Documente Academic

Documente Profesional

Documente Cultură

DEC Pump-Turbine Introduction

Încărcat de

khanhdanhimDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DEC Pump-Turbine Introduction

Încărcat de

khanhdanhimDrepturi de autor:

Formate disponibile

wwwwwwwwwwwwwwwwwwwwwwwwwr

PRESENTATION FOR PUMP-TURBINE

DONGFANG ELECTRIC MACHINERY CO., LTD

Pump-Turbine of DFEM Made PumpPump-Turbine of DFEM Made

Power Station GuangZhou 1st ShiSan Ling XianHongDian HuiZhou HeMiFeng HOHOT Outstanding achievement Main parts Cooperating with VIOTH Self-design Cooperating with ALSTOM and manufacturing 1(one) complete set unit Cooperating with ALSTOM and manufacturing 4(four) complete set units Cooperating with ALSTOM and manufacturing 4(four) complete set units Self-design and manufacturing 4(four) complete set units Operating date 93 95 97 2008 2009 2012

XianYou

2014

wwwwwwwwwwwwwwwwwwwwwwwwwr

Experiences List of DFEM Made Pump-Turbine Experiences List of DFEM Made Pump-Turbine

HuiZhou

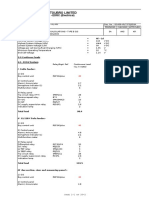

1 Turbine condition Unit Power (MW) Turbine output (MW) Maximum head (m) Rated head (m) Minimum head (m) 2 Pump condition Maximum head (m) Minimum head (m) Maximum input (MW) Maximum flow (m3/s) 3 Other Runner Diameter (m) Runner blade Guide vane Rated speed (r/min) 3.82 9 20 500 5.04 9 20 300 3.88 9 20 500 4.158 9 20 428.6 565 529 330 56.02 337.6 275 325 106 595 503 320 55.27 475 421 302 68.1 4300 306 553.7 517 509 4300 306 335 295 270 4300 306 580 521 490 4300 306 475 430 421

HeMiFeng

HOHOT

XianYou

Typical Pump-Turbine Typical Pump-Turbine

DFEM Typical Products XianHongDian 2X40MW HuiZhou 4X300MW HeMiFeng 4X300MW HOHOT 4X300MW XianYou 4X300MW

wwwwwwwwwwwwwwwwwwwwwwwwwr

Principles of Pump-Turbine Design Principles of PumpPump-Turbine Design

The Best CFD tools can be used in pump-turbine hydraulic design. Making full use of the outcomes in key technology research for large Pump-turbines. Fully use of mature and advanced proposal and structure proven by successful operations. Carefully chosen data with certain surplus. Taking the convenience for installation, maintenance, manufacturing and transportation into full consideration . Reliableadvanceddurableeasy-operationnice-looking.

Cooperation with overseas company Cooperation with overseas company

Our company has been cooperating with many famous overseas companies, such as ViothSiemens, Alstom, GE, VA-TECH, ANDRITZ, Toshiba. Among which, we have cooperated with Vioth, Alstom for pump-turbine.

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design Established test stand specially for pump-turbine Model runner diameter: 350~500 mm Maximum test head: 100 m Maximum Test discharge: 1.5m3/s Test system accuracy: 0.3% The whole system data will be got and processed automatically by computer. Pump-turbine model runner research Technical transfer from the overseas companies Based on overseas advanced runner, making hydraulic design by CFD analyze Machining the blades by 5-axis NC milling and boring machine

Test Stand For Hydraulic Machinery Test Stand For Hydraulic Machinery

DFEM Universal Test Stand For Pump-Turbine

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design

Whole analyzing Runner and Spiral case and Draft tube

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design

Efficiency

Comparison of experiment results and calculation

l tia en fid n Co

Measurements Calculations

2%

0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5

Q11/Q11 opt

CFD tools to predict performances, and comparison with measurement results

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design

Typical cavitation "bucket" curve

350

300 Required submergence NPSH/NPSHopt (%)

250

200

150

bucket curve submergence

100

50 80 85 90 95 100 Q/Qd (%) 105 110 115 120

a specific tool for entrance cavitation analysis

Pump-Turbine Basic Research Hydraulic Design Pump-Turbine Basic Research Hydraulic Design

