Documente Academic

Documente Profesional

Documente Cultură

12-16V4000 Gx3 3B Maintenance Schedule MS50005 - 00E

Încărcat de

Juan Carlos Mino EnequeDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

12-16V4000 Gx3 3B Maintenance Schedule MS50005 - 00E

Încărcat de

Juan Carlos Mino EnequeDrepturi de autor:

Formate disponibile

Technical Documentation

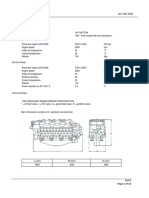

Diesel Engine 12 V 4000 Gx3 16 V 4000 Gx3 Application group 3B Maintenance Schedule MS50005/00E

Maintenance schedule 12/16V 4000 Gx3 3B

01

Preface

MTU maintenance concept

The maintenance system for MTU products is based on a preventive maintenance concept. Preventive maintenance facilitates advance planning and ensures a high level of equipment availability. The maintenance schedule is based on the load profile / load factor specified below. The time intervals at which the maintenance work is to be carried out and the relevant checks and tasks involved are average values based on operational experience and are therefore to be regarded as guidelines only. Special operating conditions and technical requirements may require additional maintenance work and/or modification of the maintenance intervals. In order to be authorized to carry out the individual maintenance jobs, maintenance personnel must have achieved a level of training and qualification appropriate to the complexity of the task in hand. The various Qualification Levels QL1 to QL4 reflect the levels of training offered in MTU courses and the contents of the tool kits required: QL1:Operational monitoring and maintenance which can be carried out during a break in operation without disassembling the engine. QL2:Component exchange (corrective only). QL3:Maintenance work which requires partial disassembly of the engine. QL4:Maintenance work which requires complete disassembly of the engine. The maintenance schedule matrix normally finishes with extended component maintenance. Following this, maintenance work is to be continued at the intervals indicated. The "Task" numbers stated in the list of jobs to be done/action to be taken indicate the relevant maintenance item. They provide a reference to the scope of parts required and appear on the labels of the appropriate replacement parts.

Notes on maintenance

Specifications for fluids and lubricants, guideline values for their maintenance and change intervals and lists of recommended fluids and lubricants are contained in the MTU Fluids and Lubricants Specifications A001061 and in the fluids and lubricants specifications produced by the component manufacturers. They are therefore not included in the maintenance schedule (exception: deviations from the Fluids and Lubricants Specifications). All fluids and lubricants used must meet MTU specifications and be approved by the relevant component manufacturer. Amongst other items, the operator/customer must carry out the following additional maintenance work: Protect components made of rubber or synthetic material from oil. Never treat them with organic detergents. Wipe with a dry cloth only. Fuel prefilter: The maintenance interval depends on how dirty the fuel is. The paper inserts in fuel prefilters must be changed every two years at the latest (Task 9998). Battery: Battery maintenance depends on the level of use and the ambient conditions. The battery manufacturers instructions must be obeyed. The relevant manufacturers instructions apply with respect to the maintenance of any components which do not appear in this maintenance schedule. This Maintenance Schedule may include components which are not installed on your engine; these may be disregarded.

Out-of-service periods

If the engine is to remain out of service for more than 1 month, carry out engine preservation procedures in accordance with the Fluids and Lubricants Specifications, MTU Publication No. A001061.

Application group

3B Continuous operation with variable load

MS50005/00E

07-02

MTU

02

Maintenance schedule 12/16V 4000 Gx3 3B

Maintenance schedule matrix

0-10.000 Operating hours

Limit, years Item Operating hours [h] 10.000 X X X X X X X X X X X X 1.000 1.500 2.000 2.500 3.000 3.500 4.000 4.500 5.000 5.500 6.000 6.500 7.000 7.500 8.000 8.500 X 9.000 X X X X X 9.500 X Daily X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Engine oil filter Engine operation Centrifugal oil filter Valve gear Fuel filter Belt drive Air filters Fuel injectors Combustion chambers Rubber sleeves Crankcase breathers Turbochargers Component maintenance Fuel delivery pump Cylinder heads Extended component maintenance

