Documente Academic

Documente Profesional

Documente Cultură

Cigreb2 4

Încărcat de

Nguyễn Tăng LâmDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cigreb2 4

Încărcat de

Nguyễn Tăng LâmDrepturi de autor:

Formate disponibile

7.

KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K B2 - 4

Increasing of 110 kV Power Transmission Line Capacity by Using GTACSR/GZTACSR Conductors

Borut Zemljari

IBE Consulting Engineers Hajdrihova 4, Ljubljana E-mail: borut.zemljaric@ibe.si,

Franc Jakl

University of Maribor, Faculty of Electrical Engineering, Computer Sciences and Information Technology Smetanova 17, 2000 Maribor E-mail: franc.jakl@uni-mb.si

Abstract As a consequence of increasing power consumption, new power generator facilities connected to the transmission grid, increasing standards for reliability and quality of electric power delivery, owners of transmission power lines are forced to increase power capacity of particular overhead transmission lines in the grid. That can be made by using gap type conductors. Because of their unique construction and mechanical material properties, significant increase of power capacity can be reached without tower line modification.

Poveanje prenosne moi 110 kV daljnovoda z uporabo GTACSR/GZTACSR vodnikov

Povzetek Poveevanje porabe elektrine energije, vkljuevanje novih elektroenergetskih objektov v prenosno daljnovodno omreje, zvievanje norm zanesljivosti dobave in kakovosti elektrine energije zahtevajo od upravljavcev prenosnega in distribucijskega omreja poveevanje zmogljivosti obstojeega daljnovodnega omreja oziroma njegovih delov. Prenosno mo daljnovoda je mogoe poveati z zamenjavo obstojeih vodnikov z novimi vodniki z reo, ki s svojimi konstrukcijsko mehanskimi lastnostmi omogoajo visoke prenosne kapacitete pri visokih temperaturah ob zelo ugodnih povesnih karakteristikah, ki ne zahtevajo poseganja v nosilne elemente daljnovoda stebre.

I. INTRODUCTION High voltage overhead transmission lines provide a reliable and economic manner to transmit large amounts of electric power. As demands for electricity grows, there is a need for additional transmission lines or uprating existing ones to maintain or improve reliability of power delivery. Today, as the construction of new lines, rebuilding and upgrading of existing electric transmission lines become increasingly difficult, new approaches are being devoted to increase the current capacity by using new type of conductors. The paper presents a possible approach to increase the power capacity of existing 110 kV transmission lines with Gap conductors. The conductors were developed in Japan in late 1960s. Gap type conductor is a high temperature, low sag conductor with a nominal power capacity which is up to 2 times higher

than the capacity of the standard ACRS conductor. Gap conductors allow to increase the power capacity of the line without tower strengthening. This is a very good solution in cases where reliability N-1, N-2 must be met. The first part of the paper deals with the construction of the gap type conductor. It is followed by the presentation of increasing 110 kV one circuit transmission line capacity equipped with standard ACSR 240/40 by replacing them with GTACSR/GZTACSR 240. Calculation of conductors ampacity, sags and power losses are presented. Increased currents have an influence on the electromagnetic field under the transmission line, for which the basic calculations are presented. The intent is not to provide a basis for setting policy but to provide insight into an uprating method in order to facilitate thinking about a good alternative of increasing power transmission line capacity.

B2 - 21

7. KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K B2 - 4

II. GAP TYPE CONDUCTORS The conductors known as Gap type consist of an extra high strength steel core surrounded by stranded layers of aluminum alloy. The inner alloy is made from trapezoidal wires to form a tube. The inner diameter of this layer is larger then outer steel core diameter. Thus a gap is formed, which is filled with high temperature silicone grease. Figure 1 shows gap type GTACSR conductor. Conductors GTACSR use heat resistant aluminum alloy (TAl) and can withstand up to 150C and have the same mechanical properties as hard drawn aluminum. Conductors GZTACSR use super heatresistant aluminum alloy (ZTAl) and they withstand up to 210C and have the same mechanical properties as hard drawn aluminum. TAl and ZTAl have the same mechanical and electrical properties except for the allowable temperature.