Softwares for pressure fluctuations prediction

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Basic Research Rigidity & Strength Calculation Analysis Pump-Turbine Basic Research Rigidity & Strength Calculation Analysis

Pump-turbine integrity rigidity and strength calculation analysis Simulation the true turbines discharge, normal operation, load-rejection and runaway condition. Using ANSYS calculation software to calculate static stress for whole unit and large components. Using ADINA calculation software to calculate the runner and shaft system fem dynamic stress.

Pump-Turbine Basic Research Rigidity & Strength Calculation Analysis Pump-Turbine Basic Research Rigidity & Strength Calculation Analysis

Load distribution on obverse surface of blade

Load distribution On water Load distribution way surface of crown on back surface of blade Load distribution On non-waterway nonsurface of band and crow

Load distribution On waterway surface of band

Intensity calculation of runner at any load condition

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Basic Research Rigidity & Strength Calculation Analysis Pump-Turbine Basic Research Rigidity & Strength Calculation Analysis

Combining calculation of spiral case and stay vane

Stress distribution of wicket gate

Stress distribution of head cover

Stress distribution of bottom ring

Pump-Turbine Basic Research Rigidity & Strength Calculation Analysis Pump-Turbine Basic Research Rigidity & Strength Calculation Analysis

p5

DIAPHRAG M E ORIFICE PLATE Qtot

R5 Couvercle Anneau flottant Floating ring Ressorts Springs Cover

p1 Q int

p2

p3 Qext

R1 R2 R3 R4

ANSYS calculation of seal ring

Fig 1

Bearing force

Sealing water

Shaft

ANSYS calculation of seal ring distortion Design and calculation of main shaft seal

10

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Structure Design and manufacture Pump-Turbine Structure Design and manufacture

Runner combination jointing

Typical Pump-Turbine Structure Typical Pump-Turbine Structure

Turbine Cross SectionPump-Turbine

20.500

CIRCULAR RAILWAY 3.5t ? 5904 3.5t ? 7880 ? 1480 18 M100x4 ? 6820 80 - M 105x4 2500 TURBINE PIT ACCES GALLERY

? 5904 Z=20 GUIDE VANES 20

2000

18.300

? 1095 h10

17.750

SERVOMOTOR AXIS

17.800

? 1500 h8 BEARING

SHAFT SEAL ? 1500

15.000

522 DISTRIBUTOR AXIS RUNNER 9 BLADES 9 ? 1480 9 -M110x4 9 -? 150

? 2700 RUNNER OUTLET ( TURBINE MODE )

()

? 5040 RUNNER INLET ( TURBINE MODE )

()

? 7130

40 - M 80x4

2000 DRAFT TUBE CONE ACCES GALLERY

PUMP MODE CLOCKWISE 300 rpm

()

9.500

TURBINE MODE COUNTERCLOCKWISE 300 rpm ()

8.500

DRAFT TUBE ELBOW ? 3596 INLET DIAMETER

11

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Structure Design and manufacture Pump-Turbine Structure Design and manufacture

Gate friction Gate shaft cone sleeve

Transferred wring moment by pin sleeves and connected by bolts between runner and main shaft

Pump-Turbine Structure Design and manufacture Pump-Turbine Structure Design and manufacture

Turbine shaft Intermediate collar

Pad

Thin oil ,self-lubricating , segment and ,selfExternal oil circulation guide bearing Adopted to HuiZhou ,HeMiFeng ,HOHOT etc.

12

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Structure Design and manufacture Pump-Turbine Structure Design and manufacture

Adapted axial shaft seal

Inflatable maintenance seal

Spring, self-adjusting face-type main shaft seal selffaceseal rings in Carbon material or Cestidur Adopted to HuiZhou ,HeMiFeng ,HOHOT , BaoQuan,Three Gorge,LongTan,XiaoWan,PuBuGou etc.