2 2 2 2 3 4 5 18

MS50005/00E

07-02

500

MTU

Maintenance schedule 12/16V 4000 Gx3 3B

03

3

Qualification level QL1 QL1

Maintenance tasks

Interval [h] [a] 2 Engine oil filter Engine operation Fit new engine oil filters each time the engine oil is changed or, at the latest, on expiry of the time limit (given in years). . Check engine oil level . Carry out visual inspection of engine for general condition and leaks. . Inspect intercooler drain system (if fitted). . Inspect service indicator of air filter. . Check relief bores of water pump(s). . Check for abnormal running noises, exhaust gas colour and vibration. . Drain off water and contamination from fuel prefilter (if fitted). . Check service indicator of fuel prefilter (if fitted). . W1008 W0500 W0501 W0502 W0503 W0505 W0506 W0507 W0508 W1009 W1002 W1001 W1241 W1005 W1006 W1011 W1250 W1046 W1041 W2000 W2002 W2003 W2004 W2006 W2007 W2008 W2009 W2010 W2011 W2070 Item Maintenance tasks Task

Daily

QL1 QL1 QL1 QL1 QL1 QL1 QL1 QL1 QL1 QL3 QL3

500 1.000 1.000 1.500 3.000 5.000 5.000 5.000 10.000 10.000 10.000

2 2 2 3 4 5 -

Centrifugal oil filter Valve gear Fuel filter Belt drive Air filters Fuel injectors Combustion chambers Rubber sleeves Crankcase breathers Turbochargers Component maintenance

Centrifugal oil filter (if fitted): Check thickness of oil residue layer, clean and fit new sleeve. . Check valve clearance. . Fit new fuel filter or new fuel filter insert. . Inspect condition of drive belts and fit new ones if necessary. Adjust tension. Fit new air filters. . Fit new fuel injectors. . Inspect cylinder chambers using endoscope. . Exchange all rubber sleeves. Crankcase breathers: Fit new filters or filter inserts. Fit new turbochargers. . Before starting maintenance work, drain the coolant and flush the cooling systems. Clean air ducting. . Clean intercoolers and inspect for leakage. . Fit new high-pressure sensor in fuel system. . Check engine coolant thermostat and fit new thermal actuator. . Check charge-air coolant thermostat and fit new thermal actuator. . Overhaul engine coolant preheating system (if fitted). . Inspect centrifugal oil filter for wear (if fitted). . Overhaul starter. . Inspect vibration damper . Overhaul charge air coolant pump. .

MS50005/00E

07-02

MTU

04

Maintenance schedule 12/16V 4000 Gx3 3B

Qualification level

Interval [h] [a]

Item

Maintenance tasks

Task

Fit new sealing materials for all components disassembled. . Overhaul engine coolant pump QL3 QL3 QL4 10.000 10.000 10.000 18 Fuel delivery pump Cylinder heads Extended component maintenance Fit new fuel delivery pump. . Overhaul cylinder heads Completely disassemble the engine. Inspect engine components as per Maintenance Manual instructions and repair or fit new components as required. . Exchange all elastomeric parts and seals for new ones. . Fit new piston rings. . Fit new conrod bearings. . Fit new crankshaft bearings. . Fit new cylinder liners. . Fit new antifriction bearings for auxiliary PTOs. . Fit new high-pressure fuel pump. . Overhaul battery-charging generator. .

W2062 W2110 W1051 W1134 W3000

W3001 W3002 W3003 W3004 W3005 W3006 W3007 W3042

MS50005/00E

07-02

MTU

S-ar putea să vă placă și

- Maintenance Schedule 6R183 - M050525 - 02EDocument4 paginiMaintenance Schedule 6R183 - M050525 - 02EdattienÎncă nu există evaluări

- MTU 4000 Maintenance ScheduleDocument35 paginiMTU 4000 Maintenance Schedulenereomad100% (8)

- Plan de Manteniemiento m53 MtuDocument9 paginiPlan de Manteniemiento m53 MtuNippur de LagashÎncă nu există evaluări

- MS15018 01eDocument162 paginiMS15018 01eاشرينكيل مسونكيلÎncă nu există evaluări

- 16 V 4000Document4 pagini16 V 4000aup0% (1)

- 3A Maintenance M050733 - 06EDocument10 pagini3A Maintenance M050733 - 06ELiya Mahagama100% (1)

- MTUDocument16 paginiMTUWira Karya Diesel40% (5)

- Мануал L33 - new - MS50199 - 01EDocument16 paginiМануал L33 - new - MS50199 - 01EAleksey100% (1)

- Part Catalog MTU 12V 4000 M73, M73L PDFDocument813 paginiPart Catalog MTU 12V 4000 M73, M73L PDFDimas Saputro100% (2)

