Documente Academic

Documente Profesional

Documente Cultură

Elastomeric Bearing Pad

Încărcat de

Mohammad Fikrie Bahrul HayatDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Elastomeric Bearing Pad

Încărcat de

Mohammad Fikrie Bahrul HayatDrepturi de autor:

Formate disponibile

Elastomeric Bearing Pads & Strips

ENGINEERED SYSTEMS

Trelleborg Elastomeric Bearing Pads & Strips

Trelleborg elastomeric structural bearing pads and strips are manufactured from premium quality natural rubber and chloroprene. The compounds comply with well-known international standards as MOPT, EN, BS, ASTM, AASHTO, etc. A range of hardnesss are available from 50 ShA to 70 shA to suit special applications. The pads nominated in the following tables have been designed using the parameters as specified in BS5400.

Vertical Loads:

Loadings shown in the table are the maximum recommended working loads. At these loads a deflection of up to 15% of the initial pad height could be expected. As these pads are not bonded to the mating surfaces, the actual deflection is determined by the frictional characteristic of the contact surfaces. Care should be taken as holes or cut outs in the pads/strips may have a substantial effect by reducing the load carrying capacity and increasing the deflection of the pad or strip.

Fv

Shear Deflection/Stiffness:

The allowable shear deformation is normally in the order of 30% to 50% of the compressed pad/strip thickness from the neutral position. Shear deflections of up to 70% may be considered but careful consideration must taken of possible slippage due to the frictional coefficient of the rubber to structure mating surfaces

FV FH

H

Trelleborg Elastomeric Bearing Pads & Strips

Rotation:

Tilting of the load bearing surfaces relative to each other causes a rotation of the bearing pad/strip. The basic limiting criterion is that no gap occurs between the structure and the pad/strip. The rotational capacity tables include the 0.0035 radians that should be allowed to accommodate design tolerances.

Fv

ROTATION

Slippage:

Non-reinforced bearing pads will spread in surface contact area when under load. The amount of spread is largely determined by the frictional coefficients of the structures surfaces mating with the rubber pad/strip. It is important to allow clearances around the pad/strip to allow for this slippage once the structures weight is imposed on the pad/strip.

Slippage Slippage

Fv

Installation:

The mating surfaces should be flat, parallel and free from cavities, gaps or protrusions. It is preferable for the structures surfaces to have a rough texture without lubrication, particularly oils and hydrocarbons. Due to slippage when compressed, a gap around all sides of the pad/strip must be provided. It is recommended that this gap be a minimum of 12mm.

Friction:

The bearing is restrained in lateral movement by the frictional coefficient between the rubber and the structure. The ratio of lateral load over vertical load should not exceed the following values: 0.35 Elastomer/wood float finish 0.30 Elastomer/steel float finish 0.25 Elastomer/steel, elastomer/in-situ concrete finish

Typical Rubber Specification:

Property

Tensile Strength

Testing standard

ASTM D412 Die C, DIN 53504, BS903.A2 ASTM D412 Die C, DIN 53504, BS903.A2

Condition

Original Aged for 96 hours @ 70 deg. C. Original Aged for 96 hours @ 70 deg. C. Original Aged for 96 hours @ 70 deg. C.