Pump-Turbine Structure Design and manufacture Pump-Turbine Structure Design and manufacture

Spiral case and stay ring: 1 Integer 2 Segmented by transport limit 3 Designing spiral case under maximum water pressure 4 Water pressure test of spiral case at site.

13

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Structure Design and manufacture Pump-Turbine Structure Design and manufacture

Stay ring: Segment Combination at site

Pump-Turbine Structure Design and manufacture Pump-Turbine Structure Design and manufacture

Gate operation control mechanism

20

18

2,63

5 47

single gate servomotor

single gate servomotor and control ring

14

wwwwwwwwwwwwwwwwwwwwwwwwwr

DRAINAGE PIPES IN THE PIT DRAINAGE PIPES IN THE PIT

Main Parts Material Table for Pump-Turbine Main Parts Material Table for Pump-Turbine

Item. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 15 Name of Part Runner Main shaft Spiral case Stay ring Head cover Bottom ring and discharge ring Gate operating ring Guide bearing Main shaft seal Guide vanes Coupling bolt Servomotor cylinder and gate lever Cone and elbow of draft tube Pit liner Wearing ring and seal ring Stay seal ring Material ZG06Cr13Ni4Mo DG20SiMn B610CFADB610D or WDB620 S500Q-Z25 S355J0+N or Q345C S355J0+N or Q345C S355J0+N or Q345C Q235C Q345C ZG06Cr13Ni4Mo 42CrMo ZG20SiMn 16Mn Q235A s135 ZCuAl10FeNi5 GB3274-88 GB3274-88 GB3274-88 GB700 GB3274-88 GB6967 GB3077-88 JB/ZQ4297 GB/T1591-1994 GB700 GB13237-91 GB/T 5231-2001 Standard and Grade (China) GB6967 JB/T6396 CF 62/WCF80 Equality America Standard ASTM A743 CA-6NM ASTM A668 CI.D

G3128-87 EN10025-6 EN10025-2 EN10025-2 EN10025-2 ASTM A36 ASTM A633m ASTM A743 CA-6NM ASTM A304 ASTM A216 WCC ASTM A516-90 Cr70 ASTM A36 ASTM A240-93b ASTM C63200

15

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine Field Test Pump-Turbine Field Test

Water pressure test of Spiral case at site

Pressure cycle

110% 100% 90%

% of pressure

80% 70% 60% 50% 40% 30% 20% 10% 0%

0 1 2 3 4 5 6 7 8 9 10

Design pressure if embedded with partial pressure time in hours

Pump-Turbine Condenser Operation Pump-Turbine Condenser Operation

16

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine maintenance mode compare Pump-Turbine maintenance mode compare

A) Dismantling PT from middle

1 step: dismantling middle shaft

Pump-Turbine maintenance mode compare Pump-Turbine maintenance mode compare

A) Dismantling PT from middle

2 step: dismantling main shaft

17

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine maintenance mode compare Pump-Turbine maintenance mode compare

A) Dismantling PT from middle

3 step: dismantling head cover

Pump-Turbine maintenance mode compare Pump-Turbine maintenance mode compare

A) Dismantling PT from middle

4 step: dismantling runner

18

wwwwwwwwwwwwwwwwwwwwwwwwwr

Pump-Turbine maintenance mode compare Pump-Turbine maintenance mode compare

B) Dismantling PT from stator

dismantling head cover

Pump-Turbine maintenance mode compare Pump-Turbine maintenance mode compare

C) Dismantling PT from movable cone of Draft tube

19

wwwwwwwwwwwwwwwwwwwwwwwwwr

Inlet spherical valve made by DFEM Inlet spherical valve made by DFEM

Ite m 1 2 3 4 5 6 7 8 9 10 11 12 Diameter (m) 1.75 1.75 1.6 2.5 1.3 2.9 2.0 1.9 1.9 1.6 1.5 2.3 Head (max) Rising head (m) 483 230 390 301 455 335 585 620 620 321 318 479.9 725 300 500 400 550 500 900 793 775 420 393 Units 2 2 1 2 3 2 2 2 2 3 2 4 Operating year 1994 2004 2006 2008 2008 2009 2010 2008 2008 2008 2009 Operating status good good good good good good

