Documente Academic

Documente Profesional

Documente Cultură

Lipase

Încărcat de

Yelesh LanjewarDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lipase

Încărcat de

Yelesh LanjewarDrepturi de autor:

Formate disponibile

INTRODUCTION Lipase are the enzyme that hydrolyze oils and fats to glycerols and free fatty acids,

carbon energy sources that can easily be utilized by many organism. Lipase chosen as Biocatalysts in the industry as a good alternative for inorganic catalysts where specific products are obtained (Sarkar, 1998). Microbial lipase constitutes an important group of biotechnologically valuable enzyme, mainly because of the special use of their applied properties and ease of mass production. Most of the well-studied microbial lipases are inducible extracellular enzymes, which are produced by various organism like, candida cylinchacae, candida rugosa, Aspergilus niger, Penicillum cyclopium, Humicola langinosa, mucor javanicus, Rhizopus arrhizus, Geotrium candidum synthesized within the cell and exported to its external surface or environment. Microbial lipases are usually extracellular enzyme, which are produced by various fungi, actinomyces, yeasts and bacteria (Hou and Johnson, 1992). Lipase (triacyl glycerol ester hydrolase (EC 3.1.1.3) catalyse the hydrolysis of fat to produce monoglycerides, diglycerides, free fatty acids and glycerol (Macrae, A.R. and Hammond, R.C. 1985) and (Godtfredsen, s.e., fogarty, W.M. and Krlly, C.T. 1990) the reaction are reversible and therefore, lipase also catalyse the formation of acylglycerols from glycerol and fatty acids.

Lipase belongs to class of serine hydrolase and therefore do not required any co-factor. The natural substrates of lipase are triacylglycerols having very low solubility in water. Under natural conditions, they catalase the hydrolysis of ester bonds at the interface between an insoluble substrate phase and the aqueous phase in which the enzyme is dissolved. Under certain experimental conditions, such as in the absence of water, they are capable of reversing the reaction. The reverse reaction leads to esterfication and formation of glycerides from fatty acids and glycerol (R.K. Saxena et.al.) Lipase catalyses the reaction Triacyl glycerol + H2O Diacyl glycerol + fatty acid anion.

This reaction goes to completion i.e. until glycerol and free fatty acids are formed. Lipase function at the oil-water interface. The amount of oil available at the interface determines the activity of the lipases. This interface area can be increased substantially to its saturation limit by the use of emulsifier as well as by agitation. The Saturation limit depends on the ingredient used as well as the physical conditions deployed. Thus, the activities of lipase can be pronouncedly increased by use of emulsifying agents as well as by method that increase the size of the emulsion micelles. Lipase are not involved in any anabolic processes. Since this enzyme acts at the oil-water interface, it can be used as a catalyst for the preparation of

industrially important compounds. Lipase catalyse the hydrolysis of triglycerides into diglycerides, monoglycerides, glycerol and fatty acids, and under certain condition the reverse reaction leads to esterfication and formation of glycerides from glycerol and fatty acids. The interaction of lipase with insoluble substances does not confirm to Michalis-Menton kinetics but instead involved two distinct steps: adsorption to an oil- water interface and subsequent lipolysis. The catalytic activity of the enzyme increases dramatically at the interface, this phenomenon being known as interfacial activation. Sarda and Desnuelle initially established the fact in 1958 and the activation of lipase caused by immobilization on a solid support has been reported in several studies. Crystallographic studies have shown that interfacial activation was associated with a conformational change. However the mechanism for triggering the opening of the lid has been unclear. Although many work have been done Lipases possess characteristic properties like substrate specificity, stereospecificity and ability to catalyses heterogeneous reactions at the interface of water insoluble systems. They differ from classic esterases in that there natural substrate are insoluble in water and their activity is maximal only when the enzyme is adsorbed to the oil-water interface. In recent year there has been a great demand for thermo stable enzyme in industrial fields (Sugihara et al., 1992). Lipases are the most workable biocatalyst and bring about a wide range of bioconversion reactions, such as hydrolysis, inter-esterfication, esterification, alcoholysis, acidolysis and aminolysis. Lipases can act on a

variety of substrates including natural oils, synthetic triglycerides and esters of fatty acids. Lipase occurs in animals, plants and microorganisms. Microbial lipases have a broad spectrum of industrial applications as they are more stable compared with plant and animal lipase and they can obtain cheaply. The biosynthesis of lipases was done by submerged culture fermentation on shake flask. Microbial lipases are produced mostly by submerged culture but solid-state fermentation can also be used. Generally the lipase production is organism specific and it is released during the late logarithmic or stationary phase. The cultivation period also varies with the microorganism and fast growing bacteria were found to secrete lipase within 48 hours. The production of lipase is mostly inducers dependent, and in many cases oils act as good inducers of the enzyme. Certain other inducers also have a profound effect on the stimulation of lipase production. They include triglycerides, free fatty acids, hydrolysable esters, bile salts and glycerol. The organisms are normally grown in a complex nutrient medium containing carbon (oil, sugars, mixed carbon sources), nitrogen and phosphorous sources and mineral salts. Compounds such as olive oil, coconut oil, castor oil and Tributyrene seem to play a vital role in lipase synthesis. Lipases production by B.Subtilis has been investigated and maximum lipase activity seen with the physical changes. The yeast extract, which is an industrial producer of lipase, has been shown to secrete extra-cellular lipase upon induction by fatty acids. This lipase is

