Documente Academic

Documente Profesional

Documente Cultură

Machine Risk Assessment Form

Încărcat de

VinjkDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Machine Risk Assessment Form

Încărcat de

VinjkDrepturi de autor:

Formate disponibile

SAFETY IN MANUFACTURING

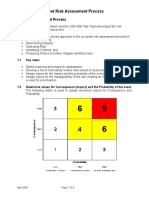

The main purpose of a risk assessment is to decide which machine should be given priority, and which parts of the machine should be safeguarded first.

Machine Risk Assessment Survey

Machine Risk assessMent suRvey Company Name Machine Name Date of Survey Machine Function Survey done by: 1. 2. 3. Identify and describe every hazardous machine motion or harmful condition towhich the workers body parts are exposed (e.g., rotating shafts, in-running nip points, shearing parts, reciprocating parts, punching action, impact hazards, flying debris, abrasive surfaces, electrical hazards, hot/toxic fluids, vapours, emissions, radiation). Be as descriptive and detailed as possible. 1. Describe the worst injury that would reasonably occur due to each hazard. Use the following descriptions as a guide: Fatal Major (normally irreversible: permanent spinal damage, loss of sight, amputation/ crushing, respiratory damage) Serious (normally reversible: loss of consciousness, burns, fractures) Minor (bruising, cuts, light abrasions)

Estimated severity of injury: Minor = 1 Serious = 5 Major = 7 Fatal = 10

Estimated likelihood of injury (see Note 1): Unlikely =1 Possible = 5 Probable = 7 Certain = 10

Estimated level of risk (see Note 2): Estimated severity estimated likelihood

2.

3.

4.

Note: Gathering this information may require repeated observations, especially when determining what the worker does when normal production flow is interrupted.

RecOMMenDeD saFeGuaRDinG tO eliMinate OR ReDuce the Risk tO an acceptable level (see nOte 3)

1.

3.

2.

4.

Note 1. The following factors may be useful when estimating the likelihood of injury: Machine cycle speed Hand feeding with foot control Operator training and experience Boredom factor (repetition) History of jams and misfeeds resulting in frequent access to danger areas of the machine Previous injuries on this machine or machines of this type

Note 2. Use the estimated level of risk to set the priority for implementing safeguarding measures. The higher the estimated level of risk, the more urgent it is to implement safeguarding solutions. Note 3. Always follow the hierarchy of safeguarding controls regardless of the perceived level of risk.

hieRaRchy OF saFeGuaRDinG cOntROls Most effective 1. Elimination or substitution Eliminate human interaction in the process Eliminate pinch points Automate material handling Mechanical hard stops Barrier guards Interlocked guards Presence-sensing devices Two-hand controls Lights, beacons, strobes Computer warnings (PLC-generated) Restricted space painted on floor Beepers Horns and sirens Warning signs and labels Safe work procedures Training Safety equipment inspections Lockout Gloves Respirators

2. Engineering controls (safeguarding technology)

3. Awareness

4. Training and procedures (administrative controls) Least effective

5. Personal protective equipment Safety eyewear Face shields Hearing protection

S-ar putea să vă placă și

- HIRAC - Work at Height TemplateDocument8 paginiHIRAC - Work at Height Templateputra2azanÎncă nu există evaluări

- Fire Alarm System BasiscsDocument26 paginiFire Alarm System BasiscsGhassan Jrab100% (1)

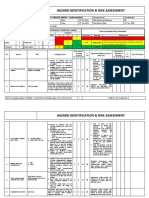

- Hazard identification and risk assessment formDocument8 paginiHazard identification and risk assessment formRaghulal ThalappalaÎncă nu există evaluări

- Noise: Guide For Risk Assessment in Small and Medium EnterprisesDocument10 paginiNoise: Guide For Risk Assessment in Small and Medium EnterprisesXozanÎncă nu există evaluări

- Apply The E.C.R.S. Technique and Identify Improvement Actions: Mechanise Some MovementsDocument13 paginiApply The E.C.R.S. Technique and Identify Improvement Actions: Mechanise Some MovementsRahul RawatÎncă nu există evaluări

- Dokumen - Tips Contoh-Hirarc PDFDocument4 paginiDokumen - Tips Contoh-Hirarc PDFtenry_03Încă nu există evaluări

- Air Pollution Control-AeeDocument2 paginiAir Pollution Control-AeedungdvÎncă nu există evaluări

- Virtusa EHS PolicyDocument1 paginăVirtusa EHS Policydeepgahlot0% (1)