- 4000 G OverhoolDocument745 pagini4000 G Overhoolaup100% (2)

- S 1600 Diesel Gen SetsDocument47 paginiS 1600 Diesel Gen Setslcsandovalr989100% (1)

- 12V Mtu 4000Document248 pagini12V Mtu 4000Mig Vazq100% (5)

- Diesel Engines 20V 4000 M93/M93L: For Vessels With Low Load Factors (1DS)Document3 paginiDiesel Engines 20V 4000 M93/M93L: For Vessels With Low Load Factors (1DS)Alberto100% (1)

- Maintenance Schedule: Diesel Engine 16V4000M73 Application Group 1BDocument27 paginiMaintenance Schedule: Diesel Engine 16V4000M73 Application Group 1BDimas SaputroÎncă nu există evaluări

- MTU TurbochargingDocument6 paginiMTU Turbochargingguichen wang0% (1)

- Especificaciones Mtu PDFDocument11 paginiEspecificaciones Mtu PDFCeciliagorraÎncă nu există evaluări

- Operating Instructions: Diesel Engine 12 V 4000 T94, T94LDocument197 paginiOperating Instructions: Diesel Engine 12 V 4000 T94, T94LCristian A.Încă nu există evaluări

- E532284 - Funcional Descrition MtuDocument42 paginiE532284 - Funcional Descrition MtuNippur de Lagash100% (1)

- Installation Conditions: Gas Engine-Generator Sets With Series 400, Series 500, and Series 4000 EnginesDocument62 paginiInstallation Conditions: Gas Engine-Generator Sets With Series 400, Series 500, and Series 4000 EnginesBen ZithaÎncă nu există evaluări

- MTU 4000 Series Diesel Engines for Stationary PowerDocument6 paginiMTU 4000 Series Diesel Engines for Stationary PowerMohamed Naser100% (6)

- Dvigatel Mtu 12v2000g65eDocument155 paginiDvigatel Mtu 12v2000g65eAziz Arrahal100% (1)

- Diesel Engines 8V 2000 M70 (BM 531.923) 12V 2000 M70 (BM 535.923) 16V 2000 M70 (BM 536.923) Maintenance Schedule M050540/02EDocument4 paginiDiesel Engines 8V 2000 M70 (BM 531.923) 12V 2000 M70 (BM 535.923) 16V 2000 M70 (BM 536.923) Maintenance Schedule M050540/02EsxturboÎncă nu există evaluări

- 4 Maintenance Schedule MS50233 01EDocument47 pagini4 Maintenance Schedule MS50233 01EImran Ul HaqÎncă nu există evaluări

- Mtu 16v4000g63Document196 paginiMtu 16v4000g63Manuel Perez0% (1)

- 16V4000 - Parts Manual 5272010459 - enDocument200 pagini16V4000 - Parts Manual 5272010459 - enDeepak Deep100% (3)

- Workshop Manual MTU4000R41Document1.846 paginiWorkshop Manual MTU4000R41AnuruddhaSamaradiwakara93% (15)

- MTU 12V4000M53 Spare Parts Catalog PDFDocument745 paginiMTU 12V4000M53 Spare Parts Catalog PDFkhaireddin100% (2)

- MTU 16V 2000 M93 Brochure SpecificationDocument2 paginiMTU 16V 2000 M93 Brochure SpecificationPedro Mas0% (1)

- Diesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)Document2 paginiDiesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)zaki100% (1)

- MTU Solution Guide Marine Oct 2022Document59 paginiMTU Solution Guide Marine Oct 2022TwinÎncă nu există evaluări

- Mtu - Oil & Gas Sales ProgramDocument63 paginiMtu - Oil & Gas Sales Programalamen ZayidÎncă nu există evaluări

- Maintenance Schedule: Diesel Engine V 4000 Mx0 Application Group 1DSDocument25 paginiMaintenance Schedule: Diesel Engine V 4000 Mx0 Application Group 1DSNabesterNajam0% (1)

- Mtu 16v2000g65 PDFDocument144 paginiMtu 16v2000g65 PDFPhạm Hoài AnhÎncă nu există evaluări

- MTU Gendrive Diesel Engine Sales ProgramDocument55 paginiMTU Gendrive Diesel Engine Sales ProgramEdutamÎncă nu există evaluări

