Documente Academic

Documente Profesional

Documente Cultură

Yuk en Flow Control Valves

Încărcat de

Ninh Trần VănDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Yuk en Flow Control Valves

Încărcat de

Ninh Trần VănDrepturi de autor:

Formate disponibile

D

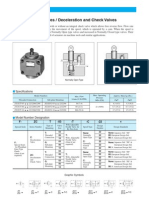

FLOW CONTROL VALVES

Maximum Flow Valve Type Maximum Operating Pressure MPa (PSI) 21(3050) 21(3050) 21(3050) 25(3630) 25(3630) 25(3630) 25(3630) 21(3050) 14(2030) 35(5080) 1

1 2 3 5 10

10

50 100

50

100

U.S.GPM 500 1000

1000 20003000 5000

Catalogue No.

20 30

200 300 500

L /min

Flow Control (& Check) Valves Pilot Operated Flow Control Valves Pilot Operated Flow Cont. & Check Valves Flow Control & Relief Valves Restrictors One Way Restrictors Throttle (& Check) Modules Deceleration (& Check) Valves Feed Control Valves Needle Valves

FG/FCG FHG FHCG FBG SRT/SRG SRCT/SRCG TC1G/TC2G ZTZG/ZCTZCG UCF1G/UCF2G

GCT GCTR

01

02 02 02

03 03 03 03

06 06 06 06 10 10

10 10 10 10 16 (Rated Flow) 16 (Rated Flow) Pub. EC-0304 Pub. EC-0305 Pub. EC-0306 Pub. EC-0307 Pub. EC-0302 Pub. EC-0303 Pub. EC-0301

03 03 01 03 01 03

06 06 03 06 04

10

02

Pub. EC-0301

FLOW CONTROL (AND CHECK) VALVES FG FCG -01/02/03/06/10 (1/8,1/4,3/8,3/4,1-1/4) PILOT OPERATED FLOW CONTROL (AND CHECK) VALVES FHG FHCG -02/03/06/10 (1/4,3/8,3/4,1-1/4) Sub-plate Mounting

Up to 21 MPa (3050 PSI), 500 L/min (132 U.S.GPM)

Flow Control and Check Valves ...... Page 2

These valves are pressure and temperature compensating type valves and maintain a constant flow rate independent of change in system pressure (load) and temperature (viscosity of the fluid). They control flow rate of the hydraulic circuit and eventually control speed of the actuator precisely. Valves with an integral check valve allow a controlled flow and reverse free flow. Repeated resetting can be made easily with a digital readout.

FLOW CONTROLS

Pilot Operated Flow Control and Check Valves ......................... Page 14

Flow control of these valves is continuously made by a hydraulically operated pilot piston mechanism which controls opening area of the orifice of the valve. With the use of these valves, shockless operation either in acceleration or deceleration can be obtained. With the compensator for the pressure and temperature, stable flow control can be obtained regardless of the changes in the pressure (load) and temperature (oil viscosity).

FG

O M O M B A B

FCG

Hydraulic Fluids

Fluid Types Any type of hydraulic fluids listed in the table below can be used.

Petroleum base oils Synthetic fluids Water containing fluids

FHG

FHCG

Use fluids equivalent to ISO VG 32 or VG 46. Use phosphate ester or polyol ester fluid. When phosphate ester fluid is used, prefix "F-" to the model number because the special seals (fluororubber) are required to be used. Use water-glycol fluid.

Note: For use with hydraulic fluids other than those listed above, please consult your Yuken representatives in advance.

Recommended Viscosity and Oil Temperatures Viscosity ranging between 15 - 400 mm2/s (77 - 1800 SSU). Oil temperatures between -15/+70C (5 - 158F). Use hydraulic fluids which satisfy the recommended viscosity and oil temperatures given above. Control of Contamination Due caution must be paid to maintaining control over contamination of the hydraulic fluids which may otherwise lead to breakdowns and shorten the life of the valves. Please maintain the degree of contamination within NAS 1638Grade 12. Use 25 m or finer line filter.

No.1

Flow Control (and Check) Valves FG FCG -01/02/03/06/10 Sub-plate Mounting

Specifications / Model Number Designation / Others

FLOW CONTROLS

Specifications

Model Numbers 4 FG FCG -01-8--11 FG FCG -02-30--30 FG FCG -03-125--30 FG FCG -06-250--30 FG FCG -10-500--30 Max. Metred Flow Capacity L /min (U.S.GPM) 8 (2.1) 30 (7.9) 125 (33) 250 (66) 500 (132) Min. Metred Flow Capacity L /min (U.S.GPM) 0.02 (.005) {0.04 (.011)} 0.05 (.013) 0.2 (.053) 21 (3050) 2 (.53) 4 (1.06) 23 (50.7) 52 (115) Max. Operating Pressure MPa (PSI) 14 (2030) Approx. Mass kg (lbs.) 1.3 (2.9) 3.8 (8.4) 7.9 (17.4)

The figures in the brace are for pressures above 7 MPa (1020 PSI).

Model Number Designation

FSpecial Seals F: Special Seals for Phosphate Ester Type Fluids (Omit if not required)

FC

Series Number F: Flow Control Valves FC : Flow Control and Check Valves

G

Type of Mounting

-01

Valve Size 01

-8

Max. Metred Flow Capacity L /min (U.S.GPM) 4 : 4 (1.06) 8 : 8 (2.1) 30 : 30 (7.9) 125 : 125 (33) 250 : 250 (66) 500 : 500 (132)

-N

Pres. Compensator Stroke Adjustment N: Applicable only for Pres. Compensator Stroke Adjustment (Option - Omit if not required)

-11

Design Number 11 30 30 30 30

Design Standards

G: Sub-plate Mounting

02 03 06 10

Refer to

Design Standards: None ........... Japanese Standard "JIS" and European Design Standard 90 ............... N. American Design Standard

Attachment

Mounting Bolts

Valve Model Numbers FG/FCG-01 FG/FCG-02 FG/FCG-03 FG/FCG-06 FG/FCG-10 Socket Head Cap Screw Japanese Std. "JIS" & N. American Design Std. European Design Std. No.10-24 UNC 2-1/4 Lg. M5 55 Lg. 5/16-18 UNC 2 Lg. M8 50 Lg. 3/8-16 UNC 3 Lg. M10 75 Lg. 5/8-11 UNC 5 Lg. M16 130 Lg. 3/4-10 UNC 6-1/2 Lg. M20 160 Lg. Qty. 4 4 4 4 4

Graphic Symbols

FG

Option

Pres. compensator stroke adjustment Can reduce jumping at the start of the actuator.

FCG

No.2

Flow Control (and Check) Valves FG FCG -01/02/03/06/10

Sub-plate / Instructions

Sub-plate

Valve Model Numbers FG FCG -01 FG FCG -02 Japanese Standard "JIS" Sub-plate Model No. FGM-01X-10 FGM-02-20 FGM-02X-20 FGM-02Y-20 FGM-03-20 FGM-03X-20 FGM-03Y-20 FGM-03Z-20 FGM-06X-20 FGM-06Y-20 FGM-06Z-20 FGM-10Y-20 Thread Size Rc 1/4 Rc 1/4 Rc 3/8 Rc 1/2 Rc 3/8 Rc 1/2 Rc 3/4 Rc 1 Rc 1 Rc 1-1/4 Rc 1-1/2 1-1/2, 2 European Design Std. Sub-plate Model No. FGM-01X-1080 FGM-02-2080 FGM-02X-2080 FGM-02Y-2080 FGM-03-2080 FGM-03X-2080 FGM-03Y-2080 FGM-03Z-2080 FGM-06X-2080 FGM-06Y-2080 FGM-06Z-2080 FGM-10Y-20 Thread Size 1/4 BSP.F 1/4 BSP.F 3/8 BSP.F 1/2 BSP.F 3/8 BSP.F 1/2 BSP.F 3/4 BSP.F 1 BSP.F 1 BSP.F 1-1/4 BSP.F 1-1/2 BSP.F 1-1/2, 2

FLOW CONTROLS

N. American Design Std. Sub-plate Model No. FGM-01X-1090 FGM-02-2090 FGM-02X-2090 FGM-02Y-2090 FGM-03-2090 FGM-03X-2090 FGM-03Y-2090 FGM-03Z-2090 FGM-06X-2090 FGM-06Y-2090 FGM-06Z-2090 FGM-10Y-2090 Thread Size 1/4 NPT 1/4 NPT 3/8 NPT 1/2 NPT 3/8 NPT 1/2 NPT 3/4 NPT 1 NPT 1 NPT 1-1/4 NPT 1-1/2 NPT 1-1/2, 2

Approx. Mass kg (lbs.) 0.8 (1.8) 2.3 (5.1) 2.3 (5.1) 3.1 (6.8) 3.9 (8.6) 3.9 (8.6) 5.7 (12.6) 5.7 (12.6) 12.5 (27.6) 16 (35.3) 16 (35.3) 37 (81.6)

FG FCG -03

FG FCG -06 FG FCG -10

Sub-plates are available. Specify the sub-plate model number from the table above. When sub-plates are not used, the mounting surface should have a good machined finish.

FGM-10Y is special type sub-plate to be used with pipe flange. When ordering FGM-10Y, specify pipe flange kit in addition to FGM-10Y referring to F3 pipe flange kits Catalogue (No. Pub. EC-3001).

Instructions

Min. required pressure difference The minimum differential pressure between inlet and outlet port is required to obtain the optimum pressure compensation. It varies according to the flow rate to be set. For details, please refer to the performance curves. Free flow Check valve pressure drops vary with flow rates. If models with check valves are used, see free flow pressure drop characteristics. Flow adjustment [FG-01] Loosen the locking screw and turn the flow adjustment dial clockwise for increase, and anti-clockwise for decrease. The dial makes about 4 revolutions from zero to full flow and the valve opening is indicated on the revolution indicator. (Refer to characteristics of "Metred Flow vs. Dial Position"). After flow adjustments, tighten the locking screw. [FG-02, 03, 06, 10] Loosen the locking screw and turn the flow adjustment handle clockwise for increase, and anti-clockwise for decrease. Open condition is indicated in digital-scale in built-in revolution indicator (Refer to the characteristics of "Metred Flow vs. Dial Position"). After flow adjustments, tighten the locking screw. Line filter To carry out flow adjustments by as small degree as 2 L /min (.53 U.S.GPM) or less, be sure to use a line filter of 10 m or finer and install it near the valve inlet.

No.3

Flow Control (and Check) Valves FG FCG -01/02/03

Installation Drawings

FG/FCG-01---11/1190

FLOW CONTROLS

DIMENSIONS IN MILLIMETRES (INCHES)

4 2

3 0 9 8

Revolution Indicator

2 1

Locking Screw 2.5(.10) Hex. Soc. Tightening Torque: 0.25 - 0.3 Nm (2.2 - 2.7 IN. lbs.)

22.5 (.89) Dia. Fully Extended 81.5(3.21) 66 (2.60) 51 (2.01) 25.5 (1.00)

7.5 (.30) 5.5(.22) Dia. Through 9(.35) Dia. Spotface 4 Places

Pressure Compensator Stroke Adjustment (Only for FG -01--N ) FCG

7.5 (.30)

Fully Extended 84(3.31) 53.5 (2.11) 45 (1.77) 44 (1.73) 17 (.67)

3(.12)

16.5 (.65) 31 (1.22)

5 (.20)

8

1

43 (1.69)

Controlled Flow Outlet or Reversed Free Flow Inlet Port Flow Adjustment Dial

58 (2.28)

13(.51) Dia.

Locating Pin 4(.16) Dia. Mounting Surface (O-Rings Furnished)

7 6

INC.

Controlled Flow Inlet or Reversed Free Flow Outlet Port

FG/FCG-02-30--30/3090, FG/FCG-03-125--30/3090

Mounting surface: FG-02: ISO 6263-AB-06-4-B FG-03: ISO 6263-AK-07-2-A

Locking Screw 2(.08) Hex. Soc. 46 (1.81) Dia. Fully Extended C D E F Controlled Flow Inlet or Reversed Free Flow Outlet Port Pressure Compensator Stroke Adjustment (Only for FG ---N ) FCG Q S T X U P 6 (.24) L

14(.55) Dia.

K J

"V" Dia. Through "W" Dia. Spotface 4 Places

234

Revolution Indicator

Locating Pin 6(.24) Dia. "Y" Places Mounting Surface (O-Rings Furnished) INC.

Controlled Flow Outlet or Reversed Free Flow Inlet Port

Flow Adjustment Handle

Model No.

