12.0 5.73 101.0

From the above dimensions, L I D = 1.0, H I D = 0.1 and

Ps = 6.0. The actual design will find the required bearing

clearance C for the above criteria. are: W = 150 N , G = 7.19 x 10 - 5 kg/s and S = 119.0 x

Assume ~ = 288 Nm/kg °C and r~ = 18.3 NS/m 2 at 106 N/m (since W = 0.120 and G-= 28.783 for A = 6.0).

293 K. From the above example it may be noted that a bearing

designed for maximum stifiness will have smaller radial

Designing for maximum load clearance and less flow rate than a bearing designed for

Referring to Fig 3(b), the maximum load will occur when maximum load.

A ~- 1.70 and the corresponding values of W = 0.152 and

G = 1 1.638. The required radial clearance is

References

J12 kzR2 1 Majumdar, B. C. On the general solution of externally pressurized

3 - 9.618 x 10 . 6 m. gas journal bearings', J Lub Tech, Trans. ASME, Series F, vol 94,

HA no 4, 1972, pp 291-296

2 Montgomery, A. G. and Sterry, F. 'A simple air bearing motor

The load and flow rate are 190 N and 10.3 x 10 - 5 kg/s. for very high rotational speed', Atomic Energy Research Establishment.

Using the simplified equation (12), the stiffness S = 98.5 x Harwell, Berkshire, England, AERE, ED/R 196 71, 1955.

3 Sneek, H. J. and Yen, K. T. 'The externally pressurized, porous-

106 N/m. wall gas-lubricated journal bearings - I', ASLE Trans. vol 7, no 3,

1964, pp 288-298

Designing for maximum stiffness 4 Mori, H., Yabe, H., Yamakage, H. and Furukwa, J. 'Theoretical

analysis of externally pressurized, porous gas journal bearings

As the bearing carries only a light load ( i e e = 0.2), equation (lst Report)',Bulletin of JSME, vo111, no 45, 1968, pp 527-

(12) can be used to find the stiffness.__Taking various values 535

of A corresponding to high values of W, at e = 0.2, from 5 Mori,H., Yabe, H., and Yamakage, H. 'Theoretical analysis of

externally pressurized, porous gas journal bearings (2nd Report)',

Fig 3(b), the necessary values of the clearance C are calculated

Bulletin of JSME, vo112, no 54, 1969, pp 1512-1518

to give the maximum values of stiffness S. The results are 6 Mori, H., Yabe, H. and Shibayama, T. 'Theoretical solution as

given in Table 1. boundary value problem for externally pressurized porous gas

bearings,' J Basic Eng Trans. ASME, Series D, vo187, no 1, 1965,

Referring to Table 1 the stiffness is seen to be a maximum pp 622-- 630

when A = 6.0, the corresponding radial clearance being C = 7 Majumdar, B. C. 'Analysis of externally pressurized porous gas

6.30 x 10 - 6 m. The load, flow and stiffness in this case journal bearings - 1,' Wear, vol 33, no 1, 1975, pp 25 35

0.6 60 0.6 60 0.6 60

05 50

,=0.8

04 40

. . . . . . .

s ~ ~,:o

_ _

• = O.8-~-~ 501~

20

0.I 0.I - ~ II0 0.I Io

~ . . ~ " ~ - - • =0 5

-~.-- ,~=0.2

=---'- "---,:o.z ~o I

°C).l I.O O6= I.O

a A b A c A

Fig 4 L o a d capacity f o r L / D = 2.0. (a) Ps = 3.0, (b) Ps = 6.0, (c) Ps = 8 . 0 *

74 T R I B O L O G Y international April 1976

S-ar putea să vă placă și

- (G. Lakshmi Narasaiah) Finite Element Analysis PDFDocument349 pagini(G. Lakshmi Narasaiah) Finite Element Analysis PDFmoljaime1326Încă nu există evaluări

- ST 36Document4 paginiST 36ray72roÎncă nu există evaluări

- Intro Slow Keyofg: Em7 G5 A7Sus4 G C/G D/F# AmDocument2 paginiIntro Slow Keyofg: Em7 G5 A7Sus4 G C/G D/F# Ammlefev100% (1)

