Documente Academic

Documente Profesional

Documente Cultură

Abdul Halim Hadzir (CD 5008)

Încărcat de

yiandrillDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Abdul Halim Hadzir (CD 5008)

Încărcat de

yiandrillDrepturi de autor:

Formate disponibile

DEVELOPMENT OF AUTOMATED STORAGE AND RETRIEVAL SYSTEM (AS/RS) PROTOTYPE

ABDUL HALIM BIN HADZIR

Report submitted in fulfilment of the requirements for the award of the degree of Bachelor of Mechanical Engineering

Faculty of Mechanical Engineering UNIVERSITI MALAYSIA PAHANG

DECEMBER 2010

ii

UNIVERSITI MALAYSIA PAHANG FACULTY OF MECHANICAL ENGINEERING I certify that the report entitled Development of Automated Storage and Retrieval System (ASRS) Prototype is written by Abdul Halim Bin Hadzir. I have examined the final copy of this report and in my opinion; it is fully adequate in terms of scope and quality for the award of the degree of Bachelor of Engineering. I herewith recommend that it be accepted in partial fulfilment of the requirements for the degree of Bachelor of Mechanical Engineering.

DAYANGKU NOORFAZIDAH AWANG SHRI Examiner Signature

iii

SUPERVISORS DECLARATION

I hereby declare that I have checked this report and in my opinion, this report is adequate in terms of scope and quality for the award of the degree of Bachelor of Mechanical Engineering.

Signature

Name of Supervisor : MUHAMMAD HATIFI BIN MANSOR Position Date : LECTURER : 6th DECEMBER 2010

iv

STUDENTS DECLARATION

I hereby declare that the work in this report is my own except for quotations and summaries which have been duly acknowledged. The report has not been accepted for any degree and is not concurrently submitted for award of other degree.

Signature Name

: : ABDUL HALIM BIN HADZIR : 6th DECEMBER 2010

ID Number : MA07013 Date

vi

ACKNOWLEDGEMENTS

Alhamdulillah, praise to be Allah for His blessings and giving me the strength along the tough journey of completing my Final Year Project as well as this report writing, for without it, I would not have been able to come this far. First and foremost, I would like to express my gratitude and appreciation to my previous and new supervisor Mr. Mohd Fadzil Faisae Bin Abd Rashid and Mr. Muhammad Hatifi Bin Mansor, for their guidance towards completion of my project from the beginning till the end. I also sincerely thanks for the spent proofreading and correcting my many mistakes. Without his main ideas and observations throughout the process of this project, this report would not be the same as presented here. My outmost thanks also go to my family who has given me support throughout my academic years especially my beloved parents. Many special thanks go to my fellow friends and member of the staff Faculty of Mechanical Engineering, UMP, who help me many ways, for the excellent understanding, co-operation, inspiration, and supports during my study here. Last but not least, thanks to individuals that has contributed either directly or indirectly to make this report. Finally, as usual, all errors and oversights are entirely my own. Thank you once again. May Allah bless all of you. Amin.

vii

ABSTRACT

This report deals with the development of automated storage and retrieval system (AS/RS) prototype. The original idea for this project is to help people which working in warehouse such as operator who wants to store and retrieve the drawer (unit loads) into and from cabinet (storage structure). The AS/RS have been widely used in distribution and productions environment. The AS/RS consists of racks and cranes (storage/retrieval machine, lifter and drawer picker) where the racks served by cranes running through aisles between the racks and its fully automated where it capable of handling drawer without interference of an operator. The development accentuate on mechanical approach. The prototype three-dimensional solid modelling of AS/RS was developed using the computer-aided drawing software. For this project PIC18F452 microcontroller was chosen as a control system. Other than that, stepper motor was used to move the storage/retrieve (S/R) machine during to store and retrieve the drawer. A program in mikroElektronika (MikroC) is written and developed to correspond with the microcontroller to move the stepper motor according to plan sequences. The real time testing was done in order to know the performance of fabricated prototype. The transaction time during depositing and retrieving the drawer into and from cabinet is successfully recorded. The development in phrase can be concluded as an innovation of design and successfully fabricated.

