Documente Academic

Documente Profesional

Documente Cultură

Fundamentals of Photo Elasticity

Încărcat de

tops123Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fundamentals of Photo Elasticity

Încărcat de

tops123Drepturi de autor:

Formate disponibile

Fundamentals of Photoelasticity

Some Useful Definitions

Strainoptic Technologies, lnc.

Principles of Photoelasticity

Stress Measurement Techniques

How Stress s Calculated

Residual Stress

Polarized Light

ndex of Refraction

Photoelasticity

Birefringence

Stress-Optical Constant

Retardation

Some Useful Definitions

Residual Stress

Residual stress is an intrinsic tension or compression

which exists in a material without an external load being

applied. n glass, so-called permanent residual stress is

induced in the primary manufacturing process. t is

relieved through annealing or subsequently added in

secondary thermal processing operations to impart

desired mechanical characteristics.

Residual Stress

When there is an equilibrium between the tensile and

compressive stresses, the glass is said to be stable. An

imbalance in residual stresses can cause unexpected

weakness or spontaneous breakage.

Polarized Light

Light moves through transparent materials in the form

of waves. The frequency of the waveform varies with

the type of light. The standard wavelength for white

light through glass is 565 nanometers (10

-9

meters).

Light

Source

Propagation

of light

beam

These waves are omnidirectional and "vibrate out at a

perpendicular angle from the direction (propagation) of

the light beam.

Polarized Light

When light passes through a polarizing lens, all

components of the light wave are blocked except for

the components of the light wave in the plane of

vibration allowed to pass by the polarizing filter.

Light

Source

Privileged

Axis of

Polarizer 1

Omnidirectional

Vectors of Light

Polarized Light

n "plane or linear polarization, only the components

of the light vector parallel to the privileged axis of the

polarizer pass through. Light may also be subject to

"circular and "elliptical polarization methods, which

involve adding devices to the light path which alter its

characteristics.

Light

Source

Privileged

Axis of

Polarizer 1

Omnidirectional

Vectors of Light

Plane

Polarized

Light

Polarized Light

f another polarizing filter is placed in the path of the

polarized light beam, and rotated 90 (perpendicular)

to the polarizing axis of the first filter, all light will be

blocked.

Light

Source

Privileged

Axis of

Polarizer 1

Privileged

Axis of

Polarizer 2

rotated 90

degrees to the

polarizing axis

of the first

filter.

Omnidirectional

Vectors of Light

Plane

Polarized

Light

No Light

(Dark Field)

Polarized Light

f the second polarizing filter is rotated to an angle

less than or greater than 90 relative to the first

polarizing lens, only the components of the light wave

vibrating in that plane will pass through the filter.

Light

Source

Privileged Axis of

Polarizer 2

<>90 Degrees

Relative to

Polarizer 1

Plane

Polarized

Light

Attenuated Light

(Variable Field)

ndex of Refraction

A material's index of refraction is defined as the speed of

light through a vacuum 3 x 10

8

meters/sec divided by the

speed of light through the material.

Photoelasticity

The property exhibited by some transparent

solids, whereby they become doubly refractive,

or "birefringent, when subjected to stress.

Birefringence

Light

Source

Plane

Polarized

Light

9

Direction of Stress

Reference

Direction

9

Direction

of Stress

Point of

nterest

When polarized light passes through a stressed

material, the light separates into two wavefronts

traveling at different velocities, each oriented

parallel to a direction of principal stress (9

, 9

)

in the material, but perpendicular to each other.

Birefringence

Birefringence results in the stressed material

having two different indices of refraction

(3

1

, 3

2

).

n most materials, the index of refraction

remains constant; however, in glass and

plastics, the index value varies as a function of

the stress applied. This gave rise to the

Stress-Optic, or "Brewster's Law .

The Stress-Optic (Brewster's) Law

(n

1

n

2

) = C

B

(9

1

9

2

)

#

n

1

,n

2

= ndices of refraction

C

B

= Stress-optical constant,

in Brewsters

9

1,

9

2

= Principal stresses

The Stress-Optic Law

This law established that birefringence is

directly proportional to the difference of

principal stresses, which is equal to the

difference between the two indices of

refraction, 3

1

-3

2

, exhibited by a stressed

material.

Therefore, birefringence can be calculated

by determining A3.