Requirement

17 Mpa Min 15.3 MPa (Min) 475% (Min) 400% (Min) 60 5 Shore A < +5 increase 30% (Max) No cracking visible by eye > 40kN/m

Elongation at Break

ASTM D412 Die C, DIN 53504, BS903.A2 ASTM D412 Die C, DIN 53504, BS903.A2

Hardness

ASTM D2240, DIN 53505, BS903.A19

Compression Set Resistance to Ozone Cracking Tear Resistance

ASTM D395, DIN 53517, BS903.A6 ASTM D1149, DIN 53509 BS903.A43

Aged for 22 hours @ 70 deg. C. 1 p.p.m. at 20% strain @ 40 deg. C. for 100 hours

ASTM D624,DIN 53507, BS903.A3

Original

Trelleborg Elastomeric Bearing Pads & Strips

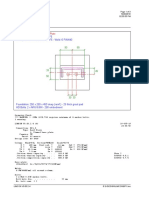

Part No. Strip Dimensions mm x mm 5 x 50 5 x 75 5 x 100 5 x 125 5 x 150 5 x 200 10 x 50 10 x 75 10 x 100 10 x 125 10 x 150 10 x 200 15 x 75 15 x 100 15 x 125 15 x 150 15 x 200 20 x 75 20 x 100 20 x 125 20 x 150 20 x 200 20 x 250 25 x 100 25 x 125 25 x 150 25 x 200 25 x 250 5 x 50 5 x 75 5 x 100 5 x 125 5 x 150 5 x 200 10 x 50 10 x 75 10 x 100 10 x 125 10 x 150 10 x 200 15 x 75 15 x 100 15 x 125 15 x 150 15 x 200 20 x 75 20 x 100 20 x 125 20 x 150 20 x 200 20 x 250 25 x 100 25 x 125 25 x 150 25 x 200 25 x 250 Working Load per Metre kN/m 200 300 400 500 600 800 100 225 400 500 600 800 150 265 415 600 800 110 200 315 450 800 1000 160 250 360 640 1000 Compressive Stiffness kN/m/mm 550 1163 2001 3061 4348 7599 138 309 550 828 1163 2001 138 244 381 550 933 77 138 215 309 550 828 88 138 198 352 550 Shear Stiffness kN/m/mm 9.0 13.5 18.0 22.5 27.0 36.0 4.5 6.8 9.0 11.3 13.5 18.0 4.5 6.0 7.5 9.0 12.0 3.4 4.5 5.6 6.8 9.0 11.3 3.6 4.5 5.4 7.2 9.0 Shear Capacity +/- mm 2 2 2 2 2 2 5 5 5 5 5 5 8 8 8 8 8 10 10 10 10 10 10 13 13 13 13 13 Rotation Capacity rad 0.022 0.010 0.006 0.004 0.003 0.002 0.044 0.029 0.022 0.014 0.010 0.006 0.044 0.033 0.026 0.022 0.013 0.058 0.044 0.035 0.029 0.022 0.014 0.055 0.044 0.036 0.027 0.022

Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O Type O

Other sizes available upon request Notes: 1. Calculations based on BS 5400. 2. Parameters for rubber: ShA= 60; Shear modulus (N/mm2)= 0.9 3. Compressive strain at approximately 15%. 4. Shear deflection approximately 50% of compressed thickness. 5. Rotation includes 0.0035 radians for construction tolerances. 6. Tolerance on the calculated stiffness value 20%. 7. Calculations based on the bearing strip mounted betwen wood float finished concrete surfaces.

ENGINEERED SYSTEMS

Trelleborg IESA, s.a. Factory & Head office: c/San Vicente, 25. E 01440 Izarra (Alava) - Spain Tel.: +34 9454377090 Fax: +34 945437050 iesa@trelleborg.com

www.trelleborgiesa.com

Trelleborg IESA, s.a. Expandite Division: c/Manzanares, 20-22 P. Industrial Jos Luis Velasco E 28500 Arganda del Rey (Madrid) - Spain Tel.: +34 918701700 Fax: +34 918703465 expandite@trelleborg.com

S-ar putea să vă placă și

- GRANOR Elastomeric Bearings Pads Strips - Series BSDocument4 paginiGRANOR Elastomeric Bearings Pads Strips - Series BSJames McguireÎncă nu există evaluări

- Bearing 1 PDFDocument1 paginăBearing 1 PDFAnkit SuriÎncă nu există evaluări

- Lead Rubber Bearings Series LRBDocument16 paginiLead Rubber Bearings Series LRBFaisal MuhammadÎncă nu există evaluări

- MAURER Spherical BearingsDocument9 paginiMAURER Spherical BearingsTiago Carvalho100% (1)

- Finite Element Analysis of Steel CordDocument6 paginiFinite Element Analysis of Steel CordSanjiv Kumar SinghÎncă nu există evaluări

- Pot Bearing DrawingDocument1 paginăPot Bearing DrawingMiguel Belda DiezÎncă nu există evaluări

- Tech Manual LRB PDFDocument16 paginiTech Manual LRB PDFShrestha BipinÎncă nu există evaluări

- Girder Stressing CalculationsDocument11 paginiGirder Stressing CalculationsSarmad WaqasÎncă nu există evaluări

- FUJI Combine Profile June 2020Document55 paginiFUJI Combine Profile June 2020Fazilat Mohammad ZaidiÎncă nu există evaluări