viii

ABSTRAK

Laporan ini membentangkan pembangunan simpanan automatik dan sistem carian (AS/RS) prototaip. Idea asal untuk projek ini adalah untuk membantu orang yang bekerja di gudang seperti operator yang ingin menyimpan dan mengambil laci (beban unit) pada kabinet (struktur simpanan). AS/RS telah banyak digunakan dalam persekitaran pengedaran dan pengeluaran. AS/RS terdiri dari rak dan kren (simpanan/carian mesin, pengangkat dan pengambil laci), di mana rak dilayani oleh kren berjalan melalui lorong antara rak-rak dan ianya sepenuhnya automatik yang mana mampu menangani laci tanpa campur tangan operator. Pembangunan ini meggunakan pendekatan mekanikal. Pemodelan AS/RS prototaip solid tiga dimensi dibangunkan menggunakan perisian melukis dibantu komputer. Untuk projek ini mikrokontroler PIC18F452 dipilih sebagai sistem kawalan. Selain itu, motor pelangkah digunakan untuk memindahkan simpanan/mengambil (S/R) mesin semasa untuk menyimpan dan mengambil laci. Sebuah program di mikroElektronika (MikroC) ditulis dan dibangunkan untuk berinteraksi dengan mikrokontroler untuk menggerakkan motor pelangkah sesuai dengan urutan yang diatur. Pengujian masa sebenar dilakukan untuk mengetahui prestasi prototaip yang dibuat. Waktu transaksi semasa menyimpan dan mengambil laci ke dan dari kabinet telah berjaya dirakam. Pembangunan ini dalam frasa mudah disimpulkan sebagai inovasi terhadap rekabentuk dan telah berjaya dibuat.

ix

TABLE OF CONTENTS

Page EXAMINERS DECLARATION SUPERVISORS DECLARATION STUDENTS DECLARATION ACKNOWLEDGEMENTS ABSTRACT ABSTRAK TABLE OF CONTENTS LIST OF TABLES LIST OF FIGURES LIST OF SYMBOLS LIST OF ABBREVIATIONS ii iii iv vi vii viii ix xiii xiv ixi xx

CHAPTER 1

INTRODUCTION

1.1 1.3 1.3 1.4 1.5

Project Background Problem Statement Objectives of the Project Project Scope Conclusion

1 2 2 3 3

CHAPTER 2 2.1 2.2

LITERATURE REVIEW 4 5 11 12 15 17 19 20

Introduction Automated Storage Systems 2.2.1 Carousel Storage Systems

2.3 2.4 2.5 2.6

AS/RS Types Sizing The AS/RS Storage Structure AS/RS Throughput Microcontroller 2.6.1 Types of Microcontroller

2.7

Conclusion

22

CHAPTER 3

METHODOLOGY

3.1 3.2 3.3

Introduction Component and Material Selection Mechanical Structure Design Process 3.3.1 3.3.2 3.3.3 Sketching Computer Aided Design Drawing Stepper Motor

23 25 25 27 28 32 33 34 34 35 38 39 40 43 44

3.4 3.5 3.6

Finalized Design Material and Equipment Preparation The Fabrication 3.6.1 Process of Fabrication

3.7

Basic Circuit for PIC 18F452 3.7.1 Stepper Motor Circuit

3.8

Software Programming Design 3.8.1 Stepper Motor Programming

3.9

Conclusion

CHAPTER 4 4.1 4.2

RESULT AND DISCUSSION 45 45 47 47 49 54 55 59 59 60 61 61

Introduction Result of Fabrication 4.2.1 Properties of Components/Part

4.3 4.4 4.5 4.6 4.7

The Modification The Real Time Testing AS/RS Working Power and Torque Transmitted Analysis The Predicaments 4.7.1 Problem of Fabrication Process 4.7.2 The Defects of Prototype The Troubleshooting 4.8.1 Solution of Fabrications Problems

4.8

xi

4.9

Conclusion

62

CHAPTER 5

CONCLUSION AND RECOMMENDATION

5.1 5.2 5.3

Introduction Conclusion Recommendation

63 63 64

REFERENCES APPENDICES A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 A14 A15 A16 A17 A18 A19 A20 B1 B2 C1 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing 2D Engineering Drawing Gantt Chart For Final Year Project 1 Gantt Chart For Final Year Project 2 Finished Prototype