Dimensions C D E F H J K L

mm (Inches) N P 9.9 (.39) Q S T U V W X 123 69 40 23 (4.84) (2.72) (1.57) (.91) 8.8 14 39 (.35) (.55) (1.54)

Y 1 2

96 76.2 38.1 9.9 116 FG FCG-02 (4.57) (3.78) (3.00) (1.50) (.39) 125 101.6 50.8 11.7 FG -03 145 FCG (5.71) (4.92) (4.00) (2.00) (.46)

104.5 82.6 44.3 24 (4.11) (3.25) (1.74) (.94)

125 101.6 61.8 29.8 11.7 (4.92) (4.00) (2.43) (1.17) (.46)

152 98 64 41 11 17.5 63 (5.98) (3.86) (2.52) (1.61) (.43) (.69) (2.48)

No.4

Flow Control (and Check) Valves FG FCG -06/10

Installation Drawings

FG/FCG-06-250--30/3090 FG/FCG-10-500--30/3090

FLOW CONTROLS

Mounting surface: FG-06: ISO 6263-AP-08-2-A

DIMENSIONS IN MILLIMETRES (INCHES)

D

Locking Screw 2(.08) Hex. Soc. 46 (1.81) Dia. Fully Extended "C" H "X" Dia. through "Y" Dia. Spotface 4 Places F P D E Controlled Flow Inlet or Reversed Free Flow Outlet Port Q Pressure Compensator Stroke Adjustment (Only for FG ---N ) FCG S T a U

Flow Adjustment Handle INC.

1 21

W L K J

Locating Pin "V" Dia. 2 Places Mounting Surface (O-Rings Furnished)

Controlled Flow Outlet or Reversed Free Flow Inlet Port Revolution Indicator

Z Only for Flow Control and Check Valves ( FCG---N )

Model No.

Dimensions C D E F H J K L N P

mm (Inches) Q S T U V W X Y Z a

17 174 133.4 99 44 20.3 184 130 105 65 16 7 17.5 26 9 103 FG -06 198 180 146.1 73 FCG (7.80) (7.09) (5.75) (2.87) (.67) (6.85) (5.25) (3.90) (1.73) (.80) (7.24) (5.12) (4.13) (2.56) (.63) (.28) (.69) (1.02) (.35) (4.06) 25 214 160 137 85 18 10 21.5 32 7.5 135 FG -10 267 244 196.9 98.5 23.5 228 177.8 144.5 61 FCG (10.51) (9.61) (7.75) (3.88) (.93) (8.98) (7.00) (5.69) (2.40) (.98) (8.43) (6.30) (5.39) (3.35) (.71) (.39) (.85) (1.26) (.30) (5.31)

No.5

Sub-plate for Flow Control (and Check) Valves

Installation Drawings

FGM-01X-10/1080/1090

5.5(.22) Dia. Through 9(.35) Dia. Spotface 4 Places 14 (.55) 51 (2.01) 36 (1.42) 18.5 (.73) 9 (.35) "A" Thd. (From Rear) 2 Places "B" Thd. "C" Deep 4 Places 5(.20) Dia. 8(.31) Deep 6 (.24)

FLOW CONTROLS

34.5 (1.36)

16.5 (.65)

43 (1.69) 12.5 (.49) 6 (.24) 63 (2.48) 76 (2.99) 88 (3.46)

55 (2.17)

17 (.67) 6(.24) Dia. 2 Places 22 (.87)

Sub-plate Model Numbers FGM-01X-10 FGM-01X-1080 FGM-01X-1090

"A" Thd. Rc 1/4 1/4 BSP.F 1/4 NPT

"B" Thd. M5 M5 No.10-24 UNC

C 14 (.55) 14 (.55) 15 (.59)

D 34.5 (1.36) 30.0 (1.18) 34.5 (1.36)

02 FGM- 02X -20/2080/2090 02Y

8.8(.35) Dia. Through 14(.55) Dia. Spotface 4 Places 23.8 (.94) 11.5 (.45) 31.9 (1.26)

DIMENSIONS IN MILLIMETRES (INCHES)

79.4 (3.13) 76.2 (3.00) 54 (2.13) E 9.5 (.37) "D" Dia. 2 Places "B" Thd. "C" Deep 4 Places 7(.28) Dia. 10(.39) Deep 14 (.55) 78 (3.07) 96 (3.78) 120 (4.72) 140 (5.51) 106 (4.17)

52.4 (2.06)

82.6 (3.25)

22 (.87) 10 (.39)

11.1 (.44)

H "A" Thd. (From Rear) 2 Places

16 (.63)

Sub-plate Model Numbers FGM-02-20 FGM-02-2080 FGM-02-2090 FGM-02X-20 FGM-02X-2080 FGM-02X-2090 FGM-02Y-20 FGM-02Y-2080 FGM-02Y-2090

"A" Thd. Rc 1/4 1/4 BSP.F 1/4 NPT Rc 3/8 3/8 BSP.F 3/8 NPT Rc 1/2 1/2 BSP.F 1/2 NPT

"B" Thd. M8 5/16-18 UNC M8 5/16-18 UNC M8 5/16-18 UNC

C 14 (.55) 18 (.71) 14 (.55) 18 (.71) 14 (.55) 18 (.71)

D 11.0 (.43) 11.7 (.46) 11.0 (.43) 14.0 (.55) 15.2 (.60) 14.0 (.55) 14.0 (.55) 15.0 (.59) 14.0 (.55)

54 (2.13)

11.1 (.44)

25 (.98)

51 (2.01)

14 (.55)

35 (1.38)

No.6

Sub-plate for Flow Control (and Check) Valves

Installation Drawings

03 FGM-03X-20/2080/2090 03Y 03Z "A" Thd. (From Rear)

2 Places

102.4(4.03) 101.6(4.00) 75(2.95) 33.2 (1.31) 0.8 (.03) H E F 20.6 (.81)

FLOW CONTROLS

"D" Dia. 2 Places "B" Thd. "C" Deep 4 Places 20(.79) Dia. 15(.59) Deep 2 Places

14.2 (.56) 101.6 (4.00) 130 (5.12)

86.5 (3.41)

28.6 (1.13)

11.1 (.44)

21.5(.85) 11(.43)

125(4.92) 146(5.75) 168(6.61)

11(.43) Dia. Through 17.5(.69) Dia. Spotface 4 Places

20 (.79)

D

J K 86.5 (3.41) 25 (.98)

Sub-plate Model Numbers FGM-03-20 FGM-03-2080 FGM-03-2090 FGM-03X-20 FGM-03X-2080 FGM-03X-2090 FGM-03Y-20 FGM-03Y-2080 FGM-03Y-2090 FGM-03Z-20 FGM-03Z-2080 FGM-03Z-2090

"A" Thd. Rc 3/8 3/8 BSP.F 3/8 NPT Rc 1/2 1/2 BSP.F 1/2 NPT Rc 3/4 3/4 BSP.F 3/4 NPT Rc 1 1 BSP.F 1 NPT

"B" Thd. M10 3/8-16 UNC M10 3/8-16 UNC M10 3/8-16 UNC M10 3/8-16 UNC

C 18 (.71) 21 (.83) 18 (.71) 21 (.83) 18 (.71) 21 (.83) 18 (.71) 21 (.83)

D 14.0 (.55) 15.0 (.59) 14.0 (.55) 17.5 (.69) 19.0 (.75) 17.5 (.69)

75 (2.95)

20.6 (.81)

11.1 (.44)

23.0 (.91)

70 (2.76)

25.6 (1.01)

16.1 (.63)

81.5 (3.21)

40 (1.57)

06X FGM-06Y-20/2080/2090 06Z

17.5(.69) Dia. Through 26(1.02) Dia. Spotface 4 Places

20.3 (.80)

52 (2.05) 1.6 (.06)

DIMENSIONS IN MILLIMETRES (INCHES)

146.1(5.75) 144.4(5.69) 104.8 (4.13) D E 22.2 (.87)

29(1.14) Dia. 2 Places "B" Thd. "C" Deep 4 Places 17(.67) Dia. 10(.39) Deep 2 Places

24 (.94) 126 (4.96) 174 (6.85)

104.8 (4.13)

41.3 (1.63)

133.4 (5.25)

35(1.38) 19(.75)

12.7 (.50)

180(7.09) 212(8.35) 250(9.84)

K J

"A" Thd. (From Rear) 2 Places

Sub-plate Model Numbers FGM-06X-20 FGM-06X-2080 FGM-06X-2090 FGM-06Y-20 FGM-06Y-2080 FGM-06Y-2090 FGM-06Z-20 FGM-06Z-2080 FGM-06Z-2090

"A" Thd. Rc 1 1 BSP.F 1 NPT Rc 1-1/4 1-1/4 BSP.F 1-1/4 NPT Rc 1-1/2 1-1/2 BSP.F 1-1/2 NPT

"B" Thd. M16 5/8-11 UNC M16 5/8-11 UNC M16 5/8-11 UNC

C 30 (1.18) 35 (1.38) 30 (1.18) 35 (1.38) 30 (1.18) 35 (1.38)

D 104.8 (4.13)

E 22.2 (.87)

F 104.8 (4.13)

H 18 (.71)

J 45 (1.77)

K 35 (1.38)

99 (3.90)

34 (1.34)

99 (3.90)

23 (.91)

60 (2.36)

40 (1.57)

No.7

Sub-plate for Flow Control (and Check) Valves

Installation Drawings

FGM-10Y-20/2090

198.4 (7.81) 196.9 (7.75) 144.5 (5.69) 140 (5.51) 34.9 73 (1.37) (2.87) 43.5(1.71) Dia. 2 Places "B" Thd. "D" Deep 8 Places (From Rear) 20(.79) Dia. 15(.59) Deep 2 Places 11 (.43)

FLOW CONTROLS

DIMENSIONS IN MILLIMETRES (INCHES)

"A" Thd. "C" Deep 4 Places 177.8 (7.00) 144.5 (5.69) 55.5 (2.19) 36 (1.42) 29 (1.14) 17.3 (.68)

68.5 (2.70) 1.6 (.06)

228 (8.98)

73 (2.87)

250 (9.84)

21.5(.85) Dia. Through 32(1.26) Dia. Spotface 4 Places 45 (1.77) 25 (.98)

73 (2.87) 244 (9.61) 284 (11.18) 334 (13.15) 48(1.89) Dia. 2 Places

50 (1.97) 80 (3.15)

Sub-plate Model Numbers FGM-10Y-20 FGM-10Y-2090

"A" Thd.

"B" Thd.

D 32 (1.26) 34 (1.34)

M20 M16 32 (1.26) 3/4-10 UNC 5/8-11 UNC 32 (1.26)

No.8

100 (3.94) SQ. Pipe Flange

73 (2.87)

Flow Control (and Check)Valves FG FCG -01/02/03/06/10

Performance Characteristics

Metred Flow vs. Differential Pressure

U.S.GPM L/min 8.2 2.15 8.0 2.10 7.8 2.05 4.2 1.10 4.0 1.05 3.8 1.00 0.022 .0055 0.020 .0050 0.018 0 0 2 4

FLOW CONTROLS

FG -01 FCG

Metred Flow vs. Viscosity

U.S.GPM L/min 2.2 8.4 8.0 2.1 2.0 7.6 1.10 4.2 1.05 4.0 1.00 3.8 .0060 0.022 .0055 0.020 .0050 0.018 0 20 0 100 40

FG -01 FCG

Flow Rate

Flow Rate

10

12

14 MPa 2000 PSI

60

80 100 120 140 160 mm2/s 700 SSU

500 1000 1500 Differential Pressure

300 500 Viscosity

U.S.GPM L/min 8.5 32 8.0 30 7.5 28 8.2 2.15 8.0 2.10 7.8 2.05 0.52 .135 .130 0.50 0.48 0 0 5

FG -02 FCG

Flow Rate

U.S.GPM L/min 31.5 8.00 30.0 28.5 7.50 8.4 2.2 8.0 2.1 7.6 2.0 .0140 0.053 .0135 0.050 .0130 .0125 0.047 0 0 20 100 40

FG -02 FCG

Flow Rate

10

15

20 21 MPa 3000 PSI

60

80 100 120 140 160 mm2/s 700 SSU

1000 2000 Differential Pressure

300 500 Viscosity

U.S.GPM L/min 130 33 125 120 31 55 14 50 13 12 45 3.5 .9 .8 3.0 .7 2.5 0 0 5

FG -03 FCG

Flow Rate

U.S.GPM L/min 131 34 125 33 32 119 52.5 13.5 50.0 13.0 12.5 47.5 3.7 .95 3.5 .90 3.3

FG -03 FCG

Flow Rate

10

15

20

21

MPa

0 20 40 60 80 100 120 140 160 mm2/s 0 100 300 500 Viscosity 700 SSU

1000 2000 Differential Pressure

3000 PSI

Flow Rate

40 38 2.75 2.50

155 150 145 11 10 9 0 0 5 1000 10 15 2000 20 21 MPa

Flow Rate

U.S.GPM 66 65 64

L/min 250 245 240

FG -06 FCG

U.S.GPM L/min 260 68 250 66 64 240 160 42 40 150 38 140 11 2.8 2.6 10 2.4 9 0 20 0 100 40

