Documente Academic

Documente Profesional

Documente Cultură

Profile Shift Coefficient

Încărcat de

Ajinkya KarandikarDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Profile Shift Coefficient

Încărcat de

Ajinkya KarandikarDrepturi de autor:

Formate disponibile

12th IFToMM World Congress, Besanon (France), June18-21, 2007

On the Distribution of the Profile Shift Coefficients Between Mating Gears in the Case of Cylindrical Gear

R.-F. Miric * University POLITEHNICA Bucharest, Romania

AbstractAspects of the distribution1 of the profile shift coefficients between mating wheels of the speed-reducing cylindrical gears of general use is analyzed in the paper. The problem of the distribution of the shift coefficient sum on each gear wheel was standardized [2], [1] or recommended in special guides [5], [7]. The paper [7] approaches this problem that will be treated in extended form in the present one. The analyzed aspects are the effects of the applying ISO/TR 4467 [5], DIN 3992 [2] and PD 6457 [7] on the report of the safety factors of tooth bending stress at each wheel, in the case of speed-reducing cylindrical gear pairs having case hardened toothing (the most employed at power transmissions of general use). The results obtained by these different methods are compared and discussed. The conclusions reveal the possibilities to use better some methods in function of the teeth number and sum profile shift coefficients, to ensure a favourable report of bending safety factors of gear wheels. Keywords: profile shift coefficients, cylindrical gears, speed-reducing gear pairs, case hardened toothing, bending safety factors.

G. Dobre University POLITEHNICA Bucharest, Romania

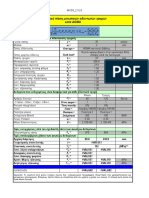

critical stress is the tooth root bending for a large range of peripheral speed [6]. The paper [6] has analyzed this problem in the case of the results specific to ISO/TR 4467 [5]. The present paper extends this treatment, including also the effects of the recommendations from DIN 3992 [2] and PD 6457 [7] on the report of the safety factors of tooth bending stress at each wheel, in the case of speed-reducing cylindrical gear pairs having case hardened toothing. The treatment implies a laborious calculus volume solved using a scientific program. The results are commented and discussed. The favorable situation is to obtain a bending safety factor at pinion equal or greater than the one of the wheel, because the pinion is more stressed as number of cycles. Applications are carried out depending on: sum of profile shift coefficients; gear ratio; pinion tooth number. The paper does not talk about the choice of the sum of profile shift coefficients. This sum results from the requirement to ensure an imposed operating center distance and it is framed in the limits recommended by DIN 3992 [2] or ISO/TR 4467 [5]. The results are compared and discussed. Conclusions and recommendations relative to the choice of a standard method for practice are formulated. II. Standardized methods for distribution of the sum of the profile shift coefficients The paper presents briefly the standardized methods for the distribution of the sum of profile shift coefficients between mating gears. A. Method DIN 3992 [2] The method gives a diagram permitting the graphically determination of the pinion profile shift coefficient, x1 , by the following procedure (figure 1): it is found out the point of coordinates: semi-sum of the profile shift coefficients, x / 2 and semi-sum of teeth numbers, (z1 + z 2 ) / 2 ; a graphical interpolation line is traced between two neighboring lines; the point of abscise z1 on this interpolation line gives

I. Introduction The problem of the distribution of the sum of profile shift coefficients on each gear wheel in the case of cylindrical gears was treated and recommended especially in standards. These recommendations were basically employed in technical literature and industrial practice. The distribution of the sum of profile shift coefficients has to ensure multiple tasks [1], [5]: avoiding undercut; avoiding narrow top lands; equalizing specific sliding, with effect on the pitting fatigue life; equalizing flash temperature; equalizing bending fatigue life. All these tasks/criteria do not be simultaneously fulfilled. AGMA 913 [1] recommends the choice of the criterion considered of great importance for practice. It is the reason why the problem of the distribution of the shift coefficient sum on each gear wheel could be met in the case of the largest used thermal treatment for cylindrical gears of general use: case hardening. In this case, the

* E-mail: mirica@meca.omtr.pub.ro E-mail: geo@ meca.omtr.pub.ro

12th IFToMM World Congress, Besanon (France), June18-21, 2007

the profile shift coefficient of the pinion, x1 .