- Risk assessment and control for yarn trolley operationsDocument2 paginiRisk assessment and control for yarn trolley operationsThachnatharen0% (1)

- Fleet Risk Assessment Process GuideDocument4 paginiFleet Risk Assessment Process GuideHaymanAHMEDÎncă nu există evaluări

- Lathe Machine Risk AssessmentDocument4 paginiLathe Machine Risk AssessmentChethan88% (8)

- First Aid Box C Checklist.Document2 paginiFirst Aid Box C Checklist.SaiMinMinÎncă nu există evaluări

- Fault Tree & Event Tree Analysis for Gas and Coal Dust ExplosionsDocument7 paginiFault Tree & Event Tree Analysis for Gas and Coal Dust Explosionssilu pradhanÎncă nu există evaluări

- 2018-Ohs Management PracticesDocument18 pagini2018-Ohs Management PracticesRohanth A PillaiÎncă nu există evaluări

- RA Installation of Earthing SystemDocument15 paginiRA Installation of Earthing Systemamal0% (1)

- Hiradc ServicingDocument4 paginiHiradc ServicingAyub Abd RahmanÎncă nu există evaluări

- Record PPEDocument1 paginăRecord PPEdila100% (1)

- Radiation Heat Transfer Lab HIRARC Form Risk AssessmentDocument4 paginiRadiation Heat Transfer Lab HIRARC Form Risk AssessmentJuliana AzwaÎncă nu există evaluări

- PPE InventoryDocument2 paginiPPE InventoryJowel MercadoÎncă nu există evaluări

- Spray Booth Risk AssessmentDocument3 paginiSpray Booth Risk AssessmentJohn Geddes100% (1)

- Lecture 5 - Industrial HygieneDocument50 paginiLecture 5 - Industrial HygieneDivyashini MohanÎncă nu există evaluări

- Hirarc & Aspect ImpactDocument21 paginiHirarc & Aspect ImpactHazru NazriÎncă nu există evaluări

- HIRARCDocument13 paginiHIRARCfaizÎncă nu există evaluări

- Accident Investigation 1Document63 paginiAccident Investigation 1Biscuit_WarriorÎncă nu există evaluări

- Risk assessment for contract bricklayersDocument16 paginiRisk assessment for contract bricklayersWeei Zhee70Încă nu există evaluări

- Electrical Risk AssessmentDocument6 paginiElectrical Risk AssessmentEman Fawzy100% (1)

- HAZARDS AND RISKS EXPLAINEDDocument20 paginiHAZARDS AND RISKS EXPLAINEDJhunrey ObnialaÎncă nu există evaluări

- AFPC Risk Assessment MatrixDocument1 paginăAFPC Risk Assessment MatrixRiyadh SalehÎncă nu există evaluări

- Hazard Risk Assessment Light Bulb ChangeDocument1 paginăHazard Risk Assessment Light Bulb ChangePHH9834Încă nu există evaluări

- Assessment For CCTV System Testing & CommissioningDocument5 paginiAssessment For CCTV System Testing & CommissioningAnonymousÎncă nu există evaluări

- Lock Out Tag Out Procedure For - : TitleDocument12 paginiLock Out Tag Out Procedure For - : TitleerwinÎncă nu există evaluări

- Hirarc SampleDocument84 paginiHirarc SampleAbdul Samad100% (1)

- Hazard Identification & Risk Assessment: Main ActivityDocument3 paginiHazard Identification & Risk Assessment: Main ActivityrajÎncă nu există evaluări

- Doe Guide To Good Practices For Lockouts and Tagouts Doe-Std-1030-96Document49 paginiDoe Guide To Good Practices For Lockouts and Tagouts Doe-Std-1030-96Titer100% (1)

- Work at Height Risk AssessmentDocument8 paginiWork at Height Risk AssessmentRebecca Winter100% (1)

- HIRAC - Work - at - Height - Template PDFDocument8 paginiHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariÎncă nu există evaluări

- LOTO Lock Removal FormDocument2 paginiLOTO Lock Removal FormdauxomÎncă nu există evaluări

- Safety and EHS Performance ReportDocument16 paginiSafety and EHS Performance Reportimam santosoÎncă nu există evaluări

- Hiaro Ser-05 20190528-1Document5 paginiHiaro Ser-05 20190528-1Prasad PÎncă nu există evaluări

- Template Initial ERA ReportDocument20 paginiTemplate Initial ERA ReportIma HishamÎncă nu există evaluări