TABLE 1 CUNDUCTORS PARAMETERS ACSR 240/40 21.8 282.5 0.985 80 GTACSR 240 20.6 279.6 0.951 150 GZTACS R 240 20.6 279.6 0.951 210 BTACSR/ACS 240/40 21.8 282.5 0.925 150

Diameter (mm) Crosssection (mm2) Weight (kg/m) Temperatu re (C)

1400 Current carring capacity (A) 1200 1000 800 600 400 200 0 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 Conductor tem perature (C) ACSR 240/40 GTACSR 240 GZTACSR 240

Fig 2. Conductors current carrying capacity Fig 1. Conductors cross-section type GTACSR Above sagging temperature all tension is born by the steel core. Because the thermal coefficient of steel is one half of that for aluminum, the thermal elongation characteristic of GTACSR/GZTACSR is smaller than that of conventional ACSR, better temperature sag increase characteristic is achieved. III. GAP CONDUCTOR CURRENT AMPACITY AND SAG Gap conductors GTACSR/GZTACSR are designed to withstand high temperatures at higher conductor ampacity than the standard ACSR conductor. To determine the highest temperature of conductor, it is important to determine the required power capacity. When transmission line uprating is done without tower modification then usually cross-section and diameter of existing conductor is not exceeded. In the paper we deal with the standard ACSR 240/40 conductor and gap conductors GTACSR 240 and GZTACSR 240. Their basic mechanical properties are shown in Table 1. Black conductor properties are also included in the table. Black conductor BTACSR/ACS 240/40 is a high temperature (up to 150C) conductor with basic of ACS core. Current carrying ampacity curves are presented in Figure 2. Curve calculations are made for 35C ambient temperature, wind velocity 0.6 m and emission coefficient 0.9. At standard temperature range up to 80C conductors ampacities are almost equal. With raising temperature up to 150C for GTACSR the current ampacity is 998 A and temperature up to 210C for GZTACSR ampacity reach 1238 A. Maximal conductor ampacity reach the ratio of 1.7 to 2.1 according to standard ACSR value at 80C. For comparison the ratio of BTACSR/ACS conductor is practically equal to GTACSR.

TABLE II MAXIMAL CUNDUCTOR AMPACITY Conductor Temperature Ampacity (C) (A) ACSR 240/40 80 586 BTACSR/ACS 240/40 150 1095 GTACSR 240 150 998 GZTACSR 240 210 1238

Ratio 100 187 170 211

Power capacity based on previously mentioned conductor ampacity shows figure 3. At maximum conductor temperature (210C) single circuit power line can transmit approximately 240 MVA. Higher temperature means higher value of conductor sag, so in case of existing power line the balance between maximum operating temperature and conductor sag need to be found. Operating at high temperature increases conductor resistance and through this power losses increase. As figure 4 shows the ratio between losses when operating up to 80C and operating up to 210C can reach 6 These conductors can be used effectively to assure enough power capacity in the operational security cases N-1 or N-2.

B2 - 22

7. KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K B2 - 4

250 Po w er cap acity (M VA ) 200 150 100 50 0 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 Conductor temperature (C) ACSR 240/40 GTACSR 240 GZTACSR 240

Fig 3. 110 kV single circuit power line capacity

1007 907 Pow er losses (kW/km ) 807 707 607 507 407 307 207 107 7 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 Conductor temperature (C) ACSR 240/40 GTACSR 240 GZTACSR 240

If the temperature of the ACSR conductor is 40C, the temperature of the GTACSR/GZTACSR conductor can be 80C with clearances still within original design value. A re-assessment of clearances under specific line usually shows that condition temperature can be uprated. Some sections can be subject to minor retensioning. If a temperature of 80C for the ACSR conductor is allowed, the gap conductor equivalent temperature is 160C. Another advantage of gap conductors can be achieved by taking into account the cooling effect and analysis of internal tensioning reserves in existing steel towers. Tension difference analysis shows that every 1kN difference in tension means around 0.5 m difference in sag. III. ELECTRIC AND MAGNETIC FIELDS Increasing current ampacity has influence on the magnetic field above the ground level while electric field stays unchanged. As we mentioned before the goal of uprating transmission line with gap conductors is increasing the power capacity without tower modification. This means that clearances to the obstacles and ground stay practically unchanged. In this chapter we present the study case of uprating a 110 kV single circuit transmission line with tower dimension shown in figure 6.

Fig 4. Conductor power losses The temperature sag properties were calculated for conductors and conditions given below: Span length 300 m, Conductors ACSR 240/40m, BTACSR/ACS 240/40 and GTACSR/GZTACSR 240, Taken boundary conductors tension at -5C and 8.4 N/m additional load is 24 kN Taken turning temperature for GTACSR/GZTACSR is 25C and tension 12.8 kN and No cooling effect of natural convection was taken in sag calculations. Figure 5 shows calculated temperature sag properties.