- Reloved - October 2015Document116 paginiReloved - October 2015Barron Fields67% (3)

- Nutrient DeficiencyDocument8 paginiNutrient Deficiencyfeiserl100% (1)

- Overall Method StatementDocument33 paginiOverall Method Statementsaranga100% (1)

- Donna Hay Magazine 2014-10-11 PDFDocument172 paginiDonna Hay Magazine 2014-10-11 PDFlekovic_tanjaÎncă nu există evaluări

- Various Methods of Tunnel Lining Design in Elastically Embedded Soil PDFDocument5 paginiVarious Methods of Tunnel Lining Design in Elastically Embedded Soil PDFNaveen RÎncă nu există evaluări

- Orthotropic Skew Slab - Coull PDFDocument13 paginiOrthotropic Skew Slab - Coull PDFjnshreyÎncă nu există evaluări

- Action Analysis For Animators by Chris WebsterDocument409 paginiAction Analysis For Animators by Chris WebsterThomas Yandex100% (8)

- 09 Passport 7K 15K Performance Guidelines PCR 3 0Document44 pagini09 Passport 7K 15K Performance Guidelines PCR 3 0thed719Încă nu există evaluări

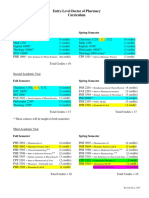

- Pharmd CurriculumDocument18 paginiPharmd Curriculum5377773Încă nu există evaluări

- Effect of Shear Friction On Solid Flow Through An Orifice (1991)Document5 paginiEffect of Shear Friction On Solid Flow Through An Orifice (1991)池定憲Încă nu există evaluări

- Mixed Convection in Non-Newtonian Fluids Along A Vertical Plate in A Porous MediumDocument10 paginiMixed Convection in Non-Newtonian Fluids Along A Vertical Plate in A Porous MediumPaul GavilanesÎncă nu există evaluări

- Predicted and Observed Behaviour of Soft Clay Foundations Stabilised With Vertical DrainsDocument8 paginiPredicted and Observed Behaviour of Soft Clay Foundations Stabilised With Vertical DrainsCEG BangladeshÎncă nu există evaluări

- Steady Steam Condensation On An Extended Surface With Suction of CondensateDocument24 paginiSteady Steam Condensation On An Extended Surface With Suction of Condensatealentan_774042Încă nu există evaluări

- Influence of Rib Stiffeners On The Buckling Strength of Elastically Supported TubesDocument9 paginiInfluence of Rib Stiffeners On The Buckling Strength of Elastically Supported TubesWaseem AkramÎncă nu există evaluări

- On The Low Frequency Elastic Response of A Spherical ParticleDocument8 paginiOn The Low Frequency Elastic Response of A Spherical ParticlesteveÎncă nu există evaluări

- Y K Wong - Comparison of Drainage Line Elements in PLAXIS 2D and 3D Applied in Consolidating Marine Clay DepositsDocument8 paginiY K Wong - Comparison of Drainage Line Elements in PLAXIS 2D and 3D Applied in Consolidating Marine Clay DepositsGoh Kay YunÎncă nu există evaluări

- Poster: Correcting The Thread Standards For Graphite Electrodes by Using Equations of Thread ProfilesDocument2 paginiPoster: Correcting The Thread Standards For Graphite Electrodes by Using Equations of Thread ProfilesEzzat SevÎncă nu există evaluări

- Cylindrically Orthotropic Circular Plates With Large Deflections 1)Document11 paginiCylindrically Orthotropic Circular Plates With Large Deflections 1)yasameenÎncă nu există evaluări

- Distribution Eddy Viscosity Length: Mixing inDocument6 paginiDistribution Eddy Viscosity Length: Mixing inGustavo Gabriel JimenezÎncă nu există evaluări

- Chapter 6Document45 paginiChapter 6Bittu Kumar SinghÎncă nu există evaluări

- Friction Factor For Turbulent Pipe FlowDocument16 paginiFriction Factor For Turbulent Pipe Flowyu won hoÎncă nu există evaluări