Power station ShiSan Ling HuanGuangTan XiaoTianDu WaWuSan ShiZiPing HeMiFeng HOHOT JinWo RenZhongHai LIZhiPing DILuo XianYou

Inlet spherical valve Design Inlet spherical valve Design

Inlet spherical Valve: 1 Two surface seal 2 Two servomotor

11

3 Hydraulic operated seal ring 4 Movable operating seal ring replaces by-pass system by-

20

wwwwwwwwwwwwwwwwwwwwwwwwwr

DFEM IS YOUR BEST CHOICE

THANKS!

HeMiFeng Power station

Type of turbine: HLP()-LJ-504 Runner diameter: 5.04m Rated speed: 300r/min Turbine condition: Maximum head: 335m Rated head: 295m Minimum head: 270m Turbine rated output: 306.0MW Pump condition: Maximum pump head: 337.6m Minimum pump head: 275.0m Max. pump discharge : 106m3/s Max. pump input: 325MW

21

wwwwwwwwwwwwwwwwwwwwwwwwwr

HuiZhou Power Station

Type of turbine: HLP()-LJ-382 Runner diameter: 3.82m Rated speed: 500r/min Turbine condition: Maximum head: 553.7m Rated head: 517m Minimum head: 509m Turbine rated output: 306.0MW Pump condition: Maximum pump head: 565m Minimum pump head: 529m Max. pump discharge : 56.02m3/s Max. pump input: 330MW

22

S-ar putea să vă placă și

- AlternatorDocument28 paginiAlternatorAnonymous GRqJf8dz6100% (1)

- By: Mr. Augosto M. DirectoDocument34 paginiBy: Mr. Augosto M. DirectoJames RojasÎncă nu există evaluări

- Converting To Variable Speed at A Pumped-Storage PlantDocument9 paginiConverting To Variable Speed at A Pumped-Storage Plantle hoai NamÎncă nu există evaluări

- Govenor DroopDocument29 paginiGovenor Droophosein30100% (2)

- Generator SizingDocument4 paginiGenerator SizingWaleed Mohammed FekryÎncă nu există evaluări

- Hydraulic Turbines Od ThaperDocument90 paginiHydraulic Turbines Od ThaperVeronica Naveda Espinoza100% (1)

- Hydro TBDocument40 paginiHydro TBkstan112233Încă nu există evaluări

- Chapter 9 Hydro GeneratorDocument32 paginiChapter 9 Hydro GeneratorDivyansh Singh ChauhanÎncă nu există evaluări

- Life BulbDocument2 paginiLife Bulbnemanja_mitrovic_1Încă nu există evaluări

- Good and Bad of Mini Hydro Power Vol.2Document78 paginiGood and Bad of Mini Hydro Power Vol.2Rehmani Mehboob100% (1)

- A Guide To UK Mini-Hydro DevelopmentsDocument31 paginiA Guide To UK Mini-Hydro DevelopmentsGervásioSimãoÎncă nu există evaluări

- API 676 Datasheet PDFDocument6 paginiAPI 676 Datasheet PDFPierre Norris0% (1)

- Pleuger Electrical Submersible Pumps and Water-Filled MotorsDocument12 paginiPleuger Electrical Submersible Pumps and Water-Filled MotorsGabrielMachado100% (1)

- SHPP GL Ch3.FullDocument417 paginiSHPP GL Ch3.FullLuis Faustino Rodriguez LopezÎncă nu există evaluări

- Water Turbine ClassificationsDocument10 paginiWater Turbine ClassificationsMotasem AbushanabÎncă nu există evaluări

- Calculation of Voltage Drop and Cable Size For Motor / Elect - LoadDocument26 paginiCalculation of Voltage Drop and Cable Size For Motor / Elect - Loadkridhakarya kriyakarsaÎncă nu există evaluări