composed of several is forms with slightly differing catalytic properties. In the same yeast, using Peptone induced the production of constitutive lipase. The presence of Tween 80 and Tween 20 in the culture medium not only promoted lipase production but also changed the production of multiple forms. Various non-conventional carbon sources, like beef extract is also used to produce lipase. Other significant factors influencing lipase production include nitrogen sources, pH, incubation period (time), temperature and various oils. Over 100 lipases have been characterized to some extent, and more than 30 of these are commercially available. The identification of novel sources of lipases with unique patterns of reaction selectivity remains a strategic objective of lipase studies. Various levels of sophistication are required in the assessment of lipase activities, and they increase as one attains the differential goals of: Screening for activity (qualitative and semi-quantitative); Quantifying activity; and Characterizing kinetic patterns of selectivity. The focus of this study will be quantification of lipase activity in different physical and chemical conditions, since methods developed for this purpose can often be adapted for the other purposes as well. Lipases are unusual hydrolytic enzymes because they act on substrates providing an interface (with few exceptions). This feature has been historically used to distinguish lipases from esterases, the latter of which act on substrates in true solution.

The distinction of lipases as interfacial catalysts can make kinetic characterization a challenge, because relevant substrate concentrations are expressed in terms of area and not concentration. Lipases posses the unique feature of acting at the interface between an aqueous and a non-aqueous phase. They synthesize esters from glycerol and long chain fatty acids when the water activity is low. A true lipase splits emulsified esters of glycerin and long chain fatty acids. Lipases occur widely in nature, but microbial lipases are commercially significant because of low production cost, greater stability and wider availability than plant and animal lipases. They may originate from fungi, molds or bacteria and most of them are formed extracellular. This ready availability has created an enormous spin-off with respect to the enantioselective hydrolysis and formation of carboxyl esters. The enormous biotechnological potential of microbial lipases is related to their exquisite chemo selectivity and physioselectivity. They are readily available in large quantities because many of them can be produced in high yields from microorganisms. The crystal structures of many lipases have been solved, considerably facilitating the design of rational engineering strategies. Finally, lipases do not usually require cofactors nor do they catalyze side reactions. Microbial lipases are currently receiving much attention with the rapid development of enzyme technology.

About bacterial Lipase: As compared to plant and fungal lipase; a relatively small number of bacterial lipases have been well studied and reviewed. Generally bacterial lipases are Glycoproteins but some extracellular bacterial lipases are lipoprotein. The production of extra cellular lipase from bacteria is often dependant on nitrogen and carbon sources, inorganic salts, presence of lipids, temperature and availability of oxygen. It was reported in 1973 that enzyme production in most bacteria is affected by certain polysaccharides. Most of the Bacterial reported are constitutive and inhibited by some serine hydrolyses inhibitor. Most bacterial lipases are non-specific in substrate specificity and a few are thermo-stable. Bacillus Subtilis: There are about 39 known species of Bacillus. Bacillus Subtilis known also as the hay bacillus or grass bacillus (Madigan M. Martinko J. 2005), is a Gram positive, catalase positive, bacterium commonly found in soil. A member of the Genus Bacillus, B. Subtilis is rod shaped, and has the ability to form a tough, protective endospore, allowing the organism to tolerate extreme environmental condition. Unlike several other well-known species .B. subtilis has historitically been classified as obligate aerobes, though recent research has demonstrated that this is not strictly correct (Nakano MM, Zuber P 1998)

Scientific Classification:Domain Bacteria Phylum firmicutes Class - Bacilli Order - Bacillates Family Bacillaceae Genus Bacillus Species Subtilis. (Ehrenberg 1835) Cohn 1872.