12,5 12 C o n d u cto r sag (m ) 11,5 11 10,5 10 9,5 9 8,5 8 7,5 0 20 40 60 80 100 120 140 160 180 200 Conductor temperature (C) ACSR 240/40 BTACSR/ACS 240/40 GTACSR/GZTACSR 240

Fig 6. Single circuit 110 kV line tower head Calculations of electric and magnetic field are made under the transmission line 1 m above ground and 9 m mean height conductors above ground. Precaution values according to Slovenian Law [5, 6] in case that the existing line is for low- frequency 50 Hz electric field 1.8 kV/m and for low-frequency 50 Hz magnetic field 15 T . Figure 7 presents the electric field.

Fig 5. Conductors temperature sag curve

B2 - 23

7. KONFERENCA SLOVENSKIH ELEKTROENERGETIKOV Velenje 2005 CIGRE K B2 - 4

1.6 1.4

110 kV

Increased current ampacity has influence on the magnetic field above the ground level while electric field stays unchanged. Comparing calculated values with required yields to conclusion that uprating is possible. REFERENCES [1] A.J. Peterson, S. Hoffmann, Transmission Line Conductor Design Comes of Age, Transmission and Distribution World, pp. 62-68, June 2003

Electric f ield [ kV/m]

1.2 1 .8 .6 .4

-20 -15 -10 -5 0 5 D istance f rom tow er axis [ m] 10 15 20

Fig 7. Electric field The increased magnetic field is shown in figure 8. At power capacity 50 MVA magnetic field in line axis is 5 T, at 100 MVA is 10.5 T, at 150 MVA is 16 T and at 200 MVA it reaches approximately 21 T.

22 20 18 Magnetic field [microT ] 16 14 12 10 8 6 4

-20 -15 -10 -5 0 5 D istance f rom tow er axis [ m] 10 15 20

[2] M.J. Tunstal, S.P. Hoffmann, N.S. Derbyshire, M.J. Pyke, Maximising the Ratings of National Grids Existing Transmission Lines Using High Temperature, Low Sag Conductors, CIGRE, Paper 22-202, Paris, 2000 [3] F. Jakl, K. Baki, A New Generation of Overhead Line Conductors, Paper No. 2-4 on Vidmar's Day, Ljubljana, 1998 [4] Conductors for uprating of overhead lines, ELECTRA, No 213, April 2004

262 A (50 MVA) 525 A (100 MVA) 788 A (150 MVA) 1050 A (200 MVA)

[5] Ordinance on Electromagnetic Radiation in the Natural and Living Environment, Official Gazette of the Republic of Slovenia, No. 70-3819/96 [6] Regulatory on the First Measurements and Operational Monitoring for the Non-Ionizing Radiation Sources and Conditions for its Performance, Official Gazette of the Republic of Slovenia, No. 70-3819/96 [7] Low Sag Up-rating Conductor for Up-rating ACSR 240/40, JTD 80-0142, J-Power Systems Corporation, August 2002

Fig 8. Magnetic field Comparing calculated values with required yields to conclusion that uprating is possible. IV. CONCLUSION

We present an electrical conductor that allows the current capacity of an overhed wire conductor to be doubled over that of convential ACSR conductor. That can be done by restringing the conductors on existing towers. This conductors can be used effectively to assure enough increase power capacity in the cases N-1, N-2 operational security in areas where rebuilding the steel towers is connected with right of way problems. Gap conductors GTACSR/GZTACSR are designed to withstand high temperatures at higher conductor ampacity than the standard ACSR conductor. Because of unique construction, sags at high temperatures are much lower than in standard ACSR conductors.

B2 - 24

S-ar putea să vă placă și

- Solution Manual for 100 Genesys Design Examples: Second EditionDe la EverandSolution Manual for 100 Genesys Design Examples: Second EditionÎncă nu există evaluări

- HTLS and HVDC Solutions For Overhead Lines Uprating: 1. AbstractDocument5 paginiHTLS and HVDC Solutions For Overhead Lines Uprating: 1. Abstractdandanache1970Încă nu există evaluări

- 14F3099X00 Ampacity Wire WisdomDocument2 pagini14F3099X00 Ampacity Wire WisdomAnonymous IvZSKJCÎncă nu există evaluări

- B2 103 2012Document9 paginiB2 103 2012Hugh EdwardsÎncă nu există evaluări

- Pilot Installation of GTACSR Conductors in The Spanish Power SystemDocument5 paginiPilot Installation of GTACSR Conductors in The Spanish Power Systemelsayed abdemagiedÎncă nu există evaluări