- Electromechanical and Hydro MechanicalComponentsDocument42 paginiElectromechanical and Hydro MechanicalComponentsMOHD SALMANÎncă nu există evaluări

- Instructions To Mod. Zyt5402tzj Mobile Drilling RigDocument135 paginiInstructions To Mod. Zyt5402tzj Mobile Drilling RigYimmy Alexander Parra MarulandaÎncă nu există evaluări

- Hydro Turbine Manual 2009.2Document44 paginiHydro Turbine Manual 2009.2Archil Kokhtashvili100% (1)

- API 676 Pump Rotary DatasheetDocument6 paginiAPI 676 Pump Rotary DatasheetvuongÎncă nu există evaluări

- Company REDocument11 paginiCompany REVincsÎncă nu există evaluări

- Wampu HPP Installation For The EMDocument71 paginiWampu HPP Installation For The EMlufiman100% (1)

- A Seminar On Damodar Valley CorporationDocument30 paginiA Seminar On Damodar Valley Corporationatul mishra100% (5)

- Apf142252 Ga200wDocument102 paginiApf142252 Ga200wRicardo Lopez Padua50% (2)

- Micro Tubular TurbinesDocument8 paginiMicro Tubular TurbinesAshutosh VashishthaÎncă nu există evaluări

- DC Battery Sizing FukudaDocument2 paginiDC Battery Sizing FukudaChinJHÎncă nu există evaluări

- GBT 8564-2003 Specification For Installation of Hydraulic Turbine Generator UnitsDocument104 paginiGBT 8564-2003 Specification For Installation of Hydraulic Turbine Generator Unitsearizabal100% (3)

- Battery Sizing 3 Trafo (Latest)Document20 paginiBattery Sizing 3 Trafo (Latest)jm.mankavil6230Încă nu există evaluări

- Teachers Manual On Hydroplants (Theory & Design)Document207 paginiTeachers Manual On Hydroplants (Theory & Design)Shashi TapsiÎncă nu există evaluări

- Caterpillar 3606 2425kVA GensetDocument6 paginiCaterpillar 3606 2425kVA GensetMuhammad Irfan KhanÎncă nu există evaluări

- Voith Eco Friendly Turbine DesignDocument8 paginiVoith Eco Friendly Turbine DesignBehailu FelekeÎncă nu există evaluări

- Glossary of Hydropower TermsDocument24 paginiGlossary of Hydropower TermsWaleed HassanÎncă nu există evaluări

- HH220i Smaster ManualDocument60 paginiHH220i Smaster Manualjacklyn ade putra100% (1)

- GEA18574 Hydro Generator Test and InspectDocument4 paginiGEA18574 Hydro Generator Test and InspecteciceranÎncă nu există evaluări

- PLEUGERDocument12 paginiPLEUGERMoe LattÎncă nu există evaluări

- Kaplan TurbineDocument72 paginiKaplan TurbinerizhaypÎncă nu există evaluări

- Marine Propulsion English Status January 2011Document20 paginiMarine Propulsion English Status January 2011Jodiel CoelhoÎncă nu există evaluări

- 3.1 Turbine and GoverningDocument90 pagini3.1 Turbine and GoverningGökhan Aytaş100% (2)

- Hyundai: Vertical Mixed / Axial FlowDocument12 paginiHyundai: Vertical Mixed / Axial FlowdkspplÎncă nu există evaluări

- Edoc - Pub - 31 Turbine and Governing PDFDocument90 paginiEdoc - Pub - 31 Turbine and Governing PDFsureshÎncă nu există evaluări

- Variable Speed OperationDocument10 paginiVariable Speed Operationmunagala balasubramanyamÎncă nu există evaluări

- Hydro Turbines - Bulb, The Complete Solution For Low HeadsDocument12 paginiHydro Turbines - Bulb, The Complete Solution For Low HeadspalanaruvaÎncă nu există evaluări

