Documente Academic

Documente Profesional

Documente Cultură

B. Walk Ways To Be

Încărcat de

ikeagharanyaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

B. Walk Ways To Be

Încărcat de

ikeagharanyaDrepturi de autor:

Formate disponibile

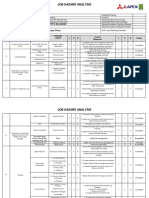

JOB HAZARD ANALYSIS FOR ELECTRICAL INSTALLATION WORK.

STE P NO I

STEP DESCRIPTION Moving of loads (materials) from one to another by hand

POTENTIAL HAZARD a. Sharp objects. b. Slippery surface. c. Obstruction. d. Heavy objects/load.

Lifting of Loads/materials from one point to another by use of crane

a. Equipment failure. b. Failure of lifting ropes/sling wire. c. Injury to personnel/equip ment damage from suspended load. d. High Noise. e. Fire /Explosion

HAZARD ELIMINATION METHOD/ MITIGATION a. Use of hand gloves while carrying sharp objects. b. Walk ways to be free from slippery materials such as grease, oil etc. c. Walk ways to be free from materials /equipment that might obstruct free movement. d. Manual lifting procedures to be applied.Also call for assistance and use step back five aside method. a. Check and confirm integrity of Lifting Equipment. Only approved/Certified certified operators to handle equipment. b. (i).Check and confirm integrity of lift ropes/shackle and sizing correctly. c. Use appropriate PPE.( hardhats, goggle) And a dedicated signal man .Restrict human traffic from the lifting activity area. d. Personnel have to wear ear protection in high

e. 3. Installation of cable channels including its associated channel supports, hold down clamps etc. a. Loose mechanical and Electrical tools. b. Height. c. Sharp edges. d. Flying dust/ metal particles. e. Improper scaffold. f. Slippery surface. a. b.

c.

d. e.

f.

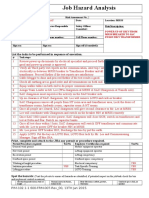

Cable integrity test for insulation resistance and continuity.

a. Electric shock. b. Equipment Failure. c. Sharp cable strands and terminals.

a.

b.

c. 5 Installation of junction boxes for outboard and boat landing a. Sharp objects. b. Body injury. c. Explosion/ Fire outbreak. a. b.

noise Area. Dedicated Fire extinguisher and a Fire watchman. Ensure that tools are proper ly kept. (i) . Personnel working at height should wear safety harness. (ii)Ensure proper communication among work crew. Mandatory use of PPE including hand gloves is required. Use of eye goggles is mandatory. Scaffold to be inspected and tagged before use. Working surface to be free from oil, grease and other slippery materials. Avoid contact with cable terminals while meggering. Only qualified technician to carry out test. Required voltage should be applied while conducting test. Ensure test equipment is properly calibrated. Wear appropriate PPE while carrying out test. Wear hand gloves. Avoid over cramping and twisting while

lighting fixtures and associated lighting fixtures.

d. Equipment failure. c.

d.

6.

Cable pulling and installation.

a. Damage to Other installed equipment and cable. b. Limited space. c. Sharp objects. d. Height. e. Loose objects/tools. f. Improper tools.

a.

b. c. d. e.

f. 7. Cable termination, Grounding and bounding. a. b. c. d. Electric shock. Fire/ Explosion. Improper Tools. Incorrect operation. e. Sharp objects. a.

b. c.

carrying out installation. Post a dedicated fire extinguisher and a fire watch man. Avoid sparks by the use appropriate tools. Use required and proper tools. Ensure hand tools are free from rust and defects. Ensure proper alignment of cables on cable channels. Use of only UV resistance ty-raps in holding cables on channels. Avoid over cramping and twisting. Wear hand gloves. Ensure the use of safety harness. Ensure no loose tools is left unsecured while working on height. Use required tools for cable glanding. Ensure cables are properly terminated to design philosophy and drawing. Do not work on life circuit. Ensure circuit is locked out and properly tagged out. Avoid sparks and use a dedicated fire extinguisher. Use correct and appropriate hand

d.

e. 8. Testing , checkout and commissioning work. a. Fire/Explosion. b. Incorrect operation/ equipment failure. c. Electric shock. d. Slippery surface. a.

b. c.

d.

9.

Housekeeping, reinstate site to original condition and demobilization

a. Body injury. b. Environmental pollution. c. Equipment Damage.

a. b.

c.

tools while terminating cables Only experienced and qualified personnel will be allowed to work during cable termination work, grounding and bounding. Wear hand protection. Ensure the use of appropriate voltage during testing. checkout for proper termination and correct philosophy to design specification. Check operational manuals and drawing for conformity. Use required tools. Avoid contact with life circuit while testing. Ensure work area is free from water and damp while testing. Remove slippery substances or materials from work area. Use required PPE. Ensure generated wastes are dispose as per MPNU standard. Ensure Materials and equipment are properly handled while loading out.