Retardation

The phase difference between the two light

vectors traveling through the material at

different velocities (fast, slow) is known as

retardation, commonly represented by the

symbol delta, 0

The retardation value divided by a material's

thickness is proportional to the difference

between the two indices of refraction, i.e.,

0t 3

Retardation of Polarized Light

Through a Stressed Material

Light

Source

Reference

Direction

Plane

Polarized

Light

Point of

nterest

Retardation

How Stress s Calculated

Retardation

Thickness * Stress-Optical Constant

Stress =

The Stress Equation

The Stress Equation

90tC

B

#

9 = Stress (in MPa*)

0 = Retardation (in nanometers)

t = Thickness

C

B

= Stress-optical constant

(in Brewsters)

*(1 MPa = 145 psi)

Principles of Photoelasticity

nstruments designed to observe objects under

polarized light are called polariscopes or strai3

viewers. The first, or fixed, polarizing filter is known

as the "polarizer. The second, or rotating, polarizing

filter is known as the "analyzer. f the analyzer has a

calibrated scale that can be used for making

quantitative measurements, it is called a polarimeter.

Principles of Photoelasticity

By rotating the second polarizing filter (a3alyzer), the

user can control the amount (intensity) of light

allowed to pass through. The components of the two

light waves that do pass through at any given angle

of analyzer rotation interfere with each other,

resulting in a characteristic color spectrum.

Plane

Polarized

Light

Point of

nterest

Retardation

Analyzer

Principles of Photoelasticity

The intensity of colors displayed when a stressed

transparent or translucent material is viewed under

polarized light is modulated by the retardation.

Principles of Photoelasticity

Each integer multiple of the standard wavelength of

light (2= 565 nm for glass; 570 nm for plastics) is

called a 1ri3e (N).

Principles of Photoelasticity

The intensity of the colors diminishes as the

retardation or fringe order increases.

Principles of Photoelasticity

The photoelastic color sequence (showing increasing stress) is:

Black (zero)

Yellow

Red

Blue-Green

Yellow

Red

Green

Yellow

Red

Green

Yellow

Red

Zero Order

First Order

Second Order

Third Order

Principles of Photoelasticity

These color patterns, visible when using polarized

light, can be used to observe and make a qualitative

evaluation of stress in an object. This method is very

subjective and requires experience and training.

Principles of Photoelasticity

A quantitative measurement of residual stress can be

obtained using a polarimeter, an instrument that

measures retardation, which is proportional to stress.

Principles of Photoelasticity

Plane Polarization

and

Circular Polarization

Principles of Photoelasticity

To determine the direction of principal stresses in a

sample, a plane polarization technique is typically

used. To do this using plane-polarized light, it is

important to first orient the sample such that the point

of interest (PO) exhibits minimum light intensity.

Principles of Photoelasticity

n this orientation, a direction of principal stress at the

point of interest (either x or y) will be parallel to the

axes of the analyzer and polarizer.

Principles of Photoelasticity

Rotating the sample 45 degrees places the sample

in the proper position for measuring retardation.

Principles of Photoelasticity

Using circularly polarized light, the measurement is

independent of the direction of the principal stresses

at the point of interest. To change a plane polarimeter

to a circular polarimeter, two -wave plates

are added to the light path as shown below.

Point of

nterest

Axis of

Polarization

(Plane

Polarizer)

Axis of

Polarization

(Analyzer)

First

1/4-Wave

Plate

Added

Retardation

(0)

Second

1/4-Wave

Plate

Added

Retardation

(0)

Principles of Photoelasticity

The relation used for calculating the retardation of

polarized light transmitted through a stressed

material is:

0C

B

t (9

x

9

y

)

#

0= Retardation (in nanometers)

C

B

= Brewster Constant

t = Material Thickness

9

x,y

= Principal Stresses

Measuring Techniques

Observation of Color Pattern Method

Compensator Method

Analyzer Rotation Method

Observation of Color Pattern Method

Strain Viewer/

Polariscope

Observation of Color Pattern Method

White light produces a complete spectrum

of light. This includes the visible spectrum

of 400 nm to 700 nm.

Observation of Color Pattern Method

The intensity of the light is modulated by

the retardation exhibited by the sample.

Observation of Color Pattern Method

Results are highly

subjective to interpretation

Can only be used for

qualitative measurements

Compensator Method

Compensator

Compensator Method

Simplest method of measuring

retardation

Compensator (wedge) is a

calibrated, handheld device

that optically adds a retardation

of equal, but opposite sign to the

sample.