FG -06 FCG

60

80 100 120 140 160 mm2/s 700 SSU

3000 PSI

Differential Pressure U.S.GPM L/min 132 Flow Rate 128 67 66 65 13.5 13.0 510 500 490 255 250 245 52 50 48 0 0 5 10 15 20 21 MPa PSI

300 500 Viscosity

FG -10 FCG

Flow Rate

U.S.GPM L/min 510 134 500 132 130 490 205 54 53 200 52 195 52 13.5 50 13.0 48 0 20 0 100 40

FG -10 FCG

60

80 100 120 140 160 mm2/s 700 SSU

1000 2000 Differential Pressure

3000

300 500 Viscosity

No.9

Flow Control (and Check) Valves FG FCG -01/02/03/06/10

Performance Characteristics

Metred Flow vs. Dial Position

FG -01 FCG

U.S.GPM L /min 1.5 Flow Rate 1.0 0.5 0 6 4 2 0 0 1 2 3 Dial Position 4 FG -01-8 FCG FG -01-4 FCG 8 Flow Rate 6 4 2 0 30 25 20 15 10 5 0 0 100 200 300 400 Handle Position 500 Flow Rate

FLOW CONTROLS

U.S.GPM L /min 2.25 8 2.0

FG -02 FCG

U.S.GPM L/min 35 30 20 10 0 140 120 100 80 60 40 20 0 0 100

FG -03 FCG

200 300 400 Handle Position

500

U.S.GPM 70 60 50 40 30 20 10 0 Flow Rate

L /min 250 200 150 100 50 0 0 100

FG -06 FCG

U.S.GPM 140 120 100 80 60 40 20 0 Flow Rate 500 600

L /min 500 400 300 200 100 0 0 100

FG -10 FCG

200 300 400 Handle Position

200 300 400 500 600 Handle Position

Min. Required Pressure Difference

FG -01 FCG FG -02 FCG FG -03 FCG

Differential Pressure

100 80 60 40 20 0

0.7 0.6 0.4 0.2 0 0 1 0 2 0.5 3 4 1.0 5 6 1.5 7 8 L /min

Differential Pressure

80 60 40 20 0

0.6 0.4 0.2 0 0 0 1 5 2 10 3 15 4 20 5 6 25 30 L /min

Differential Pressure

PSI

MPa

PSI

MPa

PSI 200 150 100 50 0

MPa 1.5 1.2 0.9 0.6 0.3 0 0 0 25 5 10

50 15

75 20

100 25

125 L /min

Flow Rate

2.0 2.5 U.S.GPM

Flow Rate

7 8 U.S.GPM

Flow Rate

30 35 U.S.GPM

Differential Pressure

1.0 0.8 0.6 0.4 0.2 0 0 0 50 100 150 200 250 L /min 60 70 U.S.GPM

Differential Pressure

PSI 150 125 100 75 50 25 0

MPa

FG -06 FCG

PSI 200 150 100 50 0

MPa 1.4 1.2 0.8 0.4 0 0 0 100 20

FG -10 FCG

200 40 60

300

400

500 L /min

10 20

30 40 50 Flow Rate

Flow Rate

80 100 120 140 U.S.GPM

No.10

Flow Control and Check Valves FCG-01/02/03/06/10

Performance Characteristics

Pressure Drop for Reversed Free Flow

Hydraulic Fluid: Viscosity 35 mm2/s (164 SSU) , Specific Gravity 0.850

PSI 80

FLOW CONTROLS

FCG-01

MPa 0.5 0.4 0.3 0.2 Throttle Fully Open (FCG-01-4) Throttle Fully Open (FCG-01-8) 0 2 4 6 8 10 12 14 L /min

FCG-02

P

PSI 80 60 40 20 0 MPa 0.5 0.4 Throttle Fully Open 0.3 0.2 0.1 0 0 10 20 30 40 50 L /min Throttle Closed

Throttle Closed

Pressure Drop

40 20 0

Pressure Drop

60

0.1 0

0.5 1.0

1.5 2.0 2.5 3.0 Free Flow

3.5 4.0 U.S.GPM

6 8 Free Flow

10

12

14 U.S.GPM

PSI 100

FCG-03

MPa 0.6

PSI

FCG-06

MPa 1.0 0.8 0.6 0.4 0.2 0 0 100 200 300 400 L /min Throttle Fully Open Throttle Closed

P Pressure Drop

150 200 L /min Throttle Closed Throttle Fully Open 0 50 100

150 125 100 75 50 25 0

Pressure Drop

75 50 25 0 0.4 0.2 0

10

20 30 Free Flow

40

50

U.S.GPM

20

40

60 Free Flow

80

100

U.S.GPM

FCG-10

PSI MPa 1.0 0.8 0.6 0.4 0.2 0 0 200 400 600 800 L /min Throttle Fully Open Throttle Closed

P Pressure Drop

150 125 100 75 50 25 0

50

100 150 Free Flow

200

U.S.GPM

For any other viscosity, multiply the factors in the table below.

Viscosity mm2/s 20 SSU 98 40 60 80 100 186 278 371 464

Factor

0.87 1.03 1.14 1.23 1.30

For any other specific gravity (G'), the pressure drop ( P') may be obtained from the formula below. P'= P (G'/0.850)

No.11

Flow Control (and Check) Valves FG FCG -01/02/03

Spare Parts List

FLOW CONTROLS

CAUTION

FG -01- - -11/1190 FCG

9 8 26 1 6 22 2 27 10 20

When making replacement of seals, please do it carefully after reading through the relevant instructions in the Operator's Manual.

35 38 36 37 33 34 29 27 32 20 28 30 31

Section X-X (FG-01 Type)

Section Y-Y (FCG-01 Type)

Section X-X (FG/FCG-01--N Type)

List of Seals

12 18 21 15

Item 23 24 25 26 27 32 38

Name of Parts O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring

Part Numbers SO-NA-P4 SO-NB-P9 SO-NB-P10 SO-NB-P16 SO-NB-P14 SO-NA-P5 SO-NB-P7

Qty. 1 2 1 1 1 1 1

Note: When ordering the seals, please specify the seal kit number from the table below.

List of Seal Kits

14 19 13 11 16 23 3 4 5 25 7 24 17

Model Numbers FG-01 FCG-01

Seal Kit Numbers KS-FG-01-11 KS-FCG-01-11

FG/FCG-02-30--30/3090 FG/FCG-03-125--30/3090

8 23 35 6 7 2 24 34 1 33 12 25

11 27 26 10 29 28

32

22

33

Section X-X (FG- Type)

List of Seals

Item 28 29 30 31 32 33 34 35 Name of Parts O-Ring Back Up Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring Part Numbers FG -03 FG -02 FCG FCG SO-NA-P4 SO-NA-P4 SO-BB-P4 SO-BB-P4 SO-NB-P5 SO-NB-P5 SO-NB-P16 SO-NB-P10A SO-NB-P18 SO-NB-P12 SO-NB-P14 SO-NB-P14 SO-NB-P28 SO-NB-P18 SO-NB-G35 SO-NB-G25 Qty. 1 1 1 1 1 1 2 1

17 19 31

20

21

14

30

13

16 15

(FCG- Type) (FG/FCG---N Type) Section X-X

List of Seal Kits

Model Numbers FG-02 FCG-02 FG-03 FCG-03 Seal Kit Numbers KS-FG-02-30 KS-FCG-02-30 KS-FG-03-30 KS-FCG-03-30

Note:When ordering the seals, please specify the seal kit number from the table right.

No.12

Flow Control (and Check) Valves FG FCG -06/10

Spare Parts List

FG/FCG-06-250--30/3090 FG/FCG-10-500--30/3090

FLOW CONTROLS

CAUTION

When making replacement of seals, please do it carefully after reading through the relevant instructions in the Operator's Manual.

8 40 6

2 40 9 36 10 42 41

14 30 15 X

37 27

26 1

Section X-X (FG- Type)

1 43 45 47 46

X 11 35 34 5 17 7 39 3 23

Section X-X (FCG- Type)

List of Seals

Item 34 35 36 37 39 40 47 Name of Parts O-Ring Back Up Ring O-Ring O-Ring O-Ring O-Ring O-Ring Part Numbers FG -10 FG -06 FCG FCG SO-NA-P4 SO-NA-P4 SO-BB-P4 SO-BB-P4 SO-NB-P34 SO-NB-P21 SO-NB-P48 SO-NB-P32 SO-NB-P50 SO-NB-P34 SO-NB-G75 SO-NB-P50 SO-NB-P32 SO-NB-P24 Qty. 1 1 1 2 1 3 1

List of Seal Kits

Model Numbers FG-06 FCG-06 FG-10 FCG-10 Seal Kit Numbers KS-FG-06-30 KS-FCG-06-30 KS-FG-10-30 KS-FCG-10-30

Note) When ordering the seals, please specify the seal kit number from the table right.

No.13

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03/06/10 Sub-plate Mounting

Specifications / Model Number Designation

FLOW CONTROLS

Specifications

Model Numbers FHG/FHCG-02-30--12 FHG/FHCG-03-125--12 FHG/FHCG-06-250--12 FHG/FHCG-10-500--12 Max. Metred Flow Capacity L /min (U.S.GPM) 30 (7.9) 125 (33) 250 (66) 500 (132) Min. Metred Flow Capacity L /min (U.S.GPM) 0.05 (.013) 0.2 (.053) 2 (.53) 4 (1.06) Max. Operating Pressure MPa (PSI) 21 (3050) Min. Pilot Pressure MPa (PSI) 1.5 (220) Approx. Mass kg (lbs.) 13 (28.7) 17 (37.5) 32 (70.6) 61 (135)

Model Number Designation

FSpecial Seals

FHC

Series Number FH: Pilot Operated Flow Control Valves FHC: Pilot Operated Flow Cont. & Check Valves

G

Type of Mounting

-02

Valve Size

-30

Max. Metred Flow L /min (U.S.GPM) 30 : 30 (7.9)

-N

Pressure Compensator Stroke Adj.

-O

With No Pilot Valve

-A100

Coil Type AC: A100 A120 A200 A240

-N

Type of Electrical Connections

-12

Design Design Standards Number

F: Special Seals for Phosphate Ester Type Fluids (Omit if not required)

02

12 None : Terminal Box Type 12 N: With Plug-in Connector (Din) 12 N: With Plug-in Connector (Din) None : Japanese Std. "JIS" 90 : N.American Design Std.

G: Sub-plate Mounting

03

125 : 125 (33)

06

250 : 250 (66)

N: Applicable only for Pres. Compensator Stroke Adjustment (Option Omit if not required)

O: Without Pilot Valve

DC: D12 D24 D48 AC DC: R100 R200

10

500 : 500 (132)

12

80 : European Design Std.

Either solenoid operated directional valve (DSG-01) or modular valve (MSW-01) can be used as a pilot valve. If no pilot valve is required, there is no needs to specify the coil type and the electrical connection type of solenoid operated directional valve.

Graphic Symbols

T P T P

O M A B A

O M B

FHG

FHCG

No.14

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03/06/10

Solenoid Ratings / Attachment / Option / Sub-plate

Solenoid Ratings

Electric Source Coil Type Frequency (Hz) 50 A100 60 50 60 50 60 50 60 Voltage (V) Source Rating 100 100 110 120 200 200 220 240 12 24 48 100 200 Serviceable Range 80 - 110 90 - 120 96 - 132 108 - 144 160 - 220 180 - 240 192 - 264 216 - 288 10.8 - 13.2 21.6 - 26.4 43.2 - 52.8 90 - 110 180 - 220

FLOW CONTROLS

Current & Power at Rated Voltage Inrush (A) 2.42 2.14 2.35 2.02 1.78 1.21 1.07 1.18 1.01 0.89 Holding (A) 0.51 0.37 0.44 0.42 0.31 0.25 0.19 0.22 0.21 0.15 2.45 1.23 0.61 0.33 0.16 Power (W)

A120 AC A200

D

29 29

A240 DC (K Series) AC DC Rectified D12 D24 D48 R100 R200

50/60

Inrush current in the above table shows rms values at maximum stroke. The coil type numbers in the shaded column are handled as optinal extras. In case these coils are required to be chosen, please confirm the time of delivery with us before ordering.

Attachment

Mounting Bolts

Valve Model Numbers FHG/FHCG-02 FHG/FHCG-03 FHG/FHCG-06 FHG/FHCG-10 Socket Head Cap Screw Japanese Std. "JIS" & European Design Std. N. American Design Std. M8 50 Lg. 5/16-18 UNC 2 Lg. M10 75 Lg. 3/8-16 UNC 3 Lg. M16 130 Lg. 5/8-11 UNC 5 Lg. M20 160 Lg. 3/4-10 UNC 6-1/2 Lg. Qty. 4 4 4 4

Option

Pres. compensator stroke adjustment Can reduce jumping at the start of the actuator.

