Documente Academic

Documente Profesional

Documente Cultură

XXL, Mar 2011

Încărcat de

emediageDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

XXL, Mar 2011

Încărcat de

emediageDrepturi de autor:

Formate disponibile

NANO LETTERS

Laser-controlled Growth of Needle-shaped Organic Nanoaggregates

Frank Balzer

Humboldt-UniVersitat zu Berlin, Institut fur Physik/ASP, InValidenstr. 110, D-10115 Berlin, Germany

2002 Vol. 2, No. 7 747-750

Horst-Gunter Rubahn* 1

Fysisk Institut, Syddansk UniVersitet, CampusVej 55, DK-5230 Odense M, Denmark

Received April 6, 2002; Revised Manuscript Received May 2, 2002

ABSTRACT

Arrays of mutually parallel oriented, single-crystalline, needle-like structures of light-emitting p-hexaphenyl molecules are generated in the focus of an argon ion laser. The cross sectional dimensions of the needles are of the order of 100 to 200 nm with lengths up to several hundred micrometers. While the orientation of the individual molecules in the needles is defined by the direction of surface dipoles, the localization on the surface, the length distribution as well as mutual distances can be adjusted via size and position of the laser focus spot.

1. Introduction. A pronounced dichroism and efficient blue light emission following electric or optical excitation make para-hexaphenyl (p-6P) thin films well-suited candidates as the optically active elements in polarized organic lightemitting diodes, full color displays, or organic semiconductor lasers.1 Adsorbed on dielectric surfaces, their molecular axes are aligned either parallel to or normal to the surface. The alignment can be altered by the growth conditions (adsorption rate, surface temperature) in combination with the choice of the underlying substrate.2-4 Light absorption, emission, and electrical properties of p-6P thin films depend strongly on the molecular orientation.5-7 For example, the threshold voltage for electroluminescence is significantly lower for molecules aligned parallel to the surface as compared to that of normal oriented molecules.8 Hence, growth conditions that favor the generation of films with parallel oriented molecules are of special interest. Due to their large luminescence quantum yield (up to 0.39) p-6P molecules might serve as versatile optoelectronic components not only if they form an ultrathin film but also if lower dimensional nanoscaled aggregates such as quantum dots or quantum wires are generated. For that purpose the formation of mutually and, with respect to the substrate surface, well-oriented aggregates with large aspect ratios would be most useful. Recently we have demonstrated that growth of p-6P on a mica surface at elevated surface temperatures results in these kind of nanostructures, namely single crystalline needles with their (111) face parallel to hh

* Corresponding author. E-mail: rubahn@fysik.sdu.dk. 10.1021/nl0255707 CCC: $22.00 Published on Web 05/10/2002 2002 American Chemical Society

the surface plane.10 The needles consist of parallel stacks of laying molecules, which are oriented along the direction of microscopic dipoles on the mica surface. They have submicrometer cross sectional dimensions and lengths as large as millimeters. Moreover, due to the strong dipole confinement of individual molecules, the needles form large domains with parallel oriented entities. In the present article we show that the growth of needlelike structures on mica substrates occurs in a rather narrow surface temperature range T 25 K at a small adsorption rate of 0.025 nm/s. This observation can be used to locally influence needle growth via laser-induced surface heating. The direction of the needles is still given by the direction of surface dipoles and they are mutually well aligned. Their length distribution and their mutual distances can be varied by changing the ratio between global and local heating. With this laser-controlled growth mechanism a significant step has been achieved toward the generation of nanostructured connecting elements between optically active surface areas. 2. Experimental. Growth of p-6P thin films on muscovite mica is performed in high vacuum (10-7 mbar). p-Hexaphenyl (TCI America) is evaporated onto the mica surface at variable surface temperatures with a deposition rate of 0.025 nm/s from a resistively heated oven with a nozzle of 0.5 mm diameter. The flux of p-6P molecules is monitored by a water cooled quartz microbalance. Low energy electron diffraction measurements ensure the single-crystallinity of the generated films and nanostructures. Thin sheets of mica (thickness L ) 120 m) are cleaved in air and are transferred immediately after cleavage into the high vacuum chamber.

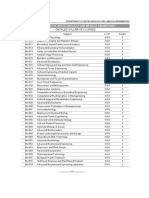

Figure 1. Fluorescence micrographs of p-6P films (mass thickness 5 nm) grown at substrate temperatures of (a) 340 K, (b) 356 K, and (c) 368 K.