- MTU 12V4000M53 Spare Parts CatalogDocument745 paginiMTU 12V4000M53 Spare Parts Catalogangelo01793% (15)

- Technical - Info MTU 20V4000L62Document7 paginiTechnical - Info MTU 20V4000L62Marvin Tejerina Garfias100% (1)

- MTU Marine SalesProgramDocument49 paginiMTU Marine SalesProgramselleriverket100% (1)

- Manual MTUDocument134 paginiManual MTUjuan pablo zuniga100% (2)

- MTU White Paper Electronic Engine ManagementDocument4 paginiMTU White Paper Electronic Engine ManagementDeepak ChachraÎncă nu există evaluări

- Operating Instructions Diesel Engine MTUDocument204 paginiOperating Instructions Diesel Engine MTUBradley Lodder100% (3)

- MTU Series 10V1600 ESN 6601002253Document154 paginiMTU Series 10V1600 ESN 6601002253Taz Uddin100% (2)

- Catalogo Afa Cummins QSK45 Series PDFDocument76 paginiCatalogo Afa Cummins QSK45 Series PDFAlexis Sanchez100% (2)

- Mtu 2000 Series MarineDocument5 paginiMtu 2000 Series MarineAlbertoÎncă nu există evaluări

- ADEC Genset Functions and ParameterDocument52 paginiADEC Genset Functions and ParameterRizki Heru Hermawan83% (23)

- 8V4000M70Document143 pagini8V4000M70chuminhÎncă nu există evaluări

- MTU 4000 With MIP v1.8Document23 paginiMTU 4000 With MIP v1.8Aurelio Serrano100% (2)

- Mtu Reach SVHC 2018-10-29 enDocument75 paginiMtu Reach SVHC 2018-10-29 enalawi50% (2)

- EN Cargador 31. 23-07-18 PDFDocument202 paginiEN Cargador 31. 23-07-18 PDFCalixto Rafael Cantillo Toncel100% (1)

- MTU Preservations Strategy UpdateDocument49 paginiMTU Preservations Strategy Updatebambang100% (2)

- 1600 Series Parts and OverviewDocument94 pagini1600 Series Parts and OverviewJorge Eraldo Albarran PoleoÎncă nu există evaluări

- Sales Program Oil Gas Industry MTU ShopDocument83 paginiSales Program Oil Gas Industry MTU ShopBogdan ApostolÎncă nu există evaluări

- ADEC™ - Error List - 2006 - MTU® PDFDocument33 paginiADEC™ - Error List - 2006 - MTU® PDFpevare100% (4)

- Spare Part Catalog 12 V 4000 G23R/526108120Document205 paginiSpare Part Catalog 12 V 4000 G23R/526108120aouinahabib100% (1)

- 00a MTU Abreviation ListDocument12 pagini00a MTU Abreviation ListJuan Rivera100% (2)

- Mtu - Technical Documentation: ServiceDocument7 paginiMtu - Technical Documentation: Servicekarbaran1391Încă nu există evaluări

- Maint Sched 12 or 8 V183 TE93Document4 paginiMaint Sched 12 or 8 V183 TE93dieseldogwillie100% (2)

- Maintenance Schedule TCG2020KDocument8 paginiMaintenance Schedule TCG2020KHendri Bowo100% (2)

- MS50117_01E_12_16_18V2000G05_3B_3DDocument12 paginiMS50117_01E_12_16_18V2000G05_3B_3DVanHoangÎncă nu există evaluări

- QSV Gas Gen-Set Maintenance GuideDocument16 paginiQSV Gas Gen-Set Maintenance GuideJuan Jose RodriguezÎncă nu există evaluări

- Maintenance Schedule For WARTSILA 20 B-C Engines Wfi 2004N007 02gbDocument12 paginiMaintenance Schedule For WARTSILA 20 B-C Engines Wfi 2004N007 02gbDimitris Paliktoglou100% (4)

- BH35 2Document4 paginiBH35 2Bipin KumarÎncă nu există evaluări

- Válvula de Alivio Vicking - AGF 7000Document2 paginiVálvula de Alivio Vicking - AGF 7000Maurilio Batista de LimaÎncă nu există evaluări

- Module 10 WoodDocument9 paginiModule 10 WoodMinari ChaengÎncă nu există evaluări

- CylindersDocument17 paginiCylindersEng-Mohammed SalemÎncă nu există evaluări

- 5500 Centrifuge Hydraulic Backdrive Operations ManualDocument138 pagini5500 Centrifuge Hydraulic Backdrive Operations ManualTaher Yusuf0% (1)