Sub-plate

Valve Model Numbers FHG -02 FHCG Japanese Standard "JIS" Sub-plate Model No. FGM-02-20 FGM-02X-20 FGM-02Y-20 FGM-03-20 FGM-03X-20 FGM-03Y-20 FGM-03Z-20 FGM-06X-20 FGM-06Y-20 FGM-06Z-20 FGM-10Y-20 Thread Size Rc 1/4 Rc 3/8 Rc 1/2 Rc 3/8 Rc 1/2 Rc 3/4 Rc 1 Rc 1 Rc 1-1/4 Rc 1-1/2 1-1/2, 2 European Design Std. Sub-plate Model No. FGM-02-2080 FGM-02X-2080 FGM-02Y-2080 FGM-03-2080 FGM-03X-2080 FGM-03Y-2080 FGM-03Z-2080 FGM-06X-2080 FGM-06Y-2080 FGM-06Z-2080 FGM-10Y-20 Thread Size 1/4 BSP.F 3/8 BSP.F 1/2 BSP.F 3/8 BSP.F 1/2 BSP.F 3/4 BSP.F 1 BSP.F 1 BSP.F 1-1/4 BSP.F 1-1/2 BSP.F 1-1/2, 2 N. American Design Std. Sub-plate Model No. FGM-02-2090 FGM-02X-2090 FGM-02Y-2090 FGM-03-2090 FGM-03X-2090 FGM-03Y-2090 FGM-03Z-2090 FGM-06X-2090 FGM-06Y-2090 FGM-06Z-2090 FGM-10Y-2090 Thread Size 1/4 NPT 3/8 NPT 1/2 NPT 3/8 NPT 1/2 NPT 3/4 NPT 1 NPT 1 NPT 1-1/4 NPT 1-1/2 NPT 1-1/2, 2 Approx. Mass kg (lbs.) 2.3 (5.1) 2.3 (5.1) 3.1 (6.8) 3.9 (8.6) 3.9 (8.6) 5.7 (12.6) 5.7 (12.6) 12.5 (27.6) 16 (35.3) 16 (35.3) 37 (81.6)

FHG -03 FHCG

FHG -06 FHCG FHG -10 FHCG

Sub-plates are available. Specify the sub-plate model number from the table above. When sub-plates are not used, the mounting surface should have a good machined finish. FGM-10Y is special type sub-plates to be used with pipe flange. When ordering FGM-10Y, specify the pipe flange kit in addition to FGM-10Y referring to F3 pipe flange kits Catalogue (No. Pub. EC-3001).

Sub-plates are common with flow control valves. For dimensions, see pages 6 to 8.

No.15

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03/06/10

Instructions

Instructions

FLOW CONTROLS

Control patterns and flow rate adjustment While the solenoid operated directional valve on ( 2 shown below), the flow rate is at the level set by the maximum flow adjustment screw and the actuator operates at the maximum speed setting. Turning the adjustment screw clockwise causes the flow rate to decrease. While the solenoid operated directional valve off ( 4 shown below), the flow rate is set by the minimum flow adjustment screw and the actuator operates at the minimum speed setting. Turning the adjustment screw clockwise causes the flow rate to increase. When the solenoid operated directional valve is turned on ( 1 shown below), the flow rate is shifted from minimum to maximum and the actuator speed is also shifted likewise. The switching time can be set by the pilot flow adjustment dial (for acceleration). Turning the adjustment dial clockwise causes the pilot flow rate to decrease. When the solenoid operated directional valve is turned off ( 3 shown below), the flow rate is shifted from maximum to minimum and the actuator speed is also shifted likewise. The switching time can be set by the pilot flow adjustment dial (for deceleration). Turning the adjustment dial clockwise causes the pilot flow rate to decrease.

1

Flow Rate

2 4 4

On

Solenoid Signal

Time

Off

Off

Tightening of flow adjustment screws and dials To adjust flow rates, slacken the lock nut or the dial setting screw. After adjustments, tighten the lock nut or the dial. Min. required pressure difference The minimum differential pressure between inlet and outlet port is required to obtain the optimum pressure compensation. It varies according to the flow rate to be set. For details, please refer to the performance curves. Free flow Check valve pressure drops vary with flow rates. If models with check valves are used, see free flow pressure drop characteristics. Line filter To carry out flow adjustments by as small degree as 2 L /min (.53 U.S.GPM) or less, be sure to use a line filter of 10 m or finer and install it near the valve inlet.

No.16

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03/06/10

Performance Characteristics

Metred Flow vs. Cylinders Stroke

FHG FHCG -02

U.S.GPM L/min 140 35 120 30 100 20 10 0 80 60 40 20 0 0 5 10 15 20

FLOW CONTROLS

U.S.GPM L/min 9 8 7 Flow Rate 6 5 4 3 2 1 0 5 0 0 5 25 20 15 10 35 30

FHG FHCG -03

Flow Rate

Min. Metred Flow Range Max. Metred Flow Range 10 15 20 25 30 35 40 45 mm

Min. Metred Flow Range Max. Metred Flow Range

D

35 40 45 mm 1.5 1.75 IN.

25

30

0.5 1.0 Cylinders Stroke

1.5 1.75 IN.

0.5

1.0 Cylinders Stroke

U.S.GPM L/min 80 300 70 250 60 Flow Rate 50 40 30 20 10 0 50 0 0 5 10 200 150 100

FHG FHCG -06

U.S.GPM L/min 600 150 125 Flow Rate 500 400 300 200 100 0 0 5 10 15

FHG -10 FHCG

Min. Metred Flow Range

100 75 50 25

Min. Metred Flow Range Max. Metred Flow Range

Max. Metred Flow Range

15 20

25

30 35

40

45 mm

20 25

30 35

40 45 mm

0.5

1.0 Cylinders Stroke

1.5

1.75 IN.

0.5

1.0 Cylinders Stroke

1.5 1.75 IN.

Other Characteristics

The following characteristics are the same as for flow control valves; Metred Flow vs. Differential Pressure Metred Flow vs. Viscosity Min. Required Pressure Difference Pressure Drop for Reversed Free Flow (only for models with check valves) See pages 9 to 11. For reference, the corresponding model No. of the flow control valves are shown below.

Valve Model No. FHG -02 FHCG FHG -03 FHCG FHG -06 FHCG FHG -10 FHCG Model No. FG -02 FCG FG -03 FCG FG -06 FCG FG -10 FCG

No.17

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03

Installation Drawings

Terminal Box Type

FLOW CONTROLS

FHG/FHCG-02-30---12/1290 FHG/FHCG-03-125---12/1290

"e" Dia. Through "f" Dia. Spotface 4 Places Controlled Flow Inlet or Reversed Free Flow Outlet Port Fully Extended 331(13.03) Fully Extended C d

Mounting surface: FHG-02: ISO 6263-AK-06-2-A FHG-03: ISO 6263-AM-07-2-A

DIMENSIONS IN MILLIMETRES (INCHES)

Model Numbers FHG/FHCG-02-30---12 FHG/FHCG-02-30---1290 FHG/FHCG-03-125---12 FHG/FHCG-03-125---1290 n Rc 1/4 1/4 NPT Rc 1/4 1/4 NPT t G 1/2 1/2 NPT G 1/2 1/2 NPT

60 (2.36)

Note: For dimensions of the valve mounting surface, see the installation drawing (P. 6 and 7) of the sub-plate used together.

F Controlled Flow Outlet or Reversed Free Flow Inlet Port

E D

Pilot Line Tank Port "T" "n" Thd. (Rear) Pilot Line Pressure Port "P" "n" Thd.

45.5 DC/R:105(4.13) (1.79) AC :95.7(3.77) 45 (1.77)

Space Needed to Remove Solenoid-Each End DC/R:55(2.17) AC :45.5(1.79) Electrical Conduit Connection "t" Thd. (Both End) Manual Actuator 6(.24) Dia. Pilot Flow Adj. Dial (For Acceleration) INC. Lock Nut 19(.75) Hex. V Max. Flow Adjustment Screw 19(.75) Hex. INC.

Pilot Flow Adj. Dial (For Deceleration) INC. 40 (1.57)

32 (1.26) Dia.

90.3 (3.56)

SOL b

(S)

75 (2.95)

Min. Flow Adjustment Screw 19(.75) Hex. U INC. N h

Fully Extended 20(.79) Q

6 (.24)

Locating Pin 6(.24) Dia. "j" Places

Mounting Surface (O-Rings Furnished)

Pressure Compensator Stroke Adjustment (Only for FHG---N )

Model Numbers

Dimensions C D E F H J K L 100.6 82.6 44.3 9 (3.96) (3.25) (1.74) (.35) 125 101.6 61.8 11.7 (4.92) (4.00) (2.43) (.46)

mm (Inches) N Q S U V X Y Z 40 23 (1.57) (.91) 274.3 69 256 209 162 129 (10.80) (2.72) (10.08) (8.23) (6.38) (5.08)

76.2 9.9 127.4 96 FHG FHCG -02 (5.02) (3.78) (3.00) (.39) 114.7 125 101.6 11.7 FHG FHCG -03 (4.52) (4.92) (4.00) (.46) Model Numbers Dimensions a d e

64 41 303.3 98 285 238 191 158 (2.52) (1.61) (11.94) (3.86) (11.22) (9.37) (7.52) (6.22)

mm (Inches) f 14 (.55) 17.5 (.69) h 39 (1.54) 63 (2.48)

j 1 2

104 8.8 38.1 FHG FHCG -02 (4.09) (1.50) (.35) 133 11 50.8 FHG FHCG -03 (5.24) (2.00) (.43)

No.18

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03

Installation Drawings

Models with Plug-in Connector

FLOW CONTROLS

FHG/FHCG-02-30---N-12/1280/1290 FHG/FHCG-03-125---N-12/1280/1290

Three positions of cable departure are available by loosening "Lock Nut" as shown. After location, tighten "Lock Nut" with torque in the range 10.3 to 11.3 Nm (91 - 100 IN.lbs.). DC/R:152(5.98) AC :142.7(5.62) DC/R:105(4.13) AC :95.7(3.77) q 48.5 (1.91)

Pilot Line Tank Port "T" "m" Thd. (Rear) Pilot Line Pressure Port "P" "m" Thd.

SOL b

Cable Departure Cable Applicable: Outside Dia. ...... 8-10 mm (.31 - .39 IN.) Conductor Area ...... Not Exceeding 1.5 mm2 (.002 SQ. IN.)

(SS)

VV XX

DIMENSIONS IN MILLIMETRES (INCHES)

Model Numbers FHG/FHCG-02-30--A-N FHG/FHCG-03-125--A-N FHG/FHCG-02-30--D-N FHG/FHCG-03-125--D-N FHG/FHCG-02-30--R-N FHG/FHCG-03-125--R-N

Dimensions SS 274 (10.79) 303 (11.93) 285 (11.22) 314 (12.36) 288 (11.34) 317 (12.48) VV 262 (10.31) 291 (11.46) 273 (10.75) 302 (11.89) 266.2 (10.48) 295.2 (11.62)

mm (Inches) XX 209 (8.23) 238 (9.37) 209 (8.23) 238 (9.37) 209 (8.23) 238 (9.37) q 39 (1.54)

Remarks

with AC Solenoid

39 (1.54)

with DC Solenoid

53 (2.09)

with AC DC Solenoid

Thread Size Model Numbers FHG/FHCG-02-30---N FHG/FHCG-03-125---N Japanese Std. "JIS" Design 12 "n" Thd. Rc 1/4 European Design Std. Design 1280 "n" Thd. 1/4 BSP.F N.American Design Std. Design 1290 "n" Thd. 1/4 NPT

For other dimensions, refer to "Terminal Box Type".

No.19

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -06/10

Installation Drawings

Terminal Box Type

FLOW CONTROLS

Mounting surface: FHG-06: ISO 6263-AP-08-2-A

FHG/FHCG-06-250---12/1290 FHG/FHCG-10-500---12/1290

Fully Extended 331(13.03) Controlled Flow Outlet or Reversed Free Flow Inlet Port Fully Extended C F

DIMENSIONS IN MILLIMETRES (INCHES)

Model Numbers FHG/FHCG-06-250---12 FHG/FHCG-06-250---1290 FHG/FHCG-10-500---12 FHG/FHCG-10-500---1290

D

q Rc 1/4 1/4 NPT Rc 1/4 1/4 NPT

r G 1/2 1/2 NPT G 1/2 1/2 NPT

K 60 (2.36)

Note: For dimensions of the valve mounting surface, see the installation drawing (P. 7 and 8) of the sub-plate used together.

E n J H L 45.5 DC/R:105(4.13) (1.79) AC :95.7(3.77) 45 (1.77)

SOL b

Pressure Compensator Stroke Adjustment (Only for FHG---N )

Controlled Flow Inlet or Reversed Free Flow Outlet Port "h" Dia. Through "m" Dia. Spotface 4 Places Space Needed to Remove Solenoid-Each End DC/R:55(2.17) AC :45.5(1.79) Electrical Conduit Connection "r" Thd. (Both End) Manual Actuator 6(.24) Dia. Pilot Flow Adj. Dial (For Acceleration) INC. Lock Nut 19(.75) Hex. X Max. Flow Adjustment Screw 19(.75) Hex. INC.