They are mounted on a copper plate which allows homogeneous heating via a tungsten filament. During film growth, radiation from an argon ion laser (multiline 456-514 nm) is focused onto the mica substrate. The measured Gaussian focus diameter is 2w ) 0.9 mm. Following growth of films with 5 nm mass thickness, the substrates are investigated in a fluorescence microscope in air. Excitation is performed with a mercury lamp centered at 365 nm. The emission is observed behind a 420 nm long pass filter with a high-resolution digital camera. 3. Results and Discussion. In Figure 1 fluorescence micrographs of p-6P films, grown on mica with 5 nm mass thickness and at various substrate temperatures of (a) 340 K, (b) 356 K, and (c) 368 K are shown. Obviously, the growth of long needles takes place only for the sample held at 356 K, whereas for slightly higher or lower surface temperatures continuous films (on a micrometer scale11) are grown. Note that in ref 10 we have reported needle growth of p-6P on mica at surface temperatures between 360 and 460 K. However, for these measurements the sample heating was not uniform, resulting in strong temperature gradients on the surface. As shown in the present paper with an

748

Figure 2. Influence of laser irradiation on the growth of p-6P thin films (mass thickness 5 nm) on mica at room temperature. Argon ion laser power 0.55 W (a), 0.72 W (b), and 0.9 W (c). The Gaussian focus diameter of the laser at the substrate surface is 0.9 mm.

improved sample holder, needle growth is observed whenever the correct temperature is obtained, hence even on sections of samples that are partially too hot. Because of the use of a polarizer in front of the camera, two domains of differently aligned molecules are visible in Figure 1c.10 In Figure 2 fluorescence micrographs are shown for 5 nm thick p-6P films, grown at room temperature on mica, but under the influence of irradiation from the Argon ion laser. From (a) to (c) the laser power has been increased from 550 mW to 720 mW and 900 mW. In Figure 2a a pronounced needle growth is observed solely inside the laser focus, probably induced by laser heating. For Figures 2b and 2c the temperature increase in the center of the laser focus is too high to allow needle growth. The area in which needle growth is allowed is successively shifted outward. Before rationalizing these observations we note that the copper plate that underlies the sample will be heated only marginally.12 In this way it will act as a heat sink, ensuring that the heating is roughly restricted to the illuminated area. Unfortunately the presence of the copper plate also makes it difficult to quantitatively estimate the laser-induced temNano Lett., Vol. 2, No. 7, 2002

Figure 3. Normalized reciprocal laser intensity vs radii rN, where needle growth is observed. The solid line is the expected increase of the distance, where a certain temperature rise occurs, with increasing laser intensity (Gaussian radius w ) 450 m).

perature increase in the center of the focus. If we neglect the heat sink and assume a free-standing mica, then with an irradiation time of 200 s, an absorption coefficient R ) 5.8 10-4 m-1,15 thermal diffusivity of mica ) 1.6 10-6 m2/s, and thermal conductivity of Kmica ) 3.1 W/Km, we calculate12 a temperature rise in the center of the laser spot of T ) 69 K for PL ) 550 mW. This agrees well with the temperature of T ) 356 K for the thermally heated sample, where needle growth is observed (Figure 1b). However, due to the presence of the copper plate, at least a two-dimensional numerical simulation (perpendicular to and radial on the surface) of heat transport through the mica is necessary. This FTCS (forward time, central space14) calculation results in a temperature increase of 11 K on the mica surface within the focus center. This value very much depends on the thermal constants of mica. If we apply instead of the average values used up to now the minimum conductivity values from ref 13, then we find a temperature increase of more than 50 K, which might be even higher if we take into account a finite thermal resistance between mica sheet and copper plate. From that we conclude that it is very likely that the needle growth is directly related to the laserinduced temperature increase on the mica surface. If the laser irradiance is too high, needle growth is not observed within the center of the laser focus, but in a ring around that spot (Figures 2b and 2c). The ring has a radius rN and width rN that both increase with increasing laser irradiance (Figure 2b and Figure 2c). Figure 3 shows that this increase is directly related to the temperature profile within the laser focus. The radial range rN is represented as horizontal bars. Because of the direct relation between the Gaussian laser beam profile and the temperature rise on the mica surface, r2 depends exponentially on PL, N PL,0 r2 N ) exp - 2 PL w

Figure 4. (a) Growth of well-separated needles within the laser irradiated spot on a p-6P film grown at 356 K. Laser power 0.5 W. (b) Growth 150 m outside the center of the focus. (c) Typical force microscopy image (3 3 m2) of parallel needles, revealing their characteristic dimensions. Height of the central needle 84 nm, width 217 nm.