- Cable 400kV CleusonDocument4 paginiCable 400kV CleusonsalvandyÎncă nu există evaluări

- Sizing Calculations For 20/3.3 KV, 12.5 MVA Transformer Feeder CableDocument9 paginiSizing Calculations For 20/3.3 KV, 12.5 MVA Transformer Feeder CableNeomax BuildersÎncă nu există evaluări

- Superconducting CablesDocument6 paginiSuperconducting CablesA. HassanÎncă nu există evaluări

- Code Calculations: Mike HoltDocument2 paginiCode Calculations: Mike HoltPhopskhongLasagaÎncă nu există evaluări

- Tech Report Alu Tub Busbars For HV SubDocument5 paginiTech Report Alu Tub Busbars For HV SuberutefauikaÎncă nu există evaluări

- Current Carrying CapacityDocument106 paginiCurrent Carrying Capacityshivender777Încă nu există evaluări

- Mod 7-Electricity in The Cement IndustryDocument324 paginiMod 7-Electricity in The Cement IndustrylovjnxÎncă nu există evaluări

- Design of High Voltage Power Supplies Un To 100kW Involving Low Cost IGBTS - Part1Document3 paginiDesign of High Voltage Power Supplies Un To 100kW Involving Low Cost IGBTS - Part1oleg anitoff100% (1)

- First Tests of Bi-Y T-FDocument8 paginiFirst Tests of Bi-Y T-FEBEÎncă nu există evaluări

- 20kV Transformer Feeder Cable: Current Carrying Capacity Short Circuit Rating Voltage Drop Earth Loop ImpedanceDocument6 pagini20kV Transformer Feeder Cable: Current Carrying Capacity Short Circuit Rating Voltage Drop Earth Loop ImpedanceNalex GeeÎncă nu există evaluări

- How To Make Calculation For A Distribution Substation 1004 KV 21600 kVADocument14 paginiHow To Make Calculation For A Distribution Substation 1004 KV 21600 kVAsalemg82Încă nu există evaluări

- High-Voltage Testing: by R. G. StudentDocument10 paginiHigh-Voltage Testing: by R. G. StudentrahulÎncă nu există evaluări

- Off Shore EarthingDocument6 paginiOff Shore Earthingharoutuon100% (1)

- Electric Arc Furnace Transformer Secondary Circuit CalculationsDocument13 paginiElectric Arc Furnace Transformer Secondary Circuit CalculationsikamelyaastutiÎncă nu există evaluări

- 3-Phase PFC KolarDocument7 pagini3-Phase PFC KolarJayant SalianÎncă nu există evaluări

- 400 KV Metal Oxide Surge Arrestor CigreDocument12 pagini400 KV Metal Oxide Surge Arrestor CigreDilip ARÎncă nu există evaluări

- TafirifezaDocument2 paginiTafirifezazafrikhan875Încă nu există evaluări

- IGCT Technology Baseline and Future Opportunities: Peter Steimer, Oscar Apeldoorn, Eric Carroll, Andreas NagelDocument6 paginiIGCT Technology Baseline and Future Opportunities: Peter Steimer, Oscar Apeldoorn, Eric Carroll, Andreas NagelculwavesÎncă nu există evaluări

- Underground Cable Ampacity With Neher McGrathDocument7 paginiUnderground Cable Ampacity With Neher McGrathJesus RodriguezÎncă nu există evaluări

- 16th National Power Systems ConferenceDocument11 pagini16th National Power Systems ConferenceHarish ReddyÎncă nu există evaluări

- K 422024 3 CTC - Ref. High Temperature Test - Final ReportDocument11 paginiK 422024 3 CTC - Ref. High Temperature Test - Final Reportifol ifolÎncă nu există evaluări

- Paper Judendorfer PackDocument7 paginiPaper Judendorfer PackRamesh EpiliÎncă nu există evaluări

- Firelli Submarine ProposalDocument23 paginiFirelli Submarine ProposalAct PornlapusÎncă nu există evaluări

- Transformadores Factor KDocument3 paginiTransformadores Factor KLuis Aguirre FloresÎncă nu există evaluări

- 11-Step Procedure For A Successful Electrical Circuit Design (Low Voltage)Document7 pagini11-Step Procedure For A Successful Electrical Circuit Design (Low Voltage)Mohammad Ather SiddiquiÎncă nu există evaluări

- Aggeler SmartEnergyStrategies2008 1Document2 paginiAggeler SmartEnergyStrategies2008 1Akshay SathianÎncă nu există evaluări