- The Response of Thermal Newtonian and Non-Newtonian E H L To The Vertical Vibration of A RollerDocument9 paginiThe Response of Thermal Newtonian and Non-Newtonian E H L To The Vertical Vibration of A RollerJuan Pablo Cano MejiaÎncă nu există evaluări

- MURTI 短轴承的流体动力润滑Document9 paginiMURTI 短轴承的流体动力润滑chenknaaÎncă nu există evaluări

- Effect of Inhomogeneity On The Stress in PipesDocument11 paginiEffect of Inhomogeneity On The Stress in Pipes002 PALASH DASÎncă nu există evaluări

- Elastoplastic Constitutive Model For Unsaturated Soil-Steel InterfaceDocument6 paginiElastoplastic Constitutive Model For Unsaturated Soil-Steel InterfaceUmed Abd-alsatarÎncă nu există evaluări

- Artículo - PK Model 1Document11 paginiArtículo - PK Model 1Esteban LesmesÎncă nu există evaluări

- Helical Flow of Power-Law Fluids: Dostal, Zitnf, and J. SestakDocument4 paginiHelical Flow of Power-Law Fluids: Dostal, Zitnf, and J. SestakHicham HichamÎncă nu există evaluări

- Dundee Final HDRDocument13 paginiDundee Final HDRFranco BrownÎncă nu există evaluări

- Von Mises' Yield Criterion and Nonlinearly Hardening Rotating ShaftsDocument17 paginiVon Mises' Yield Criterion and Nonlinearly Hardening Rotating ShaftsAnonymous UoHUagÎncă nu există evaluări

- Filament Winding Shape OptimizationDocument14 paginiFilament Winding Shape OptimizationDanielÎncă nu există evaluări

- Predicted and Observed Behaviour of Soft Clay Foundation Stabilised With Vertical DrainDocument7 paginiPredicted and Observed Behaviour of Soft Clay Foundation Stabilised With Vertical DrainChim Yan QiÎncă nu există evaluări

- Theoretical Calculations of The Distribution of Aerodynamic Loading On A Delta WingDocument35 paginiTheoretical Calculations of The Distribution of Aerodynamic Loading On A Delta WingHarsha HarÎncă nu există evaluări

- Gas-Lubricated Porous Bearings Short Journal Bearings, Steady-State SolutionDocument7 paginiGas-Lubricated Porous Bearings Short Journal Bearings, Steady-State SolutionKUSHAL D BÎncă nu există evaluări

- Simplified Model of Reynolds Equation With Linearized Ow Rate For Ultra-Thin Gas Film Lubrication in Hard Disk DrivesDocument9 paginiSimplified Model of Reynolds Equation With Linearized Ow Rate For Ultra-Thin Gas Film Lubrication in Hard Disk Drivesyousef mohamedÎncă nu există evaluări

- DCPD Lu2012Document9 paginiDCPD Lu2012CHONKARN CHIABLAMÎncă nu există evaluări

- The Analysis of The Characteristics of Infinitely Short Journal Bearings Modified by Equivalent ViscosityDocument4 paginiThe Analysis of The Characteristics of Infinitely Short Journal Bearings Modified by Equivalent ViscosityAhmed KramdiÎncă nu există evaluări

- CHAPTER 6 - ELASTO HYDRODYNAMIC THEORY - 1977 - Elasto Hydrodynamic Lubricat...Document13 paginiCHAPTER 6 - ELASTO HYDRODYNAMIC THEORY - 1977 - Elasto Hydrodynamic Lubricat...Ray BurnsÎncă nu există evaluări

- On The Shape Factor For The Maximum Pressure of The Undercut Groove FormDocument8 paginiOn The Shape Factor For The Maximum Pressure of The Undercut Groove FormVanesh KumarÎncă nu există evaluări

- Free Vibration Analysis of Cylindrical Liquid Storage TanksDocument13 paginiFree Vibration Analysis of Cylindrical Liquid Storage TanksJosué Azurín RendichÎncă nu există evaluări

- Junction of A Periodic Family of Elastic Rods With A Thin Plate. Part IIDocument55 paginiJunction of A Periodic Family of Elastic Rods With A Thin Plate. Part IIChristian MBOULLEÎncă nu există evaluări