1.0 x 0.6 0.4 0.2 x1 0 x 2 -0.2 -0.4 z 40 60 80 100 150 z1+z2 2 1+ z 2 2 Fig. 1. Graphical method of DIN 3992 [2] for distribution of the sum of profile shifts on mating gears 0 20

Line of interpolation

x1 , by all these standardized methods, the wheel profile shift coefficient is: x 2 = x x1 . (7) The presented methods differ between themselves. The figure 2 shows differences between results, by graphical representation of the pinion shift coefficient in function of the gear ratio, for some values of sum of profile shift coefficients.

0.5 x1 0.4 0.3 0.2 0.1 0 PD x=0.2 DINx=0.45 PD x=045 ISO x=0.2 ISOx=0.45

z1 z1

ISO x=0 PD x=0 DIN x=0

B. Method PD 6457 [7] PD 6457 uses computation formulae, that is, the calculus is easier in report with DIN method. Three cases are considered in this method: for general applications: 1 1 x x 1 = 1 + ; (1) 3 u 1+ u for approximate equality of bending strength factors for pinion and wheel: 1 1 x x1 = 1 + ; (2) 2 u 1+ u for approximate balance of ratios of specific sliding or slideroll ratio at extremes of contact path: 1 1 x x1 = . 1 + (3) z v1 u 1 + u Above the following sizes intervenient: the gear ratio: z u= 2 ; z1 the virtual number of teeth: z1 . z v1 = cos 3 C. Method ISO/TR 4467 [5] The ISO method defines the pinion profile shift coefficient in the form: u 1 x x1 = + , (6) u +1 1+ u where: is a factor adopted in the range 0.5 0.75 for speed reducing gears; if u > 5, the limited calculation value is u = 5. Being established the pinion profile shift coefficient,

DIN x=0.2

1.5

2.5

3.5

4.5

5.5

6.5

7.5

Fig. 2. Comparison between the values of pinion shift profile coefficient carried out by different standardized methods, for: x=0, 0.2, 0.45. The method PD 6457 [7] was applied in variant of expression (1). The expression (6) of ISO/TR 4467 [5] was used with = 0.5.

As a result, a necessary comparative analysis is done using a specific criterion defined below, that describing better the effects of the results by different methods on the gear loading capacity. III. Analysis criterion to compare the methods As shown previously, the case of the speed reducing gears of general use and having hardened tooting is considered. Their principal damage modes are: the tooth breakage; the micro-pitting. The micro-pitting influence of the distribution of the sum of profile shit coefficients is not analyzed in the restraint space of the paper. The increasing of tooth bending loading capacity by this distribution could be carried out equalizing the safety factors of wheels in this stress mode: SF1 = SF 2 , (8) that are given by [9]: F lim 1( 2) S F1( 2) = . (9) F1( 2) The limit tooth bending stress intervening above is [4]: F lim 1( 2) = FE YN 1( 2) Y rel T1( 2) YR rel T YX , (10) where: FE is the endurance strength of the even sample; YN - stress cycle factor for bending strength, spur and helical gears; Y rel T - the relative notch sensitivity factor;

(4)

(5)

12th IFToMM World Congress, Besanon (France), June18-21, 2007

YR relT

the relative roughness factor; YX the

dimension factor. An observation: YN1 = YN 2 = YN , because the numbers of cycles (rotations number) of both wheels exceed generally the limited number of 3106 cycles, specific to case hardened toothing. The tooth-root stress is [4], [9]: Ft K A K v K F K F YFa1,2 YSa1( 2) Y Y F1,2 = .(11) b1( 2) m n where: Ft is the nominal peripheral force on the reference cylinder; K A - the application factor; K v - the one dynamic; K F - the face load factor; K F - transverse load factor; YFa 1( 2) - the form factor; YSa 1( 2) - the stress correction factor; Y - the contact ratio factor; Y - the helix angle factor; b1( 2) - the face width, m n - the normal module. The expressions (9)(11) leads to the criterion report: S F2 YFa1 YSa1 Y rel T 2 b 2 = . (12) S F1 YFa 2 YSa 2 Y rel T1 b1 The values of the face widths are not generally equal, but their difference is insignificant. By simplification of the face width, the expression (12) becomes: S F2 YFa1 YSa1 Y rel T 2 . (13) S F1 YFa 2 YSa 2 Y rel T1 It is desired that:

was {0.5; 0.65; 0.7; 0.75} . This range is used only in the statistical diagram from the figure 20; in the restraint space of the paper, the diagrams of criterion report are given only for the values {0.5; 0.65; 0.75} , including the inferior and exterior limits and a value around the one mean (figures 7...9 and 1417). Another observation: the relative notch sensitivity factor, Y rel T , is taken as value in calculus for case hardened steels [4]. B. Comparison between the results of methods as regards the effect on bending strength The values of the criterion report, S F 2 / S F1 , are represented in illustrative figures below. The first range of figures 39 represent the results carried out by all methods for the number of teeth large used in industrial practice: z1 = 15 .