The net result is a light intensity

of zero, which is easily

recognized visually as black

in the color pattern.

Compensator Method

There are two types of compensators in common usage:

Babinet or "Wedge compensator (scale readout)

Babinet-Soleil or "Double-Wedge compensator

(digital readout)

Analyzer Rotation Method

Analyzer

Polarimeter (with microscope option)

Analyzer Rotation Method

The Analyzer Rotation Method uses a circular

polarimeter setup as shown below. This is called the

Tardy method. When only one -wave plate is

used, it is called the "Senarmont" method.

Point of

nterest

Axis of

Polarization

(Plane

Polarizer)

Axis of

Polarization

(Analyzer)

First

1/4-Wave

Plate

Added

Retardation

(0)

Second

1/4-Wave

Plate

Added

Retardation

(0)

Analyzer Rotation Method

The analyzer rotation method is generally used

to measure fractional levels of retardation (<570 nm).

The analyzer is rotated until a minimum light

intensity is observed.

The sample is then rotated 45 degrees from the

reference axis.

The sample is first positioned parallel to the reference

axis of the polarizer and analyzer.

Analyzer Rotation Method

Retardation is calculated from the fractional fringe

order that is read directly from the dial.

509 nm

0.9 x 565

Analyzer Rotation Method

This measurement (509 nm of retardation) is then

converted to stress using the equation below or

referring to a conversion chart.

90tC

B

#

9= Stress (in MPa)

0 = Retardation (in nanometers)

t = Thickness

C

B

= Brewster Constant

(1 MPa = 145 psi)

Analyzer Rotation Method

,250

Retardation (0 = 509 nm

Thickness (t) = 6 mm

C

B

= 2.54

9= 0tC

B

= 509/(6.0 x 2.54)

9 = /15.24

9 = 33.4 MPa or 4843 psi

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- RA - CommentsDocument8 paginiRA - Commentstops123Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Rate List Lab 17-18Document8 paginiRate List Lab 17-18tops123Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Acworth Leprosy Hospital DetailsDocument6 paginiAcworth Leprosy Hospital Detailstops123Încă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Eth 15041732 240417Document193 paginiEth 15041732 240417tops123Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Acworth Leprosy Hospital DetailsDocument6 paginiAcworth Leprosy Hospital Detailstops123Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Rate Circular 2018-2019Document8 paginiRate Circular 2018-2019tops123Încă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- NB PG Oct Nov 17Document64 paginiNB PG Oct Nov 17tops123Încă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Steel Beam Design Excel SheetDocument9 paginiSteel Beam Design Excel SheetFahad Iqbal100% (2)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- MCGM BLDG Sor 13.11Document210 paginiMCGM BLDG Sor 13.11tops123100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- U1 CH2 Railway Tractions 1Document2 paginiU1 CH2 Railway Tractions 1tops123Încă nu există evaluări

- ABP - Steel Beam Design - Edit 01Document10 paginiABP - Steel Beam Design - Edit 01tops123Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Brother RCDocument19 paginiBrother RCtops123Încă nu există evaluări

- Retirement BenefitsDocument4 paginiRetirement Benefitstops123Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Architecture Sample 2002Document5 paginiArchitecture Sample 2002tops123Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Design of Longest Span Cable Stayed Bridge - NBM MediaDocument9 paginiDesign of Longest Span Cable Stayed Bridge - NBM Mediatops123Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Notification Maharashtra Postal Circle Soritng Postal Assistant PostsDocument3 paginiNotification Maharashtra Postal Circle Soritng Postal Assistant Poststops123Încă nu există evaluări

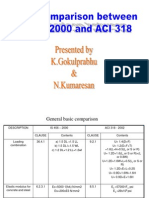

- 1.ACI 318 Code Comparison With IS456-2000Document15 pagini1.ACI 318 Code Comparison With IS456-2000tops123Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Notification For Commencement of Examination For Winter 2012Document7 paginiNotification For Commencement of Examination For Winter 2012tops123Încă nu există evaluări

- Diff BWT Is 800 101Document96 paginiDiff BWT Is 800 101tops123Încă nu există evaluări

- C 90 CDocument269 paginiC 90 Ctops123Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Functions of The Gastrointestinal Organs: Muhammad ImranDocument21 paginiFunctions of The Gastrointestinal Organs: Muhammad ImranSalman KhanÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Is.2750.1964 SCAFFOLDING PDFDocument32 paginiIs.2750.1964 SCAFFOLDING PDFHiren JoshiÎncă nu există evaluări