- Black Spot Contamination in PelletDocument13 paginiBlack Spot Contamination in PelletkhuelvÎncă nu există evaluări

- Hirarc Assignment and DiscussionDocument11 paginiHirarc Assignment and DiscussionNur IzzahÎncă nu există evaluări

- Environmental Aspect Impact Worksheet - Attachment XVDocument1 paginăEnvironmental Aspect Impact Worksheet - Attachment XVFaiqah AzmirÎncă nu există evaluări

- Hazard identification, risk assessment and control formDocument2 paginiHazard identification, risk assessment and control formmyn maliQue100% (1)

- App-16.2 - Risk Assessment For Vermeer Axis WorksDocument13 paginiApp-16.2 - Risk Assessment For Vermeer Axis Worksloveson709Încă nu există evaluări

- Environment, Health & Safety Policy: Revision No.: 00 DateDocument1 paginăEnvironment, Health & Safety Policy: Revision No.: 00 Dateanand shankarÎncă nu există evaluări

- First Aid Cases RecordDocument1 paginăFirst Aid Cases RecordFrancis Enriquez TanÎncă nu există evaluări

- Safety Signage Design eBookDocument75 paginiSafety Signage Design eBookrajoumn975% (4)

- 27.2 RISK ASSESSMENT and Analysis Cable Tray InstallationDocument3 pagini27.2 RISK ASSESSMENT and Analysis Cable Tray InstallationsalmanÎncă nu există evaluări

- Sample Safe Work Method Statement (SWMS)Document8 paginiSample Safe Work Method Statement (SWMS)Shaik NawazÎncă nu există evaluări

- L2 Risk Assessment Leakage HVAC Ducting Rectification - PlanDocument5 paginiL2 Risk Assessment Leakage HVAC Ducting Rectification - PlanHaris Risdiana100% (2)

- 1868 Sop Work at HeightDocument10 pagini1868 Sop Work at HeightAbid AzizÎncă nu există evaluări

- e-HIRARC Template Guide for Workplace Hazard Identification and Risk AssessmentDocument39 paginie-HIRARC Template Guide for Workplace Hazard Identification and Risk AssessmentMartin Bazan ObregonÎncă nu există evaluări

- 704 Area Vehicle Entry ProcedureDocument11 pagini704 Area Vehicle Entry ProcedureObominuru Egwonor FestusÎncă nu există evaluări

- Electrical Equipment Risk AssessmentDocument6 paginiElectrical Equipment Risk AssessmentPuppy Ayu Jatmiko100% (1)

- Operation of CNC Machine JSA PDFDocument2 paginiOperation of CNC Machine JSA PDFashok Kumar100% (1)

- FIMA RISK ASSESSMENT ANALYSISDocument17 paginiFIMA RISK ASSESSMENT ANALYSISNur Alisha AlishaÎncă nu există evaluări

- Radio Frequency Services Risk Assessment for Biological and Commissioning HazardsDocument39 paginiRadio Frequency Services Risk Assessment for Biological and Commissioning HazardsNajman HamdiÎncă nu există evaluări

- Lecture 7 8Document46 paginiLecture 7 8Mahmil ButtÎncă nu există evaluări

- Achines Afety: Dr. Muhammad Usman FarooqDocument44 paginiAchines Afety: Dr. Muhammad Usman FarooqAmeer HãmzäÎncă nu există evaluări

- Duas Configurações Sniper NovritschDocument1 paginăDuas Configurações Sniper NovritschVinjkÎncă nu există evaluări

- A&K Full Metal M16-A4 SPR NS15 Airsoft AEG LiPo ReadyDocument3 paginiA&K Full Metal M16-A4 SPR NS15 Airsoft AEG LiPo ReadyVinjkÎncă nu există evaluări

- G&P Rapid Fire II Airsoft AEG Rifle W - QD Barrel Extension (Package - Tan - Evike - Com Receiver - Battery + Charger) - Evike PDFDocument3 paginiG&P Rapid Fire II Airsoft AEG Rifle W - QD Barrel Extension (Package - Tan - Evike - Com Receiver - Battery + Charger) - Evike PDFVinjkÎncă nu există evaluări

- (Eb) New York Times 14 July 2017 Mandar Nos Grupos Do CanadáDocument1 pagină(Eb) New York Times 14 July 2017 Mandar Nos Grupos Do CanadáVinjkÎncă nu există evaluări