- Submerged Laminar Jet Impingement On A PlaneDocument24 paginiSubmerged Laminar Jet Impingement On A PlaneAEÎncă nu există evaluări

- H Theoretical Study of Three-Dimensional Combustion Instability in Liquid-Propellant Rocket EnginesDocument9 paginiH Theoretical Study of Three-Dimensional Combustion Instability in Liquid-Propellant Rocket EnginesAIEIMAÎncă nu există evaluări

- Flow in Pipes and Open ChannelsDocument31 paginiFlow in Pipes and Open ChannelsDelina TedrosÎncă nu există evaluări

- Predict Friction Lossin Slurry Pipes Darbyetal 1992Document5 paginiPredict Friction Lossin Slurry Pipes Darbyetal 1992Viajante_santosÎncă nu există evaluări

- HERSCHEL-BULKLEY FLUID Parameters EstimationDocument10 paginiHERSCHEL-BULKLEY FLUID Parameters EstimationgombossandorÎncă nu există evaluări

- Strain Gauges and Their MeasurementDocument22 paginiStrain Gauges and Their Measurement200110039Încă nu există evaluări

- Disk New OrleansDocument11 paginiDisk New Orleansd882011Încă nu există evaluări

- Advanced Transport Phenomena Module 8 Lecture 37: Illustrative Example: Protective Oxide Dissolution On GT BladesDocument36 paginiAdvanced Transport Phenomena Module 8 Lecture 37: Illustrative Example: Protective Oxide Dissolution On GT BladesshashwatÎncă nu există evaluări

- Demonstrating Rubber Elasticity: (I) Gives A Fascinating HisDocument3 paginiDemonstrating Rubber Elasticity: (I) Gives A Fascinating HisRicky EstepaÎncă nu există evaluări

- Airflow Through Louvers A Case StudyDocument5 paginiAirflow Through Louvers A Case Studygaju_scribdÎncă nu există evaluări

- Received 30 September 1992Document7 paginiReceived 30 September 1992Hanna ChingÎncă nu există evaluări

- Green Function of The Poisson EquationDocument9 paginiGreen Function of The Poisson EquationNicolas Enciso PuertoÎncă nu există evaluări

- Rapid Crack Propagarion in Plastic Water PipesDocument11 paginiRapid Crack Propagarion in Plastic Water PipesCody ListoeÎncă nu există evaluări

- Ane Fficient Nonlinear Solver and Convergence Analysis For A Viscoplastic Flow ModelDocument22 paginiAne Fficient Nonlinear Solver and Convergence Analysis For A Viscoplastic Flow ModelYuliza Carolina Capuñay SiesquénÎncă nu există evaluări

- Power Law and Log Law Velocity Profiles in Turbulent Boundary-Layer Flow: Equivalent Relations at Large Reynolds NumbersDocument2 paginiPower Law and Log Law Velocity Profiles in Turbulent Boundary-Layer Flow: Equivalent Relations at Large Reynolds NumbersManuel MejiaÎncă nu există evaluări

- 2002 - Comment On Hardness DefinitionsDocument5 pagini2002 - Comment On Hardness DefinitionsArun KumarÎncă nu există evaluări

- Analytical Solutions of Reduced Rigidity Plastic Bifurcation of Circular PlatesDocument8 paginiAnalytical Solutions of Reduced Rigidity Plastic Bifurcation of Circular PlatesCornel HatieganÎncă nu există evaluări

- Coil SpringDocument14 paginiCoil SpringLeti HanajÎncă nu există evaluări

- (I. 6) - UnknownDocument6 pagini(I. 6) - UnknowndarkruseÎncă nu există evaluări

- 2 - Flow in Pipes Closed Conduits (Compatibility Mode)Document28 pagini2 - Flow in Pipes Closed Conduits (Compatibility Mode)fyqahÎncă nu există evaluări

- Large Deflection Static and Dynamic Analysis of Isotropic and Orthotropic Annular PlatesDocument13 paginiLarge Deflection Static and Dynamic Analysis of Isotropic and Orthotropic Annular PlatesyasameenÎncă nu există evaluări

