Documente Academic

Documente Profesional

Documente Cultură

Centralizers

Încărcat de

DanielDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Centralizers

Încărcat de

DanielDrepturi de autor:

Formate disponibile

Acta Montanistica Slovaca

Ronk 3 (1998), 1, 24-28

Procedure for Arranging Centralizers in Casing String Run into Directional Wells

Andrzej Gonet 1, Stanislaw Stryczek 1 and Jn Pinka 2

Postup pre rozmiestnenie centrtorov na panicovej kolne urenej pre zapaenie v horizontlnch vrtoch Centrtory patria medzi najdleitejie elementrne ast technickho vybavenia panicovch koln. Centrick umiestenie panicovej kolny, obzvl v horizontlnom vrte, je jednou z podmienok kvalitnej cementcie vrtu. Centrtory s prostriedkami pre centrciu panicovej kolny a umouj rovnomern zaplnenie medzikruia vrtu cementovou suspenziou. Tento lnok pojednva o postupe metdy pre rozmiestenie minimlneho potrebnho potu centrtorov na panicovej kolne, ktor je uren pre zapaenie horizontlneho vrtu. Key words: Centralizer, Casing String, Directional Well, Three - Dimensional Space, Borehole Well.

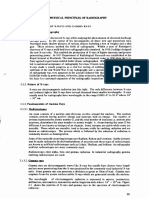

Introduction Centralizers (Weatherford, 1994) are one of the most important elementary parts of technical equipment of a casing string. Currently throughout the world more and more directional holes are being drilled, which are often located in three-dimensional space. Generally it can be said the more complicated the hole axis, the more difficult it is to maintain coaxial placement of a casing string run into such a hole. Centralizers play a significant role in limiting a number of columns of a casing string run to a hole and in minimizing the clearances in the hole (Lubinski, 1987; Wisniowski et.al., 1995). Maintaining the right clearance between the wall of the hole and the casing columns has critical impact on the quality of its sealing. Placing too many centralizers on the casing string seriously impedes running pipes into the hole and unnecessarily increases the overall cost of the hole. On the other hand too few centralizers on the casing string will not ensure proper sealing of the hole. For this reason the aim is to develop a kind of method for placing centralizers on a casing string which would take into account the spatial position of the hole as well as the load of the casing string with a minimum number of centralizers. An attempt at viewing this problem in such a light is presented in this article. At the present time when sealing of casing strings is carried out, their construction as well as recipes for sealing slurries are very carefully selected, taking into consideration such factors as the influence of temperature, pressure and time on technological parameters. The field equipment used to prepare and pump sealing slurries into the hole is continually being improved. The Casing String Load The casing string run into the hole is subject to various loads, the most important of which are axial tension, compressing, bending and torison (Gonet, 1997). Centralizers located on the casing torsion-string mediate in the above-mentioned loads and are places of contact with the holewall. The system of Kirchhoff equations was chosen for this discussion on the casing string load with centralizers run into holes. Given the assumptions presumed in this study (Gonet, 1997), the unit stresses acting on a centralizer along tangent, normal and binormal axes of the hole (Fig. 1) amount to:

N 1 = ks 2 EI q cos

1 2

[ N/m]

(1)

Faculty of Drilling, Oil and Gas, Unvezity of Mining and Metallurgy, Cracow, Poland Katedra mechanizcie, dopravy a vtania, F BERG, Technick univerzita, 043 84 Koice, Park Komenskho 14, Slovakia (Recenzovali: Prof.Ing. Jn Fabian, CSc. a Ing. Vazoslav Krpa, CSc. Revidovan verzia doruen 15.2.1998)

25

Gonet, Stryczek and Pinka: Procedure for Arranging Centralizers in Casing String Run into Directional Wells

N 2 = ks2 EI ksM1 kT1 q sin N 3 = s 3 EI

[ N/m] [ N/m]

(2) (3)

where: N1, N2, N3 T1 E I q M 1 k s - unit stress of casing along axes x , x , x respectively [ N/m] , 1 2 3 - tangent tensile force of the casing [ N], 2 - Youngs modulus of the casing material [ N/m ], 4 - axial moment of inertia [m ] , - unit weight of the casing immersed in fluid [ N/m] , - momentum acting along axis x [ N .m] , 1 o - deviation angle of the hole's axis [ ], - curvature of the casing's axis in the hole [1/m], - torsion of the casing's axis in the hole [1/m].