S F2 S F1 1.06

1.04 1.02 1.00 0.98 1 2 3 4 5 6 u 7 Fig. 3. Criterion report in the case of DIN 3992 [2], for the number of pinion teeth of 15, in function of gear ratio and sum of shift profile coefficients in the range indicated at the point IV, A

S F2 <1, (14) S F1 because the pinion is more stressed as number of cycles, so this safety factor has to be greater as the one of the wheel. This is the main analysis criterion pursued in the comparison of the results carried out by different methods. Finally, a statistical analysis of these results is developed, to include all results.

IV. Analysis of the results carried out by different methods A. Calculus data The following data ranges are considered: numbers of pinion teeth: z1 {12; 13; 14; 15; 16; 17; 18; 19} ; gear ratios: u {1.12; 1.25; 1.4; 1.6; 1.8; 2; 2.24; 2.5;

S F2 1.06 S F1 1.05

1.04 1.03 1.02 1.01 1.00 1 2 3 4 5 6 u 7 Fig. 4. Criterion in the case of PD 6457 [7] in variant given by (1), for the number of pinion teeth of 15, in function of gear ratio and the sum of shift profile coefficients in the range indicated at the point IV, A

2.8; 3.15; 3.55; 4; 4.5; 5; 5.6; 6.3; 7.1} sums of profile shift coefficients: x {0; 0.05; 0.1; 0.15; 0.2; 0.25; 0.3; 0.35; 0.4; 0.45; 0.5; 0.55; 0.6; 0.65; 0.7; 0.75; 0.8; 0.85; 0.9; 0.95; 1; 1.05; 1.1; 1.15; 1.2}. The range of values for the factor intervening in ISO

Analyzing these representations, the following conclusions could be noted. The method PD 6457 [7] in the form given by (3) is the most disadvantageous because of high values of criterion report (this means a great difference between the two bending safety factors and a low bending safety factor of

12th IFToMM World Congress, Besanon (France), June18-21, 2007

pinion). As a result, this method and variant cannot be recommended for case hardened gears.

S F 2 1.02 S F1 1.01

1.00 0.99 0.98

dimensioning of the pinion). A general observation noted for all results: increasing the sum of the profile shift coefficients, x , the criterion report has smaller values, more favorable for pinion tooth bending stress as in the case of smaller values of x .

S F2 S F1 1.01

1.00 0.99 0.98 0.97 0.96 1 3 4 5 6 u 7 Fig. 8. Criterion report in the case of ISO/TR 4467 [5] for the number of pinion teeth of 15, in function of gear ratio, = 0.65, and the sum of shift profile coefficients in the range indicated at the point IV, A

0.97

1 2 3 4 5 6 u 7 Fig. 5. Criterion in the case of PD 6457 [7] in variant given by (2), for the number of pinion teeth of 15, in function of gear ratio and the sum of shift profile coefficients in the range indicated at the point IV, A

S F2 S F1 1.12

1.10 1.08 1.06 1.04 1.02

S F 2 1.00 S F1 0.99

0.98 0.97 0.96

1 2 3 4 5 6 u 7 Fig. 6. Criterion in the case of PD 6457 [7] in variant given by (3), for the number of pinion teeth of 15, in function of gear ratio and the sum of shift profile coefficients in the range indicated at the point IV, A

0.95 1 2 3 4 5 6 u 7 Fig. 9. Criterion report in the case of ISO/TR 4467 [5] for the number of pinion teeth of 15, in function of gear ratio, = 0.75, and the sum of shift profile coefficients in the range indicated at the point IV, A

