Documente Academic

Documente Profesional

Documente Cultură

Engine Performance

Încărcat de

Syahiran SharifDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Engine Performance

Încărcat de

Syahiran SharifDrepturi de autor:

Formate disponibile

Introduction Objective This assignment was given to build students understanding about engine performance.

To understand how engine works, its history, worlds automaker, where and when engines power built and lost, how to increase engines power and decrease power lost and lastly to understand the combination between theories and practices of the engines. This assignment mainly covers 4-stroke engine performance. What is Engine? In automotive term, engine is a machine mounted in a vehicle that converts chemical energy from fuel such as gasoline, steam or electricity to physical energy and moves the vehicle, either internal combustion or external combustion engine.

Figure 1.1: Chemical equation in combustion chamber Engine Performance Engine performance is a relationship between power output, revolutions per minute, fuel or fluid consumption, and ambient conditions in which an engine operates. Ref: http://www.answers.com/topic/engine-performance Worlds automaker always do research and development about engine performance. It is because engine performance became an important criteria customer count. Engine performance shows the vehicles power output, fuel consumption, durability and comfort where it is determine the level of a vehicle whether it is a sports vehicle, fuel efficiency vehicle or luxury vehicle.

It is important for an automotive person to know about engine behavior of a vehicle such as its displacement, fuel consumption, stroke ratio, cylinder configuration and technology of an engine to figure out how to repair, build, overhaul, and maintaining an engine and provide information to customer.

Internal Combustion Engine 2-Stroke Gasoline Engine A 2-stroke engine is an internal combustion engine that completes the process cycle in one revolution of the crankshaft (an up stroke and a down stroke of the piston, compared to twice that number for a four-stroke engine). This is accomplished by using the end of the combustion stroke and the beginning of the compression stroke to perform simultaneously the intake and exhaust functions. 2-stroke engines often provide higher torque and horsepower than 4-stroke engine because of less parts movement. However, 2-stroke engine more fuel consumption because air-fuel mixture may sucked out during exhaust stroke and the engine needs to consume 2-stroke engine oil which is will be burned during power stroke.

Figure 2.1: 2-stroke cycle Ref: http://en.wikipedia.org/wiki/2_stroke

4-Stroke Gasoline Engine A four-stroke engine, also known as four-cycle, is an internal combustion engine in which the piston completes four separate strokesintake, compression, power, and exhaustduring two separate revolutions of the engine's crankshaft.

The four cycles refer to intake, compression, combustion (power), and exhaust cycles that occur during two crankshaft rotations per power cycle of the four cycle engines. The cycle begins at Top Dead Centre (TDC), when the piston is farthest away from the axis of the crankshaft. A cycle refers to the full travel of the piston from Top Dead Centre (TDC) to Bottom Dead Centre (BDC). Intake stroke: on the intake or induction stroke of the piston, the piston descends from the top of the cylinder to the bottom of the cylinder, reducing the pressure inside the cylinder. A mixture of fuel and air, or just air in a diesel engine, is forced by atmospheric (or greater) pressure into the cylinder through the intake port. The intake valve(s) then close. The volume of air/fuel mixture that is drawn into the cylinder, relative to the volume of the cylinder is called, the volumetric efficiency of the engine. Compression stroke: with both intake and exhaust valves closed, the piston returns to the top of the cylinder compressing the air, or fuel-air mixture into the combustion chamber of the cylinder head. Power stroke: this is the start of the second revolution of the engine. While the piston is close to Top Dead Center, the compressed airfuel mixture in a gasoline engine is ignited, usually by a spark plug, or fuel is injected into the diesel engine, which ignites due to the heat generated in the air during the compression stroke. The resulting massive pressure from the combustion of the compressed fuel-air mixture forces the piston back down toward bottom dead center. Exhaust stroke: during the exhaust stroke, the piston once again returns to top dead center while the exhaust valve is open. This action evacuates the burnt products of combustion from the cylinder by expelling the spent fuel-air mixture out through the exhaust valve(s). Most of the power of 4-stroke engine is located at the cylinder head. The valves, intake and exhaust port, and camshaft are the components show the characteristics of the engines. Unlike 2-stroke engine, 4-stroke engine use camshaft to inhale air-fuel mixture and release exhaust gases. Even generally 4-stroke engine are less powerful than 2-stroke engine in same displacements, today 4-stroke gasoline engine are the most widely used in today transportation. This is happen because of its less fuel consumption even a 4-stroke gasoline that can produce a same power to a 2-stroke gasoline engine.