Pathogenesis B. subtilis is not a human pathogen. It may contaminate food but rarely causes food poisoning.(Rhyan K.J, CG 2004) B. subtilis produces the proteolytic enzyme subtilisin. B. subtilis spores can survive the extreme heat during cooking. B. subtilis is responsible for causing ropiness a sticky,

stringy consistency caused by bacterial production of long-chain polysaccharides in spoiled bread dough. History In 1835, the bacterium was originally named Vibrio subtilis by Christian Gottfried Ehrenberg, (Ehrenberg, CG, 1835) and renamed Bacillus subtilis by Ferdinand Cohn in 1872. (Cohn F, 1872). Cultures of B. subtilis were used throughout the 1950s as an alternative medicine due to the immunostimulatory effects of its cell matter, which upon digestion has been found to significantly stimulate broad spectrum immune activity including activation of specific antibody IgM, IgG and IgA secretion (Ciprandi, G., A. Scordamaglia, D. Venuti, M. Caria, and G. W. Canonica, 1986). and release of CpG dinucleotides inducing INF A/Y producing activity of leukocytes and cytokines important in the development of cytotoxicity towards tumor cells. (Shylakhovenko. V.A, June 2003). It was marketed throughout America and Europe from 1946 as an immunostimulatory aid in the treatment of gut and urinary tract diseases such as Rotavirus and Shigella, (Mazza. P, 1994). but declined in popularity after the introduction of cheap consumer antibiotics, despite causing less chance of allergic reaction and significantly lower toxicity to normal gut flora. Use as model organism Bacillus subtilis is one of the best understood prokaryotes, in terms of molecular biology and cell biology. Its superb genetic amenability and relatively large size have provided the powerful tools required to investigate

a bacterium from all possible aspects. Recent improvements in fluorescence microscopy techniques have provided novel and amazing insight into the dynamic structure of a single cell organism. Research on Bacillus subtilis has been at the forefront of bacterial molecular biology and cytology, and the organism is a model for differentiation, gene/protein regulation, and cell cycle events in bacteria. (Graumann P, editor 2007) Industrial uses Lipases from fungi and bacteria serve important roles in human practices as ancient as yogurt and cheese fermentation. However, lipases are also being exploited as cheap and versatile catalysts to degrade lipids in more modern applications. For instance, a biotechnology company has brought recombinant lipase enzymes to market for use in applications such as baking, laundry detergents and even as biocatalysts (Guo Z, Xu X 2005) in alternative energy strategies to convert vegetable oil into fuel. (Gupta R, Gupta N, Rathi P 2004) and Ban K, Kaieda M, Matsumoto T, Kondo A, Fukuda H 2001). Fats and Oil Industry Fats and oil modification is one of the prime areas in food processing industry that demand novel economic and green technologies (Gupta R, Rathi P & Bradoo S, 2003). Fats and oils are important on inventory of

foods. Lipases allow us to modify the properties of lipids by altering the location of fatty acid chains in the glycerides and replacing one or more of these with new ones. In this way, a relatively inexpensive and less desirable lipid can be modified to a higher value fat (Sharma R, Christi Y & Banerjee U C, 2001). Lipases catalyze the hydrolysis, esterification and interesterification of oils and fats. Among the lipolytic conversion of oils and fats, esterification and interesterification are used to obtain value added products, such as specialty fats and partial glycerides by using positional and fatty acid specific lipases, and have greater industrial potential than fatty acid production in bulk through hydrolysis. Venkata Rao and Laxmanan (Indian Chemical Engineering, 33- 1991) constructed an immobilized lipase membrane reactor for fat and oil hydrolysis, which yielded products that require less downstream processing, thus reducing the overall processing cost. The removal of phospholipids in vegetable oils (de-gumming) using highly selective microbial phospholipases is also a recently developed environmental friendly process (Clausen K, Enzymatic oil-degumming by a novel microbial phospholipase, 1999). Flavour Enhancement by Lipases The production of low molecular weight esters as flavour compounds by biotechnological processes has potential interest for the food industry. The use of naturally available substrates and enzymes is an essential part of the

process design. Laboret and Perrand(Shieh C J & Chang S W, 2001) performed direct esterification of citronellol and geraniol with short-chain fatty acids, catalyzed by free lipase from M. miehei, which gave high yields in n-hexane. The initiative to scale-up applications was also attempted, using a reactor that allowed the production of ester in quantities up to 100 cm3. Lipases for Pharmaceutical Application Microbial lipases are used to enrich PUFAs from animal and plant lipids, and their mono and diacylglycerides are used to produce a variety of pharmaceuticals (Dong H, Gao S, Han S P & Cao S G, 1999). PUFAs are increasingly used as food additives, pharmaceuticals and nutraceuticals because of their metabolic benefits. Many PUFAs are essential for normal synthesis of lipid membranes and prostaglandins. Microbial lipases are used to obtain PUFAs from animal and plant lipids, such as menhaden oil, tuna oil and borage oil. Free PUFAs and their mono and diacylglycerides are subsequently used to produce a variety of pharmaceuticals (Sharma R, Chisti Y & Banerjee U C, 2001) Liposomes are used in the medical field to optimize the action of drugs by transporting them to target areas, thus circumventing drug waste inactivation and anatomical barriers (Linko Y Y & Wu X Y, 1996).