( )

(1)

with PL,0 denoting the minimal laser power suitable for needle growth (i.e., rN ) 0 for PL ) PL,0). In Figure 3 this relation

Nano Lett., Vol. 2, No. 7, 2002

is plotted as a solid line. It agrees very well with the measured radii. So far we have investigated the effect of laser irradiation on needle growth on an otherwise structureless film. Now we investigate conditions where needle growth occurs already without laser irradiation. The sample grown at 356 K (Figure 1b) shows long, densely packed needles. If we irradiate this sample during growth with 0.5 W laser power, we find within the laser focus well separated needles with nearly constant length of 16 ( 3 m (Figure 4a). At the border of the laser focus the length and density of the needles are increasing (Figure 4b), until the density reaches that of the rest of the sample (Figure 1b). The true dimensions of the needles that have been generated that way (width 200 nm, height 100 nm) are shown in Figure 4c with the help of atomic force microscopy.16 Obviously, behind a simple heating of the sample, laser irradiation also leads to a more complex manipulation of aggregate dimensions in terms of thermal or even nonthermal

749

laser desorption and growth inhibition. Size-dependent desorption characteristics are well investigated for metallic aggregates on dielectrics,17 and they can be used to control also the growth of metallic nanoparticles.18 In summary, we have demonstrated that irradiation with an argon ion laser during growth of p-6P films allows one to stimulate and to manipulate the generation of nanometer scaled, needle-shaped aggregates. Since it is also possible to modify the mutual distances between the needles, it will be possible to locally induce needle growth on predefined areas of a substrate that contains an optoelectronically active pattern. The minimum structure size achievable with this method is given by (a) the intrinsic restrictions in width and height of the needles that depend on adjustable growth conditions and allow the laser-induced formation of aggregates with submicrometer dimensions; and (b) the focus diameter (a few micrometers) and the thermal diffusion length. The latter factors, however, concern the length of the needles. This length is mainly determined by the size of the surface dipole domains and the size of the uncovered mica substrate. Acknowledgment. We are grateful to the Danish Research Foundation SNF for financial support and to E. J. Kintzel, Jr. for atomic force microscopy on our samples. We also like to thank one of the referees for pointing out the complex thermal behavior of our system.

References

(1) Tessler, N. AdV. Mater. 1999, 11, 363. (2) Era, M.; Tsutsui, T.; Saito, S. Appl. Phys. Lett. 1995, 67, 2436. (3) Yase, K.; Han, E.-M.; Yamamoto, K.; Yoshida, Y.; Takada, N.; Tanigaki, N. Jpn. J. Appl. Phys. 1997, 36, 2843. (4) Zojer, E.; Koch, N.; Puschig, P.; Meghdadi, F.; Niko, A.; Resel, R.; Ambrosch-Draxl, C.; Knupfer, M.; Fink, J.; Bredas, J. L.; Leising, G. Phys. ReV. B 2000, 61, 16538. (5) Athouel, L.; Froyer, G.; Riou, M. T. Synth. Met. 1993, 55-57, 4734. (6) Athouel, L.; Froyer, G.; Riou, M. T.; Schott, M. Thin Solid Films 1996, 274, 35. (7) Mikami, T.; Yanagi, H. Appl. Phys. Lett. 1998, 73, 563. (8) Yanagi, H.; Okamoto, S. Appl. Phys. Lett. 1997 71, 2563. (9) Ariu, M.; Bongiovanni, G.; Loi, M. A.; Mura, A.; Piaggi, A.; Rossi, L.; Graupner, W.; Meghdadi, F.; Leising, G. Chem. Phys. Lett. 1999, 313, 405. (10) Balzer, F.; Rubahn, H.-G. Appl. Phys. Lett. 2001, 79, 3860. (11) Balzer, F.; Rubahn, H.-G. Proc. SPIE 2002, 4642. (12) Ready, J. F. Effects of High-Power Laser Radiation; Academic Press: New York, 1971. (13) Thermophysical Properties of Matter Vol. X; Touloukian, Y. S., Powell, R. W., Eds.; IFI/Plenum: New York-Washington, 1973. (14) Ozisik, M. N. Heat Transfer; McGraw-Hill: New York, 1985. (15) Balzer, F.; Gerlach, R.; Schober, M.; Rubahn, H.-G. Surf. Sci. 1998, 402-404, 841. (16) Kintzel, E. J., Jr.; private communication, 2001. (17) Manson, J. R.; Renger, M.; Rubahn, H.-G. Phys. Lett. A 1996, 224, 121. (18) MacDonald, K. F.; Fedotov, V. A.; Pochon, S.; Ross, K. J.; Stevens, G. C.; Zheludev, N. I.; Brocklesby, W. S.; Emelyanov, V. I. Appl. Phys. Lett. 2002, 80, 1643.