S-ar putea să vă placă și

- HSE Alert PDFDocument2 paginiHSE Alert PDFjavariam99Încă nu există evaluări

- Task Analysis Form for Proposed Tonnering Facility at Silo 7Document4 paginiTask Analysis Form for Proposed Tonnering Facility at Silo 7boyettÎncă nu există evaluări

- Incident Investigation Report: For Personal Damage, Environmental Harm & Near MissesDocument10 paginiIncident Investigation Report: For Personal Damage, Environmental Harm & Near MissesMiracle DavidÎncă nu există evaluări

- EXHIBIT O.site Safety and Health Plan - SHP 098 00. 20150615Document31 paginiEXHIBIT O.site Safety and Health Plan - SHP 098 00. 20150615safetydmrcÎncă nu există evaluări

- JHA ANALYSIS SCALE REMOVAL VESSELDocument2 paginiJHA ANALYSIS SCALE REMOVAL VESSELRiyadh SalehÎncă nu există evaluări

- Method Statement for Boom LiftingDocument5 paginiMethod Statement for Boom LiftingNishar BalkavadeÎncă nu există evaluări

- Risk Ass - ProcessDocument4 paginiRisk Ass - ProcessBalakrishnan Sivagnanam SÎncă nu există evaluări

- Approved Hemp For Installation of New Crude Oil Heater Package at Dps Dal-13-110Document12 paginiApproved Hemp For Installation of New Crude Oil Heater Package at Dps Dal-13-110Roshin99Încă nu există evaluări

- Electrical Maintenance & Testing Hazard IdentificationDocument10 paginiElectrical Maintenance & Testing Hazard IdentificationRavi ValiyaÎncă nu există evaluări

- 4 Jsa (Sie-Hse-005-F11 r1) - Precomm Ess001Document3 pagini4 Jsa (Sie-Hse-005-F11 r1) - Precomm Ess001Jannuar Ilham100% (2)

- Risk Assessment - Hot Water BoilersDocument4 paginiRisk Assessment - Hot Water BoilersUgonnaÎncă nu există evaluări

- PTW ProcedureDocument3 paginiPTW ProcedureangelaÎncă nu există evaluări

- The Definitive Employer's Guide: To General Risk AssessmentsDocument30 paginiThe Definitive Employer's Guide: To General Risk AssessmentsdertyuÎncă nu există evaluări

- OHS PROC 113 BarricadesDocument9 paginiOHS PROC 113 BarricadesPhillip L100% (1)

- ToolboxTalk 0715Document2 paginiToolboxTalk 0715Epifanio Jr Lagadan TorresÎncă nu există evaluări

- Risk Assessment GRP Tank InstallationDocument19 paginiRisk Assessment GRP Tank Installationanwer.ahmadÎncă nu există evaluări

- OTC - Letter HeadDocument3 paginiOTC - Letter HeadEngr.Syed AmjadÎncă nu există evaluări

- An Effective JHA ProcessDocument23 paginiAn Effective JHA ProcesssaiÎncă nu există evaluări

- Learn SMAW Welding SafetyDocument49 paginiLearn SMAW Welding SafetyEgghead YTCÎncă nu există evaluări

- PTW PresentationDocument15 paginiPTW PresentationSaleem Akhter100% (1)

- 0-WD010-MZ711-10002 HSE Work Permit Procedure - Rev.1 - PDFDocument11 pagini0-WD010-MZ711-10002 HSE Work Permit Procedure - Rev.1 - PDFEdu TBÎncă nu există evaluări

- Revised Job Safety Analysis for Fabrication WorkDocument7 paginiRevised Job Safety Analysis for Fabrication Workrahul jadhavÎncă nu există evaluări

- Method of Statement For Bus Duct InstallationDocument11 paginiMethod of Statement For Bus Duct InstallationMohd MuksinÎncă nu există evaluări

- Accident Investigation PolicyDocument4 paginiAccident Investigation PolicyNorman AinomugishaÎncă nu există evaluări

- Pre Commissioning and Commissioning SafetyDocument32 paginiPre Commissioning and Commissioning SafetyAssya MohammedÎncă nu există evaluări

- Safe Working PracticesDocument7 paginiSafe Working PracticesDiana ParkerÎncă nu există evaluări

- Control Subtances Hazardous HealthDocument8 paginiControl Subtances Hazardous HealthrslapenaÎncă nu există evaluări

- Battery Room HVAC Safety AnalysisDocument3 paginiBattery Room HVAC Safety AnalysisMajdiSahnounÎncă nu există evaluări