S F 2 1.05 S F1 1.04

1.03 1.02 1.01 1.00 0.99

S F 2 1.10 S F1 1.08

1.06 1.04 1.02

1 2 3 4 5 6 u 7 Fig. 7. Criterion report in the case of ISO/TR 4467 [5] for the number of pinion teeth of 15, in function of gear ratio, = 0.5, and the sum of shift profile coefficients in the range indicated at the point IV, A

1.00 1 2 3 4 5 6 u 7 Fig. 10. Criterion report in the case of DIN 3992 [2], for the number of pinion teeth of 12, in function of gear ratio and sum of shift profile coefficients in the range indicated at the point IV, A

The method PD 6457 [7] in variant given by (1), the method DIN 3992 [2] and the method ISO/TR 4467 [5] with the parameter = 0.5 determine unfavorable results in lower measure as in the previous analysis case. The methods ISO/TR 4467 [5] with the parameter = 0.650.75 and PD 6457 [7] in the form (2) give favorable results: pinion tooth bending stress is equalized or greater as the one of the wheel (the last results leading to an over-

The representation from the figures 10 and 11 give the results for the method DIN 3992 [2] for other number of teeth than the one used in the figure 3. It is noted that the criterion report is favorable regarding the pinion tooth bending stress if the sum of the profile shift coefficients is approximately 1; it is confirmed in this way the same

12th IFToMM World Congress, Besanon (France), June18-21, 2007

recommendation done by Niemann and Winter [6]. Although, the small values of x determine unfavorable values of the criterion report from the point of view of the pinion tooth bending stress even in comparison with the other methods (see the figures 5, 8 and 9).

S F2 S F1 1.04

1.03 1.02 1.01 1.00 0.99 0.98 2 3 4 5 6 u 7 1 Fig. 11. Criterion report in the case of DIN 3992 [2], for the number of pinion teeth of 19, in function of gear ratio and sum of shift profile coefficients in the range indicated at the point IV, A

It is very interesting to see the influence of the factor specific for the method ISO/TR 4467 [5], for other number of teeth as 15. The figures 1417 permit to formulate the following conclusions: the values = 0.65...0.75 determine acceptable criterion report values regarding the pinion tooth bending stress; a favorable over-dimensioning of the pinion is visible for = 0.75 , as in the case of 15 teeth (figure 9): greater pinion bending safety factor in comparison to the one of the wheel.

S F 2 1.03 S F1 1.02

1.01 1.00 0.99 0.98 0.97 1 2 3 4 5 6 u 7 Fig. 14. Criterion report in the case of ISO/TR 4467 [5] for the number of pinion teeth of 12, in function of gear ratio, = 0.65, and the sum of shift profile coefficients in the range indicated at the point IV, A

Analyzing the figures 4, 12 and 13 of results carried out by the method PD 6457 [7] in variant (2), it can observe that this method is useful for all values of the sum x , the criterion report having small values for high values of sum x , and values around 1 for small values of x .

S F 2 1.03 S F1 1.02

1.01 1.00 0.99 0.98

S F 2 1.01 S F1 1.00

0.99 0.98

0.97 0.96 1 2 3 4 5 6 u 7 Fig. 12. Criterion in the case of PD 6457 [7] in variant given by (2), for the number of pinion teeth of 12, in function of gear ratio and the sum of shift profile coefficients in the range indicated at the point IV, A 0.97 0.96 1 2 3 4 5 6 u 7 Fig. 15. Criterion report in the case of ISO/TR 4467 [5] for the number of pinion teeth of 19, in function of gear ratio, = 0.65, and the sum of shift profile coefficients in the range indicated at the point IV, A

S F 2 1.01 S F1

1.00

S F 2 1.00 S F1 0.99

0.98

0.99 0.97 0.96 0.97 1 2 3 4 5 6 u 7 Fig. 13. Criterion in the case of PD 6457 [7] in variant given by (2), for the number of pinion teeth of 19, in function of gear ratio and the sum of shift profile coefficients in the range indicated at the point IV, A 0.95 1 2 3 4 5 6 u 7 Fig. 16. Criterion report in the case of ISO/TR 4467 [5] for the number of pinion teeth of 12, in function of gear ratio, = 0.75, and the sum of shift profile coefficients in the range indicated at the point IV, A 0.94

0.98

12th IFToMM World Congress, Besanon (France), June18-21, 2007

S F 2 1.00 S F1 0.99

0.98 0.97 0.96

report has to be less than 1 to ensure a good pinion tooth bending stress: the method DIN 3992 [2] leads to a majority of criterion report values above 1; the method PD 6457 [7] is good for the variant 2; the method ISO/TR 4467 [5] is excellent for = 0.65...0.75 .