NL0255707

750

Nano Lett., Vol. 2, No. 7, 2002

S-ar putea să vă placă și

- Guoyin Shen, Ho-Kwang Mao and Russell J. Hemley - Laser-Heated Diamond Anvil Cell Technique: Double-Sided Heating With Multimode Nd:YAG LaserDocument5 paginiGuoyin Shen, Ho-Kwang Mao and Russell J. Hemley - Laser-Heated Diamond Anvil Cell Technique: Double-Sided Heating With Multimode Nd:YAG LaserDeez34PÎncă nu există evaluări

- Direct Writing Three-Dimensional Crystalline Pattern in Glass With Ultrashort Pulse LaserDocument4 paginiDirect Writing Three-Dimensional Crystalline Pattern in Glass With Ultrashort Pulse LaserMustafa EL-BoghdadyÎncă nu există evaluări

- Laser-Induced Nanocomposite Formation For Printed NanoelectronicsDocument4 paginiLaser-Induced Nanocomposite Formation For Printed NanoelectronicsRoxana Cristina PopescuÎncă nu există evaluări

- Parents, Oct 2011Document5 paginiParents, Oct 2011emediageÎncă nu există evaluări

- Optica 5 2 175 PDFDocument5 paginiOptica 5 2 175 PDFLoubnanÎncă nu există evaluări

- Laser Heating Effect On Raman Spectra of Si NanocrDocument6 paginiLaser Heating Effect On Raman Spectra of Si NanocrDani AmayaÎncă nu există evaluări

- Layer Compression and Enhanced Optical Properties of Few-Layer Graphene Nanosheets Induced by Ion IrradiationDocument18 paginiLayer Compression and Enhanced Optical Properties of Few-Layer Graphene Nanosheets Induced by Ion IrradiationCarla Míriam FerreiraÎncă nu există evaluări

- Catchpole-Red Shifting The Surface Plasmon Resonance of Silver Nanoparticles For Light Trapping in Solar CellsDocument9 paginiCatchpole-Red Shifting The Surface Plasmon Resonance of Silver Nanoparticles For Light Trapping in Solar CellsVenus DilluÎncă nu există evaluări

- Ncomms 9251Document8 paginiNcomms 925118969868226patrickÎncă nu există evaluări

- Tratamente Termice Moderne Aplicate Organelor de Mașini EnglezaDocument5 paginiTratamente Termice Moderne Aplicate Organelor de Mașini EnglezaamocatoÎncă nu există evaluări

- The Role of Substrate Temperatures On Photoconductivity For Insb FilmsDocument5 paginiThe Role of Substrate Temperatures On Photoconductivity For Insb FilmsInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Received December 15, 2008Document8 paginiReceived December 15, 2008Khoa HuỳnhÎncă nu există evaluări

- Letters To Nature: Femtosecond Time-Resolved X-Ray Diffraction From Laser-Heated Organic FilmsDocument3 paginiLetters To Nature: Femtosecond Time-Resolved X-Ray Diffraction From Laser-Heated Organic FilmsZia Ur RehmanÎncă nu există evaluări

- Photoacoustic Studies of Annealed Cdsxse1-X (X 0.26) Nanocrystals in A Glass MatrixDocument6 paginiPhotoacoustic Studies of Annealed Cdsxse1-X (X 0.26) Nanocrystals in A Glass MatrixVigneshwaran MuruganÎncă nu există evaluări

- 2005 - Ambrosio Et Al. - Thermal Processes in Metal-Coated Fiber Probes For Near-Field Experiments - Applied Physics LettersDocument4 pagini2005 - Ambrosio Et Al. - Thermal Processes in Metal-Coated Fiber Probes For Near-Field Experiments - Applied Physics LettersClaudio BiaginiÎncă nu există evaluări

- Trager APB09 PDFDocument9 paginiTrager APB09 PDFmadrnessÎncă nu există evaluări

- Transmission Increase Upon Switching of VO2 Thin Films On Microstructured SurfacesDocument3 paginiTransmission Increase Upon Switching of VO2 Thin Films On Microstructured Surfacesmasum.sÎncă nu există evaluări

- Cdse Nanoparticles Synthesized by Laser Ablation: Epla, 2008Document6 paginiCdse Nanoparticles Synthesized by Laser Ablation: Epla, 2008Krishna PrasadÎncă nu există evaluări