- Part 11Document4 paginiPart 11pravishnÎncă nu există evaluări

- HTLS Conductor ComparisonDocument45 paginiHTLS Conductor ComparisonJamil Salman Marcos100% (1)

- Stress On Outer Cable Connection of MV Gas-InsulatDocument5 paginiStress On Outer Cable Connection of MV Gas-Insulatsajind3883Încă nu există evaluări

- Breaking The Ice: De-Icing Power Transmission Lines With High-Frequency, High-Voltage ExcitationDocument7 paginiBreaking The Ice: De-Icing Power Transmission Lines With High-Frequency, High-Voltage Excitationkunchamspandana_4871Încă nu există evaluări

- 1C UG GourammisDocument7 pagini1C UG Gourammisgosalhs9395Încă nu există evaluări

- Power Upgrading of Transmission Lines by Combining Ac & DCDocument68 paginiPower Upgrading of Transmission Lines by Combining Ac & DCrashidmd42100% (2)

- A Two-Stage Power Converter For Welding Applications With Increased Efficiency and Reduced FilteringDocument6 paginiA Two-Stage Power Converter For Welding Applications With Increased Efficiency and Reduced FilteringIrshad NabiÎncă nu există evaluări

- Core Loss TestingDocument8 paginiCore Loss Testingcompaq1501100% (1)

- Sizing of Power Cables For Circuit Breaker Controlled FeedersDocument25 paginiSizing of Power Cables For Circuit Breaker Controlled Feedersakash_ing7683100% (1)

- Line Conductors and Supporting Structures OriginalDocument80 paginiLine Conductors and Supporting Structures OriginalRida100% (1)

- HTLSC STACIR Rev1 PDFDocument22 paginiHTLSC STACIR Rev1 PDFShuvan MabuÎncă nu există evaluări

- S&C Custom Metal-Enclosed Switchgear: (Select Values From Table On Page 2.)Document29 paginiS&C Custom Metal-Enclosed Switchgear: (Select Values From Table On Page 2.)Luis CabimasÎncă nu există evaluări

- Section NexansDocument112 paginiSection NexansRudanekÎncă nu există evaluări

- O.H.T.L: Over Head Transmission LineDocument24 paginiO.H.T.L: Over Head Transmission Lineprof-hamadaÎncă nu există evaluări

- 2.2.06 DiDocument5 pagini2.2.06 DiMauro MarafonÎncă nu există evaluări

- MV CalDocument11 paginiMV CalrezaqesÎncă nu există evaluări

- Sizing of Power Cables For Circuit Breaker Controlled FeedersDocument15 paginiSizing of Power Cables For Circuit Breaker Controlled FeedersAlmir Mahmutovic100% (1)

- Electromagnetic Interference Issues of Power Electronics Systems With Wide Band Gap Semiconductor DevicesDocument6 paginiElectromagnetic Interference Issues of Power Electronics Systems With Wide Band Gap Semiconductor DevicesDinesh KumarÎncă nu există evaluări

- Switchyard Design Basis ReportDocument19 paginiSwitchyard Design Basis Reportrukmagoud67% (3)

- B3 104Document11 paginiB3 104Marko KojicÎncă nu există evaluări

- Ampacity of 230kV Taungoo-Loikaw LineDocument6 paginiAmpacity of 230kV Taungoo-Loikaw Line정상진Încă nu există evaluări

- Conductor Size, General: Table C-2 NEC References For Conductor SizingDocument4 paginiConductor Size, General: Table C-2 NEC References For Conductor SizingYashwanth NÎncă nu există evaluări

- Novel Concept in High Voltage Generation: Powerformertm: A New Generator, Powerformertm, Which IsDocument4 paginiNovel Concept in High Voltage Generation: Powerformertm: A New Generator, Powerformertm, Which IsnandhakumarmeÎncă nu există evaluări

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenDe la EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenEvaluare: 4 din 5 stele4/5 (2)

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingDe la EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingEvaluare: 4.5 din 5 stele4.5/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Temperature Measurement: Temperature Assemblies and Transmitters For The Process IndustryDocument32 paginiTemperature Measurement: Temperature Assemblies and Transmitters For The Process IndustryfotopredicÎncă nu există evaluări

- Psyche Finals: Trans 2: Psychotic Disorder: SchizophreniaDocument4 paginiPsyche Finals: Trans 2: Psychotic Disorder: SchizophreniajisooÎncă nu există evaluări