- The Crack Tip Strain Field of AISI 4340: Experimental MeasurementsDocument9 paginiThe Crack Tip Strain Field of AISI 4340: Experimental Measurementsfrederico wlassakÎncă nu există evaluări

- حل امتحان بيئة اعمال سنة 2023Document4 paginiحل امتحان بيئة اعمال سنة 2023Ahmed MohsenÎncă nu există evaluări

- 10.1016@0375 96018690121 0 PDFDocument4 pagini10.1016@0375 96018690121 0 PDFRakesh DabgarÎncă nu există evaluări

- Tables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiDe la EverandTables of Coefficients for the Analysis of Triple Angular Correlations of Gamma-Rays from Aligned NucleiÎncă nu există evaluări

- C*-Algebra Extensions and K-Homology. (AM-95), Volume 95De la EverandC*-Algebra Extensions and K-Homology. (AM-95), Volume 95Încă nu există evaluări

- SD 2Document9 paginiSD 2api-3750765Încă nu există evaluări

- SD 1Document11 paginiSD 1api-3750765Încă nu există evaluări

- SD 4Document5 paginiSD 4api-3750765Încă nu există evaluări

- Gas BearingsDocument8 paginiGas BearingssirwarameshÎncă nu există evaluări

- ContentDocument7 paginiContentapi-3750765Încă nu există evaluări

- Chemical Bonds WorksheetDocument2 paginiChemical Bonds WorksheetJewel Mae MercadoÎncă nu există evaluări

- Top Coat-200 - Data PDFDocument4 paginiTop Coat-200 - Data PDFLiliana GeorgianaÎncă nu există evaluări

- Texto CuritibaDocument1 paginăTexto CuritibaMargarida GuimaraesÎncă nu există evaluări

- Complete Processing Lines For Extruded Pet FoodDocument13 paginiComplete Processing Lines For Extruded Pet FoodденисÎncă nu există evaluări

- Communication Guide: For Vita 62 Compliant VPX Power SuppliesDocument8 paginiCommunication Guide: For Vita 62 Compliant VPX Power Suppliesk.saikumarÎncă nu există evaluări

- Ask A Monk EnlightenmentDocument16 paginiAsk A Monk EnlightenmentPetruoka EdmundasÎncă nu există evaluări

- Navy Supplement To The DOD Dictionary of Military and Associated Terms, 2011Document405 paginiNavy Supplement To The DOD Dictionary of Military and Associated Terms, 2011bateljupko100% (1)

- FAJASDocument891 paginiFAJASCecilia GilÎncă nu există evaluări

- Hot Topic 02 Good Light Magazine 56smDocument24 paginiHot Topic 02 Good Light Magazine 56smForos IscÎncă nu există evaluări

- 3.1 - Sequences and SeriesxbxhhdDocument92 pagini3.1 - Sequences and SeriesxbxhhdHelloÎncă nu există evaluări

- Datasheet Ark XH Battery System EngDocument2 paginiDatasheet Ark XH Battery System EngLisa CowenÎncă nu există evaluări

- Ii 2015 1Document266 paginiIi 2015 1tuni santeÎncă nu există evaluări

- Furuno CA 400Document345 paginiFuruno CA 400Димон100% (3)

- The Variable Resistor Has Been AdjustedDocument3 paginiThe Variable Resistor Has Been AdjustedPank O RamaÎncă nu există evaluări

- Comparison of 3 Tests To Detect Acaricide ResistanDocument4 paginiComparison of 3 Tests To Detect Acaricide ResistanMarvelous SungiraiÎncă nu există evaluări

- JHS 182Document137 paginiJHS 182harbhajan singhÎncă nu există evaluări

- Comparative Performance of Some Cattle Breeds Under Barani Conditions of PakistanDocument4 paginiComparative Performance of Some Cattle Breeds Under Barani Conditions of PakistanMasood HassanÎncă nu există evaluări

- Microbiology Part 3Document74 paginiMicrobiology Part 3Authentic IdiotÎncă nu există evaluări

- Energy Transfer in Cell During Exercise and Oxygen Metabolism and Transport - PalakDocument85 paginiEnergy Transfer in Cell During Exercise and Oxygen Metabolism and Transport - Palakpalooo4Încă nu există evaluări