Documente Academic

Documente Profesional

Documente Cultură

2008 08 Beacon Measuring Process Safety Performance

Încărcat de

Harshad SolankiDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2008 08 Beacon Measuring Process Safety Performance

Încărcat de

Harshad SolankiDrepturi de autor:

Formate disponibile

http://www.aiche.org/CCPS/Publications/Beacon/index.

aspx

Messages for Manufacturing Personnel

Sponsored by CCPS Supporters

August 2008

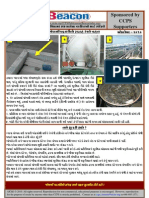

Measuring Process Safety Performance

The July 2008 Process Safety Beacon discussed the meaning of Process Safety, and also said that traditional measures of safety performance such as injury rates, lost time injuries, etc., are not good measures of how good a job we are doing on process safety. So, how can we tell whether or not our process safety management activities are effective? How can we tell if our performance is improving over the years? How do we know how one plant, or unit in a plant, is performing compared to others? How will we decide where to focus our attention so we can get better? If the traditional safety measures are not good for monitoring process safety performance, we need to invent new measures that will. Many industry organizations, including CCPS, are actively working to develop new ways to measure process safety performance. But these tools cannot be effective unless everybody in the process industry workforce understands what these tools are, and why they are needed. And, most important, we all have to understand what our role will be in using any new process safety measurement tools. We need to understand what types of events we need to report, and how to report them in our organization.

Do you know?

CCPS, working with a number of industrial, labor, and government organizations, has developed tools for measuring process safety performance. The report recommending specific measurement tools was issued in December 2007, and can be found at the CCPS web site, http://www.aiche.org/ccps/. Two types of measurements proposed lagging indicators, which measure actual outcomes and past performance (the number of process safety incidents which have occurred), and leading indicators which measure process safety management activities, and which are believed to be useful in predicting future performance. Lagging indicators will measure, for example, the number of releases of hazardous material or energy from plant equipment, fires and explosions, and process related injuries. Leading indicators will measure, for example, plant mechanical integrity, action item follow up, management of change, and process safety training.

What can you do?

Understand what your company is doing to measure process safety performance. Learn and understand the specific measures that your company is using. Know what kinds of incidents need to be reported under your companys process safety measurement program. Be familiar with how to report process safety incidents in your plant. Be diligent in reporting incidents. Remember that a company cannot improve process safety performance if it does not know about incidents that occur in the plant. Understand leading indicators of process safety performance for your plant and how to report them. Download and read the CCPS report on measuring process safety performance.

How does your organization measure process safety performance?

AIChE 2008. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for the purpose of resale by anyone other than CCPS is strictly prohibited. Contact us at ccps_beacon@aiche.org or 212-591-7319

The Beacon is usually available in Afrikaans, Arabic, Chinese, Danish, Dutch, English, French, German, Gujarati, Hebrew, Hindi, Hungarian, Indonesian, Italian, Japanese, Korean, Malay, Marathi, Persian, Polish, Portuguese, Russian, Spanish, Swedish, Tamil, Thai, Turkish, and Vietnamese.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Delphi 7-Interbase TutorialDocument78 paginiDelphi 7-Interbase Tutorialdee26suckÎncă nu există evaluări

- Blood On The Altar: The Secret History of The World's Most Dangerous Secret SocietyDocument172 paginiBlood On The Altar: The Secret History of The World's Most Dangerous Secret Societypermindex198467% (3)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- 47 QM-013 Master Inspection CharacteristicsDocument7 pagini47 QM-013 Master Inspection CharacteristicsElanÎncă nu există evaluări

- Panchanguli Devi Mantra To Forecast FutureDocument1 paginăPanchanguli Devi Mantra To Forecast FutureHAREESHÎncă nu există evaluări

- CICS Question AnswersDocument45 paginiCICS Question AnswersVarun Kumar100% (1)

- The Tales Themselves - An Overview by Dr. Anna ChallengerDocument15 paginiThe Tales Themselves - An Overview by Dr. Anna Challengerhimkeraditya100% (2)