1000

Frequency of occurrence

800 600 4 400 200 0 0.94

0.95 1 2 3 4 5 6 u 7 Fig. 17. Criterion report in the case of ISO/TR 4467 [5] for the number of pinion teeth of 19, in function of gear ratio, = 0.75, and the sum of shift profile coefficients in the range indicated at the point IV, A

Statistical frequency distributions of the criterion report were calculated for each method for all the data presented at point IV A (three data). In the statistical process, the whole variation interval of the criterion report values was divided into 20 sub-intervals, in which were counted the occurrences of the report values, which are indicated in diagrams (figures 1820).

400

1.06 S F 2 S F1 Fig. 20. Frequency of occurrence of the criterion report values in the case of ISO/TR 4467 [5], for all numbers of pinion teeth, gear ratios and profile shift coefficients in the ranges indicated at the point IV, A 1 - : = 0.5; 2 - : = 0.65; 3 - : = 0.7; 4 - : = 0.75. 0.96 0.98 1 1.02 1.04

V. Conclusion 1. The distribution of the sum of profile shift coefficients between the mating gears at cylindrical gears is recommended especially in standards, more relevant being ISO/TR 4467 [5], DIN 3992 [2] and PD 6457 [7]. 2. The criterion report of safety factors for tooth bending loading capacities of wheels (valid for the case hardening gears of general use) was applied for comparative analysis of results about different methods. This analysis was developed for ranges of numbers of pinion teeth, gear ratios and sum of profile shift coefficients. 3. The adequate methods to distribute the sum of profile shift coefficients were emphasized to better fulfill the mentioned criterion report. References

1 3 [1] AGMA 913-A98, Method for specifying the geometry of spur and helical gears, 1998. [2] DIN 3992. Profilverschiebung bei Stirnrdern mit Aussenverzahnung, 1964. [3] ISO 53, Cylindrical gears for general and heavy engineering Standard basic rack tooth profile, 1998. [4] ISO 6336, Calculation of load capacity of spur and helical gears, Part 3: Calculation of tooth bending strength, 1996. [5] ISO/TR 4467. Addendum modification of the teeth of cylindrical gears for speed-reducing and speed-increasing gear pairs, 1982. [6] Niemann, G., Winter, H. Maschinenelemente. Band II, SpringerVerlag, 1985. [7] PD 6457. Guide to the application of addendum modification to involute spur and helical gears, 1970. [8] Rdulescu, G, Dobre, G., Miric R.-F., Consideratii asupra utilizarii metodei ISO privind repartitia pe roti a sumei deplasarilor, PRASIC'90, pages 9-16, Brasov, 13-14 December 1990. [9] STAS 12268-84. Angrenaje cilindrice cu dantura n evolvent. Calcul de rezisten (Cylindrical spur gears with involute tooting. Strength calculus), 1984.

Frequency of occurrence

300 1 200 2 100 0

1.08 S F 2 1.1 S F1 Fig. 18. Frequency of occurrence of the criterion report values in the case of DIN 3992 [2], for all numbers of pinion teeth, gear ratios and profile shift coefficients in the ranges indicated at the point IV, A 1 - frequency distribution; 2 statistical mean of all values. 0.98 1 1.02 1.04 1.06 600 2

Frequency of occurrence

500 400 300 200 100 0 0.95 1 1.05 1.1

1.15 S F 2 S F1 Fig. 19. Frequency of occurrence of the criterion report values in the case of variants 13 of PD 6457 [7], for all numbers of pinion teeth, gear ratios and profile shift coefficients in the ranges indicated at the point IV, A

This statistical study permits a global evaluation of each method applied to all mentioned input data, by observing the localization of criterion report values and their statistical weight. The following conclusions can be stated by this analysis, taking into account that the best criterion

S-ar putea să vă placă și

- Spline Program Ver 1.1Document10 paginiSpline Program Ver 1.1VivekÎncă nu există evaluări

- Gears - Gear EfficiencyDocument4 paginiGears - Gear Efficiencyavinashchauhan2695Încă nu există evaluări