- Bearing DesignDocument5 paginiBearing DesignAnde BhanuÎncă nu există evaluări

- Macalloy Tension Structures Brochure Including s460 in AmericanDocument16 paginiMacalloy Tension Structures Brochure Including s460 in AmericananamarialazarÎncă nu există evaluări

- Comparative Finite Element Analysis of Pikotek VCS and RTJ PDFDocument28 paginiComparative Finite Element Analysis of Pikotek VCS and RTJ PDFAbigor45Încă nu există evaluări

- Bridge Solution BrochureDocument41 paginiBridge Solution BrochurearunjacobnÎncă nu există evaluări

- Type FRB1. 333 Ton Free Sliding Bearing DesignDocument8 paginiType FRB1. 333 Ton Free Sliding Bearing DesignAnkush SharmaÎncă nu există evaluări

- U C Jindal PDFDocument1.043 paginiU C Jindal PDFRaja Sekhar Battu100% (1)

- Design Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDocument6 paginiDesign Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDusmantaKumarSahooÎncă nu există evaluări

- TENSACCIAI Stay CablesDocument45 paginiTENSACCIAI Stay CablesAnonymous efXzvzOVÎncă nu există evaluări

- Fastener Connection To Structure - ExampleDocument12 paginiFastener Connection To Structure - ExamplekingdbmÎncă nu există evaluări

- Section Modulus CalculatorDocument14 paginiSection Modulus CalculatorSuyenthan SathishÎncă nu există evaluări

- Bridge Bearing Main - 2 Design Calculation (R-0)Document27 paginiBridge Bearing Main - 2 Design Calculation (R-0)mohan1441Încă nu există evaluări

- Timco TDS Drywall ScrewDocument2 paginiTimco TDS Drywall ScrewNajeeb AhmedÎncă nu există evaluări

- Load Combinations Section 12Document23 paginiLoad Combinations Section 12avikshit yÎncă nu există evaluări

- Ultimate Design Capacity of High Strength Friction GripDocument5 paginiUltimate Design Capacity of High Strength Friction GripSanthi KrishnaÎncă nu există evaluări

- Bearing Design Method BDocument38 paginiBearing Design Method BTeguh FahrezaÎncă nu există evaluări

- Spine Girder - Prestress DesignDocument109 paginiSpine Girder - Prestress Designarif_rubinÎncă nu există evaluări

- Walkway GratingDocument2 paginiWalkway Gratingbijukoottala100% (1)

- Plate GirderDocument74 paginiPlate Girderarif_rubin100% (1)

- Anchor Bolt Design of Channel Pinned ConnectionDocument42 paginiAnchor Bolt Design of Channel Pinned Connectionprasanth bhadranÎncă nu există evaluări

- Ke Series Bearings En1337Document16 paginiKe Series Bearings En1337Tan Nguyen CongÎncă nu există evaluări

- TN-326 Average Pre CompressionDocument3 paginiTN-326 Average Pre CompressionPartha Pratim RoyÎncă nu există evaluări

- DS Prestress HBDocument28 paginiDS Prestress HBBrian James MarzanÎncă nu există evaluări

- AGOM Pot Bearing SpecificationsDocument11 paginiAGOM Pot Bearing SpecificationsOsama Abbas100% (1)

- IRECN Bridge Bearing-3Document21 paginiIRECN Bridge Bearing-3vpmohammed100% (1)

- Jindal Deck Sheet Tr80+Document1 paginăJindal Deck Sheet Tr80+Anonymous zAFrxk100% (1)

- Anchor Bolt FAZ IIDocument4 paginiAnchor Bolt FAZ IImmaleniÎncă nu există evaluări

- Fatigue Test MBJSDocument50 paginiFatigue Test MBJSKrisna SetiawanÎncă nu există evaluări

- 4B4DC764AC39AFAD5D5F9C87B731618Document12 pagini4B4DC764AC39AFAD5D5F9C87B731618Rama KrishnaÎncă nu există evaluări

- Idea - Wheel CalculationDocument35 paginiIdea - Wheel Calculationbambang satryojatiÎncă nu există evaluări

- Red Bricks VS Aac Blocks PDFDocument11 paginiRed Bricks VS Aac Blocks PDFNIHAR SHAHÎncă nu există evaluări

- European Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Document7 paginiEuropean Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Chong Ting Sheng100% (1)