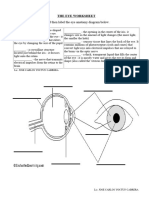

- The Eye WorksheetDocument3 paginiThe Eye WorksheetCally ChewÎncă nu există evaluări

- Microcal P20Document2 paginiMicrocal P20ctmtectrolÎncă nu există evaluări

- Sailpoint Topic Wise SyllabusDocument2 paginiSailpoint Topic Wise SyllabusKishore KodaliÎncă nu există evaluări

- Family Planning MethodsDocument20 paginiFamily Planning MethodsRoel Marcial100% (2)

- Manual ML 1675 PDFDocument70 paginiManual ML 1675 PDFSergio de BedoutÎncă nu există evaluări

- Bethelhem Alemayehu LTE Data ServiceDocument104 paginiBethelhem Alemayehu LTE Data Servicemola argawÎncă nu există evaluări

- Contemporary Architecture Is The Architecture of The 21st Century. No Single Style Is DominantDocument2 paginiContemporary Architecture Is The Architecture of The 21st Century. No Single Style Is DominantShubham DuaÎncă nu există evaluări

- Ancient To Roman EducationDocument10 paginiAncient To Roman EducationAnonymous wwq9kKDY4100% (2)

- Blank Freeway Walls Replaced With Local Designs - Press EnterpriseDocument5 paginiBlank Freeway Walls Replaced With Local Designs - Press EnterpriseEmmanuel Cuauhtémoc Ramos BarajasÎncă nu există evaluări

- Zanussi Parts & Accessories - Search Results3 - 91189203300Document4 paginiZanussi Parts & Accessories - Search Results3 - 91189203300Melissa WilliamsÎncă nu există evaluări

- Important Instructions For Winter-2020 MCQ Based Online ExaminationDocument1 paginăImportant Instructions For Winter-2020 MCQ Based Online Examinationdenoh32751Încă nu există evaluări

- Aloe Vera An Ancient Herb For Modern Dentistry-A LDocument7 paginiAloe Vera An Ancient Herb For Modern Dentistry-A LRuth Ransel Yadao ValentinÎncă nu există evaluări

- Workshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Document33 paginiWorkshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Ilie Viorel75% (4)

- Artificial Intelligence and Expert Systems: Management Information Systems, 4 EditionDocument27 paginiArtificial Intelligence and Expert Systems: Management Information Systems, 4 Editionabhi7219Încă nu există evaluări

- School Form 8 Grade 3Document20 paginiSchool Form 8 Grade 3Mimi Ng PinasÎncă nu există evaluări

- AlligentDocument44 paginiAlligentariÎncă nu există evaluări

- Green ChemistryDocument17 paginiGreen ChemistryAaditya RamanÎncă nu există evaluări

- Section ADocument7 paginiSection AZeeshan HaiderÎncă nu există evaluări

- Water Works RTADocument15 paginiWater Works RTAalfaza3Încă nu există evaluări

- COE301 Lab 2 Introduction MIPS AssemblyDocument7 paginiCOE301 Lab 2 Introduction MIPS AssemblyItz Sami UddinÎncă nu există evaluări

- Principles of Volumetric AnalysisDocument5 paginiPrinciples of Volumetric AnalysisMax TennerÎncă nu există evaluări

- Summer Internship Project Report ANALYSIDocument60 paginiSummer Internship Project Report ANALYSIKshitija KudacheÎncă nu există evaluări

- Practice Paper Pre Board Xii Biology 2023-24-1Document6 paginiPractice Paper Pre Board Xii Biology 2023-24-1salamnaseema14Încă nu există evaluări

- Amazon VS WalmartDocument5 paginiAmazon VS WalmartBrandy M. Twilley100% (1)

- The 100 Best Books For 1 Year Olds: Board Book HardcoverDocument17 paginiThe 100 Best Books For 1 Year Olds: Board Book Hardcovernellie_74023951Încă nu există evaluări

- English 9 Week 5 Q4Document4 paginiEnglish 9 Week 5 Q4Angel EjeÎncă nu există evaluări

- The Frozen Path To EasthavenDocument48 paginiThe Frozen Path To EasthavenDarwin Diaz HidalgoÎncă nu există evaluări

- Ethernet: Outline Multiple Access and Ethernet Intro Ethernet Framing CSMA/CD Protocol Exponential BackoffDocument25 paginiEthernet: Outline Multiple Access and Ethernet Intro Ethernet Framing CSMA/CD Protocol Exponential BackoffcheckÎncă nu există evaluări