Figure 2.2: 4-stroke cycle Ref: http://en.wikipedia.org/wiki/4_stroke

Rotary Engine Rotary engine is an engine that using wankel to do 4 cycle just like 4-stroke engine instead of piston. Rotary engine also have intake and exhaust port but did not using valve to open and close combustion chamber, but the wankel rotation open and close the ports. Rotary engine may produce twice the power of 4-stroke engine in same displacements because of less parts movements and simpler cycle. However the engine is not popular among automaker and costumer because of its higher maintenance and higher expertise needed.

Stroke Ratio: Undersquare VS Oversquare Stroke ratio is a term which is used to describe the ratio between the diameter of the cylinder bore and the length of the piston stroke within its cylinders. Ref: http://www.answers.com/topic/stroke-ratio Stroke ratio usually described in bore: stroke form.

Undersquare Bore 1: >1 Stroke Nowadays most automaker love to produce undersquare engine than oversquare engine. It is because undersquare engine generally less fuel consumption, more durable (because of lower RPM use) and cheaper (because of the engine material). Undersquare engine, or called longstroke engine, has longer stroke than bore of the cylinder and produce higher torque and lower horsepower than oversquare engine. It also uses lower gear-ratio value. Undersquare engine less consume fuel because it is use lower RPM to accelerate and maintaining top speed.

Figure 3.1: Stroke is longer than bore Oversquare Bore >1: 1 Stroke Oversquare engine, also called short-stroke engine, has longer bore than stroke of a cylinder. Generally it is using more fuel consumption than undersquare engine because oversquare engine use higher RPM to generate power. Oversquare engine also use higher gear-ratio value to counter its low torque. Oversquare engine is more practical in racing use than undersquare engine because oversquare engine has wider powerband. Cars that use oversquare engine are F1, Ferrari 599 GTB Fiorano, Porche Carrera GT, Nissan Skyline, Honda S2000 and Toyota Supra. Ref: http://en.wikipedia.org/wiki/

Cylinder Head In4-stroke gasoline engine, cylinder head are the most important section that determines and controls the power of an engine. The parts that will be discussed are valves, camshaft, carburetor and fuel injection. Valves Valves are the parts that open and close the intake and exhaust ports during intake and exhaust stroke. Large valves provide more volumetric efficiency at high rpm (more horsepower), but lagging while in low rpm (less torque). Large valve also reduce engine braking. Same things are happen between two valves and four valves per cylinder. Two valves provide more torque at lower rpm, but four valves provide more horsepower at higher rpm.

Figure 4.1: 4 valves produce more torque and horsepower than 2 valves in high rpm Camshaft Camshaft is the component that controls the valves to open and close cylinder ports. Camshaft lift and duration determine the amount of air-fuel mixture that enters combustion chamber. Duration is the number of crankshaft degrees of engine rotation during which the valve is off the seat. The larger the duration of camshaft, the higher the rpm needed to provide maximum horsepower, but large duration may cause rough idle, less torque at low rpm and higher fuel consumption.

Figure 4.2: Camshaft profiles The camshaft lift is the resultant net rise of the valve from its seat. Large lift may provide volumetric efficiency at higher rpm and generate more horsepower, but will cause lagging at lower rpm, rough idle and higher fuel consumption. Duration and lift of camshaft determines the overlapping effect in combustion chamber. Overlap is an event where both intake valve and exhaust valve open in a same time. Air-fuel mixture not only inhaled because of the vacuum effect of piston when going to BDC, but also when exhaust gases exhaled from combustion chamber, vacuum effect to the outside environment are generated. The larger the duration and lift of camshaft, the overlapping effect will become more powerful. Valves can be driven one or two camshafts. SOHC stands for single overhead camshaft, which is using only a camshaft to drive intake and exhaust valves. SOHC provide less rotating part because only using one camshaft pulley and the timing belt are shorter compare to DOHC. DOHC stands for double overhead camshaft, which is using two camshafts, one camshaft drive the intake valves and the other one drive the exhaust valves. Although DOHC have more rotating parts, but using double camshaft may reduce the friction during driving the valvetrain, which resulting more efficient powerband and faster air-fuel mixture entering the combustion chamber.