- Structural changes in thin amorphous silicon filmsDocument7 paginiStructural changes in thin amorphous silicon filmsmileivandaÎncă nu există evaluări

- Surface Plasmon Resonance PHD ThesisDocument6 paginiSurface Plasmon Resonance PHD Thesisrwzhdtief100% (2)

- Crossover in The Magnetic Properties of Nanostructured MetalsDocument5 paginiCrossover in The Magnetic Properties of Nanostructured MetalsviniciushiperÎncă nu există evaluări

- Efficient laser operation and continuous-wave diode pumping of Cr2+:ZnSeDocument3 paginiEfficient laser operation and continuous-wave diode pumping of Cr2+:ZnSeAlexanderÎncă nu există evaluări

- Nanocrystalline Metals Prepared by High-Energy Ball Milling: II. Experimental DetailsDocument5 paginiNanocrystalline Metals Prepared by High-Energy Ball Milling: II. Experimental DetailsMohamed KhalifaÎncă nu există evaluări

- Fluorescence Microscopy With Diffraction Resolution Barrier Broken by Stimulated EmissionDocument5 paginiFluorescence Microscopy With Diffraction Resolution Barrier Broken by Stimulated EmissionAMÎncă nu există evaluări

- High Resolution Polarization Gratings in Liquid Crystals: Related ArticlesDocument4 paginiHigh Resolution Polarization Gratings in Liquid Crystals: Related ArticlesSergei SlussarenkoÎncă nu există evaluări

- Project Course Report (Spintronics)Document16 paginiProject Course Report (Spintronics)Arvind RaoÎncă nu există evaluări

- Compression and Heating of A Laser-Produced Plasma Using Single and Double Induction CoilsDocument8 paginiCompression and Heating of A Laser-Produced Plasma Using Single and Double Induction CoilsPaulÎncă nu există evaluări

- Articles: Photoluminescence Properties of Sno Nanoparticles Synthesized by Sol-Gel MethodDocument5 paginiArticles: Photoluminescence Properties of Sno Nanoparticles Synthesized by Sol-Gel MethodVikas PatilÎncă nu există evaluări

- Scalable Quantum Photonics With Single Color Centers in Silicon CarbideDocument18 paginiScalable Quantum Photonics With Single Color Centers in Silicon CarbidepippoaÎncă nu există evaluări

- Klaui MagneticAnisotropyEngineeringYhinFilm PhysRevApplied2014Document6 paginiKlaui MagneticAnisotropyEngineeringYhinFilm PhysRevApplied2014astro123321Încă nu există evaluări

- Fusion Engineering and DesignDocument10 paginiFusion Engineering and DesignMahdi EslamiÎncă nu există evaluări

- Thermal Diffusivity Measurements Based On Laser Induced Heat Transfer in Low-Conductivity Thin FilmsDocument6 paginiThermal Diffusivity Measurements Based On Laser Induced Heat Transfer in Low-Conductivity Thin FilmsViji55555Încă nu există evaluări

- Physica B: F.H. Arago N, P.E.N. de Souza, J.A.H. Coaquira, P. Hidalgo, D. Gouv EaDocument5 paginiPhysica B: F.H. Arago N, P.E.N. de Souza, J.A.H. Coaquira, P. Hidalgo, D. Gouv EaValmir JuniorÎncă nu există evaluări

- 28 935 952Document18 pagini28 935 952vsinisa1Încă nu există evaluări

- 1AO.3.4 PaperDocument3 pagini1AO.3.4 PaperDavid Garcia0% (1)

- Powerful High Efficiency Gasb TPV and PV CellsDocument4 paginiPowerful High Efficiency Gasb TPV and PV CellsAnisse ChialiÎncă nu există evaluări

- tmpBF5F TMPDocument6 paginitmpBF5F TMPFrontiersÎncă nu există evaluări

- P R Letters: Hysical EviewDocument5 paginiP R Letters: Hysical EviewSauvik ChatterjeeÎncă nu există evaluări

- Wright 1981Document10 paginiWright 1981Alvaro Ruiz AvendañoÎncă nu există evaluări

- Laser Processes for n+ Emitter Formation in c-Si Solar CellsDocument5 paginiLaser Processes for n+ Emitter Formation in c-Si Solar CellsDu RoyÎncă nu există evaluări

- Jorge Filevich Et Al - Bow Shocks Formed by Plasma Collisions in Laser Irradiated Semi-Cylindrical CavitiesDocument7 paginiJorge Filevich Et Al - Bow Shocks Formed by Plasma Collisions in Laser Irradiated Semi-Cylindrical CavitiesOlyvesÎncă nu există evaluări