65

66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88

xii

C2 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10

Finished Prototype Programming for Drawer Coordinate X=1 and Y=1 (Drawer 1) Programming for Drawer Coordinate X=2 and Y=1 (Drawer 2) Programming for Drawer Coordinate X=3 and Y=1 (Drawer 3) Programming for Drawer Coordinate X=4 and Y=1 (Drawer 4) Programming for Drawer Coordinate X=5 and Y=1 (Drawer 5) Programming for Drawer Coordinate X=1 and Y=2 (Drawer 6) Programming for Drawer Coordinate X=2 and Y=2 (Drawer 7) Programming for Drawer Coordinate X=3 and Y=2 (Drawer 8) Programming for Drawer Coordinate X=4 and Y=2 (Drawer 9) Programming for Drawer Coordinate X=5 and Y=2 (Drawer 10)

89 90 91 92 93 94 95 97 98 101 103

xiii

LIST OF TABLES

Table No. 2.1 2.2 4.1 4.2

Title

Page 5 7 47 52

The differences between AS/RS and Carousel storage system Types of materials generally stored in a factory Properties of components Velocity and acceleration of S/R machine for drawer coordinate x=1 and y=2 Velocity and acceleration of S/R machine for drawer coordinate x=5 and y=2 Velocity and acceleration of lifter for drawer coordinate x=1 and y=2 Velocity and acceleration of lifter for drawer coordinate x=5 and y=2 Velocity and acceleration of drawer picker for drawer coordinate x=1 and y=2 Velocity and acceleration of drawer picker for drawer coordinate x=5 and y=2 Transaction time Torque and power transmitted Problems encountered during the progress of fabrication Defects of the fabricated AS/RS Solution for problems faced during fabrication Future prospects for defection of fabricated AS/RS

4.3

52

4.4

52

4.5

53

4.6

53

4.7

53

4.8 4.9 4.10 4.11 4.12 5.1

54 58 59 60 61 64

xiv

LIST OF FIGURES

Figure No. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 Unit load AS/RS Mini load AS/RS Man-on-board AS/RS Deep-lane AS/RS Horizontal carousels Vertical carousels

Title

Page 8 9 9 10 11 12 13 15

Classification of various AS/RS options Top and side views of a unit load AS/RS, with nine storage compartments horizontally (ny = 9) and six compartments vertically (nz = 6). Microcontroller feature PIC 18F452 microcontroller Flow Chart for Project Methodology Single mast of S/R machine Double mast of S/R machine Front view of AS/RS Left side view of AS/RS Right side view of AS/RS Top view of AS/RS Isometric view of AS/RS 103-807-S unipolar stepper motor PM42S-048 unipolar stepper motor Hydraulic shear machine

2.9 2.10 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 3.10 3.11

21 22 24 27 27 28 29 29 30 31 32 32 35

xv

LIST OF FIGURES

Figure No. 3.12 3.13 3.14 3.15 3.16 3.17 3.18 3.19 4.1 4.2 4.3 4.4 4.5a 4.5b 4.5c 4.5d 4.5e 4.5 6.1 6.2 6.3

Title

Page 36 36 37 38 39 40 41 42 46 46 48 48 49 50 50 51 51 51 66 67 68

Truma bend V series machine Drilling machine Rivet pop gun Schematic circuit diagram for PIC 18F452 Schematic diagram for stepper motor circuit Process flow chart for PIC programming MikroC compiler WinPIC800 interface Control system circuit Isometric view of AS/RS prototype Modification of AS/RS prototype The complete prototype S/R machine move to right Drawer picker move forward Drawer picker move reversely with the drawer S/R machine move to left until initial position Drawer picker move forward until arrive P/D station Transaction involves retrieving the drawer from cabinet Technical drawing for S/R machine Technical drawing for lifter Technical drawing for drawer picker

xvi

LIST OF FIGURES

Figure No. 6.4 6.5 6.6 6.7 6.8 6.9 6.10 6.11 6.12 6.13 6.14 6.15 6.16 6.17 6.18 6.19 6.20 6.21 6.22 6.23 6.24