- Characteristics Series CE, CP, C: 2 Way Slip-In Cartridge ValvesDocument17 paginiCharacteristics Series CE, CP, C: 2 Way Slip-In Cartridge Valvess_waqarÎncă nu există evaluări

- Gastec Qa 198Document24 paginiGastec Qa 198CristianÎncă nu există evaluări

- Integrated Control of Braking and SteeringDocument10 paginiIntegrated Control of Braking and SteeringakkkkÎncă nu există evaluări

- 1190 1Document88 pagini1190 1TONÎncă nu există evaluări

- Single Aisle Maintenance Practice Training Manual CFM56 Engine Run Up Course (M70) ChecklistsDocument28 paginiSingle Aisle Maintenance Practice Training Manual CFM56 Engine Run Up Course (M70) ChecklistsLucas GabrielÎncă nu există evaluări

- Transverse Analysis of Full-Scale Precast Segmental Box Girder Segments WithDocument11 paginiTransverse Analysis of Full-Scale Precast Segmental Box Girder Segments WithbistsushantÎncă nu există evaluări

- Design Report of Diesel Engine, Air Cooled (15Kw)Document26 paginiDesign Report of Diesel Engine, Air Cooled (15Kw)Roshan ShajuÎncă nu există evaluări

- GT 1 Serdang Exh Repair ReportDocument4 paginiGT 1 Serdang Exh Repair ReportIB IsmadyÎncă nu există evaluări

- LEKX6306 Torque CurvesDocument11 paginiLEKX6306 Torque Curvesmijael1393100% (1)

- MeasurIT Flexim Fastening Parts 0910Document5 paginiMeasurIT Flexim Fastening Parts 0910cwiejkowskaÎncă nu există evaluări

- Kr451 Nepiro Ergo PR enDocument4 paginiKr451 Nepiro Ergo PR enForum PompieriiÎncă nu există evaluări

- Moment and Centre of gravity-CIE NOTESDocument7 paginiMoment and Centre of gravity-CIE NOTESJennieÎncă nu există evaluări

- Fixed Free Fixed Free Plate PDFDocument7 paginiFixed Free Fixed Free Plate PDFbeenaÎncă nu există evaluări

- Anchor Bolt Design Using Anchor ReinforcementDocument8 paginiAnchor Bolt Design Using Anchor Reinforcementtiger_lxfÎncă nu există evaluări

- Escort Limited Champion F 11 Brand Name - FarmtracDocument12 paginiEscort Limited Champion F 11 Brand Name - Farmtrachugo fernandezÎncă nu există evaluări

- Laws of Floatation ExplainedDocument2 paginiLaws of Floatation Explainedtarak dasÎncă nu există evaluări

- Repair Stuck Grease Pumps EX2600-7Document7 paginiRepair Stuck Grease Pumps EX2600-7TLK ChannelÎncă nu există evaluări

- BQ Rmu PlinthDocument3 paginiBQ Rmu Plinthaqeel_al_triniÎncă nu există evaluări

- Gear TrainsDocument16 paginiGear Trainsraju100% (1)

- Basic Motor Technical + Safe Area MotorsDocument74 paginiBasic Motor Technical + Safe Area MotorsmayureshrmahajanÎncă nu există evaluări

- Branch Name B.E. Aeronautical Engineering: Semes Ter Subject Name Subject Code Exam Date SessionDocument99 paginiBranch Name B.E. Aeronautical Engineering: Semes Ter Subject Name Subject Code Exam Date SessionCoding HintsÎncă nu există evaluări

- 9 Info and Work Sheet Service Steering System2Document47 pagini9 Info and Work Sheet Service Steering System2DEATHSTAR GAMINGÎncă nu există evaluări

- Hydraulic Accumulator (High Pressure) - Test and Charge: Pruebas y AjustesDocument16 paginiHydraulic Accumulator (High Pressure) - Test and Charge: Pruebas y AjustesBrayan Sánchez ParedesÎncă nu există evaluări

- Edge Effects in Thin Film DelaminationDocument15 paginiEdge Effects in Thin Film DelaminationAdamRaczÎncă nu există evaluări

- Group 7 Final Project PhysicsDocument8 paginiGroup 7 Final Project PhysicsJoshua Ray MananquilÎncă nu există evaluări