- Truss DesignDocument16 paginiTruss DesignRabindraUpretiÎncă nu există evaluări

- API5LDocument3 paginiAPI5LputrudeÎncă nu există evaluări

- Design of Elastomeric BearingsDocument6 paginiDesign of Elastomeric BearingsHarshitha GaneshÎncă nu există evaluări

- Anchor BoltsDocument4 paginiAnchor BoltsGibbs PerÎncă nu există evaluări

- BEAMDocument7 paginiBEAMAnonymous sfkedkym100% (1)

- L11 Mechanical FastenersDocument91 paginiL11 Mechanical FastenersSHADES 4 ALLÎncă nu există evaluări

- Pot Bearings PDFDocument12 paginiPot Bearings PDFFurtado23Încă nu există evaluări

- Comparision - LRB & FPBDocument8 paginiComparision - LRB & FPBAnastasia YesicaÎncă nu există evaluări

- Kirby Sheeting Panel Charts PDFDocument2 paginiKirby Sheeting Panel Charts PDFAnonymous ELujOV3Încă nu există evaluări

- Image PDFDocument44 paginiImage PDFAkshay Kumar SahooÎncă nu există evaluări

- Slab Formworks DesignDocument26 paginiSlab Formworks DesignevilmurdocÎncă nu există evaluări

- Pages From Hilti BE 500Document1 paginăPages From Hilti BE 500Anonymous S7Cq7ZDgPÎncă nu există evaluări

- Amendment No. 3 December 2021 TO Is 6911: 2017 Stainless Steel Plate, Sheet and Strip - SpecificationDocument4 paginiAmendment No. 3 December 2021 TO Is 6911: 2017 Stainless Steel Plate, Sheet and Strip - SpecificationshamrajjÎncă nu există evaluări

- Spherical Bearings CalculationsDocument2 paginiSpherical Bearings CalculationsPallab GhoshÎncă nu există evaluări

- Elastomeric Bearing Pads and Strips Brochure 2010Document4 paginiElastomeric Bearing Pads and Strips Brochure 2010Anton Husen PurboyoÎncă nu există evaluări

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 paginiElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkÎncă nu există evaluări

- General Utility Compression Frames C13Z00Document4 paginiGeneral Utility Compression Frames C13Z00Fernando QuirozÎncă nu există evaluări

- Jaw Crusher 2013Document8 paginiJaw Crusher 2013dexsaÎncă nu există evaluări

- Alustar (Perfis & Secções)Document49 paginiAlustar (Perfis & Secções)Jeovani DanielÎncă nu există evaluări

- Har Wal CatalogDocument136 paginiHar Wal CatalogkaoblekstenaÎncă nu există evaluări

- Preview of API 610 12th EditionDocument7 paginiPreview of API 610 12th EditionHatem ShawkiÎncă nu există evaluări

- Parts Breakdown 259Document4 paginiParts Breakdown 259Luis ParaisoÎncă nu există evaluări

- PAAE229540 Manual en PDFDocument522 paginiPAAE229540 Manual en PDFSalman Kapoor100% (1)

- Towimor C30B-PK114Document246 paginiTowimor C30B-PK114john smithÎncă nu există evaluări

- GEMU090 Iceomatic Service ManualDocument25 paginiGEMU090 Iceomatic Service Manualdan themanÎncă nu există evaluări

- Wartsila 32 Diesel Engine AnalysisDocument8 paginiWartsila 32 Diesel Engine Analysisivanadityan100% (1)

- ZS 4, ZS 4 VSD & ZS 4 VSD+ - enDocument32 paginiZS 4, ZS 4 VSD & ZS 4 VSD+ - enwael72Încă nu există evaluări

- United States Patent (10) Patent No.: US 6,793,224 B2: Stratton (45) Date of Patent: Sep. 21, 2004Document14 paginiUnited States Patent (10) Patent No.: US 6,793,224 B2: Stratton (45) Date of Patent: Sep. 21, 2004Dagger HashimotoÎncă nu există evaluări

- Splash Lubrication PDFDocument32 paginiSplash Lubrication PDFRajender KumarÎncă nu există evaluări

- Mechanical Puller Catalog - EUDocument20 paginiMechanical Puller Catalog - EUSergiSerranoÎncă nu există evaluări

- Danfoss Hydraulic Motor WD WP - WRDocument68 paginiDanfoss Hydraulic Motor WD WP - WRLuc DionneÎncă nu există evaluări