- Newton's Forward Difference Formula - From Wolfram MathWorldDocument1 paginăNewton's Forward Difference Formula - From Wolfram MathWorldVinjkÎncă nu există evaluări

- A&K Full Metal M16-A4 SPR NS15 Airsoft AEG LiPo ReadyDocument3 paginiA&K Full Metal M16-A4 SPR NS15 Airsoft AEG LiPo ReadyVinjkÎncă nu există evaluări

- Tokyo Marui VSR-10 G-Spec Airsoft Sniper Rifle With Mock Suppressor (Color - OD Green) - EvikeDocument2 paginiTokyo Marui VSR-10 G-Spec Airsoft Sniper Rifle With Mock Suppressor (Color - OD Green) - EvikeVinjkÎncă nu există evaluări

- Architectural Acoustics SuperconductivityDocument42 paginiArchitectural Acoustics SuperconductivityVinjkÎncă nu există evaluări

- Gmail - Failing To Listen To God - in Touch - August 3, 2017Document3 paginiGmail - Failing To Listen To God - in Touch - August 3, 2017VinjkÎncă nu există evaluări

- Exam1sol PDFDocument3 paginiExam1sol PDFVinjkÎncă nu există evaluări

- (Eb) New York Times 14 July 2017 Mandar Nos Grupos Do CanadáDocument1 pagină(Eb) New York Times 14 July 2017 Mandar Nos Grupos Do CanadáVinjkÎncă nu există evaluări

- Newton's Interpolation FormulaeDocument7 paginiNewton's Interpolation FormulaeVinjkÎncă nu există evaluări

- PhysicsLAB - Derivation of Bohr's Model For The Hydrogen SpectrumDocument4 paginiPhysicsLAB - Derivation of Bohr's Model For The Hydrogen SpectrumVinjkÎncă nu există evaluări

- A&K Full Metal M16 SPR MOD-2 Airsoft AEG Sniper Rifle - EvikeDocument3 paginiA&K Full Metal M16 SPR MOD-2 Airsoft AEG Sniper Rifle - EvikeVinjkÎncă nu există evaluări

- Deriving Simpsons Rule Using Newton InterpolationDocument4 paginiDeriving Simpsons Rule Using Newton InterpolationVinjkÎncă nu există evaluări

- Example 3 - Bisection MethodDocument2 paginiExample 3 - Bisection MethodRyan IrfandiÎncă nu există evaluări

- Eletric RocketsDocument8 paginiEletric RocketsVinjkÎncă nu există evaluări

- Electric Field of Charged Ring: Q λ = Q/2πa dqDocument1 paginăElectric Field of Charged Ring: Q λ = Q/2πa dqVinjkÎncă nu există evaluări

- HSL ReportDocument24 paginiHSL ReportVinjkÎncă nu există evaluări

- Bohr ModelDocument36 paginiBohr ModelManu SharmaÎncă nu există evaluări

- Electric Field, Line ChargeDocument3 paginiElectric Field, Line ChargeVinjkÎncă nu există evaluări

- Electric Field, Line ChargeDocument3 paginiElectric Field, Line ChargeVinjkÎncă nu există evaluări

- Manual RepetidorDocument3 paginiManual RepetidorVinjkÎncă nu există evaluări

- mapBW 45 2014 11 20Document2 paginimapBW 45 2014 11 20VinjkÎncă nu există evaluări

- HSE Investigation ReportDocument6 paginiHSE Investigation ReportVinjkÎncă nu există evaluări

- IntroductionDocument8 paginiIntroductionThomas ShelbyÎncă nu există evaluări

- HSL ReportDocument24 paginiHSL ReportVinjkÎncă nu există evaluări

- Cambridge Face2face Upper Intermediate WorkbookDocument85 paginiCambridge Face2face Upper Intermediate WorkbookVinjk0% (1)

- 4D Examples 4Document2 pagini4D Examples 4VinjkÎncă nu există evaluări

- US Marines Close Quarters Combat Manual FMFM 07Document99 paginiUS Marines Close Quarters Combat Manual FMFM 07lokyle100% (1)

- CIE Sociology A-Levels Research MethodsDocument11 paginiCIE Sociology A-Levels Research MethodsPrasunÎncă nu există evaluări

- Digital Elevation Model Dem Extraction F PDFDocument312 paginiDigital Elevation Model Dem Extraction F PDFMarian VanguÎncă nu există evaluări

- استخدام نظام SPSS في تحليل البيانات الإحصائية د محمود خالد عكاشةDocument38 paginiاستخدام نظام SPSS في تحليل البيانات الإحصائية د محمود خالد عكاشةfethi.hammouÎncă nu există evaluări