Figure 4.3: VG30E is SOHC and VG30DE is DOHC. VG30DE provide higher horsepower as shown. Both engines are Nissan Fairlady Z engines.

Air-Fuel Mixing Device The air-fuel mixing devices that are usually used in vehicle are carburetor and fuel injection. Carburetor is used in conventional engine that using distributor. Carburetor inhale fuel through main jet port and air through pilot jet port. Carburetor supply air-fuel mixture to combustion chamber in vapor form. The weaknesses of using carburetor are carburetor can be adjusted to only having one stage. To reduce fuel consumption carburetor are adjusted to lean (air 14.7: <1 fuel), but cannot revving to higher rpm. To increase horsepower carburetor are adjusted to rich (air 14.7: >1 fuel), but fuel consumption will increase and powerband is suffered during low rpm, and also resulting the fuel not 100% burning and the unburned fuel may harden on top of the piston and cylinder wall, which may cause scratch. Fuel injection is used in engine that is using ECU (electronic control unit). Fuel injection spray air-fuel mixture to combustion chamber in much smaller vapor, which will create more efficient combustion and decrease fuel consumption. Fuel injection can be adjusted to vary its response in different rpm and air-fuel mixture demand. The only weakness of fuel injection system is higher maintenance.

Variable Valve Timing Torque and horsepower often cannot be combined. This is because once the engine are built for low rpm power or fuel efficiency, the engine cannot provide power in higher rpm, thus will result low horsepower. And once the engine is built for high rpm efficiency and high horsepower, the engine cannot provide fuel efficiency which will result higher cost in maintaining. VTEC, stands for Variable valve timing and electronic control, developed by Honda to increase volumetric efficiency at higher rpm, thus will create high horsepower. But at the same time, may provide fuel efficiency if running under low rpm. VTEC using two camshafts profile and electronically switch to one another. The switching operation between the two cam lobes is controlled by the ECU which takes account of engine oil pressure, engine temperature, vehicle speed, engine speed and throttle position. Using these inputs, the ECU is programmed to switch from the low lift to the high lift cam lobes when the conditions mean that engine output will be improved. At the switch point a solenoid is actuated which allows oil pressure from a spool valve to operate a locking pin which binds the high RPM cam follower to the low RPM ones. From this point on, the poppet valve opens and closes according to the high-lift profile, which opens the valve further and for a longer time.

Figure 4.4: VTEC operation Ref: http://en.wikipedia.org/wiki/VTEC

After VTEC, Mitsubishi Motors has developed a system to counter back Honda variable valve timing system called MIVEC. MIVEC stands for Mitsubishi Innovative Valve timing Electronic Control system, similar to VTEC purpose, to increase high rpm volumetric efficiency while maintaining fuel efficiency in low rpm run. Toyota also has developed a variable valve timing called VVT-i, stands for variable valve timing with intelligence. But instead of changing cam profile, VVT-i is using overlap to increase high rpm volumetric efficiency.

Modification Todays cars are mostly made for fuel efficiency and environmental friendly. However, in some cases, cars are needed to be tuned to take part in performance events such as rally. So that there are some parts in the engine that need to be changed. Exhaust Stock exhaust is made for fuel efficiency and environmental friendly thus limiting its full performance. Changing stock exhaust to aftermarket exhaust has to be considered carefully since there are types of aftermarket exhaust. 4-2-1 extractor is used to enhance low rpm power. But usually 4-2-1 extractor is used for street and daily use. 4-1 extractor is used to enhance high rpm power.

Figure 5.1: 4-2-1 extractor

10

4-1 extractors are designed based on engineering formula. Each and every pipe is calculated for optimum length and size to produce a siphoning effect. By utilizing a 4-1 design, we no longer have the issue of pressure / siphoning effects that stock and traditional 4-2-1 designs have.