Title

Page 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 88

Technical drawing for drawer (unit load) Technical drawing for cabinet (storage structure) Technical drawing for spur gear holder Technical drawing for spur gear shaft Technical drawing for pinion 38 teeths Technical drawing for gear 73 teeths Technical drawing for pinion D40 mm Technical drawing for rack gear 388 mm Technical drawing for pinion D24 mm Technical drawing for rack gear 109 mm Technical drawing for pulley D20 mm Technical drawing for pulley D20 mm track Technical drawing for pulley D30 mm Technical drawing for pulley D30 mm middle Technical drawing for pulley D40 mm Technical drawing for pulley D40 mm track Technical drawing for AS/RS assembly Project planning for FYP 1 Project planning for FYP 2 Front view of AS/RS prototype Right side view of AS/RS prototype

xvii

LIST OF FIGURES

Figure No. 6.25 6.26

Title

Page 89 89

Left side view of AS/RS prototype Top view of AS/RS prototype

xviii

LIST OF SYMBOLS

ny nz W L H x y z a, b, and c

Number of load compartments along the length of the aisle Number of load compartments that make up the height of the aisle Width of the one aisle of the AS/RS rack structure Length of the one aisle of the AS/RS rack structure Height of the one aisle of the AS/RS rack structure Depth of dimensions of a unit load Width of dimensions of a unit load Height of dimensions of a unit load Allowances designed into each storage compartment to provide clearance for the unit load and to account for the size of the supporting beams in the rack structure. The cycle time of a single command cycle The velocity of the S/R machine along the length of the AS/RS The velocity of the S/R machine in the vertical direction of the AS/RS

Tpd

Pickup and deposit time The cycle time for dual command cycle Number of single command cycles performed per hour Number of dual command cycles per hour

U Rc Rt T F

System utilization during the hour Total S/R cycle rate Total number of transaction performed per hour Torque Weight

xix

LIST OF SYMBOLS

r P

Radius of gear Power Angular velocity

Number of gears teeth

xx

LIST OF ABBREVIATIONS

AS/RS AGV S/R I/O P/D FCFS NN 3D RAM ROM PROM EPROM ICs PIC PSP A/D C 3D

Automated Storage And Retrieval System Automated Guided Vehicle Storage/Retrieval Input/output Pick/Deposit First Come First Serve Nearest Neighbour Three dimensional Random access memory Read only memory Programmable read-only memory Erasable programmable read-only memory Integrated circuits Programmable interface controller Parallel slave port Analog-to-digital Computer Three dimension

CHAPTER 1

INTRODUCTION

1.1

PROJECT BACKGROUND

An automated storage and retrieval system (AS/RS) can be defined as a storage system that performs storage and retrieval operations with speed and accuracy under a defined degree of automation (Aslam,Gardezi, and Hayat, 2009). The performance of any manufacturing industry depends mostly on its material handling and storage system.

Generally, AS/RS refers to a variety of computer-controlled methods for automatically depositing and retrieving loads to and from defined storage locations. Within an automated storage system environment, there are having several layouts such as horizontal carousels, vertical carousels, vertical lift modules, and fixed aisle storage and retrieval systems. The latter utilizing special storage retrieval (S/R) machines to do the work needed to insert, extract and deliver loads to designated input/output locations. AS/RS have many benefits including savings in labour cost, improved material flow and inventory control, high floor space utilization, increased safety and stock rotation. AS/RS, carousels/rotary racks, automated guided vehicles (AGV) systems, and robotic systems are some of the most commonly used material handling systems in manufacturing industries.

The right application of AS/RS provides a long list of user benefits. It has been demonstrated time and time again that automated storage and retrieval systems are proven technologies capable of effectively and consistently handling and buffering raw materials, work-in-process inventories and finished goods of all kinds, and making it possible to totally integrate material handling storage. This system works by enable user

to store their packages in the safe place and retrieve the packages correctly without the limit of human working hours. The system can be extended from medium to large storage capacity without difficulty to redesign the storage management. In this project, the design and development of AS/RS prototype was concentrated for small unit loads (small drawer). The capacity of the designated AS/RS to store various parts is ten of drawer. The developed storage structure (cabinet) of AS/RS consists of two rows and five columns to store parts in vertical and horizontal direction.

1.2

PROBLEM STATEMENT

This AS/RS is designed to reduce the error rates and increased reliability while savings labour costs and floor space. Material storage can be performed manually but the automated methods for storing and retrieving materials are more efficient. With the conventional system, need a lot of labour touching the material which can lead to errors and contribute the longer time since automated system is more accurate with higher stock reliability, for these reasons, safety stock figures can be lower, which means storage costs will be reduced. Other than that, the possibilities of error occur during storing and retrieving of the items at original location and find the items in shelving can sometimes be difficult.