- Diagram of 6 Steps in ISO 27001 Risk Management enDocument1 paginăDiagram of 6 Steps in ISO 27001 Risk Management enOzzo InfanteÎncă nu există evaluări

- What Is Our Purpose?: Planning The InquiryDocument4 paginiWhat Is Our Purpose?: Planning The InquiryasimaÎncă nu există evaluări

- 6e Learning ModelDocument3 pagini6e Learning Modelapi-293759392Încă nu există evaluări

- You Can Improve Your Memory!Document7 paginiYou Can Improve Your Memory!Niger_silverfox0% (1)

- 1Document3 pagini1Ronil JainÎncă nu există evaluări

- Introduction To Case Study - Tellis, Winston MDocument14 paginiIntroduction To Case Study - Tellis, Winston Mi_pistikÎncă nu există evaluări

- Integrated Marketing in The Digital WorldDocument30 paginiIntegrated Marketing in The Digital WorldSweets BlessingÎncă nu există evaluări

- Factors Affecting Consumer Purchase of Online Groceries in IndiaDocument6 paginiFactors Affecting Consumer Purchase of Online Groceries in IndiaSiddharth Singh TomarÎncă nu există evaluări

- Statistics For Business and Economics: Anderson Sweeney WilliamsDocument45 paginiStatistics For Business and Economics: Anderson Sweeney WilliamsBrenda BernardÎncă nu există evaluări

- 12 HUMSS Chapter 1Document6 pagini12 HUMSS Chapter 1Mayjoy SardallaÎncă nu există evaluări

- Formal Letter To DPWHDocument1 paginăFormal Letter To DPWHjoshua humirang100% (2)

- Probiotics GuidelinesDocument20 paginiProbiotics GuidelinesMadan Mohan Sharan SinghÎncă nu există evaluări

- Return from Leave Process OverviewDocument8 paginiReturn from Leave Process Overviewjen quiambaoÎncă nu există evaluări

- Asia Pacific Occupational Therapy Congress ProgrammeDocument8 paginiAsia Pacific Occupational Therapy Congress ProgrammeRLedgerdÎncă nu există evaluări

- EPIC Consulting GroupDocument13 paginiEPIC Consulting GroupMuhammad Moazam Shahbaz100% (1)

- Multiple Choice Criteria For A Good QuestionnaireDocument7 paginiMultiple Choice Criteria For A Good QuestionnaireGhitaÎncă nu există evaluări

- Talent Identification DissertationDocument5 paginiTalent Identification DissertationWriteMyPaperOneDayHartford100% (1)

- Avian Navigation - Pigeon Homing As A ParadigmDocument233 paginiAvian Navigation - Pigeon Homing As A ParadigmEmi CastilloÎncă nu există evaluări

- Oral Hygiene in VentilatorDocument136 paginiOral Hygiene in VentilatorFelicia Risca RyandiniÎncă nu există evaluări

- Fakulti Kejuruteraan & Alam Bina, Universiti Kebangsaan Malaysia (UKM), 43650, BangiDocument14 paginiFakulti Kejuruteraan & Alam Bina, Universiti Kebangsaan Malaysia (UKM), 43650, BangiDiana ZulkifliÎncă nu există evaluări

- APA Style: Punctuation and MechanicsDocument4 paginiAPA Style: Punctuation and MechanicsLuis QuanÎncă nu există evaluări

- Review of LitretureDocument6 paginiReview of LitretureKeerrthana NairÎncă nu există evaluări

- Mkt344 Mid Final Questions Summer21Document3 paginiMkt344 Mid Final Questions Summer21Nayeem YousufÎncă nu există evaluări

- PUBH6003 Health Systems and EconomicsDocument14 paginiPUBH6003 Health Systems and EconomicsFrancis Dave Peralta BitongÎncă nu există evaluări

- Mind The Gap:: Digital England - A Rural PerspectiveDocument60 paginiMind The Gap:: Digital England - A Rural PerspectiveRanjith KumarÎncă nu există evaluări

- Airware: An Urban and Industrial Air Quality Assessment and Management Information SystemDocument19 paginiAirware: An Urban and Industrial Air Quality Assessment and Management Information SystemducklingsterÎncă nu există evaluări

- SE125 Fall20 HWK 4 Solution PDFDocument18 paginiSE125 Fall20 HWK 4 Solution PDFdebashmitamondalÎncă nu există evaluări