The origin of the coordinate system (Fig. 1) is always located at the casing string's axis in a place where the next lower centralizer is situated. This means that the first centralizer is located by counting from the bottom of the casing string. The next ones are counted in succession and together with an increase in the number of centralizers, the coordinate's system is shifted upward in such a way that its beginning is always at the lower centralizer whose placement was last designated. The elementary length of the casing string is always matched to the distance between neighboring centralizers. The curvature and torsion of the elementary arc for the axis of the casing string run into the hole are approximated on the basis of geophysical measurements made earlier in a given hole. Depending on the measuring equipment used, the spatial placement of the hole's axis may be determined for example by the tangent, trapezoidal or Mercury methods (Walstrom, 1972). When the type and location of the centralizers on the casing string are properly chosen, the axes of the hole and casing string are close to each other. Therefore it can be assumed, with very little error, that the curvature and torsion on the elementary arc are constant. The momenta acting on the casing string are dependent upon the casing string's curvature and torsion as well as upon the way it is run into the hole. Unit resultant force acting on a centralizer is equal to the the diagonal of a cuboid constructed on three sides suited to the unit stresses N1, N2, N3 respectively. However the total resultant force N acting on a centd ralizer is a product of the unit stress and length L of a casing between neighboring c centralizers, that is:

Fig. 1. The unit stresses acting on a centralizer located on a casing string in the hole.

26

Acta Montanistica Slovaca

Ronk 3 (1998), 1, 24-28

N d = Lc [ N 1 + N 2 + N 3 ] 0.5

[N]

(4)

Each type of centralizer has its own characteristics (API Specification, 1990; Weatherford 1994), from which an permissible load, which will be called N [N], is chosen earlier. Given the c assumption that the stress on a centralizer, whose distance is defined, does not exceed the permissible stress, the maximum distance for placing the successive centralizer is calculated as follows:

Lc =

Nc [( ks EI q cos ) + ( ks EI ksM1 kT1 q sin ) 2 + ( s 2 EI ) 2 ]0.5

2 2 2

[m]

(5)

Limitations A casing string run into a hole undergoes fluctuation of stress. Centralizers which are improperly located can become damaged during the run and become the cause of complications. For this reason, the entire methodology of locating centralizers on a casing string consists of the part suited to the goal of ultimately placing of the casing in a hole as well as the part with limitations resulting from their translation in a hole. This is particularly significant in these intervals of a hole in which the largest curvatures and torsions of the casing occur. Verification of the centralizers' placement is based on calculating the quotient of the maximum translation of the casing axis and the radial clearance given by the following formula:

S=

where: R i R z C i D i

Ri Rz Ci Di Ri Rz

[dimensionless] (6)

- radius of the hole at the i-th intersection [mm], - outer radius of the casing string [mm], - bending of a centralizer due to a side-load at i-th intersection [mm], - maximum bending of the casing at i-th intersection [mm].

If the quotient defined by the equation (6) is not less than 0,67 in the tested intervals of casing run into the hole, then the distances between centralizers calculated using equation (5) are not subject to change (Fig. 2). Otherwise the distance between these centralizers should be decreased enough so that the stand-off attains a value of 0,67.

Fig. 2. Centralization of centralizers casing string in directional well.

27

Gonet, Stryczek and Pinka: Procedure for Arranging Centralizers in Casing String Run into Directional Wells

The above procedure is repeated for all centralizers starting with the one situated lowest on the casing string run into a hole. Conclusions 1. The casing string run into a hole is subject to various loads depending on: - the unit weight of the casing string, - the stiffness of the casing string, - the technology of running the casing string run into a hole, - the spatial placement of the hole's axis. 2. For a hole calculated in three-dimensional space, the distance between successive centralizers is calculated according to the equation (5). This distance depends on the permissible stress resulting from the technical characteristics of a given type of a centralizer, the placement of the holes axis, the local load of the casing and their parameters. 3. The ultimate placement of centralizers in the casing string should be determined by verifying along the trajectory of the holes axis the condition (6) stating that the quotient of the greatest clearance of the casings axis and of the radial clearance does not exceed the permissible value if 0,67. As the rheology parameters of sealing slurries and sealing technologies improve, this value should decrease. The support of the State Committee for Scientific Research is fully acknowledged.