- Phy Mock SolDocument17 paginiPhy Mock SolA PersonÎncă nu există evaluări

- Spline Stress CalculationDocument8 paginiSpline Stress CalculationSantiago MolinaÎncă nu există evaluări

- Introduction To Direct Gear DesignDocument15 paginiIntroduction To Direct Gear DesignburaktuncerÎncă nu există evaluări

- Gear CorrectionDocument17 paginiGear CorrectionMurugesanÎncă nu există evaluări

- Kisssoft Tut 016 E WormgearDocument16 paginiKisssoft Tut 016 E WormgearIbraheem KhressÎncă nu există evaluări

- Gear Generating Profile Shift CalculationsDocument2 paginiGear Generating Profile Shift CalculationsSanjay Shelar0% (1)

- Module ListDocument21 paginiModule ListLuis TestaÎncă nu există evaluări

- Spur Gear Design by IIT MadrasDocument28 paginiSpur Gear Design by IIT MadrasC.S.ABHILASHÎncă nu există evaluări

- Agma 917-B97Document92 paginiAgma 917-B97Mauricio AdameÎncă nu există evaluări

- Kisssoft Tut 007 E BearingsDocument12 paginiKisssoft Tut 007 E BearingsIkshit JainÎncă nu există evaluări

- Product Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Document598 paginiProduct Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Dispatch TranstechgearsÎncă nu există evaluări

- Agma 2015 915-1-A02Document152 paginiAgma 2015 915-1-A02neno2405Încă nu există evaluări

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMADocument1 paginăΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskÎncă nu există evaluări

- Kisssoft Tut 010 E GearlifetimeDocument23 paginiKisssoft Tut 010 E GearlifetimeLuis TestaÎncă nu există evaluări

- Iso 6336-1-2006 C1-2008Document2 paginiIso 6336-1-2006 C1-2008Anonymous opp9k40% (1)

- Gear Nomenclature As Per ACMEDocument10 paginiGear Nomenclature As Per ACMEponnivalavans_994423Încă nu există evaluări

- Iso 53 Indian StandardsDocument12 paginiIso 53 Indian StandardsErhan GencÎncă nu există evaluări

- Σχεδιασμός Σε Κάμψη Μετωπικών Οδοντωτών Τροχών Κατά Agma: F Sk Kkkkk S Mbj SkkDocument1 paginăΣχεδιασμός Σε Κάμψη Μετωπικών Οδοντωτών Τροχών Κατά Agma: F Sk Kkkkk S Mbj SkkkstayroskÎncă nu există evaluări

- Analysis of The Yokeless and Segmented Armature MachineDocument7 paginiAnalysis of The Yokeless and Segmented Armature MachineSeksan KhamkaewÎncă nu există evaluări

- International Standard: Rolling Bearings - Radial Bearings - TolerancesDocument11 paginiInternational Standard: Rolling Bearings - Radial Bearings - TolerancesCAT MINING SHOVELÎncă nu există evaluări

- Agma 914 b04Document45 paginiAgma 914 b04Nursena SEVİNÇÎncă nu există evaluări

- Gear Lubrication FZG Wind TurbinesDocument9 paginiGear Lubrication FZG Wind Turbinesrbulnes2350Încă nu există evaluări

- Worm DriveDocument6 paginiWorm DriveRavi Kiran MeesalaÎncă nu există evaluări

- AGMA Technical PaperDocument14 paginiAGMA Technical PaperLuis TestaÎncă nu există evaluări

- ANL TruckDocument162 paginiANL Truckmail_krkÎncă nu există evaluări

- Gear Tip ReliefDocument1 paginăGear Tip ReliefSanjay ShelarÎncă nu există evaluări

- KISSsoft Calculation Programs For Machine DesignDocument22 paginiKISSsoft Calculation Programs For Machine DesignAbhijeet DeshmukhÎncă nu există evaluări

- Gears - Engineering InformationDocument138 paginiGears - Engineering InformationGiang T LeÎncă nu există evaluări

- Gearbox Design and Analysis - ProgramDocument4 paginiGearbox Design and Analysis - Programمحمد نتعيÎncă nu există evaluări

- Losses in Gear Box ModellingDocument10 paginiLosses in Gear Box ModellingSiva ReddyÎncă nu există evaluări

- Normas - ISO-1328-2-2020 Tolerancias de Flancos para Engranajes RectosDocument10 paginiNormas - ISO-1328-2-2020 Tolerancias de Flancos para Engranajes RectosJulian Carvajal PerezÎncă nu există evaluări