- Beacon EnglishDocument1 paginăBeacon EnglishselvajanarÎncă nu există evaluări

- 2008-12-Beacon - Static Electric Discharge Causes Fire - December 2008Document1 pagină2008-12-Beacon - Static Electric Discharge Causes Fire - December 2008liveconnectionz282Încă nu există evaluări

- Beacon GujaratiDocument1 paginăBeacon GujaratiHarshad SolankiÎncă nu există evaluări

- Beacon GujaratiDocument1 paginăBeacon GujaratiHarshad SolankiÎncă nu există evaluări

- 2008 10 Ice Ruptures Causes FireDocument1 pagină2008 10 Ice Ruptures Causes FireHarshad SolankiÎncă nu există evaluări

- 2009 04 Be PreparedDocument1 pagină2009 04 Be PreparedHarshad SolankiÎncă nu există evaluări

- Beacon EnglishDocument1 paginăBeacon EnglishHarshad SolankiÎncă nu există evaluări

- Beacon HindiDocument1 paginăBeacon HindiHarshad SolankiÎncă nu există evaluări

- Beacon GujaratiDocument1 paginăBeacon GujaratiHarshad SolankiÎncă nu există evaluări

- 2009 03 Fatality Caused by Unloading The Wrong ChemicalDocument1 pagină2009 03 Fatality Caused by Unloading The Wrong ChemicalHarshad SolankiÎncă nu există evaluări

- Beacon GujaratiDocument1 paginăBeacon GujaratiHarshad SolankiÎncă nu există evaluări

- 2008 09 Plant SecurityDocument1 pagină2008 09 Plant SecurityHarshad SolankiÎncă nu există evaluări

- Beacon GujaratiDocument1 paginăBeacon GujaratiHarshad SolankiÎncă nu există evaluări

- 2009 05 Mechanical IntegrityDocument1 pagină2009 05 Mechanical IntegrityHarshad SolankiÎncă nu există evaluări

- Spill Containment BeaconDocument1 paginăSpill Containment BeaconselvajanarÎncă nu există evaluări

- 2009 01 Fire While Filling Portable ContainerDocument1 pagină2009 01 Fire While Filling Portable ContainerHarshad SolankiÎncă nu există evaluări

- 2008 04 Gasoline Pipeline Damaged by Construction Causes FireDocument1 pagină2008 04 Gasoline Pipeline Damaged by Construction Causes FireHarshad SolankiÎncă nu există evaluări

- 2008 07 What Is Process SafetyDocument1 pagină2008 07 What Is Process SafetyHarshad SolankiÎncă nu există evaluări

- Dust Explosion 2008 05 BeaconDocument1 paginăDust Explosion 2008 05 BeaconHaresh PatelÎncă nu există evaluări

- 2008 03 Do Your Shutoff Systems Actually WorkDocument1 pagină2008 03 Do Your Shutoff Systems Actually WorkHarshad SolankiÎncă nu există evaluări

- 2008 11 Laboratory Refrigerator ExplosionsDocument1 pagină2008 11 Laboratory Refrigerator ExplosionsHarshad SolankiÎncă nu există evaluări

- 2008 06 Halon Cylinder Becomes RocketDocument1 pagină2008 06 Halon Cylinder Becomes RocketHarshad SolankiÎncă nu există evaluări

- 2008 02 How Can You Use The BeaconDocument1 pagină2008 02 How Can You Use The BeaconHarshad SolankiÎncă nu există evaluări

- 2008 01 2007 Beacon Review - Remember The Lessons LearnedDocument1 pagină2008 01 2007 Beacon Review - Remember The Lessons LearnedHarshad SolankiÎncă nu există evaluări

- Oil Tank Fire Caused by Static Discharge: Sponsored by Ccps SupportersDocument1 paginăOil Tank Fire Caused by Static Discharge: Sponsored by Ccps SupportersNarasimmaraj NagarajanÎncă nu există evaluări

- 2007 11 Cold Embrittlement and Thermal StressDocument1 pagină2007 11 Cold Embrittlement and Thermal StressHarshad SolankiÎncă nu există evaluări