Pilot Line Tank Port "T" "q" Thd. (Rear) Pilot Line Pressure Port "P" "q" Thd. 90.3 (3.56) Pilot Flow Adj. Dial (For Deceleration) INC. 40 (1.57)

32 (1.26) Dia.

75 (2.95)

(U)

Min. Flow Adjustment Screw 19(.75) Hex. V Q N t INC.

Mounting Surface (O-Rings Furnished)

aa

Locating Pin "f" Dia. 2 Places

Model Numbers

Dimensions C D E F H J K L 174 133.4 73.1 20.3 (6.85) (5.25) (2.88) (.80) 228 177.8 98.5 25.1 (8.98) (7.00) (3.88) (.99) mm (Inches) h 17.5 (.69) 21.5 (.85) m n t

mm (Inches) N Q S U V X Y Z 105 65 18 335.3 130 317 270 223 (4.13) (2.56) (.71) (13.20) (5.12) (12.48) (10.63) (8.78) 137 85 23 365.3 160 347 300 253 (5.39) (3.35) (.91) (14.38) (6.30) (13.66) (11.81) (9.96)

17 66.5 180 146.1 FHG FHCG -06 (2.62) (7.09) (5.75) (.67) FHG FHCG -10 Model Numbers 21 (.83) 244 196.9 23.5 (9.61) (7.75) (.93)

Dimensions a d e f 16 (.63) 18 (.71)

aa

190 7 165 FHG FHCG -06 (7.48) (6.50) (.28) 220 10 195 FHG FHCG -10 (8.66) (7.68) (.39)

26 103 99 44 (1.02) (1.73) (4.06) (3.90) 32 135 144.5 61 (1.26) (2.40) (5.31) (5.69)

No.20

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -06/10

Installation Drawings

Models with Plug-in Connector

FLOW CONTROLS

FHG/FHCG-06-250---N-12/1280/1290 FHG/FHCG-10-500---N-12/1280/1290

Three positions of cable departure are available by loosening "Lock Nut" as shown. After location, tighten "Lock Nut" with torque in the range 10.3 to 11.3 Nm (91 - 100 IN.lbs.). Pilot Line Tank Port "T" "q" Thd. (Rear) Pilot Line Pressure Port "P" "q" Thd. DC/R:152(5.98) AC :142.7(5.62) DC/R:105(4.13) AC :95.7(3.77) 48.5 m (1.91)

SOL b

Cable Departure Cable Applicable: Outside Dia. ...... 8-10 mm (.31 - .39 IN.) Conductor Area ...... Not Exceeding 1.5 mm2 (.002 SQ. IN.)

(UU)

XX

DIMENSIONS IN MILLIMETRES (INCHES)

YY

Model Numbers FHG/FHCG-06-250--A-N FHG/FHCG-10-500--A-N FHG/FHCG-06-250--D-N FHG/FHCG-10-500--D-N FHG/FHCG-06-250--R-N FHG/FHCG-10-500--R-N

Dimensions UU 335 (13.19) 365 (14.37) 346 (13.62) 376 (14.80) 349 (13.74) 379 (14.92) XX 323 (12.72) 353 (13.90) 334 (13.15) 364 (14.33) 327.2 (12.88) 357.2 (14.06)

mm (Inches) YY 270 (10.63) 300 (11.81) 270 (10.63) 300 (11.81) 270 (10.63) 300 (11.81) m 39 (1.54)

Remarks

with AC Solenoid

39 (1.54)

with DC Solenoid

53 (2.09)

with AC DC Solenoid

Thread Size Model Numbers FHG/FHCG-06-250---N FHG/FHCG-10-500---N Japanese Std. "JIS" Design 12 "q" Thd. Rc 1/4 European Design Std. Design 1280 "q" Thd. 1/4 BSP.F N.American Design Std. Design 1290 "q" Thd. 1/4 NPT

For other dimensions, refer to "Terminal Box Type".

No.21

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03/06/10

Lead Wire Connection

FLOW CONTROLS

Details of Receptacle

Terminal Box Type Plug-in Connector Type

Power Supply

Ground

1

1-Power Supply

3

SOL. b

2

Indicator Light Ground

With DC solenoids, polarity is no question.

Do not perform wiring while the power is on. Doing so may result in electric shock, burns or death. Make the wiring properly. Improper wiring will cause an irregular movement of the machine, resulting in a grave accident.

Electrical Circuit

Type of Electrical Conduit Connection Electric Source AC DC AC DC Rectified

Indicator Light Voltage-Surge Suppressor

Indicator Light Power Supply Power Supply SOL. Common Ground Common Ground

Indicator Light Power Supply SOL. Common Ground

Terminal Box Type

Voltage-Surge Suppressor

Indicator Light (Integrated in "N1" model only) SOL. 1-Power Supply 1-Power Supply SOL. 2-Power Supply Ground Indicator Light (Integrated in "N1" model only) 2-Power Supply Ground Voltage-Surge Suppressor (Circuit composed in coil) 2-Power Supply Ground 1-Power Supply

Plug-in Connector Type

No.22

1 2 3

2-Power Supply

DANGER

SOL.

Rectifier Circuit

Voltage-Surge Suppressor

SOL.

Rectifier Circuit

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03

Spare Parts List CAUTION

FLOW CONTROLS

When making replacement of seals, please do it carefully after reading through the relevant instructions in the Operator's Manual.

Terminal Box Type

Models with Plug-in Connector

FHG/FHCG-02-30---12/1290 FHG/FHCG-03-125---12/1290

63 49 57 55 60 59 51

SOL b

FHG/FHCG-02-30---N-12/1280/1290 FHG/FHCG-03-125---N-12/1280/1290

63 62 50

SOL b

52 58 54 53

61 56 11 29 10 4 34 23 35 7 8 6 2 24 1 33 25 12

5 3 32 9 22

14 33 30 13 16 15

17 19 31 21 20

(FHG- Type)

(FHCG- Type) Section X-X

FHG FHCG ---N Type

List of Seals

Item 29 30 31 32 33 34 35 57 58 59 60 61 Name of Parts O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring Back Up Ring O-Ring Part Numbers FHG -03 FHG -02 FHCG FHCG SO-NB-P20 SO-NB-P20 SO-NB-P5 SO-NB-P5 SO-NB-P16 SO-NB-P10A SO-NB-P18 SO-NB-P12 SO-NB-P14 SO-NB-P14 SO-NB-P28 SO-NB-P18 SO-NB-G35 SO-NB-G25 SO-NB-P9 SO-NB-P9 SO-NB-P10A SO-NB-P10A SO-NA-P26 SO-NA-P26 SO-BB-P26 SO-BB-P26 SO-NB-P38 SO-NB-P38 Qty. 1 1 1 1 1 2 1 2 2 2 4 2

Pilot Valves See page 25 for the pilot valve model numbers to be used. List of Seal Kits

Model Numbers FHG-02 FHCG-02 FHG-03 FHCG-03 Seal Kit Numbers KS-FHG-02-12 KS-FHCG-02-12 KS-FHG-03-12 KS-FHCG-03-12

Note) When ordering the seals, please specify the seal kit number from the table right. In addition to the above seals, seals for pilot valves are included in the seal kit.

No.23

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -06/10

Spare Parts List CAUTION

FLOW CONTROLS

When making replacement of seals, please do it carefully after reading through the relevant instructions in the Operator's Manual.

Terminal Box Type

Models with Plug-in Connector

FHG/FHCG-06-250---12/1290 FHG/FHCG-10-500---12/1290

62 49 57 55 61 51

SOL b

FHG/FHCG-06-250---N-12/1280/1290 FHG/FHCG-10-500---N-12/1280/1290

63 63 50 52 58 54 53

SOL b

14 59 60 56 35 7 39 23 26 1 40 8 6 4 2 40 36 9 10 42 41 1 45 43 47 46 11

X X

3 5 17 37 27

(FHG- Type) Section X-X

(FHCG- Type) Section X-X

List of Seals

Item 35 36 37 39 40 47 57 58 59 60 61 Name of Parts O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring Back Up Ring O-Ring Part Numbers FHG -10 FHG -06 FHCG FHCG SO-NB-P20 SO-NB-P20 SO-NB-P34 SO-NB-P21 SO-NB-P48 SO-NB-P32 SO-NB-P50 SO-NB-P34 SO-NB-G75 SO-NB-P50 SO-NB-P32 SO-NB-P24 SO-NB-P9 SO-NB-P9 SO-NB-P10A SO-NB-P10A SO-NA-P26 SO-NA-P26 SO-BB-P26 SO-BB-P26 SO-NB-P38 SO-NB-P38 Qty. 1 1 2 1 3 1 2 2 2 4 2

Pilot Valves See page 25 for the pilot valve model numbers to be used. List of Seal Kits

Model Numbers FHG-06 FHCG-06 FHG-10 FHCG-10 Seal Kit Numbers KS-FHG-06-12 KS-FHCG-06-12 KS-FHG-10-12 KS-FHCG-10-12

Note) When ordering the seals, please specify the seal kit number from the table right. In addition to the above seals, seals for pilot valves are included in the seal kit.

No.24

Pilot Operated Flow Control (and Check) Valves

FHG FHCG -02/03/06/10

Spare Parts List

List of Pilot Valves

Type of Electrical Conduit Connections Pilot Valve Model Numbers Valve Model Numbers Item No.62 Throttle and Check Modular Valves Item No.63 Solenoid Operated Directional Valves

FLOW CONTROLS

Remarks

Terminal Box Type

FHG/FHCG-02- 30-FHG/FHCG-03-125-FHG/FHCG-06-250-FHG/FHCG-10-500-FHG/FHCG-02- 30-FHG/FHCG-03-125-FHG/FHCG-06-250-FHG/FHCG-10-500-FHG/FHCG-02- 30-FHG/FHCG-03-125-FHG/FHCG-06-250-FHG/FHCG-10-500--

-12 -12 -12 -12 -1290 -1290 -1290 -1290 -N-12 -N-12 -N-12 -N-12 -N-1280 -N-1280 -N-1280 -N-1280 -N-1290 -N-1290 -N-1290 -N-1290

MSW-01-X-50

DSG-01-2B2-

-60

Japanese Std. "JIS"

MSW-01-X-5090

DSG-01-2B2-

-6090

N. American Design Std.

MSW-01-X-50

DSG-01-2B2-

-N-60

Japanese Std. "JIS"

Plug-in Connector Type

FHG/FHCG-02- 30-FHG/FHCG-03-125-FHG/FHCG-06-250-FHG/FHCG-10-500-FHG/FHCG-02- 30-FHG/FHCG-03-125-FHG/FHCG-06-250-FHG/FHCG-10-500--

MSW-01-X-50

DSG-01-2B2-

-N-60

European Design Std.

MSW-01-X-5090

DSG-01-2B2-

-N-6090

N. American Design Std.

Note: 1. Fill a coil type (a symbol representing current/voltage) in section marked . 2. For the detail of the MSW-01 valve O-rings, see the Catalogue No. Pub. EC-1402. 3. For the detail of the DSG-01 valve O-rings, see the Catalogue No. Pub. EC-0402.

No.25

Pub. EC-0302

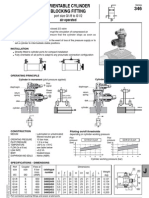

FLOW CONTROL AND RELIEF VALVES FBG-03/06/10 (3/8, 3/4, 1-1/4)

Sub-plate Mounting

Model Number Designation / Specifications Up to 25 MPa (3630 PSI), 500 L/min (132 U.S.GPM)

FLOW CONTROLS

These valves are flow control valves having the functions of metre-in type flow control and pressure control. Inlet pressure is always maintained 0.6 MPa (87 PSI) higher than the load pressure. In a conventional flow control method, power consumption is wasteful since the pump pressure goes up to the preset system pressure regardless of the load pressure. While, the power saving valves control the pump pressure by maintaining a differential pressure as little as 0.6 MPa (87 PSI) against the load pressure, thereby, the power can be remarkably saved. Moreover, with lthe temperature compensator, a stable flow control can be made regardless of oil temperature. Setting and repeat setting of flow can be made easily with an adjustment knob having digital scales.