Study number: 249.620.01 at the Department of Drilling, Oil and Gas of the University of Mining and Metallurgy in Cracow, Poland.

References

API Specification 10D for Bow-Spring Casing Centralizers, 1990. Gonet, A.: A Method of Placing Centralizers on Casings. IX. International Conference, Kosice, September 2-4, 1997. Lubinski, A.: Developments in Petroleum Engineering. Gulf, Houston 1987. Mechanical Cementing Products. Weatherford, Houston 1994. Walstrom, J.E. et al.: A Comparison of Various Directional Survey Models and an Approach to Modell Error Analysis. Journal of Petroleum Technology, August, 1972. Wisniowski, R., Gonet, A., & Capik M.: Numerical Aided Decision Making Regarding Centralizers Placement on Casing String. International Conference on Applied Mathematical Methods in Science and Technology, Cracow, June 20-21, 1995. Strnite, K. & Pinka, J.: Drilling Data Handbook. Olympia Koice, 1993.

28

S-ar putea să vă placă și

- Sun 2020 IOP Conf. Ser. Earth Environ. Sci. 570 042021Document8 paginiSun 2020 IOP Conf. Ser. Earth Environ. Sci. 570 042021杨跃辉Încă nu există evaluări

- Effect of Gap Between Pad and Vessel For Moment Loading On NozzleDocument7 paginiEffect of Gap Between Pad and Vessel For Moment Loading On NozzleRiccardo CozzaÎncă nu există evaluări

- 6940 21524 1 PBDocument10 pagini6940 21524 1 PBSanthosh KumarÎncă nu există evaluări

- Wind TestingDocument22 paginiWind TestingNoel BinoyÎncă nu există evaluări

- An Energy Approach For Predicting Springback of Metal Sheets After Double-Curvature Forming, Part I: Axisymmetric StampingDocument22 paginiAn Energy Approach For Predicting Springback of Metal Sheets After Double-Curvature Forming, Part I: Axisymmetric Stampingsani_buangÎncă nu există evaluări

- 04a Torsion of ThinWalled StructuresDocument35 pagini04a Torsion of ThinWalled StructuresYan NingÎncă nu există evaluări

- Ada453908 PDFDocument30 paginiAda453908 PDFDani Quirante Flaaut EtcÎncă nu există evaluări

- Optimizing Supersonic Nozzle Geometry for Uniform FlowDocument14 paginiOptimizing Supersonic Nozzle Geometry for Uniform FlowSanjay Kumar AdvaniÎncă nu există evaluări

- Multi-Vane Expanders-Geometry and Vane Kinematics - BadrDocument24 paginiMulti-Vane Expanders-Geometry and Vane Kinematics - BadrTodd StevensÎncă nu există evaluări

- Plume Interference Effects On Missile BodiesDocument3 paginiPlume Interference Effects On Missile BodiesHossein AkbarshahiÎncă nu există evaluări

- Square Cylinder (Corner Shapes) - 1998tamura PaperDocument12 paginiSquare Cylinder (Corner Shapes) - 1998tamura PaperAjith KumarÎncă nu există evaluări

- How To Measure The Load On Following ShaftDocument5 paginiHow To Measure The Load On Following ShaftGogyÎncă nu există evaluări

- Slope Failure Verification of Buried Steel PipelinesDocument15 paginiSlope Failure Verification of Buried Steel PipelinesalexrodriguezabcÎncă nu există evaluări

- Design of Concrete Shell Roofs For Amphi TheatreDocument58 paginiDesign of Concrete Shell Roofs For Amphi TheatreGuru Raja100% (1)

- Diseño de Anclajes en HormigonDocument32 paginiDiseño de Anclajes en HormigonnagenolÎncă nu există evaluări

- 2005 Swartz Trapezoidal Tapered RingsDocument13 pagini2005 Swartz Trapezoidal Tapered RingsJames HillÎncă nu există evaluări

- Computational Analysis On Different Shape MissilesDocument6 paginiComputational Analysis On Different Shape MissilesRed RainÎncă nu există evaluări