1.3

OBJECTIVES OF THE PROJECT

The objectives of this project are:

i.

To design a prototype of automated storage and retrieval system (AS/RS) for small loads.

ii. iii.

To integrate microcontroller on the storage/retrieval (S/R) machine. To fabricate, assemble, and test the prototype as following a design.

1.4

PROJECT SCOPE

This project focuses on design and fabrication of the AS/RS prototype. The design was developed using Solidworks software. Other than that, programmable autonomously storage/retrieve (S/R) machine is used in conjunction to store and retrieve the small drawer. Furthermore, design of electronic circuit to suit the software programming. Generally, every technology has its limitations, and for this project it is no exception. The movement of this system is limited to store and retrieve the small unit loads (drawer) into and from storage structure (cabinet).

This equipment is not durable. It cannot expose too much to any work pressure since it is available in portable small component. This system requires higher initial investment for start-up process. The design of this system needs precise decision making to get the best mechanism.

1.5

CONCLUSION

Chapter 1 has been discussed briefly about project background, problem statement, objective and scope of the project on development of automated storage and retrieval system to achieve the objective mentioned. This chapter is as a fundamental for the project and act as a guidelines for project research completion.

CHAPTER 2

LITERATURE REVIEW

2.1

INRODUCTION

This chapter summarizes the general of AS/RS development highlighting the most recent research in this area. Automated storage and retrieval systems (AS/RS) have been widely used worldwide in distribution and production environments since their introduction in the 1950s. For both in production and distribution environments, AS/RS are used for putting products in store and for retrieving those products from storage to P/D station in other word to fulfil an order.

Between 1994 and 2004, there has been a continuously increase in the number of AS/RS used in distribution environments in the United State (Roodbergen and Vis, 2008). The AS/RS consists of four scheduling policies. A scheduling policy is a combination of a storage rule and retrieval rule. The storage rule in all cases was firstcome-first-serve (FCFS), closest open location to the dock. The retrieval rules examined were FCFS, nearest neighbour (NN) which minimize the expected travel time from the current location to the target location and from location to the dock and two variations of NN that set limits on maximum waiting time for items. The results showed that the throughput for all systems was maximized when using those schedules (Randhawa and Shroff, 1994).

There are many factors was depends on AS/RS which is the dimensions of the storage rack, the horizontal and vertical speed of the crane, whether the crane perform single or dual cycles, initial loading of the system, and sequencing of storage and retrieval operations.

2.2

AUTOMATED STORAGE SYSTEMS

The primary examples of automated storage systems are automated storage and retrieval system (AS/RS) and carousel storage systems. The general objective of storage system is to store materials for a certain period. Normally the basic AS/RS consists of rack structure for storing load and the motions of a storage/retrieval mechanism are linear (x-y-z direction) compare to a basic carousel system uses bins or baskets hanging from an overhead conveyors that revolve around an oval track loop to transport the bins or baskets to a load/unload station (Groover, 2008). The differences between an AS/RS and a carousel storage system are presented in Table 2.1. The types of materials that are stored by most manufacturing companies are shown in Table 2.2. Actually, most production plants use conventional or manual method for storing and retrieving items into and from storage. Automated methods are appropriate for those companies to treat the problem storage especially for worldwide company.

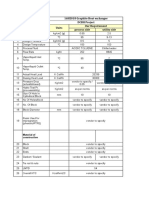

Table 2.1: The differences between AS/RS and carousel storage system

Feature Storage structure

Basic AS/RS

Basic carousel storage system Rack system to support Baskets or bins suspended pallets from overhead conveyor trolleys Linear motion storage/retrieval machine S/R machine compartments structure of Revolution of overhead (S/R) conveyor trolleys around oval track

Motions

Storage/ retrieval operation

travels to Conveyor revolve to bring in rack baskets to load/unload station

Replication capacity

of

storage Multiple aisles each consist Multiple carousels each of rack structure and S/R consist of oval track and machine. suspended bins Source: Groover, 2008

S-ar putea să vă placă și

- Single Cylinder Four Stroke Diesel Engine Test RigDocument24 paginiSingle Cylinder Four Stroke Diesel Engine Test RigDigvijay Todkar100% (1)