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Science Update Programme: Conductive Polymers: From Research To ProductsDocument60 paginiScience Update Programme: Conductive Polymers: From Research To ProductsAnand GillÎncă nu există evaluări

- Sweetpotato and GingerDocument157 paginiSweetpotato and GingerwalterÎncă nu există evaluări

- MSDS Biflex TC TermiticideDocument15 paginiMSDS Biflex TC TermiticideAhmad IssaÎncă nu există evaluări

- BCH 4053 Biochemistry I Fall 2001 DRDocument14 paginiBCH 4053 Biochemistry I Fall 2001 DRw127092Încă nu există evaluări

- Directed C-H Activation: by Nicholas MassaroDocument11 paginiDirected C-H Activation: by Nicholas MassaroArianneÎncă nu există evaluări

- ROSE ROS00002 ws201770948Document1 paginăROSE ROS00002 ws201770948johan.suhuyanli1284Încă nu există evaluări

- Empirical FormulaDocument2 paginiEmpirical FormulaTanweerÎncă nu există evaluări

- Ethanol (96 Per Cent) (1317)Document2 paginiEthanol (96 Per Cent) (1317)Mulayam Singh Yadav100% (1)

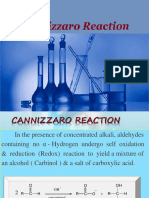

- Named ReactionsDocument15 paginiNamed ReactionsSony mulgundÎncă nu există evaluări

- SOP - Quenching Pyrophoric MaterialsDocument5 paginiSOP - Quenching Pyrophoric Materialsdhavalesh1Încă nu există evaluări

- Additive Coatings and Inks Ver 2.1 2021Document8 paginiAdditive Coatings and Inks Ver 2.1 2021nano100% (1)

- Biology Form 4 Compilation of ExperimentsDocument28 paginiBiology Form 4 Compilation of Experimentsriyashree50% (4)

- MSDS SunCW3-OX90Document6 paginiMSDS SunCW3-OX90Iman FaisalÎncă nu există evaluări

- Zinc Stearate Production by Precipitatio PDFDocument7 paginiZinc Stearate Production by Precipitatio PDFLeslie Gotica Tarapa SinticalaÎncă nu există evaluări

- CB - n990 Epdm ProfilesDocument3 paginiCB - n990 Epdm ProfilesMartha GuzmanÎncă nu există evaluări

- Rna Therapeutic, Pendekatan Baru Dalam Terapi Gen: Amarila MalikDocument11 paginiRna Therapeutic, Pendekatan Baru Dalam Terapi Gen: Amarila MalikAndi Zahriah NurhidayahÎncă nu există evaluări

- DNA Extraction OverviewDocument14 paginiDNA Extraction OverviewNicholas SoÎncă nu există evaluări

- CrudepalmoilandfractionsDocument13 paginiCrudepalmoilandfractionselenitabastosÎncă nu există evaluări

- QUE 1 TestDocument22 paginiQUE 1 TestKrishnaKanthÎncă nu există evaluări

- Research On Excess Bentonite DisposalDocument8 paginiResearch On Excess Bentonite DisposalBlessing IdikaÎncă nu există evaluări

- DNA RecombinantDocument54 paginiDNA RecombinantLuthfi LazuardiÎncă nu există evaluări

- Element Is Antiperspirant Deo FormularyDocument17 paginiElement Is Antiperspirant Deo FormularyMiguel Vera100% (1)

- Contribución de Cepas de Picha Manshurica Al Perfil Aromatico de Los Vinos OrganicoDocument13 paginiContribución de Cepas de Picha Manshurica Al Perfil Aromatico de Los Vinos OrganicoJaydi EspinozaÎncă nu există evaluări

- Compressed Gas Association CGA V-1 Cylinder Valve ConnectionsDocument4 paginiCompressed Gas Association CGA V-1 Cylinder Valve ConnectionsmauroÎncă nu există evaluări

- KAPA Single Indexed Adapter Kits CalculatorDocument23 paginiKAPA Single Indexed Adapter Kits Calculatorabhish22_slsÎncă nu există evaluări

- Brandstaedter Willi MichaelDocument202 paginiBrandstaedter Willi MichaelApril JuneÎncă nu există evaluări

- Lab Report Exp 2Document12 paginiLab Report Exp 2Syuhada Aminuddin0% (2)

- FA-derivatyzacja AChromDocument13 paginiFA-derivatyzacja AChromReza AzghadiÎncă nu există evaluări

- Biological Inorganic Chemistry: Electron TransferDocument14 paginiBiological Inorganic Chemistry: Electron TransferChris LittleÎncă nu există evaluări

- 04 Reactive IntermediatesDocument115 pagini04 Reactive IntermediatesMuhammad ArsalanÎncă nu există evaluări