- Use of Pre-Splitting Technique As An Alternative Approach ToDocument4 paginiUse of Pre-Splitting Technique As An Alternative Approach Toalvaroaac4Încă nu există evaluări

- Fatigue Performance of Laser Beam Welded A36 SteelDocument3 paginiFatigue Performance of Laser Beam Welded A36 SteelDaniel VenturiÎncă nu există evaluări

- Document 2Document14 paginiDocument 2matias79Încă nu există evaluări

- Fulltext 3Document6 paginiFulltext 3ijal84Încă nu există evaluări

- Measure Concrete Quality with Pulse Velocity TestingDocument4 paginiMeasure Concrete Quality with Pulse Velocity TestingKamal PakdamanÎncă nu există evaluări

- Session 4 Management Covering Blast DesignDocument112 paginiSession 4 Management Covering Blast DesignSebastián MorenoÎncă nu există evaluări

- Verification of The Wind Response of A Stack Structure: D. Makovička, J. Král, D. MakovičkaDocument7 paginiVerification of The Wind Response of A Stack Structure: D. Makovička, J. Král, D. Makovičkahkd3Încă nu există evaluări

- Analysis and Design of Members For TensionDocument84 paginiAnalysis and Design of Members For TensionicpertacortaÎncă nu există evaluări

- Comparison of Tunnel Blast Design ModelsDocument9 paginiComparison of Tunnel Blast Design ModelsAntonio RamosÎncă nu există evaluări

- OWEMES Fatigue Design 2003 Tcm4-29402Document15 paginiOWEMES Fatigue Design 2003 Tcm4-29402yuxi liuÎncă nu există evaluări

- LAB TESTS OF RAILWAY TRACKS WITH RESILIENT UNDERSLEEPER PADSDocument15 paginiLAB TESTS OF RAILWAY TRACKS WITH RESILIENT UNDERSLEEPER PADSHossam AtifÎncă nu există evaluări

- Fatigue Damage Analysis of Offshore Structures Using Hot Spot Stress and Notch Strain ApproachesDocument9 paginiFatigue Damage Analysis of Offshore Structures Using Hot Spot Stress and Notch Strain ApproachesnapoleonmÎncă nu există evaluări

- Influence of Ring Stiffeners On A Steel Cylindrical Shell: D. Lemák, J. StudničkaDocument8 paginiInfluence of Ring Stiffeners On A Steel Cylindrical Shell: D. Lemák, J. StudničkaOTPIDIÎncă nu există evaluări

- Beam-To-Beam Joints With Bolted End-Plate Connections Concerning Steel Platforms Angra 2 NPPDocument10 paginiBeam-To-Beam Joints With Bolted End-Plate Connections Concerning Steel Platforms Angra 2 NPPihpeterÎncă nu există evaluări

- Stress Concentrations For Slotted Plates in Bi-Axial Stress: D. W. A. Rees, H. Bahai, S. TaylorDocument7 paginiStress Concentrations For Slotted Plates in Bi-Axial Stress: D. W. A. Rees, H. Bahai, S. TaylorYasser BahaaÎncă nu există evaluări

- Nozzle Stress ClassificationDocument6 paginiNozzle Stress ClassificationHitesh SuvarnaÎncă nu există evaluări

- Experimental study on stitching reinforcement of composites with circular holesDocument5 paginiExperimental study on stitching reinforcement of composites with circular holeskhudhayer1970Încă nu există evaluări

- Anexo D-1, ISRM Journal E Villaescusa (AE - 2002)Document13 paginiAnexo D-1, ISRM Journal E Villaescusa (AE - 2002)jorge_e_alvarez_cÎncă nu există evaluări

- Ramkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryDocument34 paginiRamkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryMaynak DeyÎncă nu există evaluări

- Bell e Mehta 1989Document4 paginiBell e Mehta 1989Nelson LondoñoÎncă nu există evaluări

- Sca1989 08Document16 paginiSca1989 08Rosa K Chang HÎncă nu există evaluări

- Design Manual To EC2Document39 paginiDesign Manual To EC2Tomas MerkeviciusÎncă nu există evaluări

- Design of Rigid Pile Caps Through An Iterative Strut-And-Tie ModelDocument12 paginiDesign of Rigid Pile Caps Through An Iterative Strut-And-Tie ModeljjohnsoneÎncă nu există evaluări