Graphic Symbol

Specifications

Model Numbers Description Max. Operating Pressure MPa (PSI) Rated Flow Metred Flow Range L /min (U.S.GPM) Pressure Adjustment Range MPa (PSI) Min. Pressure Difference Required between Inlet and Outlet Ports MPa (PSI) Pilot Drain Flow L /min (U.S.GPM) Max. Drain Line and Tank Line Back Pressure MPa (PSI) Approx. Mass kg (lbs.) . 13.3 (29.3) 27.3 (60.2) 57.3 (126) 0.5 (73) 0.5 (73) 0.5 (73) 1.5 (.40) 2.4 (.63) 3.5 (.92) 0.6 (87) 0.7 (102) 0.9 (131) L /min (U.S.GPM) FBG-03-125 25 (3630) 125 (33) 1-125 (.26-33) -25 ( -3630) FBG-06-250 25 (3630) 250 (66) 3-250 (.79-66) FBG-10-500 25 (3630) 500 (132) 5-500 (1.3-132)

-25 ( -3630)

-25 ( -3630)

See the "Min. Adjustment Pressure" for the item marked

Model Number Designation

FSpecial Seals F: Special Seals for Phosphate Ester Type Fluids (Omit if not required)

FB

Series Number

G

Type of Mounting G: Sub-plate Mounting

-03

Valve Size 03

-125

Max. Metred Flow L /min (U.S.GPM) 125 : 125 (33) 250 : 250 (66) 500 : 500 (132)

-10

Design Number 10 10 10

Design Standards

FB: Flow Control and Relief Valves

06 10

Refer to

1. Design Standards : Japanese Standard "JIS" and European Design Standard None . 90 ............... N. American Design Standard . ...............

No.1

Flow Control and Relief Valves FBG-03/06/10

Hydraulic Fluids / Instructions

Hydraulic Fluids

Fluid Types Any type of hydraulic fluids listed in the table below can be used.

Petroleum base oils Synthetic fluids Water containing fluids Use fluids equivalent to ISO VG32 or VG46.

FLOW CONTROLS

Use phosphate ester or polyol ester fluid.When phosphate ester fluid is used, prefix "F-" to the model number because the special seals (fluororubber) are required to be used. Use water-glycol fluid.

Note: For use with hydraulic fluids other than those listed above, please consult your Yuken representatives in advance.

Recommended Viscosity and Oil Temperatures

Viscosity ranging between 15 - 400 mm2/s (77 - 1800 SSU). Oil temperatures between -15/+70C (5 - 158F). Use hydraulic fluids which satisfy the recommended viscosity and oil temperatures given above.

Control of Contamination

Due caution must be paid to maintaining control over contamination of the hydraulic fluids which may otherwise lead to breakdowns and shorten the life of the valves. Please maintain the degree of contamination within NAS 1638-Grade 12. Use 25 m or finer line filter.

Instructions

Flow adjustment Loosen the locking screw and turn the flow adjustment handle clockwise to increase, and anti-clockwise to decrease. Open condition is indicated in digital-scale in built-in revolution indicator (Refer to characteristics of "Metred flow vs. Dial Position"). After flow adjustments, tighten the locking screw. Pressure adjustment To adjust the pressure, loosen the lock nut and turn the pressure adjustment screw slowly clockwise to increase pressures or anti-clockwise to decrease pressure. After adjustments, do not forget to tighten the lock nut. Drain port back pressure Note that any drain port back pressure is added to the minimum pressure. Connect the drain port, preferably with its back pressure minimized, directly to the oil tank. Relief valve throughput When the relief valve throughput is small with pressure under control, the pressure setting may become unstable. Thus, hold the rate above 10 L/min (2.6 U.S.GPM) for nominal valve size 03 and 06 or above 15 L/min (4 U.S. GPM) for nominal valve size 10. Line filter In case of controlling flow rate of less than 2 L/min (.53 U.S.GPM), be sure to use a line filter of 10m or finer at the valve inlet.

Attachment

Mounting Bolts

Valve Model Numbers FBG-03 FBG-06 FBG-10 Socket Head Cap Screw Japanese Std. "JIS" and European Design Std. N. American Design Std. M10 100 Lg. 3/8-16 UNC 4 Lg. M16 130 Lg. 5/8-11 UNC 5 Lg. M20 130 Lg. 3/4-10 UNC 5 Lg. Qty. 4 4 4

Sub-plate

Valve Model Numbers FBG-03 FBG-06 FBG-10 Japanese Standard "JIS" Sub-plate Model No. EFBGM-03Y-10 EFBGM-03Z-10 EFBGM-06X-10 EFBGM-06Y-10 EFBGM-10Y-10 Thread Size Rc 3/4 Rc 1 Rc 1 Rc 1-1/4 1-1/2, 2 European Design Standard Sub-plate Model No. EFBGM-03Y-1080 EFBGM-03Z-1080 EFBGM-06X-1080 EFBGM-06Y-1080 EFBGM-10Y-1080 Thread Size 3/4 BSP.F 1 BSP.F 1 BSP.F 1-1/4 BSP.F 1-1/2, 2 N. American Standard Sub-plate Model No. EFBGM-03Y-1090 EFBGM-03Z-1090 EFBGM-06X-1090 EFBGM-06Y-1090 EFBGM-10Y-1090 Thread Size 3/4 NPT 1 NPT 1 NPT 1-1/4 NPT 1-1/2, 2 Approx. Mass kg (lbs.) 6 6 12.5 16 37 (13.2) (13.2) (27.6) (35.3) (81.6)

Sub-plates are available. Specify the sub-plate model number from the table above. When sub-plates are not used, the mounting surface should have a good machined finish.

EFBGM-10Y is special type sub-plates to be used with pipe flange. When ordering EFBGM-10Y, specify pipe flange in addition to EFBGM-10Y referring to F3 pipe flange catalogue (No. Pub. EC3001).

No.2

Flow Control and Relief Valves FBG-03

Installation Drawings

FBG-03-125-10/1090

FLOW CONTROLS

188 (7.40) 187 (7.36) 133 (5.24) 6 (.24) 85 (3.35) Locking Screw 2(.08) Hex. Soc. Revolution Indicator 50 (1.97) 11.7 (.46) 125 (4.92) 101.6 (4.00) 50.8 (2.00)

Controlled Flow Inlet Port Drain Port 14.2 (.56)

Locating Pin 6(.24) Dia. 2 Places

Fully Extended 148 (5.83)

123

Mounting Surface (O-Rings Furnished) 41 (1.61)

Flow Adjustment Handle 46(1.81) Dia. INC. Lock Nut 14(.55) Hex. Pressure Adjustment Screw 14(.55) Hex. INC.

25 (.98) Controlled Flow Outlet Port

11(.43) Dia. Through 17.5(.69) Dia. Spotface 4 Places Tank Port Vent Port

DIMENSIONS IN MILLIMETRES (INCHES)

Sub-plate EFBGM-03Y/03Z-10/1080/1090

"C" Thd. "D" Deep 4 Places 11(.43) Dia. Through 17.5(.69) Dia. Spotface 4 Places 14.2 (.56) 11.7 (.46) 0.8 (.03) 125(4.92) 102.4(4.03) 101.6(4.00) 77.8(3.06) 50.8(2.00) 23.8(.94) 59(2.32) 20(.79) 7(.28) Dia. 7(.28) Deep 2 Places 12.7 28.6 (.50) (1.13) 88.9(3.50) 23(.91) Dia. 3 Places

101.6(4.00)

80(3.15)

100(3.94)

22.2 (.87) "E" Dia. "B" Thd.(From Rear) 11 (.43) 6(.24) Dia.

39.2 (1.54) 106.8(4.20) 146(5.75) 168(6.61)

"A" Thd. 3 Places (From Rear) "B" Thd. (From Rear)

95.3(3.75)

130(5.12)

Sub-plate Model Numbers EFBGM-03Y-10 EFBGM-03Z-10 EFBGM-03Y-1080 EFBGM-03Z-1080 EFBGM-03Y-1090 EFBGM-03Z-1090

20 (.79)

40 (1.57)

Thread Size D E "A" Thd. "B" Thd. "C" Thd. Rc 3/4 11 Rc 1/4 (.43) Rc 1 M10 18 (.71) 3/4 BSP.F 11.7 1/4 BSP.F (.46) 1 BSP.F 3/4 NPT 11 1/4 NPT 3/8-16 UNC 21 (.83) (.43) 1 NPT

61.8 (2.43) 101.6 (4.00) 130 (5.12)

No.3

Flow Control and Relief Valves FBG-06

Installation Drawings

FBG-06-250-10/1090

FLOW CONTROLS

247 (9.72) 219 (8.62) 165 (6.50) 7 (.28) 107 (4.21) Locking Screw 2(.08) Hex. Soc. Fully Extended 160 (6.30) 82 (3.23) 133.4 (5.25) 174 (6.85) 17.5(.69) Dia. Through 26(1.02) Dia. Spotface 4 Places Tank Port Drain Port Vent Port Revolution Indicator 50 (1.97) 16.9 (.67) 73 (2.87) 180 (7.09) 146.1 (5.75) Controlled Flow Inlet Port 20.3 (.80)

123

Locating Pin 16(.63) Dia. 2 Places Mounting Surface (O-Rings Furnished) 62 (2.44)

Flow Adjustment Handle 46(1.81) Dia. INC. Lock Nut 14(.55) Hex. Pressure Adjustment Screw 14(.55) Hex. INC.

25 (.98)

Controlled Flow Outlet Port

Sub-plate EFBGM-06X/06Y-10/1080/1090

"J" Thd. "K" Deep 4 Places 17.5(.69) Dia. Through 26(1.02) Dia. Spotface 4 Places 24 (.94) 17 (.67) 180(7.09) 146.1(5.75) 144.5(5.69) 118.1(4.65) 73.1(2.88) 28.1(1.11) 1.6(.06) 29(1.14) Dia. 3 Places 17(.67) Dia. 10(.39) Deep 2 Places 41.3(1.63) 12.7(.50) 20.3 (.80)

DIMENSIONS IN MILLIMETRES (INCHES)

85.7(3.37) "E" Thd. (From Rear) 3 Places

3.7(.15)

33 (1.30) 19 (.75) "L" Dia. "F" Thd. (From Rear)

212(8.35) 250(9.84)

107(4.21) 133.4(5.25)

174(6.85) 126(4.96) B 16 (.63)

6.2(.24) Dia. "H" Thd. (From Rear) D C

Dimensions mm (IN.) B C D EFBGM-06X 103.3 (4.07) 45 (1.77) 35 (1.38) EFBGM-06Y 95 (3.74) 60 (2.36) 40 (1.57) Sub-plate Model No.

Sub-plate Model No. EFBGM-06X-10 EFBGM-06Y-10 EFBGM-06X-1080 EFBGM-06Y-1080 EFBGM-06X-1090 EFBGM-06Y-1090

"E" Thd. Rc 1 Rc 1-1/4 1 BSP.F 1-1/4 BSP.F 1 NPT 1-1/4 NPT

Thread Size "F" Thd. "H" Thd. Rc 3/8 3/8 BSP.F 3/8 NPT Rc 1/4 1/4 BSP.F 1/4 NPT

"J" Thd. M 16 M 16 5/8-11 UNC

mm (IN.) K L 30 14 (1.18) (.55) 30 (1.18) 35 (1.38) 15.2 (.60) 14 (.55)

No.4

Flow Control and Relief Valves FBG-10

Installation Drawings

FBG-10-500-10/1090

FLOW CONTROLS

249 (9.80) 195 (7.68) 10 (.39) Locating Pin 18(.71) Dia. 2 Places 107 (4.21) Revolution Indicator Sling Fitting Screw "M8" Thd. 16(.63) Deep 2 Places

50 (1.97) 23.5 (.93)

315 (12.40) 244 (9.61) 196.9 (7.75) 98.5 (3.88)

Controlled Flow Inlet Port Drain Port

Fully Extended 177 (6.97)

Mounting Surface (O-Rings Furnished) Flow Adjustment Handle 46(1.81) Dia.

123

Lock Nut 14(.55) Hex. INC. 25 (.98) Tank Port Vent Port 21.5(.85) Dia. Through 32(1.26) Dia. Spotface 4 Places

70 (2.76)

Pressure Adjustment Screw 14(.55) Hex. INC. Controlled Flow Outlet Port

Sub-plate EFBGM-10Y-10/1080/1090

"D" Thd. "F" Deep 4 Places 21.5(.85) Dia. Through 32(1.26) Dia. Spotface 4 Places 36.1 (1.42) 23.5 (.93) 244(9.61) 198.4(7.81) 196.9(7.75) 162(6.38) 98.5 (3.88) 73 1.6 35 (.06) (1.38) (2.87) 43.5(1.71) Dia. 3 Places "E" Thd. "F" Deep 12 Places (From Rear) 20(.79) Dia. 15(.59) Deep 2 Places 23 (.91)

DIMENSIONS IN MILLIMETRES (INCHES)

177.8(7.00) 144.5(5.69) 119(4.69) 55.5 (2.19) 17.5 (.69)

250(9.84)

29 (1.14)

43.5 (1.71)

25 (.98)

73 73 (2.87) 72 (2.87) (2.83) 212(8.35) 284(11.18) 334(13.15)

73 (2.87)

48(1.89) Dia. 3 Places (From Rear) "H" Dia. "B" Thd. (From Rear)

224 (8.82)

6.2(.24) Dia. "C" Thd. (From Rear) 80 (3.15)

Sub-plate Model No. EFBGM-10Y-10 EFBGM-10Y-1080 EFBGM-10Y-1090 Sub-plate Model No.