- HSE Review September 2020Document36 paginiHSE Review September 2020haeferÎncă nu există evaluări

- Doku - Pub Risk-AssessmentDocument10 paginiDoku - Pub Risk-AssessmentUlviyye ElesgerovaÎncă nu există evaluări

- Hse Five Steps To Risk AssessmentDocument2 paginiHse Five Steps To Risk AssessmentNithish ShettyÎncă nu există evaluări

- Jha Lin FillingDocument6 paginiJha Lin FillingLuqman OsmanÎncă nu există evaluări

- Electrical Safety ChecklistDocument2 paginiElectrical Safety ChecklistMohamad ShariinÎncă nu există evaluări

- Health, Safety, Security, Environment, and Quality PolicyDocument1 paginăHealth, Safety, Security, Environment, and Quality PolicyVăn PhúcÎncă nu există evaluări

- CSHP Checklist 2011Document2 paginiCSHP Checklist 2011JenniferValle0% (1)

- P3-PTP-001 R0 Piping Pressure Test ProceduresDocument8 paginiP3-PTP-001 R0 Piping Pressure Test ProceduresHengÎncă nu există evaluări

- Job Hazard Analysis: List The Tasks To Be Performed in Sequence of Execution. #Document2 paginiJob Hazard Analysis: List The Tasks To Be Performed in Sequence of Execution. #Ajay KrishnanÎncă nu există evaluări

- Grease Installation&MaintenanceDocument7 paginiGrease Installation&MaintenanceAriel Orogo Papica100% (1)

- ISBN Health and Safety Self Assessment Checklist For Small Businesses 2021 08Document7 paginiISBN Health and Safety Self Assessment Checklist For Small Businesses 2021 08Essam El-DesokeyÎncă nu există evaluări

- Health Safety Requirements General Service ContractorsDocument15 paginiHealth Safety Requirements General Service ContractorsMuhammad Ashraf KadabaÎncă nu există evaluări

- 2.3 Hot WorkDocument9 pagini2.3 Hot Workvishal bailurÎncă nu există evaluări

- Management of Hazardous Chemicals ProgramDocument52 paginiManagement of Hazardous Chemicals ProgramMohamed AdelÎncă nu există evaluări

- Quality Control (QC) Plan SummaryDocument12 paginiQuality Control (QC) Plan SummaryNarendraÎncă nu există evaluări

- JSA - Winstar Pipeline CrossingDocument6 paginiJSA - Winstar Pipeline CrossingRidha BennasrÎncă nu există evaluări

- Safety Legislation, Regulation and PolicyDocument110 paginiSafety Legislation, Regulation and PolicyNichoÎncă nu există evaluări

- 001 - JobcardDocument4 pagini001 - JobcardLoh Siong FattÎncă nu există evaluări

- Name: SignDocument1 paginăName: SignAdel AlKhedawyÎncă nu există evaluări

- Hazard Register TemplateDocument1 paginăHazard Register TemplateShe Chee WahÎncă nu există evaluări

- 5.2 - Isolation of Energy SourcesDocument16 pagini5.2 - Isolation of Energy SourcesarunÎncă nu există evaluări

- ARC130 170 ManualDocument28 paginiARC130 170 ManualPhilip Rosser100% (2)

- uJJ O: J.illDocument3 paginiuJJ O: J.illEngr.Syed AmjadÎncă nu există evaluări

- JSA For Pressure Test 2ND REVISIONDocument10 paginiJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- SWP-12 Pressure TestDocument3 paginiSWP-12 Pressure TestLumin HanÎncă nu există evaluări

- Fire WatchDocument7 paginiFire WatchMateo RosasÎncă nu există evaluări

- Hse Policy StatementDocument1 paginăHse Policy StatementVICTORÎncă nu există evaluări

- Dibia Ifeanyichukwu Peter Updated CV (Resume)Document7 paginiDibia Ifeanyichukwu Peter Updated CV (Resume)wizzy basseyÎncă nu există evaluări

- Lessons Learned PDFDocument1 paginăLessons Learned PDFYasir_Wafi_1101Încă nu există evaluări

- Safe Work Method For Hydro TestDocument1 paginăSafe Work Method For Hydro TestEswar RaoÎncă nu există evaluări

- Suicide ReportDocument4 paginiSuicide ReportAlikman HadjiamerÎncă nu există evaluări

- Pilar College Individual Nominee FormDocument2 paginiPilar College Individual Nominee FormDes CuenoÎncă nu există evaluări

- Nursing responsibilities for tramadol administrationDocument2 paginiNursing responsibilities for tramadol administrationThrinÎncă nu există evaluări