- A Minimum Cost Design For An Automated WarehouseDocument284 paginiA Minimum Cost Design For An Automated Warehousekutsay100% (1)

- Formal Methods Applied to Complex Systems: Implementation of the B MethodDe la EverandFormal Methods Applied to Complex Systems: Implementation of the B MethodÎncă nu există evaluări

- Aircom System®: Airline Ticketing and Reservation SystemDocument21 paginiAircom System®: Airline Ticketing and Reservation Systemmaclean_kumiÎncă nu există evaluări

- Autopilot Design For A QuadcopterDocument118 paginiAutopilot Design For A QuadcopterTiến HồÎncă nu există evaluări

- Zain ThesisDocument55 paginiZain Thesislife is opportunityÎncă nu există evaluări

- Design An Automated Guided Vehicle (AGV) Point To Point Motion ControlDocument24 paginiDesign An Automated Guided Vehicle (AGV) Point To Point Motion Controlmaboouf100% (1)

- OpenFOAM CFD Tools For Marine PropellerDocument74 paginiOpenFOAM CFD Tools For Marine PropellerMd Shariful IslamÎncă nu există evaluări

- From Prognostics and Health Systems Management to Predictive Maintenance 2: Knowledge, Reliability and DecisionDe la EverandFrom Prognostics and Health Systems Management to Predictive Maintenance 2: Knowledge, Reliability and DecisionÎncă nu există evaluări

- Objective: September, 2014-October, 2015 Airframe Aero Designs PVT LTDDocument2 paginiObjective: September, 2014-October, 2015 Airframe Aero Designs PVT LTDvigy1990Încă nu există evaluări

- Design of Hovercraft ReportDocument24 paginiDesign of Hovercraft Reporttechfi67% (3)

- Robot Arm Control With Arduino: June 2017Document42 paginiRobot Arm Control With Arduino: June 2017Carina FelnecanÎncă nu există evaluări

- Seminar Report 2Document80 paginiSeminar Report 2ashsadsadÎncă nu există evaluări

- Static Analysis of Software: The Abstract InterpretationDe la EverandStatic Analysis of Software: The Abstract InterpretationÎncă nu există evaluări

- Automatic Work Piece Inspection Cum Counter ConveyorDocument10 paginiAutomatic Work Piece Inspection Cum Counter ConveyorIJRASETPublicationsÎncă nu există evaluări

- (About The Project XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX) For Example: Our System Is Developed For Supporting Entire GeneralDocument36 pagini(About The Project XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX) For Example: Our System Is Developed For Supporting Entire GeneralNishant ChauhanÎncă nu există evaluări

- Formal Methods: Industrial Use from Model to the CodeDe la EverandFormal Methods: Industrial Use from Model to the CodeÎncă nu există evaluări

- SCCharts - Language and Interactive Incremental CompilationDe la EverandSCCharts - Language and Interactive Incremental CompilationÎncă nu există evaluări

- Rapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationDe la EverandRapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationÎncă nu există evaluări

- Bike Rental Management SystemDocument22 paginiBike Rental Management SystemMukunthan MuthurajÎncă nu există evaluări

- Airport Technical Services TrainingDocument2 paginiAirport Technical Services TrainingAnousack KittilathÎncă nu există evaluări

- DBMS Mini-Project Report-Cloth Rental StoreDocument31 paginiDBMS Mini-Project Report-Cloth Rental StoreGargi SharmaÎncă nu există evaluări

- Thesis MainDocument91 paginiThesis MainkienukiruÎncă nu există evaluări

- Acrp07-04 FRDocument151 paginiAcrp07-04 FRZenitha AmadangiÎncă nu există evaluări

- Car ParkingDocument65 paginiCar Parkingmaniblp100% (1)

- ProjectDocument61 paginiProjectaditya7398460102Încă nu există evaluări

- A.Parveen Banu: T-Warehouse: Visual Olap Analysis On Trajectory DataDocument13 paginiA.Parveen Banu: T-Warehouse: Visual Olap Analysis On Trajectory Datapri03Încă nu există evaluări

- Design of Robotic ARM Controller Using MatlabDocument24 paginiDesign of Robotic ARM Controller Using MatlabMada Sanjaya WsÎncă nu există evaluări