- Detect and Indentity The Cause of Machinery Ma-1Document64 paginiDetect and Indentity The Cause of Machinery Ma-1sukarlem marsiahÎncă nu există evaluări

- Design and Development of Mechanism For Separation of Arecanut HuskDocument30 paginiDesign and Development of Mechanism For Separation of Arecanut HuskAkshay Kumar pn AkshayÎncă nu există evaluări

- Slurry PumpDocument78 paginiSlurry PumpFavorSea Industrial Channel Limited100% (2)

- 09 Grinding BrochureDocument56 pagini09 Grinding Brochurewouter NeirynckÎncă nu există evaluări

- Ke Stoker BrochureDocument8 paginiKe Stoker Brochurechaiya sonwongÎncă nu există evaluări

- 777F MG MotorDocument121 pagini777F MG MotorDenerMendozaLayza100% (2)

- Swinburne Test: Loss Summation Method in DC Shunt MachinesDocument8 paginiSwinburne Test: Loss Summation Method in DC Shunt MachinesDilip TheLipÎncă nu există evaluări

- Cmas 100Document4 paginiCmas 100Munkhnasan MonaÎncă nu există evaluări

- Urai Manual PDFDocument28 paginiUrai Manual PDFAlberto Velosa RoaÎncă nu există evaluări

- Plate Rolling Machine 2Document22 paginiPlate Rolling Machine 2Oluwaseyi Victor Sorinade100% (1)

- Wartsila 32 Bearing AssessmentDocument8 paginiWartsila 32 Bearing AssessmentVito Digeo100% (2)

- Forging Machines and Automated Upsetters BrochureDocument16 paginiForging Machines and Automated Upsetters BrochurecelectricÎncă nu există evaluări

- 941 WS3Document194 pagini941 WS3Luis Jesus100% (1)

- S - Ind-Me-08-Eng-Eng-12-001 Rev000 300 Hrs Maintenance InstructionDocument21 paginiS - Ind-Me-08-Eng-Eng-12-001 Rev000 300 Hrs Maintenance InstructionDeepakÎncă nu există evaluări

- Dme Cie PapersDocument5 paginiDme Cie PapersThoran BruceleeÎncă nu există evaluări

- Komatsu WB150-2Document486 paginiKomatsu WB150-2Виктор100% (1)

- d062dc07 PDFDocument47 paginid062dc07 PDFStefanos DiamantisÎncă nu există evaluări

- Adams Auto-Lubrication System DesignDocument4 paginiAdams Auto-Lubrication System DesignRobin Ace SamonteÎncă nu există evaluări

- Part 1 Operation Manual of Steam TurbineDocument157 paginiPart 1 Operation Manual of Steam TurbineAshutosh Kushwaha75% (12)

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe la EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tEvaluare: 4.5 din 5 stele4.5/5 (27)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDe la EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceEvaluare: 4 din 5 stele4/5 (19)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneDe la EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneEvaluare: 4.5 din 5 stele4.5/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDe la EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsÎncă nu există evaluări

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDe la EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureEvaluare: 4.5 din 5 stele4.5/5 (2)

- A Welder’s Handbook to Robotic ProgrammingDe la EverandA Welder’s Handbook to Robotic ProgrammingEvaluare: 5 din 5 stele5/5 (3)

- Laws of UX: Using Psychology to Design Better Products & ServicesDe la EverandLaws of UX: Using Psychology to Design Better Products & ServicesEvaluare: 5 din 5 stele5/5 (9)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesDe la EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesÎncă nu există evaluări

- Design for How People Think: Using Brain Science to Build Better ProductsDe la EverandDesign for How People Think: Using Brain Science to Build Better ProductsEvaluare: 4 din 5 stele4/5 (8)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDe la EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceÎncă nu există evaluări

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsDe la EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsÎncă nu există evaluări

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!De la EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Evaluare: 4 din 5 stele4/5 (3)

- 507 Mechanical Movements: Mechanisms and DevicesDe la Everand507 Mechanical Movements: Mechanisms and DevicesEvaluare: 4 din 5 stele4/5 (28)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessDe la EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessÎncă nu există evaluări

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsDe la EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsEvaluare: 5 din 5 stele5/5 (1)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersDe la EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersEvaluare: 4 din 5 stele4/5 (13)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDe la EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchEvaluare: 4 din 5 stele4/5 (10)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionDe la EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionÎncă nu există evaluări