- Fuel CellDocument6 paginiFuel CellSahar ShÎncă nu există evaluări

- 2022 CPP Effect-of-Solar-Panel-Support-Structure-on-the-Wind-Loading-of-Horizontal-Single-Axis-Trackers-Chowdhury-Sauder-Banks-2022Document12 pagini2022 CPP Effect-of-Solar-Panel-Support-Structure-on-the-Wind-Loading-of-Horizontal-Single-Axis-Trackers-Chowdhury-Sauder-Banks-2022Yanfei ZhuÎncă nu există evaluări

- Ajassp 2015 276 283Document8 paginiAjassp 2015 276 283JP OmerÎncă nu există evaluări

- DETERMINATION OF THE BEARING CAPACITY OF PILES ON THE BASIS OF CPT SOUNDING TESTS by József PUSZTAIDocument8 paginiDETERMINATION OF THE BEARING CAPACITY OF PILES ON THE BASIS OF CPT SOUNDING TESTS by József PUSZTAIhedyÎncă nu există evaluări

- 1 s2.0 0013794494001758 Main PDFDocument27 pagini1 s2.0 0013794494001758 Main PDFshashank soniÎncă nu există evaluări

- The Performance Prediction of A TBM in Difficult GroundDocument12 paginiThe Performance Prediction of A TBM in Difficult GroundskenÎncă nu există evaluări

- Bernitsas M.A Three-Dimensional .Mar.1982.JSR PDFDocument6 paginiBernitsas M.A Three-Dimensional .Mar.1982.JSR PDFdanilo laraÎncă nu există evaluări

- Fulltext09 (141 210)Document70 paginiFulltext09 (141 210)Maria JoseÎncă nu există evaluări

- ASME PaperDocument17 paginiASME PaperChristopher BrownÎncă nu există evaluări

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryDe la EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryÎncă nu există evaluări

- Seismic Amplitude Inversion in Reflection TomographyDe la EverandSeismic Amplitude Inversion in Reflection TomographyÎncă nu există evaluări

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysDe la EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysEvaluare: 1 din 5 stele1/5 (1)

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesDe la EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesEvaluare: 5 din 5 stele5/5 (3)

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964De la EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryÎncă nu există evaluări

- Bearing Self Study PDFDocument73 paginiBearing Self Study PDFcakendriÎncă nu există evaluări

- Annealing Effects On The Structural and Magnetic Properties of Fe-Al Silica Nanocomposites Prepared by Sequential Ion ImplantationDocument5 paginiAnnealing Effects On The Structural and Magnetic Properties of Fe-Al Silica Nanocomposites Prepared by Sequential Ion ImplantationDanielÎncă nu există evaluări

- OCTG Accessory BrochureDocument113 paginiOCTG Accessory BrochureDanielÎncă nu există evaluări

- Abbreviations DrillingDocument74 paginiAbbreviations DrillingHenk1740Încă nu există evaluări

- Transition of Deformation MechanismsDocument14 paginiTransition of Deformation MechanismsDanielÎncă nu există evaluări

- Hammer Union PresentationDocument17 paginiHammer Union PresentationDaniel100% (1)

- DATALOG Vibration v1 0Document38 paginiDATALOG Vibration v1 0DanielÎncă nu există evaluări

- Fracture Gradient Prediction ZAMORA - MAR - 89Document6 paginiFracture Gradient Prediction ZAMORA - MAR - 89DanielÎncă nu există evaluări

- Modeling of Phase TransformationDocument56 paginiModeling of Phase TransformationDaniel100% (1)

- Austenite To Ferrite Transformation Kinetics During Continous CoolingDocument8 paginiAustenite To Ferrite Transformation Kinetics During Continous CoolingDaniel100% (1)

- SANS10005 (Amdt1)Document12 paginiSANS10005 (Amdt1)Johnnie StrydomÎncă nu există evaluări

- Autodock2 4 UserguideDocument48 paginiAutodock2 4 UserguidePowellAbogadoÎncă nu există evaluări

- Heat Loss in Pipe Support PDFDocument60 paginiHeat Loss in Pipe Support PDFThaku KishorÎncă nu există evaluări