- Operating Manual Ergotech 125/ - Ergotech 2000/: EnglishDocument812 paginiOperating Manual Ergotech 125/ - Ergotech 2000/: EnglishEgidius100% (4)

- Flexibility Analysis of Thermal Generation For RE Integration in India 1Document564 paginiFlexibility Analysis of Thermal Generation For RE Integration in India 1Sanjay NandalÎncă nu există evaluări

- AF09 ... AF30 3-Pole Contactors Up To 25 HP / 600 VAC: Contactors and Overload RelaysDocument33 paginiAF09 ... AF30 3-Pole Contactors Up To 25 HP / 600 VAC: Contactors and Overload RelaysJohn LorenzoÎncă nu există evaluări

- Andritz Hydro Indonesia Presentation 2014Document24 paginiAndritz Hydro Indonesia Presentation 2014Dmz FreakzÎncă nu există evaluări

- Design of Hydroelectric Power Plants.Document54 paginiDesign of Hydroelectric Power Plants.Sanjay Singh0% (1)

- Digital Turbine GovernorDocument5 paginiDigital Turbine GovernorsherryÎncă nu există evaluări

- VOITH Small Hydro SolutionDocument18 paginiVOITH Small Hydro SolutionDustin Soria VÎncă nu există evaluări

- Design of Hydro Power by Using Turbines Kaplan OnDocument5 paginiDesign of Hydro Power by Using Turbines Kaplan Ondave chaudhuryÎncă nu există evaluări

- Hydro Electric Power PlantDocument52 paginiHydro Electric Power PlantHarpreet Singh KambojÎncă nu există evaluări

- 2.turbine and AccessoriesDocument38 pagini2.turbine and Accessoriespavankumar001Încă nu există evaluări

- Working Principle of Submersible PumpDocument5 paginiWorking Principle of Submersible PumpSatinder saini100% (1)

- 2013-05-27 Voith Francis TurbinesDocument5 pagini2013-05-27 Voith Francis TurbinesedpsousaÎncă nu există evaluări

- Hydroelectric Power Plants Electrical DesignDocument118 paginiHydroelectric Power Plants Electrical DesignavikrisadÎncă nu există evaluări

- AC Variable Frequency Drive With Static SteplessDocument0 paginiAC Variable Frequency Drive With Static Steplessswapneel_kulkarniÎncă nu există evaluări

- Bentley - Modelling Francis Turbine PDFDocument17 paginiBentley - Modelling Francis Turbine PDFAsif MuhammadÎncă nu există evaluări

- Slotless Permanent Magnet Ind-Synmotor: in Modern Industrialized Country, About 65% of Electrical Energy IsDocument11 paginiSlotless Permanent Magnet Ind-Synmotor: in Modern Industrialized Country, About 65% of Electrical Energy IsRahmathullah Saleem Basha0% (1)

- C HO 02. Reliability ManagementDocument137 paginiC HO 02. Reliability ManagementRivaldi Raka AdityaÎncă nu există evaluări

- Pico Hydro Power DesignDocument186 paginiPico Hydro Power DesignSufi Shah Hamid Jalali100% (2)

- Hydraulic Pumps: BY Abeesh Kiran A M-Tech Design and Precision Engineering Nitk Surathkal, KarnatakaDocument62 paginiHydraulic Pumps: BY Abeesh Kiran A M-Tech Design and Precision Engineering Nitk Surathkal, KarnatakaFaisal Rafique100% (1)

- L2 Francis Turbine 2020 PDFDocument73 paginiL2 Francis Turbine 2020 PDFBalkrishna ChaudharyÎncă nu există evaluări

- The Banki Water TurbineDocument28 paginiThe Banki Water Turbineamatos4716075% (4)

- 1 Selection Criteria For Turbine and Drive Krishna B. NakarmiDocument55 pagini1 Selection Criteria For Turbine and Drive Krishna B. NakarmitrxrhcpÎncă nu există evaluări

- What Are Turbines ? - Types of Turbines & Their ApplicationsDocument6 paginiWhat Are Turbines ? - Types of Turbines & Their ApplicationsAnonymous m2GmeVnY100% (1)