50 (1.97)

Thread Size "B" Thd. "C" Thd. Rc 1/4 Rc 3/8 3/8 BSP.F 1/4 BSP.F 1/4 NPT 3/8 NPT (IN.) H 11 (.43) 32 (1.26) 15.2 (.60) 34 (1.34) 14 (.55) mm F

"D" Thd. M20 3/4-10 UNC

"E" Thd. M16 5/8-11 UNC

EFBGM-10Y-10 EFBGM-10Y-1080 EFBGM-10Y-1090

115 (4.53) 177.8 (7.00) 224 (8.82)

Locking Screw 2(.08) Hex. Soc.

23 (.91)

No.5

Flow Control and Relief Valves FBG-03/06/10

Performance Characteristics

Min. Adjustment Pressure

FBG-03

Min. Adjustment Pressure Min. Adjustment Pressure

PSI MPa 150 125 100 75 50 25 0 1.0 0.8 0.6 0.4 0.2 0 0 25 50 75 100 125 L /min PSI MPa 200 1.4 175 1.2 150 1.0 125 0.8 100 0.6 75 50 0.4 25 0.2 0 0

FLOW CONTROLS

FBG-10

FBG-06

Min. Adjustment Pressure

PSI MPa 200 1.4 175 1.2 150 1.0 125 0.8 100 75 0.6 50 0.4 25 0.2 0 0

0 50 100 150 200 250 L /min 0 10 20 30 40 50 60 70 U.S.GPM

0 100 200 300 400 500 L /min 0 20 60 100 140 U.S.GPM

0 5 10 15 20 25 30 35 U.S.GPM

Flow Rate

Flow Rate

Flow Rate

Load Pressure vs. Metred Flow

FBG-03

U.S.GPM L /min 120 30 25 100 80 60 40 20 0 0 0 5 1000 10 15 2000 20 MPa 21 3000 PSI U.S.GPM L /min 70 260 250 60 200 50

FBG-06

U.S.GPM L /min 560 140 480 120 100 400 320 240 160 80 0 0 0 5

FBG-10

Metred Flow

Metred Flow

20 15 10 5 0

40 30 20 10 0

150 100 50 0 0 0 5 1000 10 15 2000 20 MPa 21 3000 PSI

Metred Flow

80 60 40 20 0

10

15 2000

20

MPa

1000

3000 PSI

Load Pressure

Load Pressure

Load Pressure

Metred Flow vs. Dial Position

Loading Pressure : 7 MPa(1020 PSI)

U.S.GPM 35 30 L /min 125 100

FBG-03

U.S.GPM 70 60 L /min 250 200 150 100 50 0 0 200 400 600 800 850

FBG-06

Flow Rate

25 20 15 10 5 0

Flow Rate

0 100 200 300 400 500 600 700

75 50 25 0

50 40 30 20 10 0

Dial Position

U.S.GPM 140 120 100 400 300 200 100 0 0 L /min 500

Fully Open

Dial Position

Fully Open

FBG-10

Flow Rate

80 60 40 20 0

100 200 300 400 500 600 700

Dial Position

Fully Open

No.6

Flow Control and Relief Valves FBG-03/06/10

Spare Parts List

FBG-03-125-10/1090 FBG-06-250-10/1090 FBG-10-500-10/1090

FLOW CONTROLS

CAUTION

When making replacement of seals, please do it carefully after reading through the relevant instructions in the Operator's Manual.

29 15 49 16 6 17 18 35 19 20 21 22

39

11

30

13 32

D

36 28 12 27

Section X-X

FBG-06,10

2 25 24

FBG-03

X

23 3 2 33 34 49 41 25 24

38 26 26 38 40 14 10 5 4 37 23 3 33 34 49 41 51 42 50 4 5 37 40

List of Seals

Item 33 34 35 36 37 38 39 40 41 42 Name of Parts Back Up Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring O-Ring FBG-03 SO-BB-P4 SO-NA-P4 SO-NA-P9 SO-NB-P9 SO-NB-P11 SO-NB-P28 SO-NB-P32 SO-NB-G30 SO-NB-G50 Part Numbers FBG-06 SO-BB-P4 SO-NA-P4 SO-NA-P9 SO-NB-P9 SO-NB-P11 SO-NB-P32 SO-NB-P42 SO-NB-P44 SO-NB-G50 SO-NB-P34 FBG-10 SO-BB-P4 SO-NA-P4 SO-NA-P9 SO-NB-P11 SO-NB-P11 SO-NB-P48 SO-NB-G55 SO-NB-G60 SO-NB-G50 SO-NB-P50 Qty. 1 1 1 1 1 3 2 1 1 1

List of Seal Kits

Model Numbers FBG-03 FBG-06 FBG-10 Seal Kit Numbers KS-FBG-03-10 KS-FBG-06-10 KS-FBG-10-10

Note: When ordering the seals, please specify the seal kit number from the table right.

No.7

Pub. EC-0303

RESTRICTORS

SRT/SRG-03/06/10 (3/8, 3/4, 1-1/4)

ONE WAY RESTRICTORS

SRCT/SRCG-03/06/10 (3/8, 3/4, 1-1/4)

Threaded Connections / Sub-plate Mounting

Up to 25 MPa (3630 PSI), 500 L/min (132 U.S.GPM)

FLOW CONTROLS

This valve is used to regulate an actuator speed in a circuit where line pressure is almost steady and small fluctuation of oil flow due to pressure changes is permitted. Integrated check valve allows reversed free flow from outlet to inlet port. Pressure balanced construction provides less effort in adjustment at high pressure.

Restrictors

One Way Restrictors

Hydraulic Fluids

Fluid Types Any type of hydraulic fluid listed in the table below can be used.

Petroleum base oils Synthetic fluids Water containing fluids Use fluids equivalent to ISO VG 32 or VG 46. Use phosphate ester or polyol ester fluid. When phosphate ester fluid is used, prefix "F-" to the model number because the special seals (fluororubber) are required to be used. Use water-glycol fluid.

Note: For use with hydraulic fluids other than those listed above, please consult your Yuken representatives in advance.

Recommended Viscosity and Temperatures Viscosity ranging between 15 - 400 mm2/s (77 - 1800 SSU). Oil temperatures between -15/+70C (5 - 158F). Use hydraulic fluids which satisfy the recommended viscosity and oil temperatures given above. Control of Contamination Due caution must be paid to maintaining control over contamination of the hydraulic fluids which may otherwise lead to breakdowns and shorten the life of the valves. Please maintain the degree of contamination within NAS 1638-Grade 12. Use 25 m or finer line filter.

No.1

Restrictors / One Way Restrictors SRT/SRG SRCT/SRCG -03/06/10

Specifications / Model Number Designation

Specifications

Model Numbers Valve Name Threaded Connection SRT-03-50/5080/5090 Restrictor SRT-06-50/5080/5090 SRT-10-50/5080/5090 SRCT-03-50/5080/5090 One Way Restrictor SRCT-06-50/5080/5090 SRCT-10-50/5080/5090 Sub-plate Mounting SRG-03-50/5090 SRG-06-50/5090 SRG-10-50/5090 SRCG-03-50/5090 SRCG-06-50/5090 SRCG-10-50/5090 Rated Flow L /min (U.S.GPM) 30 (7.9) 85 (22.4) 230 (60.7) 30 (7.9) 85 (22.4) 230 (60.7) 25 (3630) 25 (3630) Max. Operating Pres. MPa (PSI)

FLOW CONTROLS

Approx. Mass kg (lbs.) Threaded Connection 1.5 (3.3) 3.8 (8.4) 9.1 (20.1) 1.5 (3.3) 3.8 (8.4) 9.1 (20.1) Sub-plate Mounting 2.5 (5.5) 3.9 (8.6) 7.5 (16.5) 2.5 (5.5) 3.9 (8.6) 7.5 (16.5)

Rated flow stands for approximate flow rate when the pressure drop between inlet and outlet ports of the valve in fully opened condition becomes 0.3 MPa (44 PSI) maximum at fluid's specific gravity of 0.85 and kinematic viscosity of 20 mm2/s (98 SSU).

Graphic Symbols SRT / SRG

Yuken can offer flanged connection valves described below.

For details, contact us. Model Numbers SRF/SRCF-10-50 SRF/SRCF-10-5090 SRF/SRCF-16-50 SRF/SRCF-16-5090 Rated Flow L /min (U.S.GPM) 230 (60.7) 25 (3630) 500 (132) Max. Operating Pressure MPa (PSI)

SRCT / SRCG

Model Number Designation

FSpecial Seals

SR

Series Number

T

Type of Mounting

-03

Valve Size 03

-50

Design Number 50 50 50 50 50 50 50 50 50 50 50 50

Design Standards None : Japanese Std. "JIS" 80 : European Design Std. 90 : N.American Design Std. None : Japanese Std. "JIS" & European Design Std. 90 : N.American Design Std. None : Japanese Std. "JIS" 80 : European Design Std. 90 : N.American Design Std. None : Japanese Std. "JIS" & European Design Std. 90 : N.American Design Std.

T : Threaded Connection SR : Restrictor G: Sub-plate Mounting

06 10 03 06 10 03

F: Special Seals for Phosphate Ester Type Fluids (Omit if not required)

T : Threaded Connection SRC : One Way Restrictor G: Sub-plate Mounting

06 10 03 06 10

No.2

Restrictors / One Way Restrictors SRT/SRG SRCT/SRCG -03/06/10

Attachment / Sub-plate / Instructions

Attachment

Mounting Bolts

Valve Model Numbers SRG/SRCG-03 SRG/SRCG-06 SRG/SRCG-10 Socket Head Cap Screw Japanese Std. "JIS" and European Design Std. M10 45 Lg. M10 50 Lg. M10 55 Lg. N. American Design Std. 3/8-16 UNC 1-3/4 Lg. 3/8-16 UNC 2 Lg. 3/8-16 UNC 2-1/4 Lg. Qty. 4 4 6

FLOW CONTROLS

D

N. American Design Standard Sub-plate Model Numbers CRGM-03-5090 CRGM-03X-5090 CRGM-06-5090 CRGM-06X-5090 CRGM-10-5090 CRGM-10X-5090 Thread Size 3/8 NPT 1/2 NPT 3/4 NPT 1 NPT 1-1/4 NPT 1-1/2 NPT Approx. Mass kg (lbs.) 1.6 (3.5) 1.6 (3.5) 2.4 (5.3) 3.0 (6.6) 4.8 (10.6) 5.7 (12.6)

Sub-plate

Valve Model Numbers SRG SRCG -03 SRG SRCG -06 SRG SRCG -10 Japanese Standard "JIS" Sub-plate Model Numbers CRGM-03-50 CRGM-03X-50 CRGM-06-50 CRGM-06X-50 CRGM-10-50 CRGM-10X-50 Thread Size Rc 3/8 Rc 1/2 Rc 3/4 Rc 1 Rc 1-1/4 Rc 1-1/2 European Design Standard Sub-plate Model Numbers CRGM-03-5080 CRGM-03X-5080 CRGM-06-5080 CRGM-06X-5080 CRGM-10-5080 CRGM-10X-5080 Thread Size 3/8 BSP.F 1/2 BSP.F 3/4 BSP.F 1 BSP.F 1-1/4 BSP.F 1-1/2 BSP.F

Sub-plates are available. Specify the sub-plate model number from the table above. When sub-plates are not used, the mounting surface should have a good machined finish.

Instructions

Flow Adjustment Slacken the lock nut and turn the flow adjustment knob anti-clockwise to throttle flow. After achieving satisfactory performance tighten the lock nut.

No.3

Restrictors / One Way Restrictors SRT SRCT -03/06/10

Installation Drawings

SRT/SRCT-03-50/5080/5090 SRT/SRCT-06-50/5080/5090 SRT/SRCT-10-50/5080/5090

FLOW CONTROLS

DIMENSIONS IN MILLIMETRES (INCHES)

Flow Adjustment Handle

INC. C D 56 (2.20) Dia. K L

Lock Nut 19(.75) Hex. Fully Extended F

Controlled Flow Inlet or Reversed Free Flow Outlet Port "N" Thd.

"E" Dia.

Controlled Flow Outlet or Reversed Free Flow Inlet Port "N" Thd.