- Artificial Intelligence and Expert Systems: Management Information Systems, 4 EditionDocument27 paginiArtificial Intelligence and Expert Systems: Management Information Systems, 4 Editionabhi7219Încă nu există evaluări

- Thesis Statement On Lionel MessiDocument4 paginiThesis Statement On Lionel Messidwham6h1100% (2)

- Sailpoint Topic Wise SyllabusDocument2 paginiSailpoint Topic Wise SyllabusKishore KodaliÎncă nu există evaluări

- Mge - Ex11rt - Installation and User Manual PDFDocument38 paginiMge - Ex11rt - Installation and User Manual PDFRafa TejedaÎncă nu există evaluări

- LG) Pc-Ii Formulation of Waste Management PlansDocument25 paginiLG) Pc-Ii Formulation of Waste Management PlansAhmed ButtÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Chapter 5: Current and Resistance: 5.1 The Motion of Electric ChargeDocument11 paginiChapter 5: Current and Resistance: 5.1 The Motion of Electric Chargeayunna ayunniÎncă nu există evaluări

- Encephalopathies: Zerlyn T. Leonardo, M.D., FPCP, FPNADocument50 paginiEncephalopathies: Zerlyn T. Leonardo, M.D., FPCP, FPNAJanellee DarucaÎncă nu există evaluări

- Industrial Automation Using PLCDocument29 paginiIndustrial Automation Using PLCAditya JagannathanÎncă nu există evaluări

- 1980 - William Golding - Rites of PassageDocument161 pagini1980 - William Golding - Rites of PassageZi Knight100% (1)

- VRealize Operations Manager Installation and Configuration Guide For Linux and WindowsDocument98 paginiVRealize Operations Manager Installation and Configuration Guide For Linux and Windowsamdusias67Încă nu există evaluări

- Origins - and Dynamics of Culture, Society and Political IdentitiesDocument4 paginiOrigins - and Dynamics of Culture, Society and Political IdentitiesJep Jep Panghulan100% (1)

- Ahu 1997 22 1 95Document15 paginiAhu 1997 22 1 95Pasajera En TranceÎncă nu există evaluări

- The Impact of Online Games To The AcademicDocument20 paginiThe Impact of Online Games To The AcademicJessica BacaniÎncă nu există evaluări

- 2017 Hu Spence Why Globalization Stalled and How To Restart ItDocument11 pagini2017 Hu Spence Why Globalization Stalled and How To Restart Itmilan_ig81Încă nu există evaluări

- Ten Reasons To Oppose The Death PenaltyDocument5 paginiTen Reasons To Oppose The Death PenaltyAlvin ArellanoÎncă nu există evaluări

- Chapter 17 Study Guide: VideoDocument7 paginiChapter 17 Study Guide: VideoMruffy DaysÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Super Gene 1201-1300Document426 paginiSuper Gene 1201-1300Henri AtanganaÎncă nu există evaluări

- ShotcreteDocument7 paginiShotcreteafuhcivÎncă nu există evaluări

- Weather Prediction Using Machine Learning TechniquessDocument53 paginiWeather Prediction Using Machine Learning Techniquessbakiz89Încă nu există evaluări

- Mod 2 MC - GSM, GPRSDocument61 paginiMod 2 MC - GSM, GPRSIrene JosephÎncă nu există evaluări

- Curry PowderDocument8 paginiCurry PowderMahendar Vanam100% (1)

- The Eye WorksheetDocument3 paginiThe Eye WorksheetCally ChewÎncă nu există evaluări

- Nurses Guide To Family Assessment and InterventionDocument9 paginiNurses Guide To Family Assessment and InterventionKaye CorÎncă nu există evaluări

- Adolescence Problems PPT 1Document25 paginiAdolescence Problems PPT 1akhila appukuttanÎncă nu există evaluări

- The Origin, Nature, and Challenges of Area Studies in The United StatesDocument22 paginiThe Origin, Nature, and Challenges of Area Studies in The United StatesannsaralondeÎncă nu există evaluări

- Cooperative LinuxDocument39 paginiCooperative Linuxrajesh_124Încă nu există evaluări

- A Review On PRT in IndiaDocument21 paginiA Review On PRT in IndiaChalavadi VasavadattaÎncă nu există evaluări

- Test 4 MathDocument15 paginiTest 4 MathYu ChenÎncă nu există evaluări