Figure 5.2: 4-1 extractor For example when one cylinder is blowing out exhaust gases it produces a vacuum or siphoning effect in the exhaust port of another complementary cylinder. For example, when cylinder one is on the exhaust stroke a siphoning effect is produced in the exhaust port of cylinder four in a four-cylinder engine. When there is siphoning effect, the piston now no longer needs to pump the exhaust gas out. Thus, the power previously used for the pumping effort is now recovered to propel the car. Furthermore, the cylinder is cleaned of all exhaust gases and hence the incoming air-fuel mixture is now purer and produces more power. Therefore, not only is there a recovery of lost power (pumping losses) but there is actually additional power from the same amount of fuel and air that goes into the engine cylinders. By utilizing our 4-1 design, with very long runners, every stroke produces that siphoning effect at the junction of the 4 pipes. The long runners means that a scavenging effect is utilized at all times without the sucking effect that occurs in a 4-2-1 design. Ref: http://www.rpw.com.au/shop/index.php?option=com_content&task=view&id=116&Itemid=25

Spark Plug Stock spark plugs that are fitted in stock car are designed for casual use. Its produce average spark, low heat transfer and average durability. Racing spark plugs designed to produce larger spark to increase torque and horsepower, high heat transfer to reduce combustion chamber heat, and high durability to bear engines fierce work.

11

Spark plug cable Racing spark plug cable usually made of more than one core to bear engines heat and enhance heat transfer, using electric-conducting material that are low resistance to ensure larger sparks are produced, and it is wrapped with heat-proof electric insulator.

Grounding cable Usually stock car is not fitted with grounding cable. Aftermarket grounding cable designed to reduce distortion. Therefore it improves the current amperage, stronger ignitions, better performance and improved fuel economy. This is happen because electricity on a completed circuit flows from the positive terminal to the negative terminal. The same laws apply to a typical car's electric system, as electric current flows from the positive terminal of a battery, through the car's body to the negative terminal on the battery. On a car however, there is a lot of resistance in the whole electrical system. This is normally caused by poorly placed grounding points, or corrosion which is present on the grounding point. This resistance can disturb the flow of electricity so much that a car's electrical components, such as the lamps, radio and even the ECU will not be able to operate at their peak. Grounding cable capable to stabilize the voltage from the battery while reducing load on the battery. Ref: http://www.vclassmotorsport.com/template.asp?menuid=48

Fuel pressure regulator Most of performance car is made to revving in high rpm. But because of engine speeds, suction power from combustion to inhale air-fuel mixture is decreased. But since the air are lighter than fuel, the mixture become lean. Lean mixture is not helping the engine to revving. So the fuel pressure regulator is made to regularly provide enough fuel and to maintain a constant fuel pressure for proper fuel atomization. The fuel pressure regulator is able to maintain proper fuel pressure to the vehicle it has been designed for because inside the regulator housing there is a spring pushing against a diaphragm, the spring pressure has been pre-set by the manufacturer for the desired fuel pressure, so the fuel pump has to pump enough fuel and enough pressure at the same time to overcome the spring pressure. The extra fuel not needed is sent back to the fuel tank through the fuel return line. When the vehicle is at idle, there is less pressure against the fuel coming inside the regulator because the fuel pressure regulator has a vacuum hose attached to it, this way the fuel pressure will be lower ( from 5 to 10 psi depending on the system) due to the fact that the vacuum is forcing the diaphragm inside the regulator housing to have extra pressure against the spring, resulting in a lower fuel pressure when the car is at idle because there is high vacuum

12

inside the intake manifold; when you accelerate and the vacuum drops, the fuel pressure increases to allow the engine to have more fuel as it needs it.

Racing Camshaft Stock camshaft that is fitted in stock car usually designed for good low rpm torque and fuel efficiency. Racing camshaft or high cam is made to increase valve lift and duration, thus increase volumetric efficiency at higher rpm and creating one big horsepower.

Camshaft pulley, Flywheel, Piston Aftermarket camshaft pulley, flywheel and piston usually are lighter than stock parts to increase torque and reduce weight of reciprocating parts. So more horsepower are built and driving wheels receive more horsepower. Aftermarket piston also has higher compression than stock piston, so power efficiency (larger combustion) is increase in compression and power stroke.