- Thin Film Silicon Nanoparticle UV Photodetector: O. M. Nayfeh, S. Rao, A. Smith, J. Therrien, and M. H. NayfehDocument3 paginiThin Film Silicon Nanoparticle UV Photodetector: O. M. Nayfeh, S. Rao, A. Smith, J. Therrien, and M. H. Nayfehpramod gaikwadÎncă nu există evaluări

- 418 CM 1 Raman Scattering From Gallium Nitride Nanowires: Is It A Vibration Mode of N-Rich Ga-N Bond Configuration?Document4 pagini418 CM 1 Raman Scattering From Gallium Nitride Nanowires: Is It A Vibration Mode of N-Rich Ga-N Bond Configuration?crisomrÎncă nu există evaluări

- Lab Mst613 (Part B)Document10 paginiLab Mst613 (Part B)hyebibieÎncă nu există evaluări

- ApplPhysLett 83 2784 PDFDocument3 paginiApplPhysLett 83 2784 PDFEidelsayedÎncă nu există evaluări

- Optically Induced Space-Charge Fields, DC Voltage, and Extraordinarily Large Nonlinearity in Dye-Doped Nematic Liquid CrystalsDocument3 paginiOptically Induced Space-Charge Fields, DC Voltage, and Extraordinarily Large Nonlinearity in Dye-Doped Nematic Liquid CrystalsSergei SlussarenkoÎncă nu există evaluări

- Guoyin Shen, M. L. Rivers, Yanbin Wang, and S. R. Sutton - New Developments On Laser Heated Diamond Anvil CellDocument4 paginiGuoyin Shen, M. L. Rivers, Yanbin Wang, and S. R. Sutton - New Developments On Laser Heated Diamond Anvil CellDrebuioÎncă nu există evaluări

- Gao 2016Document6 paginiGao 2016Jorge Daniel Torres AlvarezÎncă nu există evaluări

- Ijaret: ©iaemeDocument9 paginiIjaret: ©iaemeIAEME PublicationÎncă nu există evaluări

- Band Gap Energy of Pure and Al-Doped Zno Thin Films: F.K. Shan, Y.S. YuDocument4 paginiBand Gap Energy of Pure and Al-Doped Zno Thin Films: F.K. Shan, Y.S. YuSalim ChahidÎncă nu există evaluări

- Tunable Attenuation in Photonic Liquid Crystal FibersDocument3 paginiTunable Attenuation in Photonic Liquid Crystal FibersSathiyanÎncă nu există evaluări

- Nature 25970Document8 paginiNature 2597018969868226patrickÎncă nu există evaluări

- Hone02 ApplphysaDocument5 paginiHone02 Applphysa1900402051mÎncă nu există evaluări

- Dror, Croitoru - 1990 - Ge-Sn-Se-Te For Infrared Optical Fibers (2) - AnnotatedDocument9 paginiDror, Croitoru - 1990 - Ge-Sn-Se-Te For Infrared Optical Fibers (2) - AnnotatedJagan KbÎncă nu există evaluări

- Fine Barium Hexaferrite Powder Prepared by The Crystallisation of GlassDocument3 paginiFine Barium Hexaferrite Powder Prepared by The Crystallisation of GlassehsanÎncă nu există evaluări

- Spectroscopy of Single Metallic Nanoparticles Using Total Internal Reflection MicrosDocument4 paginiSpectroscopy of Single Metallic Nanoparticles Using Total Internal Reflection MicrosCooper StarkÎncă nu există evaluări

- Local Atomic Structure of A High-Entropy Alloy: An X-Ray and Neutron Scattering StudyDocument4 paginiLocal Atomic Structure of A High-Entropy Alloy: An X-Ray and Neutron Scattering StudyBuluc GheorgheÎncă nu există evaluări

- Optical controlled thermal experiments simulations nanometer scaleDocument6 paginiOptical controlled thermal experiments simulations nanometer scale김영규Încă nu există evaluări

- Optical and Thermodynamic Properties of HgBa2CuO4+δ SuperconductorDocument30 paginiOptical and Thermodynamic Properties of HgBa2CuO4+δ SuperconductorpetrÎncă nu există evaluări

- აუტომოტივი, თებერვალი 2009Document100 paginiაუტომოტივი, თებერვალი 2009emediageÎncă nu există evaluări

- აუტომოტივი, თებერვალი 2009Document100 paginiაუტომოტივი, თებერვალი 2009emediageÎncă nu există evaluări