- Barista Skills Foundation Curriculum enDocument4 paginiBarista Skills Foundation Curriculum enCezara CarteșÎncă nu există evaluări

- Structural Health MonitoringDe la EverandStructural Health MonitoringDaniel BalageasÎncă nu există evaluări

- Auditory Evoked Potentials - AEPs - Underlying PrinciplesDocument19 paginiAuditory Evoked Potentials - AEPs - Underlying PrinciplesMansi SinghÎncă nu există evaluări

- India Biotech Handbook 2023Document52 paginiIndia Biotech Handbook 2023yaduraj TambeÎncă nu există evaluări

- 2011-11-09 Diana and AtenaDocument8 pagini2011-11-09 Diana and AtenareluÎncă nu există evaluări

- Comparison Between Different Commercial Gear Tooth Contact Analysis Software PackagesDocument16 paginiComparison Between Different Commercial Gear Tooth Contact Analysis Software PackagesAbhijeet DeshmukhÎncă nu există evaluări

- Profile Shift CoefficientDocument6 paginiProfile Shift CoefficientShyam N NelluliÎncă nu există evaluări

- Ins 020 Inclusion of Casing StiffnessDocument12 paginiIns 020 Inclusion of Casing StiffnessfrancanÎncă nu există evaluări

- Asymmetric Cylindrical GearsDocument6 paginiAsymmetric Cylindrical Gearsकृष्णकुमार दत्तात्रेय जोशीÎncă nu există evaluări

- THESIS - PHD - TE IN SPUR GEARS - STATIC AND DYNAMIC FINITE ELEMENT MODELLING AND DESIGN OPTIMISATION PDFDocument267 paginiTHESIS - PHD - TE IN SPUR GEARS - STATIC AND DYNAMIC FINITE ELEMENT MODELLING AND DESIGN OPTIMISATION PDFAsha Venkataram100% (1)

- Micropitting Method A B in KisssoftDocument2 paginiMicropitting Method A B in Kisssoftsardhan.rajender84Încă nu există evaluări

- Approximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingDocument11 paginiApproximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingCan CemreÎncă nu există evaluări

- AGMADocument7 paginiAGMADipakÎncă nu există evaluări

- A Kinematic Analysis of Meshing Polymer Gear TeethDocument16 paginiA Kinematic Analysis of Meshing Polymer Gear TeethsandeepÎncă nu există evaluări

- Contact Pattern Analysis Training ProgramDocument4 paginiContact Pattern Analysis Training ProgramRAJIV GandhiÎncă nu există evaluări

- Kisssoft Changelog Version 2020 - Service Pack 4: WrongDocument14 paginiKisssoft Changelog Version 2020 - Service Pack 4: WrongpasswordÎncă nu există evaluări

- Gear Box Design: Mech 420 Major ProjectDocument62 paginiGear Box Design: Mech 420 Major ProjectAtul DahiyaÎncă nu există evaluări

- Comparison of AGMA .2001, and ISO, 6336 Ratings Tor Four Gear Sets-McvittieDocument4 paginiComparison of AGMA .2001, and ISO, 6336 Ratings Tor Four Gear Sets-McvittiewholenumberÎncă nu există evaluări

- Excite CrankshaftdynamicsDocument4 paginiExcite CrankshaftdynamicssarditomoÎncă nu există evaluări

- Iso 13282013Document15 paginiIso 13282013Kailas KatharÎncă nu există evaluări

- Kisssoft Tut 009 E GearsizingDocument20 paginiKisssoft Tut 009 E GearsizingLuis TestaÎncă nu există evaluări

- KISSsys ANL 15 910 Bevel DiffDocument20 paginiKISSsys ANL 15 910 Bevel Diffsardhan.rajender84100% (1)

- 2 Gear BasicsDocument6 pagini2 Gear BasicsMohamed Adel RizkÎncă nu există evaluări

- Face Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannDocument8 paginiFace Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannosaniamecÎncă nu există evaluări

- Montage Kit 4x4 FGDocument30 paginiMontage Kit 4x4 FGsousou0033Încă nu există evaluări