- Multi Operation Machine Using Scotch Yoke MechanismDocument65 paginiMulti Operation Machine Using Scotch Yoke MechanismCrispÎncă nu există evaluări

- Advanced Design Environment For Screw MachinesDocument9 paginiAdvanced Design Environment For Screw MachineshebsonbezerraÎncă nu există evaluări

- Design and Manufacturing of QuadcopterDocument47 paginiDesign and Manufacturing of QuadcopterDebashish Behera100% (3)

- Robotic Harvesting of Asparagus Using Machine Learning - B180129MEDocument28 paginiRobotic Harvesting of Asparagus Using Machine Learning - B180129METejo NathÎncă nu există evaluări

- Autonomous Control of Quadcopter UAV PDFDocument56 paginiAutonomous Control of Quadcopter UAV PDFOla Sbihat100% (1)

- CS Project Sample 33 PagesDocument33 paginiCS Project Sample 33 PagesBalachander VenkatasubramanianÎncă nu există evaluări

- Academic Year 2021 - 2022 Question Bank: Part ADocument2 paginiAcademic Year 2021 - 2022 Question Bank: Part AHgffhhÎncă nu există evaluări

- Aircraft Parametric 3dDocument131 paginiAircraft Parametric 3dUNsha bee komÎncă nu există evaluări

- Extending Equipment’s Life Cycle – The Next Challenge for Maintenance: 1, #12De la EverandExtending Equipment’s Life Cycle – The Next Challenge for Maintenance: 1, #12Încă nu există evaluări

- Engineering Applications: A Project Resource BookDe la EverandEngineering Applications: A Project Resource BookEvaluare: 2.5 din 5 stele2.5/5 (1)

- CadCam Lab Report FileDocument30 paginiCadCam Lab Report FileAzher Uddin100% (1)

- Conveyor Belt Motor Using Control Grafcet As Programming Tool - 24 PagesDocument24 paginiConveyor Belt Motor Using Control Grafcet As Programming Tool - 24 PagesLandry KlipÎncă nu există evaluări

- Designing SCADA Application Software: A Practical ApproachDe la EverandDesigning SCADA Application Software: A Practical ApproachÎncă nu există evaluări

- FinalDocument49 paginiFinalA-31 Abhinav VermaÎncă nu există evaluări

- Project Report Pranav FinalDocument41 paginiProject Report Pranav Finalshreyash ghongadeÎncă nu există evaluări

- Robot Arm Control With Arduino 3Document42 paginiRobot Arm Control With Arduino 3Rashmi Ranjan RrsÎncă nu există evaluări

- General Aviation Aircraft Design: Applied Methods and ProceduresDe la EverandGeneral Aviation Aircraft Design: Applied Methods and ProceduresEvaluare: 4.5 din 5 stele4.5/5 (29)

- Analysis of Different Bit Carry Look Ahead Adder Using Verilog CodeDocument8 paginiAnalysis of Different Bit Carry Look Ahead Adder Using Verilog Codekhaja mohiddienÎncă nu există evaluări

- Midterm I RevisionxsDocument18 paginiMidterm I RevisionxsAhmed El TayebiÎncă nu există evaluări

- Project Report On Reverse Engineering: Guide: Prof Biswanath DoloiDocument31 paginiProject Report On Reverse Engineering: Guide: Prof Biswanath DoloiBIPLAB MONDALÎncă nu există evaluări

- Robot Arm Control With Arduino: June 2017Document42 paginiRobot Arm Control With Arduino: June 2017Priya UiopÎncă nu există evaluări

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionDe la EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionÎncă nu există evaluări

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsDe la EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsÎncă nu există evaluări

- Aerodynamic Analysis of An Aeroplane With Various Intensities For Different MaterialsDocument44 paginiAerodynamic Analysis of An Aeroplane With Various Intensities For Different MaterialsMedandrao. Kavya SreeÎncă nu există evaluări

- Grey Hound Fleet ManagerDocument91 paginiGrey Hound Fleet ManagerPuspala Manojkumar100% (1)

- Automated Guided Vehicle (AGV) Full TextDocument62 paginiAutomated Guided Vehicle (AGV) Full Textazriffaris100% (2)

- Multirotor Sizing Methodology With Flight Time EstimationDocument23 paginiMultirotor Sizing Methodology With Flight Time EstimationJose Antonio Siñani VilteÎncă nu există evaluări