- აუტომოტივი, თებერვალი 2009Document100 paginiაუტომოტივი, თებერვალი 2009emediageÎncă nu există evaluări

- Simple JAVA (Russian)Document231 paginiSimple JAVA (Russian)Dana DingaÎncă nu există evaluări

- აუტომოტივი, თებერვალი 2009Document100 paginiაუტომოტივი, თებერვალი 2009emediageÎncă nu există evaluări

- აუტომოტივი, თებერვალი 2009Document100 paginiაუტომოტივი, თებერვალი 2009emediageÎncă nu există evaluări

- აუტომოტივი, თებერვალი 2009Document100 paginiაუტომოტივი, თებერვალი 2009emediageÎncă nu există evaluări

- აუტომოტივი, თებერვალი 2009Document100 paginiაუტომოტივი, თებერვალი 2009emediageÎncă nu există evaluări

- Fenvik, მარტი 2012Document7 paginiFenvik, მარტი 2012emediageÎncă nu există evaluări

- მირიანა, თებერვალი 2012Document100 paginiმირიანა, თებერვალი 2012emediageÎncă nu există evaluări

- g, იანვარი 2012Document7 paginig, იანვარი 2012emediageÎncă nu există evaluări

- The First Magazine Test, თებერვალი 2012Document43 paginiThe First Magazine Test, თებერვალი 2012emediageÎncă nu există evaluări

- გაზეთი ქართული, მარტი 2011Document2 paginiგაზეთი ქართული, მარტი 2011emediageÎncă nu există evaluări

- Simple JAVA (Russian)Document231 paginiSimple JAVA (Russian)Dana DingaÎncă nu există evaluări

- დიალოგი, ივნისი 2010Document76 paginiდიალოგი, ივნისი 2010emediageÎncă nu există evaluări

- დიალოგი, იანვარი 2012Document68 paginiდიალოგი, იანვარი 2012emediageÎncă nu există evaluări

- დდდ, მარტი 2012Document4 paginiდდდ, მარტი 2012emediageÎncă nu există evaluări

- Awake!, Jul 2011Document4 paginiAwake!, Jul 2011emediageÎncă nu există evaluări

- Fenvik, მარტი 2012Document180 paginiFenvik, მარტი 2012emediageÎncă nu există evaluări

- Fenvik, მარტი 2012Document180 paginiFenvik, მარტი 2012emediageÎncă nu există evaluări

- Synthesis of Metal-Loaded Poly (Aminohexyl) (Aminopropyl) Silsesquioxane Colloids and Their Self-Organization Into DendritesDocument4 paginiSynthesis of Metal-Loaded Poly (Aminohexyl) (Aminopropyl) Silsesquioxane Colloids and Their Self-Organization Into DendritesemediageÎncă nu există evaluări

- Css3 Cheat SheetDocument1 paginăCss3 Cheat SheetPhilip SoaresÎncă nu există evaluări

- მირიანა, თებერვალი 2012Document100 paginiმირიანა, თებერვალი 2012emediageÎncă nu există evaluări

- დიალოგი, ივნისი 2010Document76 paginiდიალოგი, ივნისი 2010emediageÎncă nu există evaluări

- Fenvik, მარტი 2012Document50 paginiFenvik, მარტი 2012emediageÎncă nu există evaluări

- მირიანა, თებერვალი 2012Document100 paginiმირიანა, თებერვალი 2012emediageÎncă nu există evaluări

- You and Your Family, Apr 2011Document5 paginiYou and Your Family, Apr 2011emediageÎncă nu există evaluări

- You and Your Family, Jan 2011Document4 paginiYou and Your Family, Jan 2011emediageÎncă nu există evaluări

- მირიანა, თებერვალი 2012Document100 paginiმირიანა, თებერვალი 2012emediageÎncă nu există evaluări

- You and Your Family, Oct 2011Document5 paginiYou and Your Family, Oct 2011emediageÎncă nu există evaluări

- Nano Energy: Mayue Shi, Hanxiang Wu, Jinxin Zhang, Mengdi Han, Bo Meng, Haixia ZhangDocument9 paginiNano Energy: Mayue Shi, Hanxiang Wu, Jinxin Zhang, Mengdi Han, Bo Meng, Haixia ZhangGabriella CsernákÎncă nu există evaluări

- STM TheoryDocument38 paginiSTM TheoryAmintujy Singh RajputÎncă nu există evaluări

- Introduction To Technical Textile Medical TextileDocument96 paginiIntroduction To Technical Textile Medical Textilegrsenthilkumar3Încă nu există evaluări