- WEG Hydrogenerators Gh20 14824113 Manual EnglishDocument51 paginiWEG Hydrogenerators Gh20 14824113 Manual EnglishGuilherme RosaÎncă nu există evaluări

- Motor PDFDocument81 paginiMotor PDFmaungÎncă nu există evaluări

- CP220i Manual Standard Part Numbers Complete - MasterDocument67 paginiCP220i Manual Standard Part Numbers Complete - Masterjacklyn ade putra100% (1)

- Catalog Bomba de Paletas General Eaton PDFDocument200 paginiCatalog Bomba de Paletas General Eaton PDFJunior Enrique Yataco ArizaÎncă nu există evaluări

- Product Bulletin - DOEN DJ100G eDocument8 paginiProduct Bulletin - DOEN DJ100G eeeÎncă nu există evaluări

- 6-Doosan CigrePrep - 1222MVA GEN Development - FontRevID31VER89Document23 pagini6-Doosan CigrePrep - 1222MVA GEN Development - FontRevID31VER89Yogananda Madhava SettyÎncă nu există evaluări

- Physgen Unit 5Document13 paginiPhysgen Unit 5emji miraÎncă nu există evaluări

- Nujira MIPI PresentationDocument20 paginiNujira MIPI PresentationjeremyhendyÎncă nu există evaluări

- Split Type Room Air Conditioner Wall Mounted Type: Downloaded From Manuals Search EngineDocument25 paginiSplit Type Room Air Conditioner Wall Mounted Type: Downloaded From Manuals Search EnginePauloÎncă nu există evaluări

- 2020-2029 Aleco-Apec PSPPDocument19 pagini2020-2029 Aleco-Apec PSPPRellora Mark AndreiÎncă nu există evaluări

- MC B2004 38 - PRC1088Document3 paginiMC B2004 38 - PRC1088Sokolov ShermenÎncă nu există evaluări

- Case 3Document3 paginiCase 3Najmi Shafiz RozmanÎncă nu există evaluări

- Units and Measurements - DPPDocument7 paginiUnits and Measurements - DPPManish ShrungareÎncă nu există evaluări

- Yokogawa CW121Document3 paginiYokogawa CW121Pithoon UngnaparatÎncă nu există evaluări

- Trade of Electrician: Standards Based ApprenticeshipDocument21 paginiTrade of Electrician: Standards Based ApprenticeshipAhmad HamoudaÎncă nu există evaluări

- Energy Logic For Telecom White Paper PDFDocument16 paginiEnergy Logic For Telecom White Paper PDFfadil3m2422Încă nu există evaluări

- Problem SetDocument4 paginiProblem SetPaul KellyÎncă nu există evaluări

- Rajshree Sen PDFDocument18 paginiRajshree Sen PDFRavin PÎncă nu există evaluări

- Enerwaste Green HubDocument20 paginiEnerwaste Green Hubgaby.hernandez485703Încă nu există evaluări

- Wind Energy Training Ch#4Document44 paginiWind Energy Training Ch#4Munseb AliÎncă nu există evaluări

- Renewable Energy ReportDocument61 paginiRenewable Energy ReportHojin HaÎncă nu există evaluări

- Seasonal Assessment of Resource Adequacy For The ERCOT Region (SARA) Winter 2022/23Document21 paginiSeasonal Assessment of Resource Adequacy For The ERCOT Region (SARA) Winter 2022/23Rebecca SalinasÎncă nu există evaluări

- CEABo KStudy Guide SIDocument12 paginiCEABo KStudy Guide SIAli AlghanimÎncă nu există evaluări

- GaqtertretDocument46 paginiGaqtertretPrince HeheÎncă nu există evaluări

- Lecture 2: Load Allocation Across A Feeder: ECE 5984: Power Distribution System AnalysisDocument18 paginiLecture 2: Load Allocation Across A Feeder: ECE 5984: Power Distribution System Analysisante mitarÎncă nu există evaluări