Air filter Aftermarket air filter is more porous. So more air flow is inhaled to combustion chamber and the air flow is faster than using stock air filter.

Electronic control unit Stock ECU is made following the law and to protect engine from high revving damage, and also want to equal the engine capability and car limit. Aftermarket ECU usually has no cut-off, so engine may revving to its most capability with no restrictions, and tuner also may tune the car following the way they want.

13

Forced induction There are two types of forced induction that is supercharger and turbocharger. Supercharger driven using belt that is connected to crankshaft pulley and inhale air using air compressor device that are rotation using belt. Generally supercharger used to enhance low-to-mid rpm usage.

Figure 5.3: Car boot mounted with supercharger Turbocharger usually is used to enhance mid-to-high rpm usage. Instead of using belt, turbocharger is using exhaust gases pressure that rotating the turbine and inhale air. Air is compressed then cooled when flowing through intercooler before entering combustion chamber. Turbocharger is more efficient than supercharger because belt that is driving the supercharger is wasting horsepower.

Figure 5.4: Turbocharger cross-section

14

Figure 5.5: Turbocharger operation

Dynamometer Test Dynamometer or dyno is a device that used to calculated engine performance. It can calculate air-fuel mixture, torque, horsepower and rpm.

Figure 5.6: Horsepower and air-fuel mixture graph

15

Dynamometers are useful in the development and refinement of modern day engine technology. The concept is to use a dyno to measure and compare power transfer at different points on a vehicle, thus allowing the engine or drivetrain to be modified to get more efficient power transfer. For example, if an engine dyno shows that a particular engine achieves 400 Nm (300 lbfft) of torque, and a chassis dynamo shows only 350 Nm (260 lbfft), one would know to look to the drivetrain for the major improvements. Dynamometers are typically very expensive pieces of equipment, reserved for certain fields that rely on them for a particular purpose. There are essentially 3 types of dynamometer test procedures 1. Steady state (only on brake dynamometers), where the engine is held at a specified RPM (or series of usually sequential RPMs) for a desired amount of time by the variable brake loading as provided by the PAU (power absorber unit). 2. Sweep test (on inertia or brake dynamometers), where the engine is tested under a load (inertia or brake loading), but allowed to "sweep" up in RPM in a continuous fashion, from a specified lower "starting" RPM to a specified "end" RPM. 3. Transient test (usually on AC or DC dynamometers), where the engine power and speed are varied throughout the test cycle. Different test cycles are used in different jurisdictions. Ref: http://en.wikipedia.org/wiki/Dynamometer

16

Reference http://www.answers.com/topic/engine-performance http://en.wikipedia.org/wiki/2_stroke http://en.wikipedia.org/wiki/4_stroke http://www.answers.com/topic/stroke-ratio http://en.wikipedia.org/wiki/VTEC http://www.rpw.com.au/shop/index.php?option=com_content&task=view&id=116&Itemid=25 http://www.vclassmotorsport.com/template.asp?menuid=48 http://en.wikipedia.org/wiki/Dynamometer

17

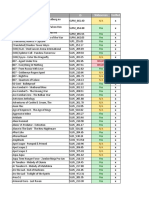

Index air-fuel mixture camshaft combustion chamber cylinder duration exhaust fuel consumption fuel efficiency head intake lift piston oversquare rotary rpm supercharger turbocharger undersquare valve variable valve timing wankel 2,3,6,7,8,11,12,15 3, 6, 7 1,3,4,6,7,8,13,14 2,3,4,5,6,8,11 6,7,13 2,3,4,7,10,11,14 1,2,3,5,6,7,8 1,9,10,13 3,6,7 2,3,4,6,7 6,7,9,13 2,3,4,7,8,11,13 4,5 4 5,6,7,8,9,10,12,14,15,16 14 14,15 4,5 3,4,6,7,9,10,13 9,10 4

18

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- A Brief Tutorial On Studio MonitorsDocument18 paginiA Brief Tutorial On Studio MonitorsCurtis O'BrienÎncă nu există evaluări