- Time Supplement July 2006Document24 paginiTime Supplement July 2006raymondn_21Încă nu există evaluări

- Biotechnology and Medical Engineering Department CoursesDocument20 paginiBiotechnology and Medical Engineering Department CoursesData LoggerÎncă nu există evaluări

- ResearchGate publication on nanocomposites and applicationsDocument15 paginiResearchGate publication on nanocomposites and applicationsTanzil ZaidiÎncă nu există evaluări

- Shroff S.R.Rotary Institute of Chemical Technology: Mechanical Engineering DepartmentDocument29 paginiShroff S.R.Rotary Institute of Chemical Technology: Mechanical Engineering DepartmentPrashant PatilÎncă nu există evaluări

- Interface Enhancement of Glass Fiber/Unsaturated Polyester Resin Composites With Nano-Silica Treated Using Silane Coupling AgentDocument7 paginiInterface Enhancement of Glass Fiber/Unsaturated Polyester Resin Composites With Nano-Silica Treated Using Silane Coupling AgentElias Arenas PanccaÎncă nu există evaluări

- Team Members - Microsystems - TL@NTUDocument5 paginiTeam Members - Microsystems - TL@NTUsuraj07031981Încă nu există evaluări

- Introduction to Nanorobotics and Their ApplicationsDocument25 paginiIntroduction to Nanorobotics and Their ApplicationsSharifa RahamadullahÎncă nu există evaluări

- NanodiagnosticsDocument28 paginiNanodiagnosticsAnoopInderÎncă nu există evaluări

- The Major Impacts of NanotechnologyDocument10 paginiThe Major Impacts of NanotechnologyAnaliza GinezaÎncă nu există evaluări

- Individualists Tending Toward The Wild Communiques PDFDocument88 paginiIndividualists Tending Toward The Wild Communiques PDFShuzikuÎncă nu există evaluări

- Globalbrainchip Mesogens Staninger 1 6 12Document23 paginiGlobalbrainchip Mesogens Staninger 1 6 12Martin humeÎncă nu există evaluări

- IJNTR02050006 بحثي دكتوراهDocument7 paginiIJNTR02050006 بحثي دكتوراهHaidar AlmayahyÎncă nu există evaluări

- Nano Technology in Electrical EngineeringDocument17 paginiNano Technology in Electrical Engineeringkevinblaze006867% (3)

- Nanorobotics in Medical FieldDocument10 paginiNanorobotics in Medical FieldIJRASETPublicationsÎncă nu există evaluări

- Application of Nanoparticles in MedicineDocument20 paginiApplication of Nanoparticles in MedicineBandita DattaÎncă nu există evaluări

- Why Does The Future Not Need Us.Document19 paginiWhy Does The Future Not Need Us.Tammy Zore78% (9)

- Microfluidic GroupsDocument9 paginiMicrofluidic GroupsPratyushAgarwalÎncă nu există evaluări

- NanoCare Brochure EN PDFDocument20 paginiNanoCare Brochure EN PDFyanuarÎncă nu există evaluări

- Applied Physics: (3 Credit Hours Course)Document16 paginiApplied Physics: (3 Credit Hours Course)Usman Shakeelssp20pg03Încă nu există evaluări

- Nanotechnology in Defence: A Study of DRDODocument70 paginiNanotechnology in Defence: A Study of DRDOMohit PatilÎncă nu există evaluări

- SEMINAR On NanocompositesDocument30 paginiSEMINAR On NanocompositesRama GaurÎncă nu există evaluări

- Emerging Droplet Micro Uidics: Chemical Reviews May 2017Document78 paginiEmerging Droplet Micro Uidics: Chemical Reviews May 2017AfshaÎncă nu există evaluări

- Sensor Based Autonomous Medical Nanorobots A Cure To DemyelinationDocument7 paginiSensor Based Autonomous Medical Nanorobots A Cure To DemyelinationArul PrakashÎncă nu există evaluări

- IEEE Xplore - SearchResultDocument4 paginiIEEE Xplore - SearchResultSalman KhanÎncă nu există evaluări

- An Improved Hummers Method For Eco-Friendly Synthesis of Graphene OxideDocument5 paginiAn Improved Hummers Method For Eco-Friendly Synthesis of Graphene OxideFamiloni LayoÎncă nu există evaluări

- Xiao Y 2014 PHD ThesisDocument211 paginiXiao Y 2014 PHD ThesisclcÎncă nu există evaluări

- Engineering Materials For Electrical Engineers: INGE 3045Document43 paginiEngineering Materials For Electrical Engineers: INGE 3045Seema SharmaÎncă nu există evaluări