Model Numbers SRT/SRCT-03-50 SRT/SRCT-03-5080 SRT/SRCT-03-5090 SRT/SRCT-06-50 SRT/SRCT-06-5080 SRT/SRCT-06-5090 SRT/SRCT-10-50 SRT/SRCT-10-5080 SRT/SRCT-10-5090

Dimensions mm (Inches) C 72 (2.83) 100 (3.94) 138 (5.43) D 36 (1.42) 50 (1.97) 69 (2.72) E 44 (1.73) 58 (2.28) 80 (3.15) F 150.5 (5.93) 180 (7.09) 227 (8.94) H 53.5 (2.11) 66.5 (2.62) 86 (3.39) J 38 Dia. (1.50) 62 Sq. (2.44) 80 Sq. (3.15) K 46 (1.81) 64 (2.52) 82 (3.23) L 22 (.87) 31 (1.22) 40 (1.57)

Thd. Size "N" Thd. Rc 3/8 3/8 BSP.F 3/8 NPT Rc 3/4 3/4 BSP.F 3/4 NPT Rc 1-1/4 1-1/4 BSP.F 1-1/4 NPT

No.4

Restrictors / One Way Restrictors SRG SRCG -03

Installation Drawings

FLOW CONTROLS

Mounting surface: ISO 5781-AG-06-2-A

SRG/SRCG-03-50/5090

Flow Adjustment Handle Lock Nut 19(.75) Hex.

INC.

56 (2.20) Dia. Controlled Flow Outlet or Reversed Free Flow Inlet Port

31 (1.22)

D

Locating Pin 6(.24) Dia.

Fully Extended 150.5(5.93)

32 (1.26)

42.9 (1.69)

11(.43) Dia. Through 17.5(.69) Dia. Spotface 4 Places

11.7 (.46)

33.3 (1.31) 66.7 (2.63) 90 (3.54)

Controlled Flow Inlet or Reversed Free Flow Outlet Port

30 (1.18) 64 (2.52)

Mounting Surface (O-Rings Furnished) 6 (.24)

DIMENSIONS IN MILLIMETRES (INCHES)

Sub-plate 03 CRGM- 03X -50/5080/5090

10 (.39) 1.7 (.07) 8.8(.35) Dia. Through 14(.55) Dia. Spotface 4 Places 42.9 (1.69) 35.7 (1.41) 31.8 (1.25) 90 (3.54) 70 (2.76) 66.7 (2.63) 33.3 (1.31) 13(.51) Dia. 2 Places 32 (1.26) 15 (.59)

"B" Thd. 20(.79) Deep 4 Places

7.1 (.28)

"A" Thd. (From Rear) 2 Places

7(.28) Dia. 10(.39) Deep

Sub-plate Model Numbers CRGM-03-50 CRGM-03-5080 CRGM-03-5090 CRGM-03X-50 CRGM-03X-5080 CRGM-03X-5090

"A" Thd. Rc 3/8 3/8 BSP.F 3/8 NPT Rc 1/2 1/2 BSP.F 1/2 NPT

10 (.39)

19.5 (.77) 21 (.83) 61 (2.40) 82 (3.23) 102 (4.02)

"B" Thd. M10 3/8-16 UNC M10 3/8-16 UNC

90 (3.54)

No.5

Restrictors / One Way Restrictors SRG SRCG -06

Installation Drawings

FLOW CONTROLS

Mounting surface: ISO 5781-AH-08-2-A

SRG/SRCG-06-50/5090

Flow Adjustment Handle

INC. 56 (2.20) Dia. 37 (1.46)

Lock Nut 19(.75) Hex.

Controlled Flow Outlet or Reversed Free Flow Inlet Port

Locating Pin 6(.24) Dia. Fully Extended 180(7.09)

36.5 (1.44)

60.3 (2.37)

11(.43) Dia. Through 17.5(.69) Dia. Spotface 4 Places

11.3 (.44)

39.7 (1.56) 79.4 (3.13) 102 (4.02)

Controlled Flow Inlet or Reversed Free Flow Outlet Port

35 (1.38) 36 (1.42) 79 (3.11)

Mounting Surface (O-Rings Furnished) 6 (.24)

Sub-plate 06 CRGM- 06X -50/5080/5090

102 (4.02) 79.4 (3.13) 39.7 (1.56) 22(.87) Dia. 2 Places

DIMENSIONS IN MILLIMETRES (INCHES)

11.3 (.44) 8.8(.35) Dia. Through 14(.55) Dia. Spotface 4 Places

E "K" Thd. 20(.79) Deep 4 Places 15 (.59)

60.3 (2.37) 49.2 (1.94) 44.5 (1.75)

104 (4.09)

22 (.87)

11.1 (.44)

"J" Thd. (From Rear) 2 Places

7(.28) Dia. 10(.39) Deep

Sub-plate Model Numbers CRGM-06-50 CRGM-06-5080 CRGM-06-5090 CRGM-06X-50 CRGM-06X-5080 CRGM-06X-5090

Dimensions A 124 (4.88) B 10 (.39) C 77 (3.03) 82.3 (3.24) 136 (5.35) 16 (.63) 80 (3.15) 82.3 (3.24)

mm (Inches) D 27 (1.06) E 36 (1.42) F 110 (4.33) H 7 (.28)

"J" Thd. Rc 3/4 3/4 BSP.F 3/4 NPT Rc 1

"K" Thd. M10 3/8-16 UNC M10 3/8-16 UNC

22 (.87) 24 (.94) 22 (.87) 45 (1.77) 136 (5.35) 0

1 BSP.F 1 NPT

No.6

Restrictors / One Way Restrictors SRG SRCG -10

Installation Drawings

SRG/SRCG-10-50/5090

FLOW CONTROLS

Mounting surface: ISO 5781-AJ-10-2-A

Flow Adjustment Handle Lock Nut 19(.75) Hex.

INC. 56 (2.20) Dia. Controlled Flow Outlet or Reversed Free Flow Inlet Port 42 (1.65)

D

Locating Pin 6(.24) Dia.

Fully Extended 227(8.94)

84.1 (3.31) 44 (1.73)

42.1 (1.66)

11(.43) Dia. Through 17.5(.69) Dia. Spotface 6 Places

11.1 (.44)

48.4 (1.91) 96.8 (3.81) 119 (4.69)

Controlled Flow Inlet or Reversed Free Flow Outlet Port

40 (1.57) 41 (1.61) 90 (3.54)

Mounting Surface (O-Rings Furnished)

6 (.24)

Sub-plate 10 CRGM- 10X -50/5080/5090

12 (.47) 9.6 (.38) 11(.43) Dia. Through 17.5(.69) Dia. Spotface 4 Places 140 (5.51) 116 (4.57) 96.8 (3.81) 48.4 (1.91)

DIMENSIONS IN MILLIMETRES (INCHES)

28(1.10) Dia. 2 Places 7(.28) Dia. 10(.39) Deep

E 19 (.75)

84.1 (3.31) 67.5 (2.66) 62.7 (2.47) 42.1 (1.66)

126 (4.96)

21 (.83)

16.7 (.66)

"H" Thd. (From Rear) 2 Places

11.6 (.46) 120 (4.72)

"J" Thd. 20(.79) Deep 6 Places

Sub-plate Model Numbers CRGM-10-50 CRGM-10-5080 CRGM-10-5090 CRGM-10X-50 CRGM-10X-5080 CRGM-10X-5090

Dimensions A 150 (5.91) B 12 (.47) C 96 (3.78)

mm (Inches) D 30 (1.18) E 45 (1.77) F

"H" Thd.

"J" Thd.

Rc 1-1/4 M10 135 1-1/4 BSP.F (5.31) 1-1/4 NPT 3/8-16 UNC Rc 1-1/2 M10 167 1-1/2 BSP.F (6.57) 1-1/2 NPT 3/8-16 UNC

177 (6.97)

25.5 (1.00)

104 (4.09)

22 (.87)

50 (1.97)

No.7

Restrictors / One Way Restrictors SRT/SRG SRCT/SRCG -03/06/10

Performance Characteristics

Hydraulic Fluid: Viscosity 30 mm2/s (141 SSU), Specific Gravity 0.850

FLOW CONTROLS

Metred Flow vs Adjustment Handle Revolutions

P: Differential Pressure MPa (PSI)

SRT SRCT SRG-03, SRCG-03

P=25 (3630) P=20 (2900) P=16 (2320) U.S.GPM L /min 45 11 40 10 35 8 30 25 6 20 4 15 10 2 5 0 0 0 1 2 P=10 (1450) P=7 (1020)

SRT SRCT SRG-06, SRCG-06

P=16 (2320) P=10 (1450) P=7 (1020) U.S.GPM L /min 120 30 25 100 80 60 40 20 0 0 1 2 3 4 5 6 7 8 9 10 P=4 (580) P=2 (290) P=1 (145) P=0.5 (70) P=20 (2900) P=25 (3630)

Flow Rate

Flow Rate

P=4 (580) P=2 (290) P=1 (145) P=0.5 (70)

20 15 10 5

Fully Open Adj. Handle Position (Number of turns)

Fully Open Adj. Handle Position (Number of turns)

SRT SRCT SRG-10, SRCG-10

P=16 (2320) P=10 (1450) U.S.GPM 90 80 70 60 50 40 30 20 10 0 L /min 350 300 250 200 150 100 50 0 0 P=7 (1020) P=4 (580) P=2 (290) P=1 (145) P=0.5 (70) P=20 (2900) P=25 (3630)

Flow Rate

10

12

14

Fully Open Adj. Handle Position (Number of turns)

Pressure Drop

SRT SRCT SRG-03, SRCG-03

PSI 50 40 30 20 10 0 MPa 0.4 0.3 0.2 0.1 0 0 5 10 15 20 25 30 35 40 45 L /min 0 2 4 6 8 10 12 U.S.GPM

SRT SRCT SRG-06, SRCG-06

PSI 50 40 30 20 10 0 MPa 0.4 0.3 0.2 0.1 0 0 20 0 5 40 10 60 15 80 100 120 L /min 20 25 30 U.S.GPM

Pressure Drop

Controlled Flow Spool Fully Open

Pressure Drop

Free Flow Spool Closed

Free Flow Spool Closed

Controlled Flow Spool Fully Open

Flow Rate

Flow Rate

SRT SRCT SRG-10, SRCG-10

PSI 70 60 50 40 30 20 10 0

Pressure Drop

MPa 0.5 0.4 0.3 0.2 0.1 0 0 0

Free Flow Spool Closed

Controlled Flow Spool Fully Open 100 20 40 200 60 300 350 L /min 80 90 U.S.GPM

Flow Rate

Applicable only for one way restrictor (Model No. SRC)

No.8

Restrictors / One Way Restrictors SRT/SRG SRCT/SRCG -03/06/10

Spare Parts List

SRT/SRCT-03-50/5080/5090 SRT/SRCT-06-50/5080/5090 SRT/SRCT-10-50/5080/5090

FLOW CONTROLS

CAUTION

When making replacement of seals, please do it carefully after reading through the relevant instructions in the Operator's Manual.

17 16 10

9 4 15 5

For SRCT

3 2 14 12 11 18 6 7 1 13 8

List of Seals

Item 12 13 14 Name of Parts O-Ring O-Ring O-Ring Part Numbers SRT -10 SRT -06 SRT -03 SRCT SRCT SRCT SO-NB-P7 SO-NB-P7 SO-NB-P7 SO-NB-P29 SO-NB-P15 SO-NB-P21 SO-NB-P20 SO-NB-P22.4 SO-NB-P36 Qty. 1 1 1

List of Seal Kits

Model Numbers SRT/SRCT-03 SRT/SRCT-06 SRT/SRCT-10 Seal Kit Numbers KS-SRT-03-50 KS-SRT-06-50 KS-SRT-10-50

Note: When ordering the seals, please specify the seal kit number from the table right.

SRG/SRCG-03-50/5090 SRG/SRCG-06-50/5090 SRG/SRCG-10-50/5090

For SRCG

10 17 18 9 4 16 3 12 15 19 5 1 2 14 6 11 20 7 13 8

List of Seals

Item 12 13 14 15 Name of Parts O-Ring O-Ring O-Ring O-Ring SRG -03 SRCG SO-NB-P7 SO-NB-P15 SO-NB-P20 SO-NB-P18 Part Numbers SRG -06 SRCG SO-NB-P7 SO-NB-P21 SO-NB-P22.4 SO-NB-P28 SRG -10 SRCG SO-NB-P7 SO-NB-P29 SO-NB-P36 SO-NB-P32 Qty. 1 1 1 2

List of Seal Kits

Model Numbers SRG/SRCG-03 SRG/SRCG-06 SRG/SRCG-10 Seal Kit Numbers KS-SRG-03-50 KS-SRG-06-50 KS-SRG-10-50

Note: When ordering the seals, please specify the seal kit number from the table right.

No.9

Pub. EC-0304

THROTTLE MODULES TC1G-01 / 03 (1 / 8 , 3 / 8) THROTTLE AND CHECK MODULES TC2G-01 / 03 (1 / 8 , 3 / 8) Gasket Mounting

Specifications / Model Number Designation Up to 25 MPa (3630 PSI), 80 L/min (21.1 U.S.GPM)

Used as pilot choke valves for solenoid controlled pilot operated directional valves and pilot operated directional valves.

FLOW CONTROLS

D

Graphic Symbols

Throttle Modules Valve Size Standard Type

Solenoid Operated Directional Valve

Throttle and Check Modules Standard (Metre-out) Type

Solenoid Operated Directional Valve

With Check

Metre-in Type

01

P A B T P A B T