- Samsung Galaxy Watch 5 Pro User ManualDocument131 paginiSamsung Galaxy Watch 5 Pro User Manualzyron100% (1)

- ENIRAM - Guide To Dynamic Trim Optimization 280611 PDFDocument14 paginiENIRAM - Guide To Dynamic Trim Optimization 280611 PDFPhineas MagellanÎncă nu există evaluări

- 6000 Most Common Korean Words - For All TOPIK Levels PDFDocument232 pagini6000 Most Common Korean Words - For All TOPIK Levels PDFZac67% (3)

- SAP Group Reporting 1909Document28 paginiSAP Group Reporting 1909SUDIPTADATTARAY86% (7)

- List of Tyre Pyrolysis Oil Companies in IndiaDocument2 paginiList of Tyre Pyrolysis Oil Companies in IndiaHaneesh ReddyÎncă nu există evaluări

- How The Audiences Feel Closer and Connected To Their Culture With StorytellingDocument7 paginiHow The Audiences Feel Closer and Connected To Their Culture With Storytellingmarcelo quezadaÎncă nu există evaluări

- PASSAGE ONE (Questions 1-4)Document5 paginiPASSAGE ONE (Questions 1-4)Vian LonkzeerÎncă nu există evaluări

- PienaDocument1 paginăPienaMika Flores PedroÎncă nu există evaluări

- Instruction Manual: Slit Lamp Bon SL-EDocument20 paginiInstruction Manual: Slit Lamp Bon SL-EVladimir LevchenkoÎncă nu există evaluări

- Researchpaper Should Removable Media Be Encrypted - PDF - ReportDocument15 paginiResearchpaper Should Removable Media Be Encrypted - PDF - ReportSakshi Dhananjay KambleÎncă nu există evaluări

- Barriers of CommunicationDocument5 paginiBarriers of CommunicationIVY YBAÑEZÎncă nu există evaluări

- IPE SakibBhaiMagicChothaDocument55 paginiIPE SakibBhaiMagicChothaTousif SadmanÎncă nu există evaluări

- Casio AT 1 Service ManualDocument28 paginiCasio AT 1 Service ManualMario Gabriel MoralliÎncă nu există evaluări

- Advanced Office Add-In DevelopmentDocument40 paginiAdvanced Office Add-In DevelopmentReadoneÎncă nu există evaluări

- BFISDocument1 paginăBFISEverestÎncă nu există evaluări

- BM Stake Holders Case Study 1st November 2023Document2 paginiBM Stake Holders Case Study 1st November 2023Arsath malik ArsathÎncă nu există evaluări

- History of Computer ReviewerDocument10 paginiHistory of Computer ReviewerNeil Andrew Aliazas78% (9)

- 50+ MATLAB Projects For Engineering StudentsDocument5 pagini50+ MATLAB Projects For Engineering StudentsaamyaÎncă nu există evaluări

- Pearson Letter To ParentsDocument2 paginiPearson Letter To ParentsPatricia WillensÎncă nu există evaluări

- Entropy Equation For A Control VolumeDocument12 paginiEntropy Equation For A Control VolumenirattisaikulÎncă nu există evaluări

- AIMMS Modeling Guide - Linear Programming TricksDocument16 paginiAIMMS Modeling Guide - Linear Programming TricksgjorhugullÎncă nu există evaluări

- Presentation DelcorteDocument15 paginiPresentation Delcortecarlos2685Încă nu există evaluări

- Law of DemandDocument16 paginiLaw of DemandARUN KUMARÎncă nu există evaluări

- World Link YolaDocument3 paginiWorld Link YolaHamilton Obando100% (1)

- NC Error PropagationDocument12 paginiNC Error PropagationSalman KhanÎncă nu există evaluări

- WideScreen Code For PS2 GamesDocument78 paginiWideScreen Code For PS2 Gamesmarcus viniciusÎncă nu există evaluări

- (English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)Document41 pagini(English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)YaaroÎncă nu există evaluări

- FINAL ReportDocument48 paginiFINAL ReportMythri RangaswamyÎncă nu există evaluări

- THE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFDocument3 paginiTHE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFUjjwalÎncă nu există evaluări