- 2007 10 We Have LiftoffDocument1 pagină2007 10 We Have LiftoffHarshad SolankiÎncă nu există evaluări

- 2007 08 Hazards of Temporary Confined SpacesDocument1 pagină2007 08 Hazards of Temporary Confined SpacesHarshad SolankiÎncă nu există evaluări

- 2007 09 Hot Work PermitsDocument1 pagină2007 09 Hot Work PermitsHarshad SolankiÎncă nu există evaluări

- FunctionsDocument28 paginiFunctionsT RÎncă nu există evaluări

- Identity Politics Challenges To Psychology S UnderstandingDocument12 paginiIdentity Politics Challenges To Psychology S UnderstandingDiego GonzalezÎncă nu există evaluări

- Precis Writing Class AssignemntDocument2 paginiPrecis Writing Class AssignemntRohit KorpalÎncă nu există evaluări

- Ms Word: 1. Creating and Editing DocumentsDocument12 paginiMs Word: 1. Creating and Editing DocumentsTehreem FatimaÎncă nu există evaluări

- Plural and Singular Rules of NounsDocument6 paginiPlural and Singular Rules of NounsDatu rox AbdulÎncă nu există evaluări

- English Week PaperworkDocument6 paginiEnglish Week PaperworkYusnamariah Md YusopÎncă nu există evaluări

- Grade-7 TOSDocument6 paginiGrade-7 TOSmerlyn m romerovÎncă nu există evaluări

- Lecture Five/Part2: 8086 Instruction Set2 Bit Manipulation InstructionDocument17 paginiLecture Five/Part2: 8086 Instruction Set2 Bit Manipulation InstructionBinod AdhikariÎncă nu există evaluări

- English 8thDocument153 paginiEnglish 8thCarlos Carreazo MÎncă nu există evaluări

- Hazrat Shaikh Shah Kareem Allah Chisti Known As Ashiq Khaja Barkas HyderabadDocument53 paginiHazrat Shaikh Shah Kareem Allah Chisti Known As Ashiq Khaja Barkas HyderabadMohammed Abdul Hafeez, B.Com., Hyderabad, IndiaÎncă nu există evaluări

- Arts G10 First QuarterDocument9 paginiArts G10 First QuarterKilo SanÎncă nu există evaluări

- Unit 3 The Teaching and Learning of ESOLDocument46 paginiUnit 3 The Teaching and Learning of ESOLIlya VilsonÎncă nu există evaluări

- LP2012Document4 paginiLP2012Anonymous PnznvixÎncă nu există evaluări

- Works: Oland ArthesDocument27 paginiWorks: Oland ArthesManuel De Damas Morales100% (1)

- Online Assessment Guide-2019-10-24Document36 paginiOnline Assessment Guide-2019-10-24Dr.Fouzia KirmaniÎncă nu există evaluări

- Veeam Backup Replication White PaperDocument28 paginiVeeam Backup Replication White Paperlutung kasarungÎncă nu există evaluări

- Introduction To Sigtran:: A White PaperDocument16 paginiIntroduction To Sigtran:: A White PaperEbo BentilÎncă nu există evaluări

- Sujet Dissertation Droit Constitutionnel Licence 1Document7 paginiSujet Dissertation Droit Constitutionnel Licence 1BuyPapersForCollegeUK100% (1)

- 8 English 1Document5 pagini8 English 1Leonilo C. Dumaguing Jr.Încă nu există evaluări

- TornadoDocument25 paginiTornadoMuni Sankar MatamÎncă nu există evaluări

- Soal PTS Inggris Kelas XDocument6 paginiSoal PTS Inggris Kelas XN picturesÎncă nu există evaluări

- Xxwelcome To Marriland'S Pokemon Black and White Walkthrough!Document49 paginiXxwelcome To Marriland'S Pokemon Black and White Walkthrough!Hairul Anuar NgademinÎncă nu există evaluări

- Laser WORKS 8 InstallDocument12 paginiLaser WORKS 8 InstalldavicocasteÎncă nu există evaluări