- Isis DriveDocument18 paginiIsis DriveTms ArnÎncă nu există evaluări

- Review and Comparison of LTCA in Commercial Gear Software - ADF - SMT User Conference - 10 - 21 - 19 PDFDocument23 paginiReview and Comparison of LTCA in Commercial Gear Software - ADF - SMT User Conference - 10 - 21 - 19 PDFAdam FoltzÎncă nu există evaluări

- SKF Rolling Bearings InformationDocument117 paginiSKF Rolling Bearings InformationchoongzjÎncă nu există evaluări

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De la EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonÎncă nu există evaluări

- Design and Optimization of A Medium Altitude Long Endurance UAV Wingbox StructureDocument8 paginiDesign and Optimization of A Medium Altitude Long Endurance UAV Wingbox StructureamirÎncă nu există evaluări

- Design Practical Eden Swithenbank Graded PeDocument7 paginiDesign Practical Eden Swithenbank Graded Peapi-429329398Încă nu există evaluări

- Remedy MidTier Guide 7-5Document170 paginiRemedy MidTier Guide 7-5martin_wiedmeyerÎncă nu există evaluări

- Heart Rate Variability Threshold As An Alternative.25Document6 paginiHeart Rate Variability Threshold As An Alternative.25Wasly SilvaÎncă nu există evaluări

- ISO-3046-4-2009 (Gobernador de Velocidad)Document8 paginiISO-3046-4-2009 (Gobernador de Velocidad)David GastelumÎncă nu există evaluări

- Controlador DanfossDocument2 paginiControlador Danfossfrank.marcondes2416Încă nu există evaluări

- Furnace Temperature & PCE ConesDocument3 paginiFurnace Temperature & PCE ConesAbdullrahman Alzahrani100% (1)

- Rab Sikda Optima 2016Document20 paginiRab Sikda Optima 2016Julius Chatry UniwalyÎncă nu există evaluări

- Lakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoDocument2 paginiLakh Only) Being The Amount Covered Under The Aforesaid Dishonoured Cheque, and So AlsoShivam MishraÎncă nu există evaluări

- BSDDocument26 paginiBSDEunnicePanaliganÎncă nu există evaluări

- PR Earth Users Guide EMILY1Document2 paginiPR Earth Users Guide EMILY1Azim AbdoolÎncă nu există evaluări

- Zambia National FormularlyDocument188 paginiZambia National FormularlyAngetile Kasanga100% (1)

- VLT 6000 HVAC Introduction To HVAC: MG.60.C7.02 - VLT Is A Registered Danfoss TrademarkDocument27 paginiVLT 6000 HVAC Introduction To HVAC: MG.60.C7.02 - VLT Is A Registered Danfoss TrademarkSamir SabicÎncă nu există evaluări

- Assignment RoadDocument14 paginiAssignment RoadEsya ImanÎncă nu există evaluări

- Advantages Renewable Energy Resources Environmental Sciences EssayDocument3 paginiAdvantages Renewable Energy Resources Environmental Sciences EssayCemerlang StudiÎncă nu există evaluări

- National Employment Policy, 2008Document58 paginiNational Employment Policy, 2008Jeremia Mtobesya0% (1)

- VLSI Implementation of Floating Point AdderDocument46 paginiVLSI Implementation of Floating Point AdderParamesh Waran100% (1)

- ASHRAE Elearning Course List - Order FormDocument4 paginiASHRAE Elearning Course List - Order Formsaquib715Încă nu există evaluări

- Qualitrol 900 910Document6 paginiQualitrol 900 910chennupati999Încă nu există evaluări

- Contemp Person Act.1Document1 paginăContemp Person Act.1Luisa Jane De LunaÎncă nu există evaluări

- Channel & Lomolino 2000 Ranges and ExtinctionDocument3 paginiChannel & Lomolino 2000 Ranges and ExtinctionKellyta RodriguezÎncă nu există evaluări

- Hydraulics and PneumaticsDocument6 paginiHydraulics and PneumaticsRyo TevezÎncă nu există evaluări

- JBF Winter2010-CPFR IssueDocument52 paginiJBF Winter2010-CPFR IssueakashkrsnaÎncă nu există evaluări

- STARCHETYPE REPORT ReLOADED AUGURDocument5 paginiSTARCHETYPE REPORT ReLOADED AUGURBrittany-faye OyewumiÎncă nu există evaluări

- JCIPDocument5 paginiJCIPdinesh.nayak.bbsrÎncă nu există evaluări