- Practical Logbook: Medical Parasitology Department GIT Module 104Document16 paginiPractical Logbook: Medical Parasitology Department GIT Module 104Kareem DawoodÎncă nu există evaluări

- Allopurinol: Gouty Nephropathy and Renal DialysisDocument3 paginiAllopurinol: Gouty Nephropathy and Renal DialysisAnonymous G26HIUtzVÎncă nu există evaluări

- Journal of Cleaner Production: Waqas Nawaz, Muammer KoçDocument20 paginiJournal of Cleaner Production: Waqas Nawaz, Muammer Koçthe unkownÎncă nu există evaluări

- Insanity Xbox Nutrition Guide PDFDocument77 paginiInsanity Xbox Nutrition Guide PDFIrving Piojin Piin PiinÎncă nu există evaluări

- Guiasgold2023 16235v2.1 Es-Pocket WMVDocument55 paginiGuiasgold2023 16235v2.1 Es-Pocket WMVFABIO JAVIER BRAVO SALDARRIAGAÎncă nu există evaluări

- What To Do When You Dont Know What To DoDocument118 paginiWhat To Do When You Dont Know What To DoRoxanne FreytesÎncă nu există evaluări

- Laura Mitchell - An Introduction To Orthodontics-Oxford University Press (2013) PDFDocument326 paginiLaura Mitchell - An Introduction To Orthodontics-Oxford University Press (2013) PDFGavrilescu Mihai84% (25)

- Addenbrookes Hospital Level 2 Floor PlanDocument1 paginăAddenbrookes Hospital Level 2 Floor PlanMidiangr0% (1)

- Physical Fitness TestDocument8 paginiPhysical Fitness Testalaskador03Încă nu există evaluări

- 2015 EHS Challanges Enablon Reportv9Document15 pagini2015 EHS Challanges Enablon Reportv9Anonymous sfY8T3q0100% (1)

- Vegetarianism 1.0Document1 paginăVegetarianism 1.0Sachi AnandÎncă nu există evaluări

- Fever 1793 Study Guide Chapter 6 - 10Document3 paginiFever 1793 Study Guide Chapter 6 - 10Dawson WolfpmsingÎncă nu există evaluări

- Truvivity by NutriliteDocument10 paginiTruvivity by Nutriliteโยอันนา ยุนอา แคทเธอรีน เอี่ยมสุวรรณÎncă nu există evaluări

- BoltonDocument26 paginiBoltonDryashpal SinghÎncă nu există evaluări

- Prevent Dengue: Learn Aedes Mosquito FactsDocument30 paginiPrevent Dengue: Learn Aedes Mosquito FactstahseenhassantirmiziÎncă nu există evaluări

- End Indifference - Pope: Stray Bullet Cases Hit 36 Firecrackers Injure 459Document56 paginiEnd Indifference - Pope: Stray Bullet Cases Hit 36 Firecrackers Injure 459Art JasmeÎncă nu există evaluări

- Classic Series Price List Effective February 2023Document1 paginăClassic Series Price List Effective February 2023Yusuf Patria SandiÎncă nu există evaluări

- VW50180 en 2000-07-01Document3 paginiVW50180 en 2000-07-01Bruno BrasseurÎncă nu există evaluări

- The Program Proposal - DiabetesDocument11 paginiThe Program Proposal - DiabetesRifa'atul Mahmudah100% (2)

- NAAG Letter - Veteran Treatment Court Coordination Act of 2019Document5 paginiNAAG Letter - Veteran Treatment Court Coordination Act of 2019Russ LatinoÎncă nu există evaluări

- Measuring Tools For Management (LCM-Rubina)Document14 paginiMeasuring Tools For Management (LCM-Rubina)Ruel BariaÎncă nu există evaluări

- Brady J. - Environmental Management in Organizations. The IEMA Handbook (2005)Document459 paginiBrady J. - Environmental Management in Organizations. The IEMA Handbook (2005)Wan Naqib Hamidon100% (5)

- Stunting in IndonesiaDocument218 paginiStunting in IndonesiaPratamaOktaRickyÎncă nu există evaluări

- Ward D - Freida McFaddenDocument239 paginiWard D - Freida McFaddenHassan ZayanÎncă nu există evaluări

- Dody Firmanda 2009 - KPIs RS Krakatau Medika 6 Agustus 2009Document40 paginiDody Firmanda 2009 - KPIs RS Krakatau Medika 6 Agustus 2009Dody Firmanda100% (6)

- Iso 13485 Sample5Document7 paginiIso 13485 Sample5Hilario AlinabonÎncă nu există evaluări

- PhD Fluid MechanicsDocument4 paginiPhD Fluid MechanicsGooftilaaAniJiraachuunkooYesusiinÎncă nu există evaluări