- Lesson 5.3 The Energy Flow From Environment To CellsDocument17 paginiLesson 5.3 The Energy Flow From Environment To CellsJENNILYN CASTILLOÎncă nu există evaluări

- Solvent EndodonticiDocument7 paginiSolvent EndodonticiValentina BadiuÎncă nu există evaluări

- Heat Transfer Jan2003 or 220852Document2 paginiHeat Transfer Jan2003 or 220852Nizam Institute of Engineering and Technology LibraryÎncă nu există evaluări

- Michael FaradayDocument33 paginiMichael FaradayRezie Dampog DellavaÎncă nu există evaluări

- Modified Hydrotest 6barDocument4 paginiModified Hydrotest 6barMohamed ElarabiÎncă nu există evaluări

- Multicam Plastics BrochureDocument2 paginiMulticam Plastics BrochureMoe KimoÎncă nu există evaluări

- Presence of Oxalative Ions in GuavaDocument11 paginiPresence of Oxalative Ions in GuavaPra MÎncă nu există evaluări

- The Secrets of the Bermuda Triangle RevealedDocument13 paginiThe Secrets of the Bermuda Triangle RevealedJude FrancesÎncă nu există evaluări

- Thwaites MethodDocument1 paginăThwaites MethodJen ChaiÎncă nu există evaluări

- Statistics 2 For Chemical Engineering: Department of Mathematics and Computer ScienceDocument37 paginiStatistics 2 For Chemical Engineering: Department of Mathematics and Computer ScienceKhuram MaqsoodÎncă nu există evaluări

- Design of Anchor BlockDocument4 paginiDesign of Anchor BlockDeepak Das TamrakarÎncă nu există evaluări

- Form 5-06 PDFDocument1 paginăForm 5-06 PDFAlma PustaÎncă nu există evaluări

- MSDS IzonilDocument2 paginiMSDS Izonilabdul azizÎncă nu există evaluări

- (CG) SHS Core - Physical Science PDFDocument17 pagini(CG) SHS Core - Physical Science PDFFeinrir0% (1)

- EDC Manual PDFDocument83 paginiEDC Manual PDFMrinal MitraÎncă nu există evaluări

- AISI 4140 Alloy Steel PropertiesDocument3 paginiAISI 4140 Alloy Steel PropertiesSatrio AmiruddinÎncă nu există evaluări

- Surface PreparationDocument13 paginiSurface PreparationDacher Daniel100% (1)

- Gcse Ocr DT FlashcardsDocument8 paginiGcse Ocr DT Flashcardsapi-256027312Încă nu există evaluări

- Agard PDFDocument245 paginiAgard PDFPARAMASIVAM JAYARAMANÎncă nu există evaluări

- SEKOLAH MENENGAH KEBANGSAAN PANGKOR SCIENCE EXAMDocument5 paginiSEKOLAH MENENGAH KEBANGSAAN PANGKOR SCIENCE EXAMnazgaÎncă nu există evaluări

- Saponification ProcessDocument4 paginiSaponification ProcessAddison JuttieÎncă nu există evaluări

- 24029962Document269 pagini24029962smrndrdasÎncă nu există evaluări

- Referat - Padurariu George-OctavianDocument20 paginiReferat - Padurariu George-OctavianGeorge PadurariuÎncă nu există evaluări

- Elements 2011 - v7 4 Continental CrustDocument76 paginiElements 2011 - v7 4 Continental CrustAndrea SanderÎncă nu există evaluări

- Identificación de Flavonoides, Lactonas Sesquiterpenicas, Compuestos Fenolicos y Taninos de La Manzanilla.Document13 paginiIdentificación de Flavonoides, Lactonas Sesquiterpenicas, Compuestos Fenolicos y Taninos de La Manzanilla.Mabel Pinto Coronel67% (3)

- Lubrizol Hydraulic FluidsDocument6 paginiLubrizol Hydraulic Fluidsrohit_12346Încă nu există evaluări

- Using Uv Spectrophotometric Method To Determine The Linearity of Vildagliptin (VLD) Brands.Document4 paginiUsing Uv Spectrophotometric Method To Determine The Linearity of Vildagliptin (VLD) Brands.Alex American-ajiras BrondÎncă nu există evaluări