- Bachelort EindopdrachtDocument119 paginiBachelort EindopdrachtDashuai WuÎncă nu există evaluări

- Work OverDocument3 paginiWork OverDaniil GhilescuÎncă nu există evaluări

- 4wd SystemDocument31 pagini4wd SystemManuales Transmisiones AutomaticasÎncă nu există evaluări

- 1169a AopDocument12 pagini1169a AopBAYARD BernardÎncă nu există evaluări

- Project Plan TemplateDocument4 paginiProject Plan TemplateEricKangÎncă nu există evaluări

- Sao Paulo Brand BookDocument104 paginiSao Paulo Brand Booknicoagudelo82Încă nu există evaluări

- Introduction To Boltzmann LearningDocument2 paginiIntroduction To Boltzmann LearningnvbondÎncă nu există evaluări

- VDA Volume 6.3 2016 Chapter 9.1 Process Audit Action PlanDocument8 paginiVDA Volume 6.3 2016 Chapter 9.1 Process Audit Action PlanYo GoldÎncă nu există evaluări

- Unit-I Introduction To Erp Enterprise Resource Planning (ERP) Is An Integrated Computer-Based SystemDocument51 paginiUnit-I Introduction To Erp Enterprise Resource Planning (ERP) Is An Integrated Computer-Based Systemchandru5g100% (4)

- Software Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzDocument2 paginiSoftware Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzRobertVeklotzÎncă nu există evaluări

- Swiss FCM Ordinance - EuPIA QDocument6 paginiSwiss FCM Ordinance - EuPIA Qiz_nazÎncă nu există evaluări

- Manual Yamaha Clavinova P100Document69 paginiManual Yamaha Clavinova P100Nelon Rocha100% (1)

- Ford Fiesta Specifications: Exterior DimensionsDocument2 paginiFord Fiesta Specifications: Exterior DimensionsBuhuntuUhuÎncă nu există evaluări

- SB658Document3 paginiSB658ricardo novoa saraviaÎncă nu există evaluări

- Catalog07 PDFDocument13 paginiCatalog07 PDFdeig15050% (2)

- Cu Ext 2015Document4 paginiCu Ext 2015mohammedzuluÎncă nu există evaluări

- Mac Puarsa MRL SCHEMATICDocument28 paginiMac Puarsa MRL SCHEMATICthanggimme.phanÎncă nu există evaluări

- S2N Gyro Interface ManualDocument20 paginiS2N Gyro Interface ManualAfrizal Setiawan100% (1)

- Casting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HDocument1 paginăCasting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HCarlos Ediver Arias RestrepoÎncă nu există evaluări

- Texture Formats Used by CFS3Document2 paginiTexture Formats Used by CFS3Hillmen HussinÎncă nu există evaluări

- LS-VINA EHV Cable's CatalogueDocument36 paginiLS-VINA EHV Cable's CatalogueDjar Ndoeth0% (1)

- TV FaultsDocument1.026 paginiTV Faultsdasho1Încă nu există evaluări

- Toyota 5L Terminales de EcmDocument9 paginiToyota 5L Terminales de EcmAlfred Nayb Cañoli Ildefonso0% (1)

- Reduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentDocument4 paginiReduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentjesusÎncă nu există evaluări

- Three-Phase Induction Motor Dynamic Mathematical ModelDocument3 paginiThree-Phase Induction Motor Dynamic Mathematical Modelsajs201100% (3)

- Civil Engineering Interview QuestionsDocument12 paginiCivil Engineering Interview Questionsjadgug100% (1)

- Instrumentation For Measurement of Roof Convergence in Coal MinesDocument9 paginiInstrumentation For Measurement of Roof Convergence in Coal MinessamratÎncă nu există evaluări

- Inlet Modules Model Code: ExampleDocument1 paginăInlet Modules Model Code: ExamplemhasansharifiÎncă nu există evaluări

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocument2 pagini16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaÎncă nu există evaluări

- HILTI Typical Plumbing ApplicationsDocument140 paginiHILTI Typical Plumbing ApplicationskuraimundÎncă nu există evaluări

- Transport ModellingDocument37 paginiTransport ModellingRiza Atiq Abdullah Rahmat100% (6)